Lamellar separator with sump

A flake-like separator technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of being taken away or discharged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

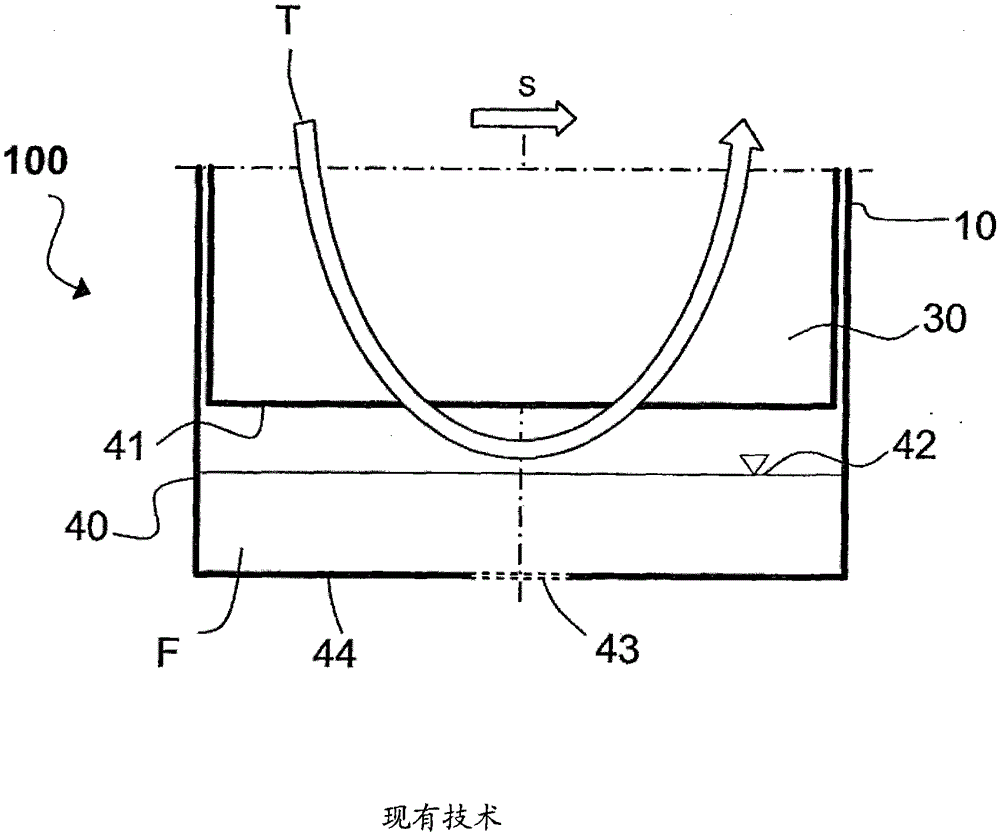

[0019] figure 1 The lower base region of a lamellar separator 100 according to the prior art is shown. The lamellar separator 100 is surrounded by a housing 10 into which the sump 40 is integrated. The laminar separator 100 has vertically oriented laminar profiles placed parallel to each other and spaced apart, the laminar profiles together forming a lamellar separation space, figure 1 Only the lower part of an individual laminar profiled part 30 can be seen in FIG. The lower edge of the lamellar profile 30 is indicated by 31 . The liquid-laden fluid flows through the lamellar separator 100 in a specific flow-through direction S, and the liquid droplets are separated from the flowing fluid on the wall surfaces of the laminar separator 30 in a known manner. The separated droplets coalesce and drain downwards due to gravity into a sump 40 provided for this purpose. The collected liquid F can be discharged through a discharge opening 43 (shown by dotted lines) located in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com