Vortex solidification underground water remediation system and method

A groundwater remediation and groundwater technology, applied in chemical instruments and methods, contaminated groundwater/leachate treatment, water supply equipment, etc., can solve the problems of large water pumping, inability to ensure effective removal of pollutants, long treatment cycle, etc., to achieve The water output is small, the cycle is short, and the effect of ensuring purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

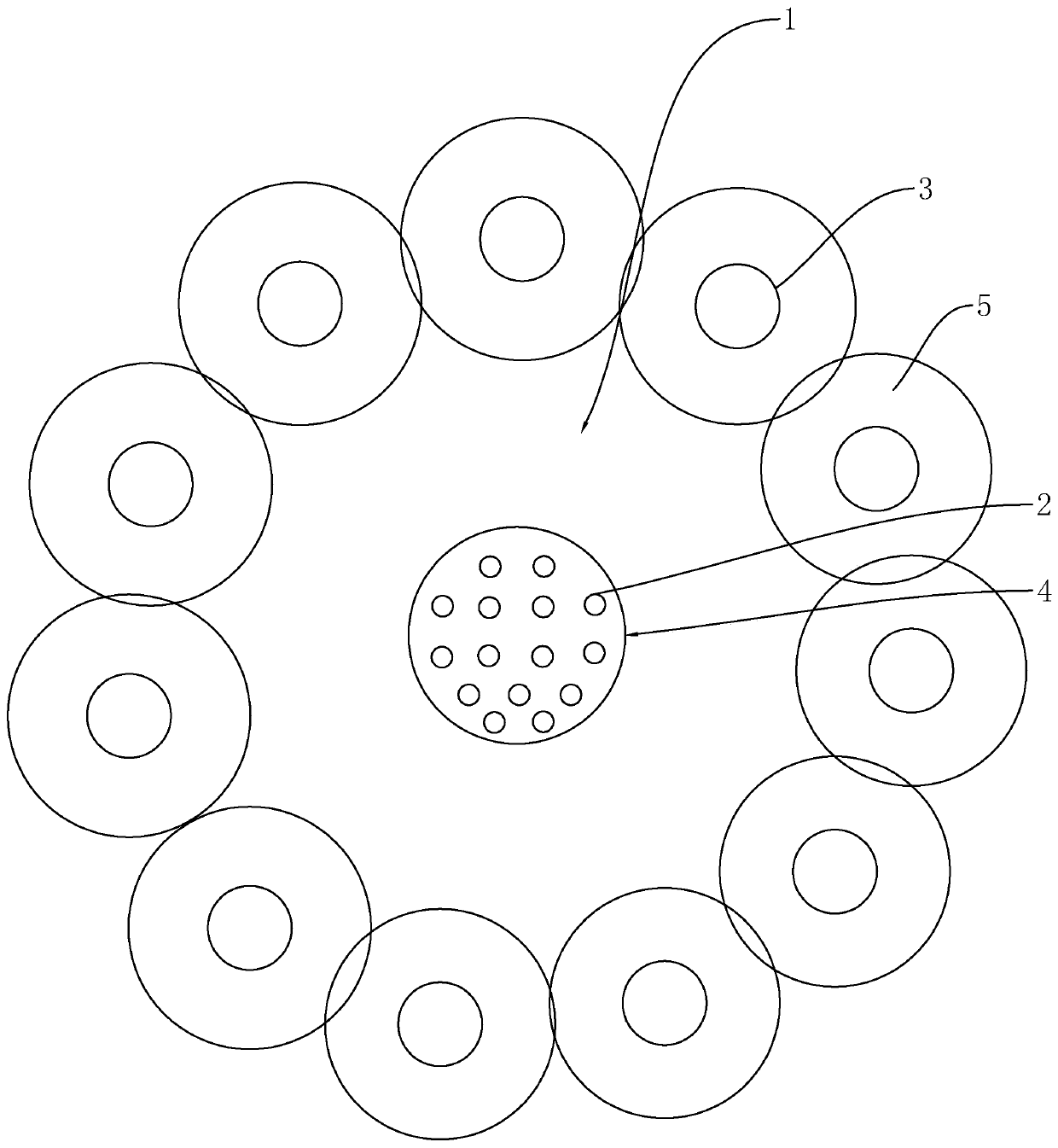

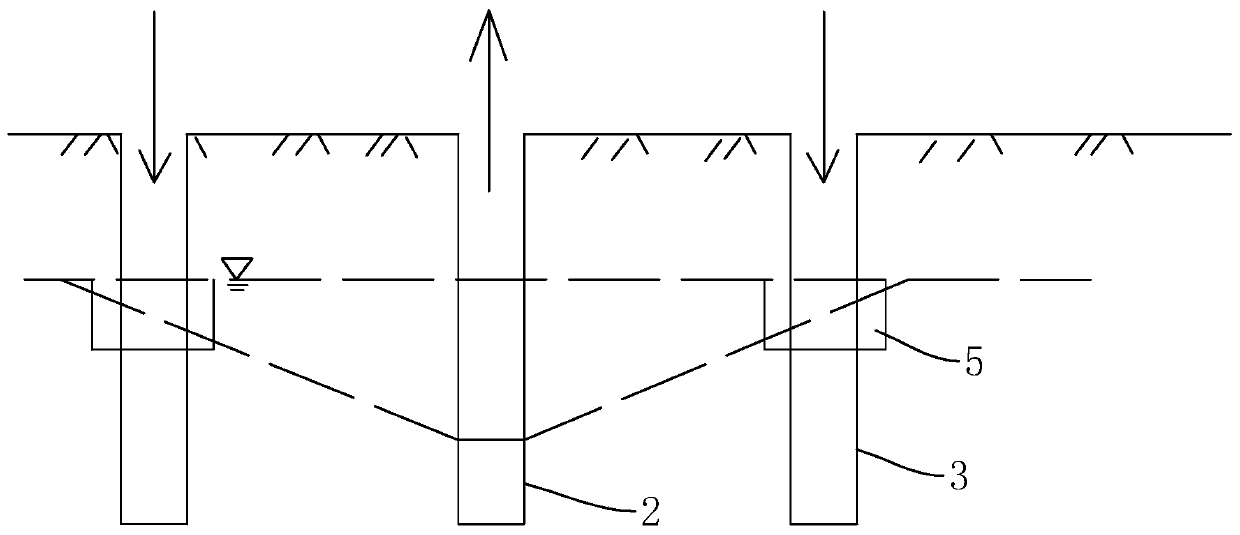

[0037] refer to figure 1 and figure 2 , is a vortex-solidified groundwater restoration system disclosed by the present invention, which is set in the groundwater repair area 1, including a pumping well 2, a water injection well 3 and a fence 5, and the pumping well 2 is set in the center of the repairing area 1, with a diameter of 20- 40cm. The depth is drilled below the groundwater pollution layer, and a water pump is arranged in the pumping well 2 for pumping water outwards. A plurality of water injection wells 3 are evenly spaced along the outer contour of the restoration area 1 , the diameter of the water injection wells 3 is 20-40 cm, and the distance between adjacent water injection wells 3 is 2-4 m. The depth is drilled below the groundwater pollution layer, and the depth is shallower than that of the pumping well 2. Multiple water injection wells 3 surround the repair area 1 to form a circular recharge well group. The distance between the water injection well 3 and ...

Embodiment 2

[0045] A vortex solidification groundwater restoration method disclosed in the present invention comprises the following steps:

[0046] S1. Forming the pumping well group 4: Drilling and injecting multiple pumping wells 2 at intervals in the middle of the repair area 1, the pumping wells 2 are drilled below the groundwater pollution layer, and the multiple pumping wells 2 form the pumping well group 4;

[0047] S2. Forming an annular reinjection well group: setting up a plurality of water injection wells 3 at intervals along the outer contour of the restoration area 1, and drilling the water injection wells 3 below the polluted groundwater layer;

[0048] S3. Form fence 5: Inject inorganic inert adsorption material into each water injection well 3 to form fence 5 by using the high-pressure rotary spraying method, and the inorganic inert adsorption material diffuses outward to make fence 5 enclose repair area 1;

[0049] S4. Groundwater restoration: pump water with large flow ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com