Impingement Cooling Structures for Gas Turbines

A cooling structure, gas turbine technology, applied in the cooling of the engine, the cooling of the turbine/propulsion device, the mechanical equipment, etc., can solve the problem of reducing the effect of the impact cooling effect, etc., to reduce the impact, enhance the cooling effect, and reduce the gas The effect of lateral flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

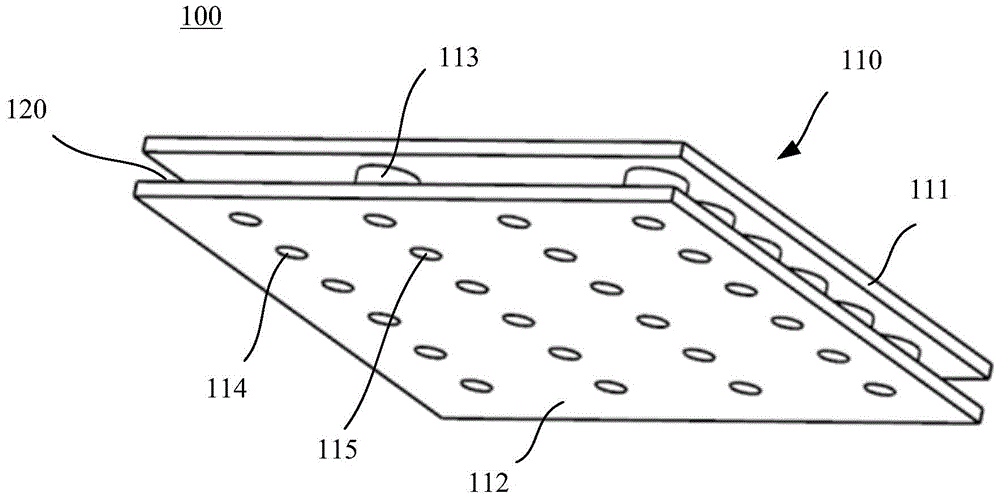

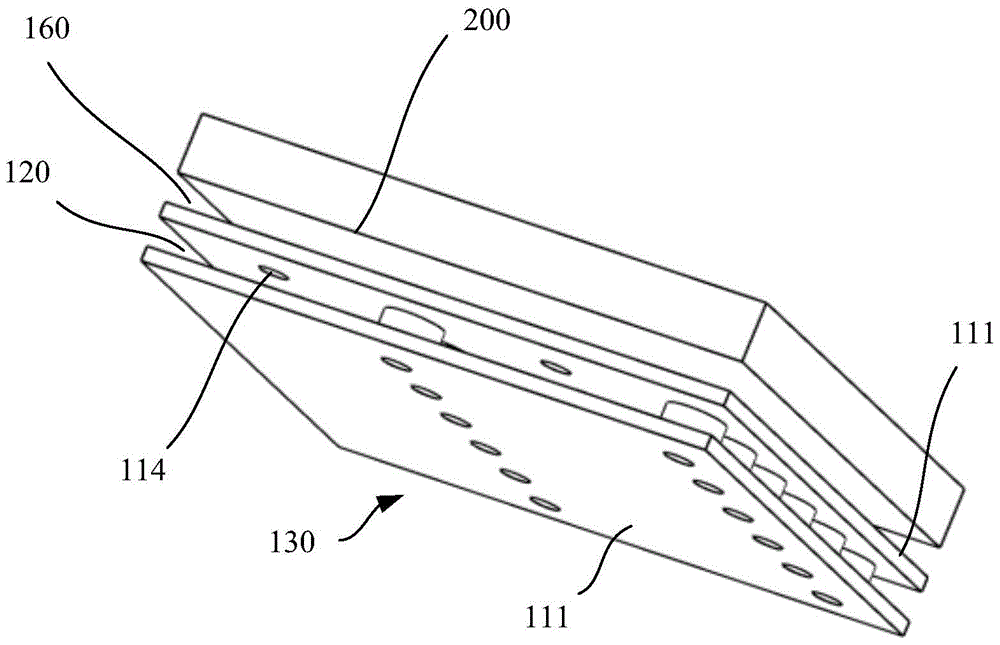

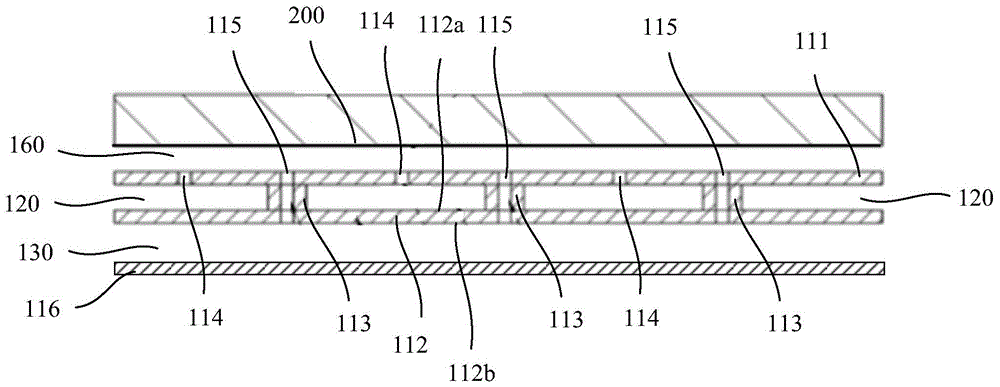

[0024] figure 1 A perspective view showing an impingement cooling structure according to an embodiment of the present invention. figure 2 A schematic diagram of cooperation between the impingement cooling structure and the wall to be cooled according to an embodiment of the present invention is shown. image 3 A schematic cross-sectional view showing an impingement cooling structure according to an embodiment of the present invention. refer to Figure 1-3 As shown, an impingement cooling structure 100 for a gas turbine in this embodiment includes an impingement bushing 110 , a gas outlet 114 , a gas return port 115 , a gas introduction area 120 , and a gas outlet area 130 . The impact bushing 110 is spaced opposite to the wall surface 200 to be cooled, forming an impact channel 160 . Here, the wall to be cooled may be the middle wall of the turbine blade or the wall of the combustion chamber. A plurality of gas outlets 114 are distributed over the impingement liner 110 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com