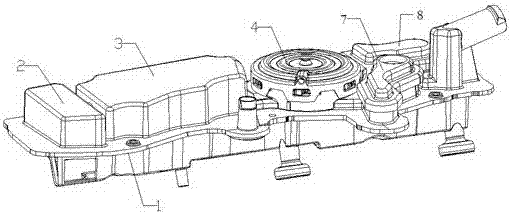

Oil-gas separator

A technology of oil and gas separator and separator, which is applied in the direction of machine/engine, engine components, mechanical equipment, etc., can solve the problems of high engine oil consumption, high crankcase pressure, complicated disassembly and assembly process, etc., to reduce oil consumption, Efficient and thorough separation to ensure the effect of separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

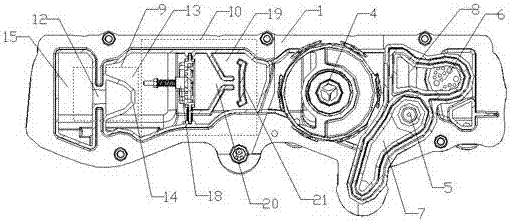

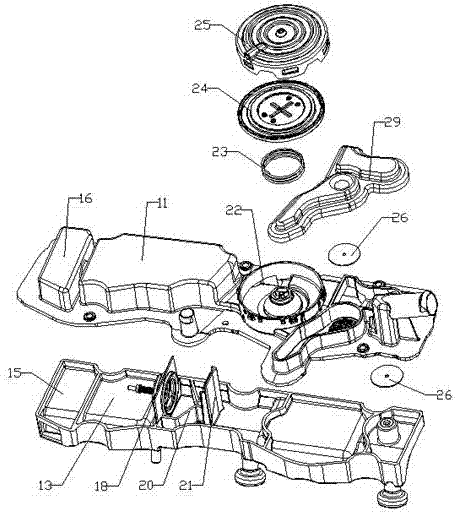

[0035] Crankcase blow-by gas enters from the entrance of the blow-by gas gathering chamber 2, and the gas passing through the speed-increasing channel 12 impacts on the arc-shaped baffle 14, and the relatively large oil particles in the gas adhere to the arc-shaped baffle 14, and finally due to the action of gravity The gas falls in the coarse separation chamber 13 , while the gas that separates larger oil particles overflows from the gaps 17 on both sides of the arc-shaped baffle 14 , and then enters the fine separation chamber 19 through the felt valve 18 .

[0036] When the blow-by gas of the engine is small, the pressure difference between the two ends of the felt valve 18 is small, and the felt valve 18 is in a closed state at this time, and all the gas passes through the felt valve body 31. Blocked by the body 31, it gradually accumulates in the felt valve body 31, and finally drips into the cavity of the separator body 1 due to the effect of gravity. The flow velocity o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com