Flue gas desulfurization system for sintering machines

A technology of desulfurization system and sintering machine, applied in the field of desulfurization system, can solve the problems of low desulfurization rate and absorbent utilization rate of semi-dry method, high transportation cost, etc., and achieve the effect of increasing desulfurization reaction time, effective humidity and increasing height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

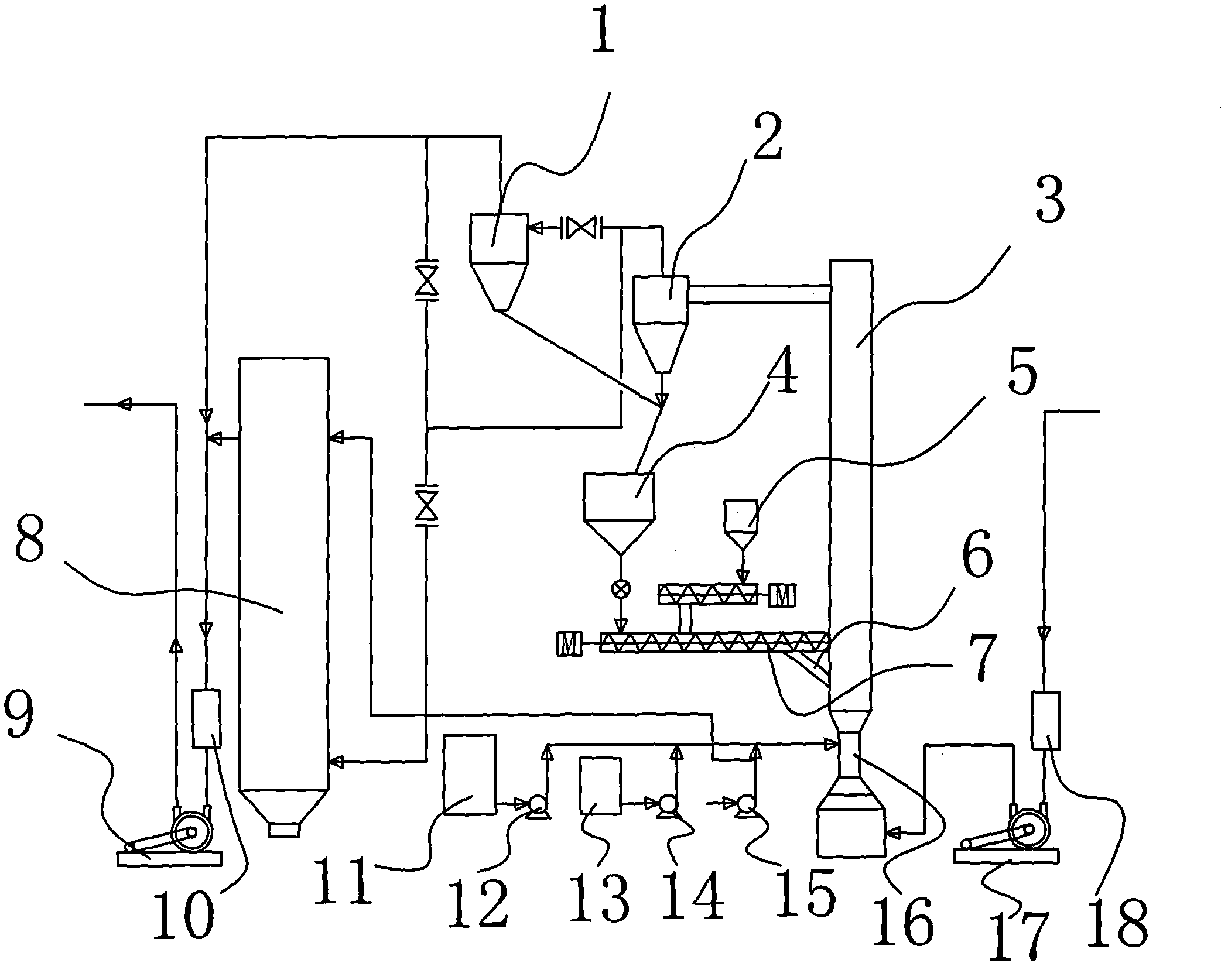

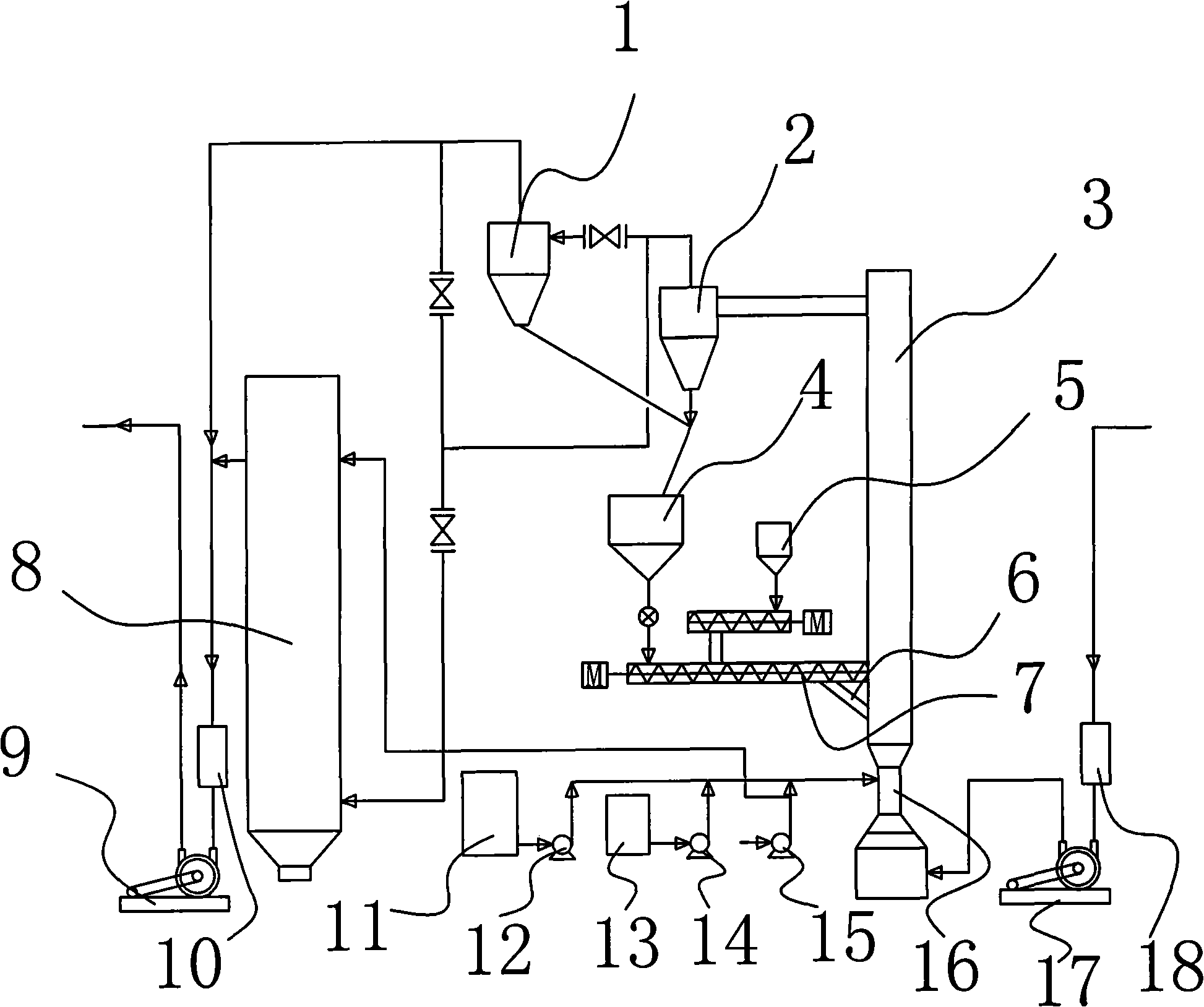

[0027] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

[0028] A flue gas sintering machine desulfurization system, including a reactor 3, a flue gas induced draft unit, a physical state separation unit, a solid matter return and packing unit, an absorbent adding unit, and a data acquisition unit; wherein,

[0029] The bottom of the reactor 1 is set as a Venturi part 16 of Venturi structure, and above the Venturi part 16 is a column with a height of 24.6m and a diameter of 2.4m;

[0030] The flue gas induction unit includes an induced fan 17 that transports the pre-dust-removed sintering machine flue gas to the bottom of the reactor 3 through the fan pipe;

[0031] The physical state separation unit includes a primary cyclone separator 2 connected to the exhaust port at the top of the reactor 3, a secondary cyclone separator 1 connected to the primary cyclone separator 2, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com