Constant-difference pressure compensation valve

A technology of pressure compensation and fixed difference, which is applied to valve details, safety valves, balance valves, etc., can solve problems such as large pressure difference fluctuations, and achieve the effect of reducing the range of pressure difference fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

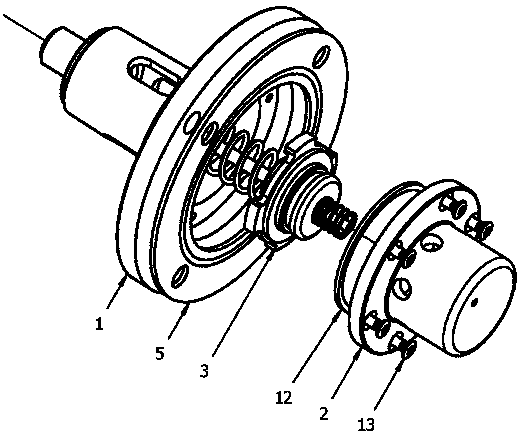

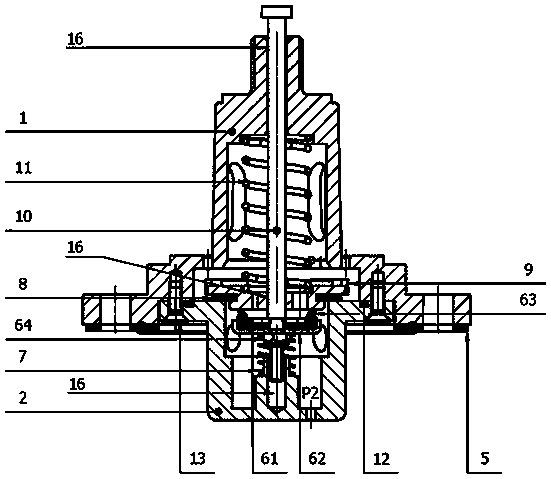

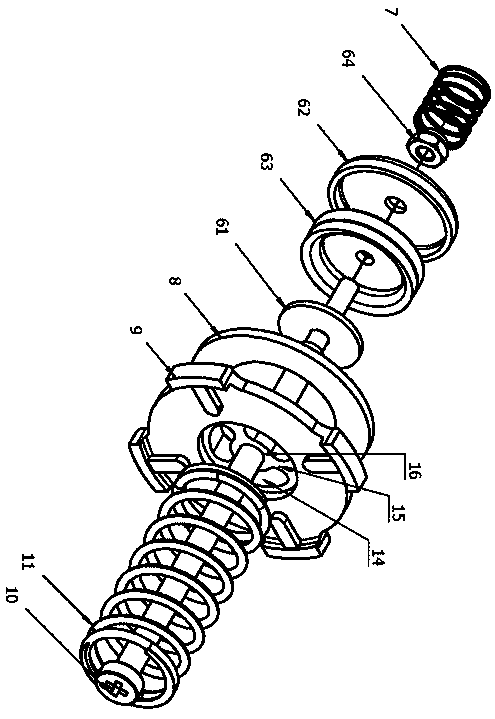

[0014] like figure 1 , 2 As shown, a constant differential pressure compensation valve includes an upper cylinder body 1, a lower cylinder body 2, a differential pressure generator 3, a gasket I5, an O-ring 12, and a countersunk screw 13. The upper cylinder 1 and the lower cylinder 2 are fixedly connected by countersunk screws 13, the O-ring 12 is installed on the lower cylinder 2, the differential pressure generator 3 is installed on the screw 10 inside the upper and lower cylinders, and the gasket I5 is installed On upper cylinder 1.

[0015] Upper cylinder body 1 upper end exterior is screw thread, has 3 waist grooves 14 on its cylinder body, and the inside is a hollow structure, and an aperture is arranged as guide hole 16 above, and the following is a step hole, and the lower end and the inside are connected by flanges.

[0016] The upper end of the lower cylinder body 2 is connected by a flange, and there are six holes on the cylinder body. The inside is a hollow struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com