Method for removal of NOx from flue gas by UV catalytic oxidation

A catalytic oxidation and flue gas technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of interfering with UV photocatalytic effect, affecting the appearance of smoke plume, and low ozone concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

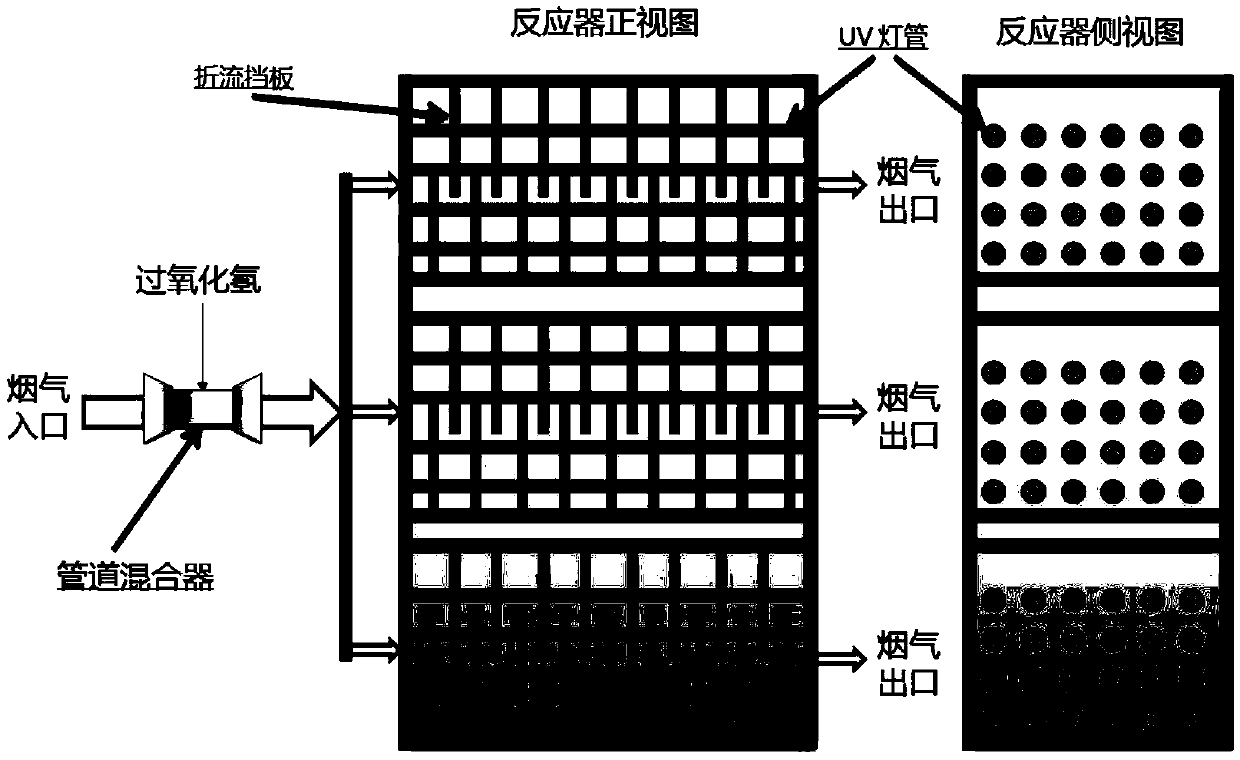

Image

Examples

Embodiment 1

[0030] NO content is 512mg / m 3 (working condition) mixed gas (others are N 2 ), the temperature is 190°C, the pressure is 1atm, and the flow rate is 1800m 3 / h, add 27.5% H 2 o 2 Aqueous solution 30L / h, reacted at 130°C in a UV irradiation reactor, treated with 10% NH 3 After the aqueous solution is absorbed at 20°C, the NO content in the exhaust gas is 5mg / m3, and the NO 2 It is 140mg / m3.

Embodiment 2

[0032] NO content is 468mg / m 3 (working condition) mixed gas (others are N 2 ), the temperature is 185°C, the pressure is 1atm, and the flow rate is 1500m 3 / h, add 27.5% H 2 o 2 Aqueous solution 25L / h, reacted at 111°C in a UV irradiation reactor, treated with 10% NH 3 After the aqueous solution is absorbed at 15°C, the NO content in the exhaust gas is 7mg / m 3 , NO 2 132mg / m 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com