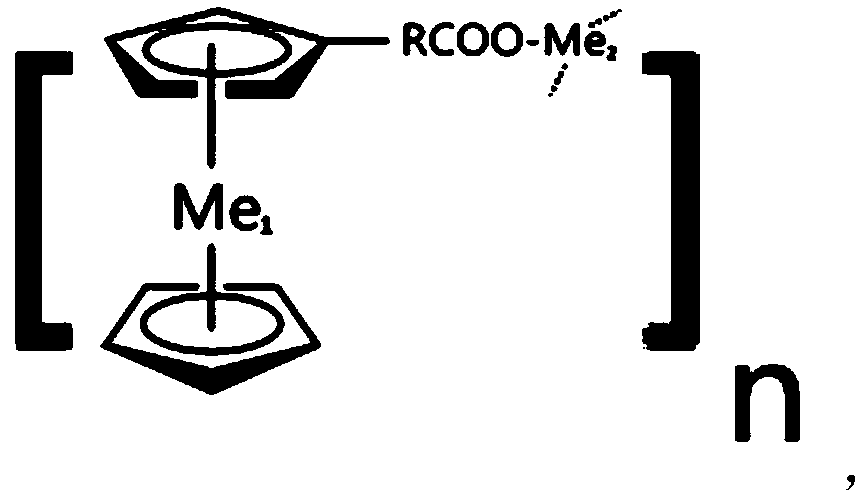

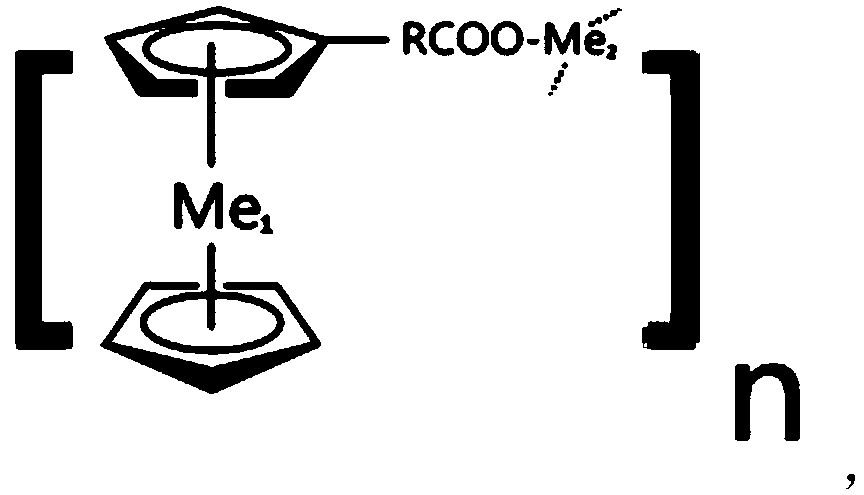

Oligomeric coordination heterozygous organometallic catalyst, preparation method and application thereof

An organometallic and catalyst technology, which is applied in the field of oligomeric coordination hybrid organometallic catalysts, can solve the problems of easily polluted environment, easy occurrence of bubbles, scales, bubbling, and high waste rate in polyurethane products, and achieves low reaction catalytic activity, Strong targeted catalytic properties, no effect of highly toxic heavy metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment provides an oligomeric coordination hybrid metal catalyst. 80g of NaOH was weighed and dissolved in 300g of water, 132.2g of cyclopentadiene was weighed and dissolved in 300g of THF and placed in a three-necked flask, the magnetic stirrer was turned on, the NaOH solution was gradually added dropwise to the THF solution, and after 1-2 hours of reaction, Add 129.6g NiCl 2 , the temperature was kept at 70-80 °C for 2-3 hours, the reaction mixture was left to stand, the solution was layered, the lower layer was green crystals, the upper layer solution was filtered off, and the lower layer of crystals was washed with deionized water for 2-3 times. The residual water is removed by the steamer to obtain nickelocene. The temperature was lowered to below 50°C, THF was added to dissolve the obtained nickelocene, 60g of butyllithium was added to stir the reaction, and CO was introduced into the reaction system. 2 Gas, keep the temperature at 70-80 ℃ and react for...

Embodiment 2

[0047]This embodiment provides an oligomeric coordination hybrid metal catalyst. 80g of NaOH was weighed and dissolved in 300g of water, 132.2g of cyclopentadiene was weighed and dissolved in 300g of THF and placed in a three-necked flask, the magnetic stirrer was turned on, the NaOH solution was gradually added dropwise to the THF solution, reacted for 1-2 hours, and then added 129.6g NiCl 2 , the temperature was kept at 70-80 °C for 2-3 hours, the reaction mixture was left standing, the solution was layered, the lower layer was green crystals, the upper layer solution was filtered off, and the lower layer crystals were washed with an aqueous solution for 2-3 times, and then removed with a reduced pressure rotary evaporator Residual water, get two nickelocene. Cool to below 50°C, add THF to dissolve it, add 60g butyllithium to stir the reaction, and pass CO 2 Gas, keep the temperature at 70-80 ℃ and react for about 1-2 hours to get a dark green liquid, stop passing CO 2 ga...

Embodiment 3

[0049] This embodiment provides an oligomeric coordination hybrid metal catalyst. 80g of NaOH was weighed and dissolved in 300g of water, 132.2g of cyclopentadiene was weighed and dissolved in 300g of THF and placed in a three-necked flask, the magnetic stirrer was turned on, the NaOH solution was gradually added dropwise to the THF solution, reacted for 1-2 hours, and then added 126.7g FeCl 2 , the temperature was kept at 70-80 °C for 2-3 hours, the reaction mixture was left to stand, the solution was layered, the lower layer was orange crystals, the upper layer solution was filtered off, and the lower layer of crystals was washed with an aqueous solution for 2-3 times, and then removed with a reduced pressure rotary evaporator Residual water, ferrocene. Cool to below 50°C, add THF to dissolve it, add 60g butyllithium to stir the reaction, and pass CO 2 Gas, keep the temperature at 70-80 °C and react for about 1-2 hours to get a brown liquid, stop passing CO 2 gas, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com