Polyether polyol as well as preparation method and application thereof

A technology of polyether polyol and polyether monomer, which is applied in the field of polyurethane synthetic leather, can solve the problems of poor folding resistance and rough creases, and achieve the effects of excellent processing performance, low energy consumption and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

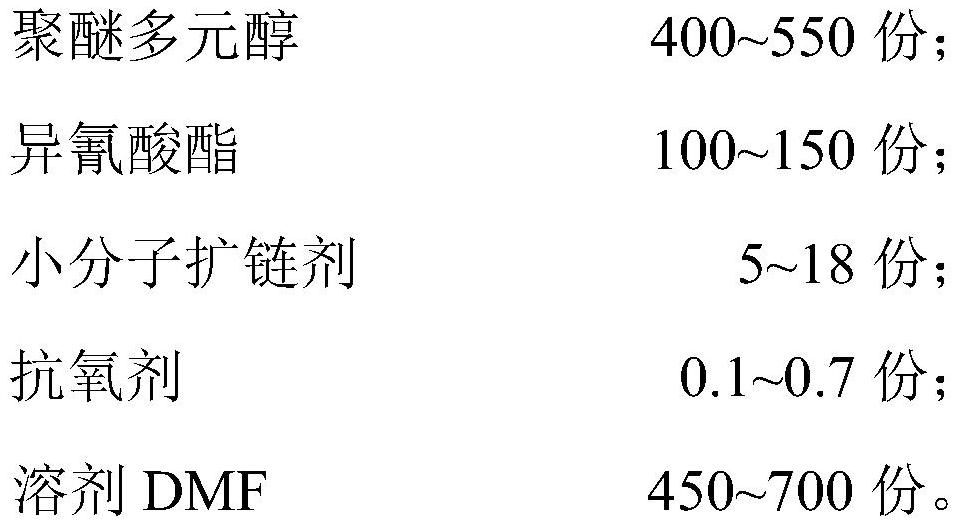

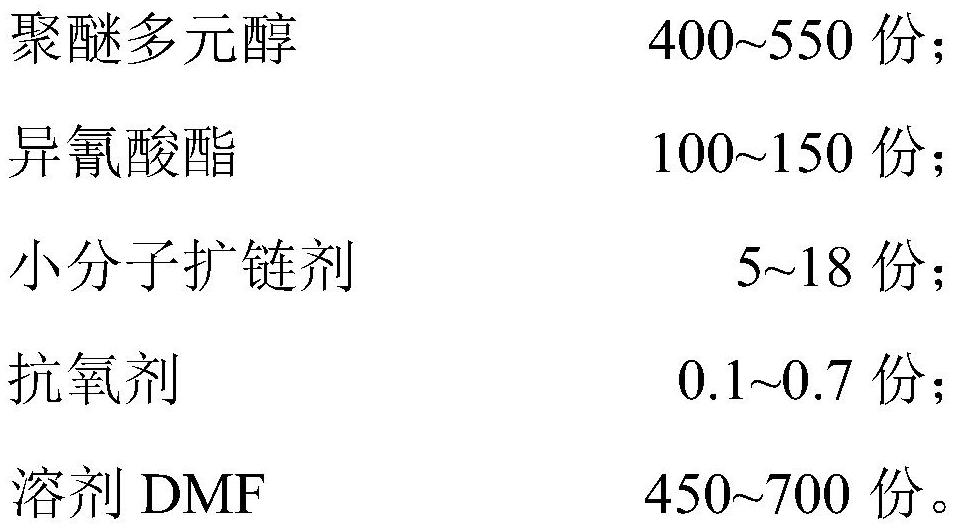

Method used

Image

Examples

Embodiment 1

[0029] 12mL ethylene glycol, 75mL polyether monomer PO, 16mL toluene, 1.5MPa CO 2 , and 0.3 g of a bimetallic catalyst were added to the reactor, and the polymerization reaction was carried out at 110° C. After the reaction was carried out for 90min, it was cooled to room temperature, and then the excess CO in the reactor was 2 Evacuate, then wash the autoclave with solvent, filter and remove the bimetallic catalyst. The obtained polyol was repeatedly washed with deionized water, and vacuum-dried at 90° C. to eliminate solvent and unreacted polyether monomers. The final produced CO 2 The hydroxyl value of the base polyether polyol is 110, and the acid value is 0.35.

[0030] Wherein the bimetallic catalyst is prepared according to the following method: 9g of barium carbonate and 11mL of ethyl ethoxy acetate are dissolved in 43mL of deionized water, stirred at 45°C for 30min to obtain solution A; then 0.6g of hexacyanocobalt Potassium acid potassium was mixed with 15mL deio...

Embodiment 2

[0032] 14mL propylene glycol, 75mL polyether monomer PO, 16mL cyclohexane, 1.7MPa CO 2 , and 0.2 g of bimetallic catalyst were added to the reactor, and the polymerization reaction was carried out at 115°C. After the reaction was carried out for 90min, it was cooled to room temperature, and then the excess CO in the reactor was 2 Evacuate, then wash the autoclave with solvent, filter and remove the bimetallic catalyst. The obtained polyol was repeatedly washed with deionized water, and vacuum-dried at 95° C. to eliminate solvent and unreacted polyether monomers. The final produced CO 2 The hydroxyl value of the base polyether polyol is between 110 and the acid value is 0.35.

[0033] Wherein the bimetallic catalyst is prepared according to the following method: 10g of barium chloride and 10mL of cyclohexane are dissolved in 45mL of deionized water, stirred at 48°C for 30min to obtain solution A; 0.8g of potassium hexacyanoferrate Compatible with 16mL of deionized water and...

Embodiment 3

[0035] 17mL methyl propylene glycol, 80mL polyether monomer PO, 20mL acetone, 2MPa CO 2 , and 0.5 g of a bimetallic catalyst were added to the reactor, and the polymerization reaction was carried out at 120° C. After the reaction was carried out for 90min, it was cooled to room temperature, and then the excess CO in the reactor was 2 Evacuate, then wash the autoclave with solvent, filter and remove the bimetallic catalyst. The obtained polyol was repeatedly washed with deionized water, and vacuum-dried at 95° C. to eliminate solvent and unreacted polyether monomers. The final produced CO 2 The hydroxyl value of the base polyether polyol is 114, and the acid value is 0.3.

[0036]Wherein the bimetallic catalyst is prepared according to the following method: 11g of zinc chloride and 13mL of ethyl acetate are dissolved in 47mL of deionized water, stirred at 50°C for 30min to obtain solution A; 0.9g of hexacyanodinickelic acid Potassium was mixed with 18mL deionized water and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com