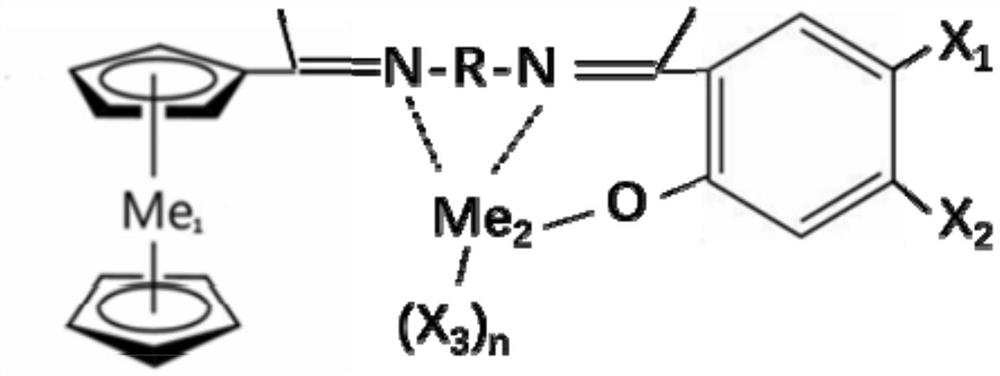

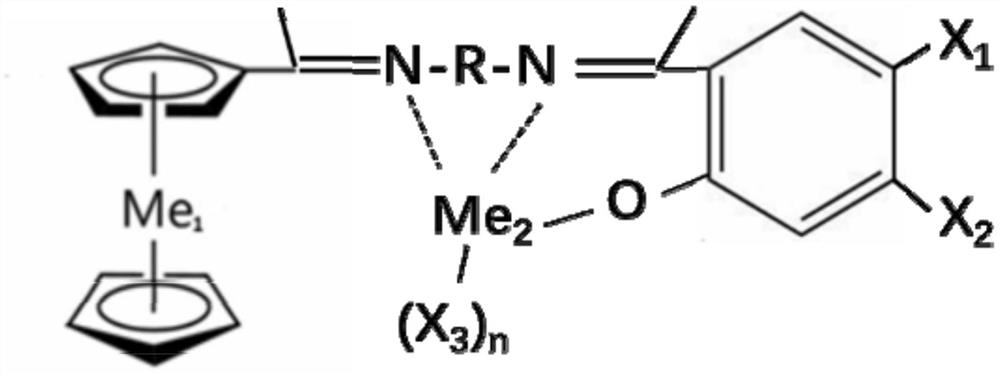

Polyurethane reaction type organic metal catalyst as well as preparation method and application thereof

An organometallic and reactive technology, applied in organic chemistry, chemical instruments and methods, metallocene, etc., can solve problems such as severe toxicity, personal injury, cumbersomeness, etc., achieve strong targeted catalytic characteristics, reduce waste rate, and solve bubble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] This example provides the preparation of polyurethane reactive organometallic catalyst.

[0062] (1) In a reactor equipped with a stirrer, a thermometer, and a condensing reflux device, add 18.6 grams of ferrocene, add 70-75ml of dichloromethane to completely dissolve it; under nitrogen protection, slowly add 7.3 grams of N , N-dimethylformamide, keep warm at -10°C to -5°C, continue to stir for 10-20min after the dropwise addition; slowly add 15.3 grams of phosphorus oxychloride into the above reactor, and slowly stir after the dropwise addition Raise the temperature to 40-50°C, reflux for 18-20h; distill methylene chloride under reduced pressure at a temperature lower than 60°C, pour the residue into ice water at 0-4°C, stir, stand still, and suction filter, and use the filtrate Saturated sodium bicarbonate solution was neutralized to pH=7, extracted with ether, the extract was dried with molecular sieves, suction filtered, and rotary evaporated to obtain the product f...

Embodiment 2

[0066] This example provides the preparation of polyurethane reactive organometallic catalyst.

[0067] (1) In a reactor equipped with a stirrer, a thermometer, and a condensing reflux device, add 18.6 grams of ferrocene, add 70-75ml of dichloromethane to completely dissolve it; under nitrogen protection, slowly add 7.3 grams of N , N-dimethylformamide, keep warm at -10°C to -5°C, continue to stir for 10-20min after the dropwise addition; slowly add 15.3 grams of phosphorus oxychloride into the above reactor, and slowly stir after the dropwise addition Raise the temperature to 40-50°C, reflux for 18-20h; distill methylene chloride under reduced pressure at a temperature lower than 60°C, pour the residue into ice water at 0-4°C, stir, stand still, and suction filter, and use the filtrate Saturated sodium bicarbonate solution was neutralized to pH=7, extracted with ether, the extract was dried with molecular sieves, suction filtered, and rotary evaporated to obtain the product f...

Embodiment 3

[0071] This example provides the preparation of polyurethane reactive organometallic catalyst.

[0072] (1) In a reactor equipped with a stirrer, a thermometer, and a condensing reflux device, add 18.6 grams of ferrocene, add 70-75ml of dichloromethane to completely dissolve it; under nitrogen protection, slowly add 7.3 grams of N , N-dimethylformamide, keep warm at -10°C to -5°C, continue to stir for 10-20min after the dropwise addition; slowly add 15.3 grams of phosphorus oxychloride into the above reactor, and slowly stir after the dropwise addition Raise the temperature to 40-50°C, reflux for 18-20h; distill methylene chloride under reduced pressure at a temperature lower than 60°C, pour the residue into ice water at 0-4°C, stir, stand still, and suction filter, and use the filtrate Saturated sodium bicarbonate solution was neutralized to pH=7, extracted with ether, the extract was dried with molecular sieves, suction filtered, and rotary evaporated to obtain the product f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com