Centrifugal fan, extractor hood applying same and control method

A technology of centrifugal fans and range hoods, applied in application, pump control, oil fume removal, etc., can solve problems such as unsatisfactory effects, and achieve the effects of optimizing vortex, reducing lateral flow, and improving secondary flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

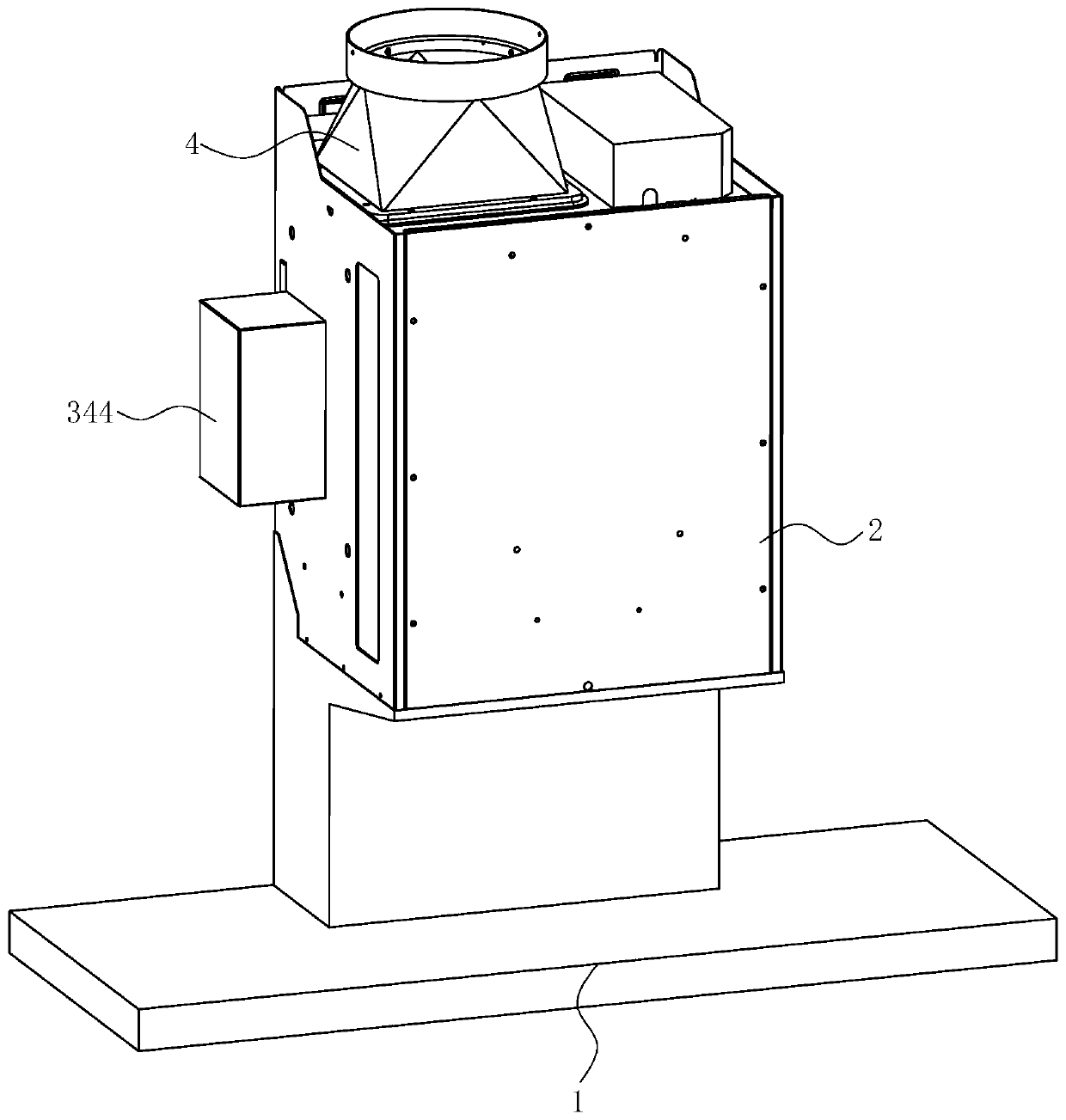

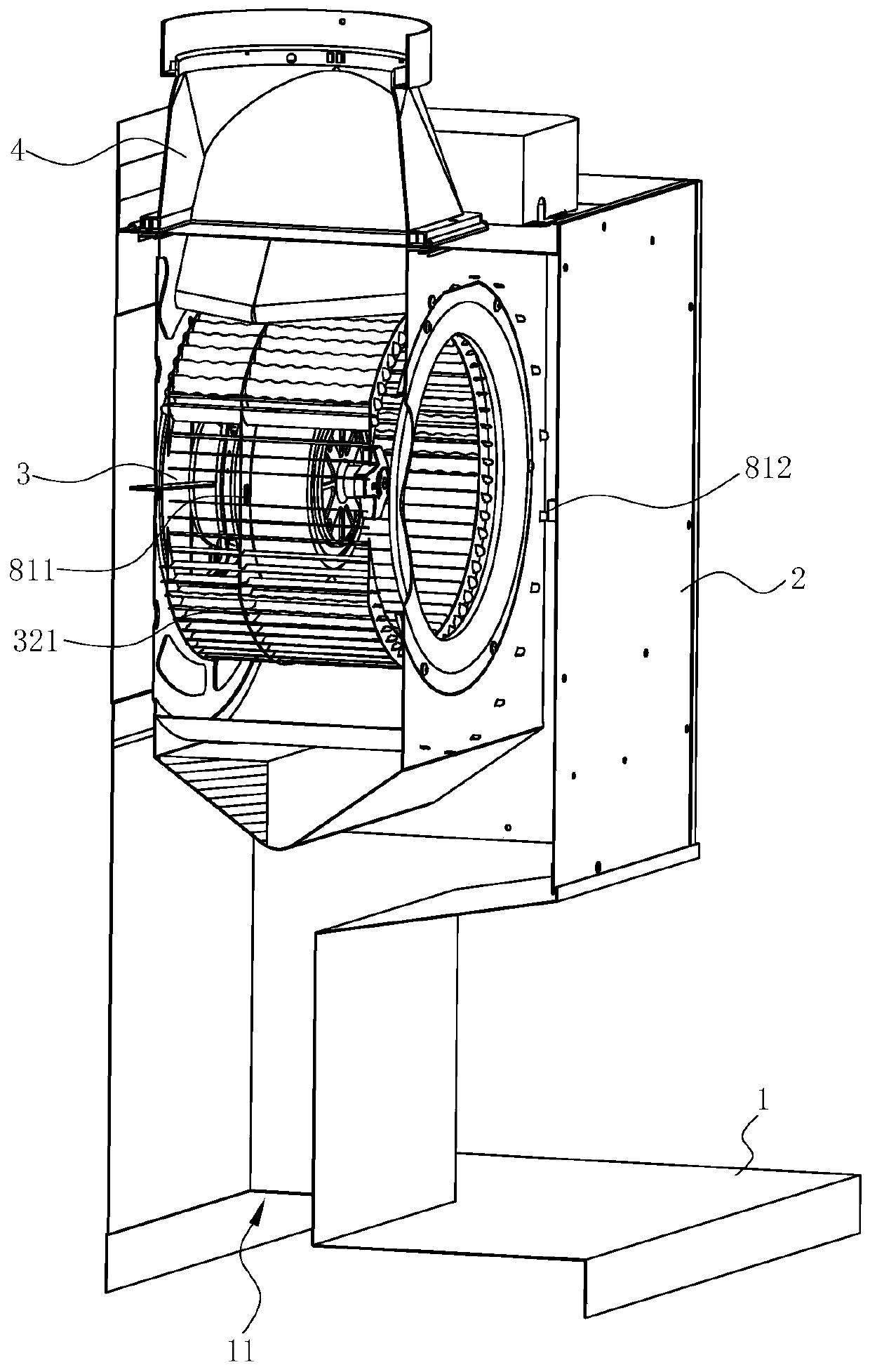

[0048] see Figure 1 to Figure 6, a range hood, comprising a fume collecting hood 1, a casing 2 arranged above the fume collecting hood 1 and a centrifugal fan 3 arranged in the casing 2, and an outlet hood 4 is arranged at the outlet of the centrifugal fan 3. The fume collecting hood 1 is provided with an air inlet 11 . Therefore, under the action of the centrifugal fan 3 , the oil fume is sucked into the inside of the range hood through the air inlet 11 from the lower part of the range hood, and is discharged to the public flue through the air outlet hood 4 .

