Coal bed gas exploiting auxiliary filter device

A filtering device and technology for coalbed methane, which are applied in the fields of mining fluids, filtration of dispersed particles, and earthwork drilling, etc., can solve the problems of affecting the filtering ability and quality, decreasing the filtering effect, affecting the quality, etc., so as to improve the filtering ability and filtering effect. Improve the convenience of control and the effect of high-quality and high-efficiency filtration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

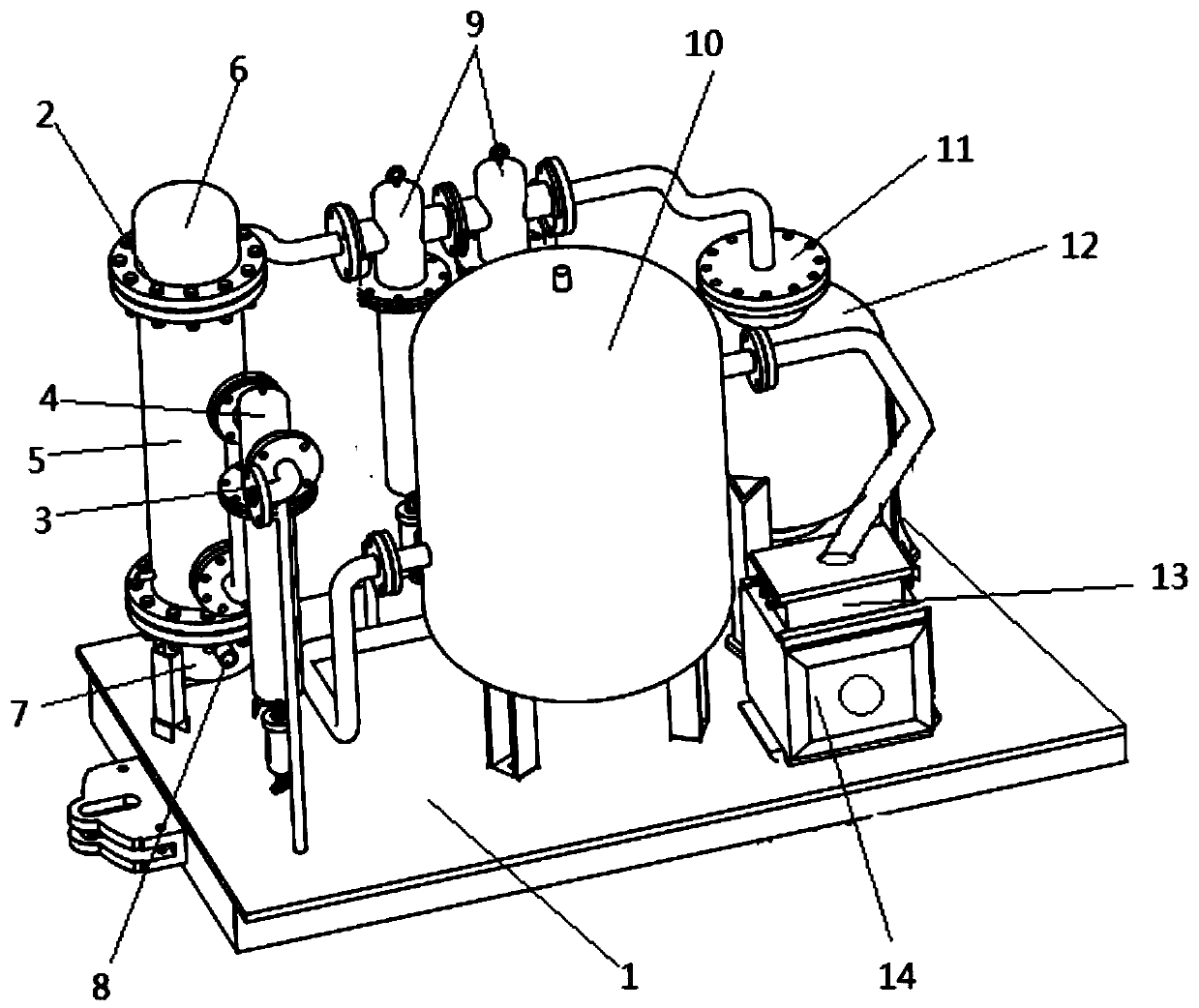

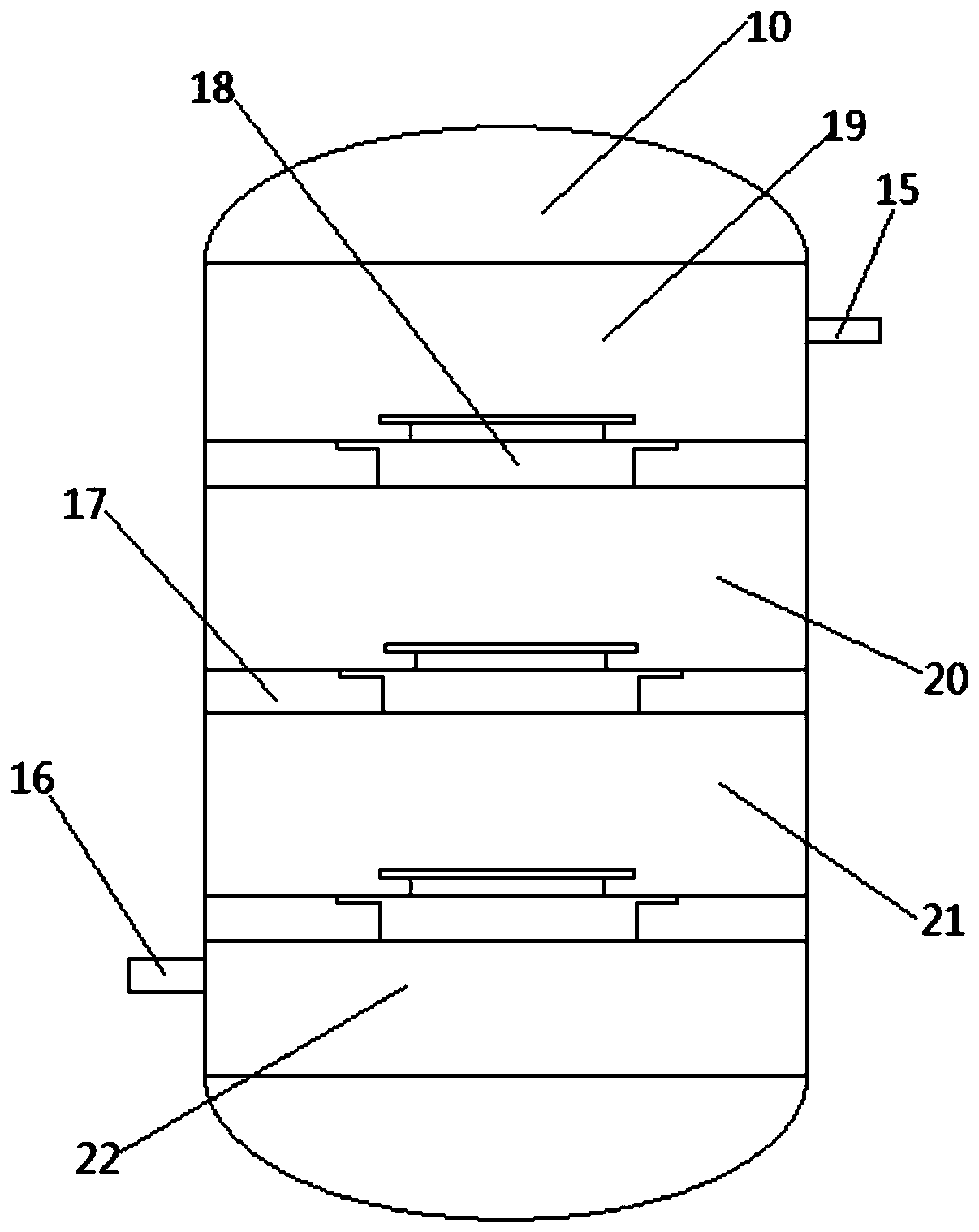

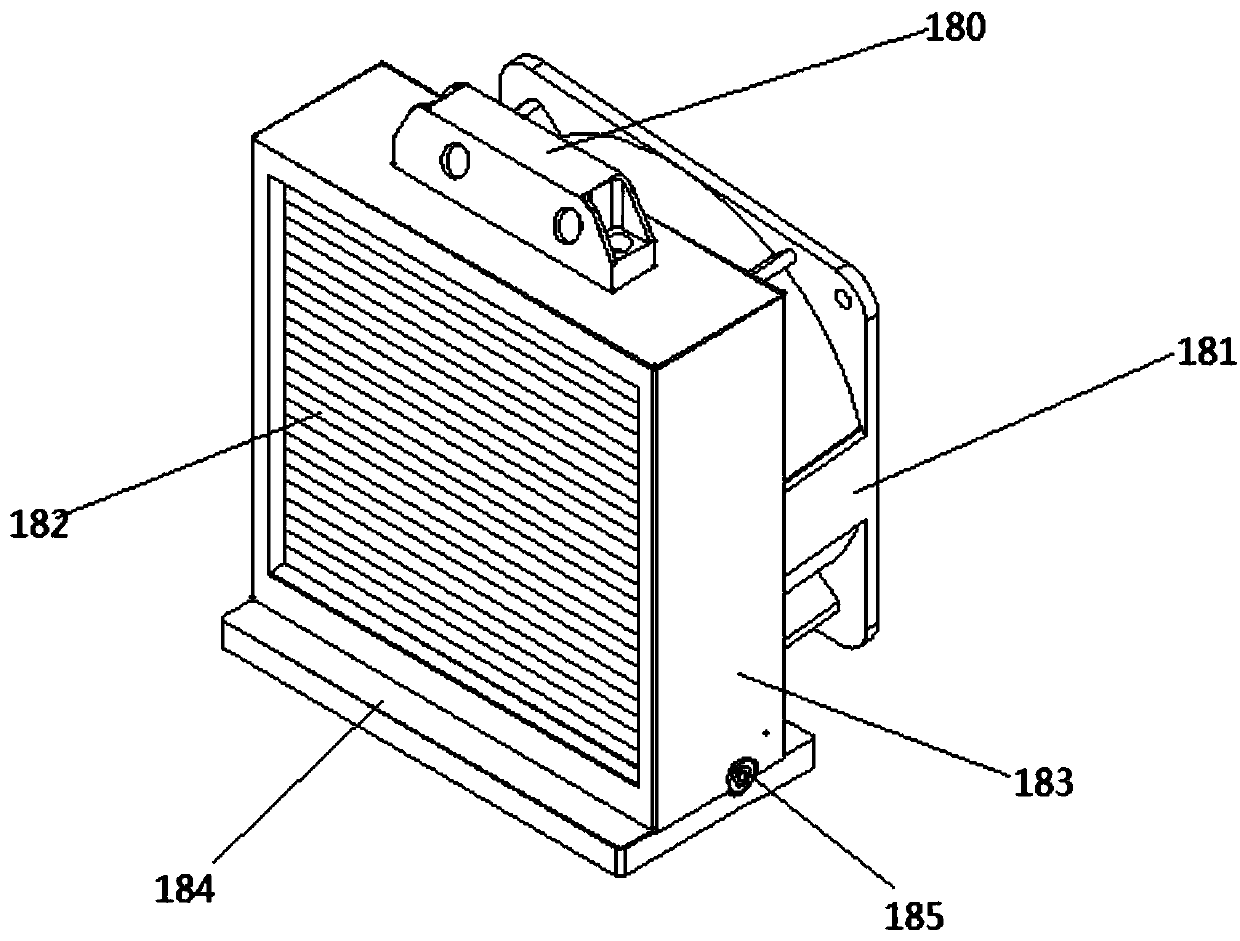

[0021] see Figure 1~4 , in an embodiment of the present invention, an auxiliary filter device for coalbed methane extraction, including a connecting joint mechanism, a primary filter residue powder mechanism, a water vapor filtering mechanism, a transfer tank 12, a filter tank 10 and a final filter box 13, wherein the connecting joint The inlet end of the mechanism is connected to the coalbed methane exploitation mechanism, the gas outlet end of the connection joint mechanism is connected to the primary filter residue powder mechanism, the output end of the primary filter residue powder mechanism is connected to the water vapor filter mechanism, and the water vapor filter mechanism The output end of the mechanism is connected to the filter tank 10 through the transfer tank 12, and the output end of the filter tank is connected to the final filter box 13. The horizontal partition 17, the filter group 18 is embedded in the horizontal partition, between two adjacent horizontal p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com