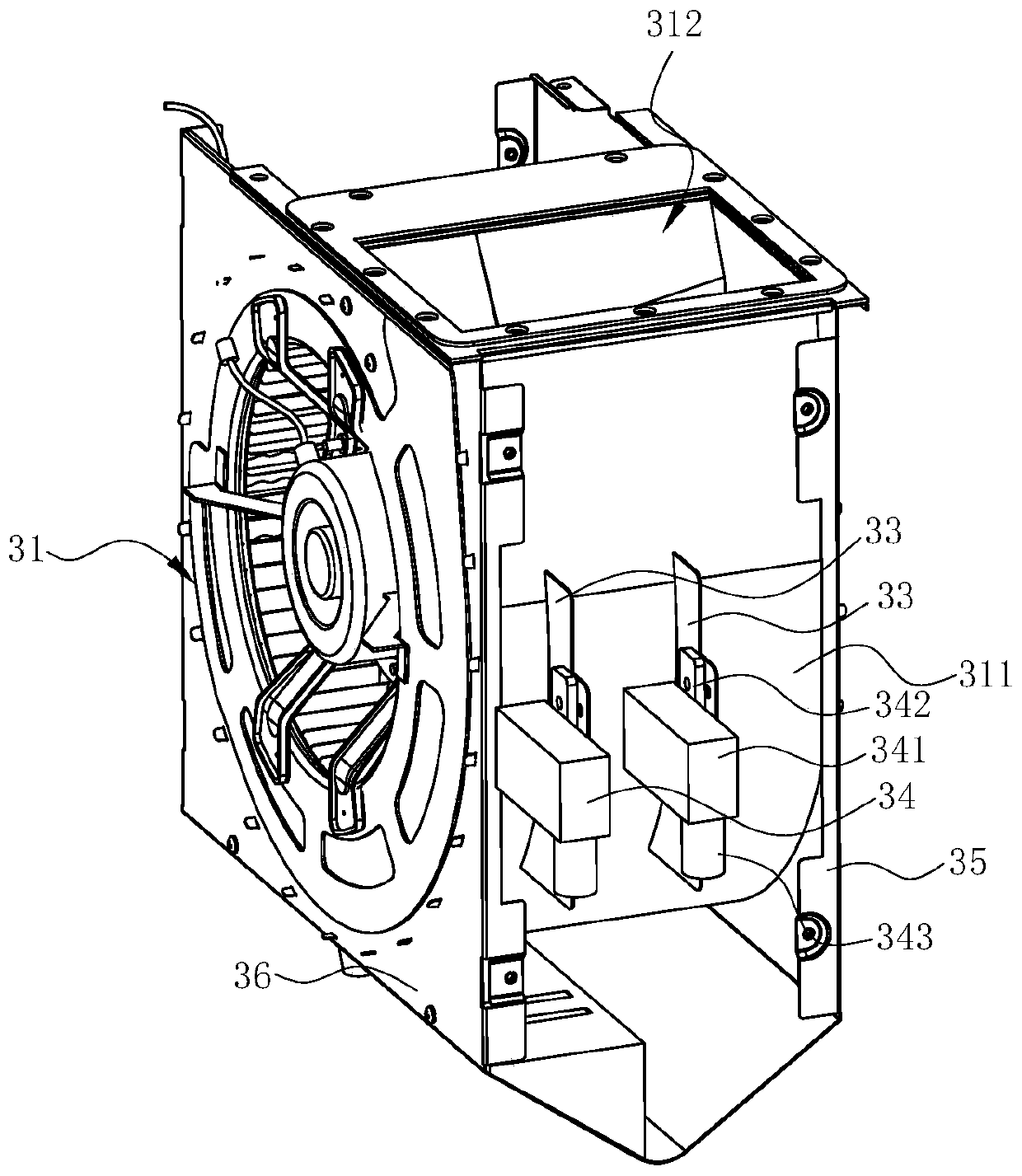

[0049] The centrifugal fan 3 includes a volute 31, an impeller 32 arranged in the volute 31, a front air deflector 35 and a rear air deflector 36. The volute 31 includes a ring wall 311, and the front end of the ring wall 311 is fixed on the front wind deflector 35, The rear end of the ring wall 311 is fixed on the rear wind deflector 36 . The annular wall 311 , the front air deflector 35 and the rear air deflector ...

Embodiment 2

[0061] see Figure 11 to Figure 14 , the top of the air outlet hood 4 is provided with an outlet pipe 5 and communicated with each other. The working condition detection device is a flow velocity measurement device provided on the outlet pipe 5, including a rectifying grille 61 arranged in the outlet pipe 5, a pitot tube 62 arranged on the inner side of the peripheral wall of the outlet pipe 5, and a feedback unit 63 arranged on the peripheral wall of the outlet pipe 5. On the outside, on the oil fume flow path, the pitot tube 62 is located downstream of the straightening grille 61 . The rectifying grille 61 makes the air flow into the outlet pipe 5 and is rectified by the rectifying grille 61, so that the airflow near the pitot tube 62 is uniform and the measurement is more accurate. The pitot tube 62 adopts the prior art, and its outer peripheral wall is provided with a static pressure measurement hole 621 for measuring the static pressure Ps, and the bottom end is provided...

Embodiment 3

[0069] see Figure 16 to Figure 18 , in this embodiment, the difference from the second embodiment is that the working condition detection device is a static pressure measuring device arranged on the outlet pipe 5, including a rectifying grille 61 arranged in the outlet pipe 5, The static pressure pipe 62 ′ on the inner side of the peripheral wall and the feedback unit 63 on the outer side of the peripheral wall of the outlet pipe 5 are located downstream of the rectifying grille 61 on the oil fume flow path. The rectification grid 61 makes the air flow into the outlet pipe 5 and is rectified by the rectification grid 61, so that the air flow near the static pressure pipe 62' is uniform and the measurement is more accurate. The static pressure pipe 62' adopts the prior art, and its outer peripheral wall is provided with a static pressure measuring hole 621' for measuring the static pressure Ps.

[0070] Its control method see Figure 19 , including the following steps:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com