Natural mineral/activated carbon composite material and preparation method thereof

A technology of natural minerals and composite materials, applied in chemical instruments and methods, alkali metal oxides/hydroxides, water pollutants, etc., can solve the problems of difficult to control production conditions, low adsorption capacity, and high production costs of adsorbents, To achieve the effect of improving wettability and improving adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

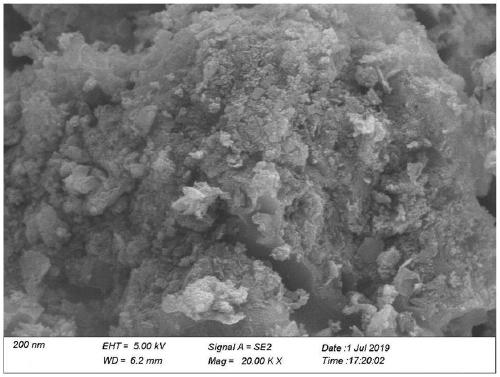

[0031] (1) Weigh 10g asphalt powder, 20g KOH powder and 20g attapulgite, put them in a pulverizer and stir for 2min to obtain a uniform powder mixture;

[0032] (2) Put the mixture in a corundum porcelain boat, put it into a horizontal tube furnace and pass nitrogen gas, raise the temperature in the horizontal tube furnace to 800 °C at a rate of 10 °C / min and maintain it for 60 min, After the temperature in the horizontal tube furnace is naturally cooled to room temperature, take out the reaction product; put the product into a beaker and add 1L of water for stirring, while continuously adding concentrated hydrochloric acid and measuring the pH value of the solution at any time until the pH value is 2. Stop Hydrochloric acid was added dropwise, and finally washed with water to neutrality, and placed in an oven, dried at 80°C to obtain a natural mineral / activated carbon composite material.

Embodiment 2

[0034] (1) Weigh 10g of catalytic cracking oil slurry, 20g of NaOH powder and 10g of bentonite, put them in a pulverizer and stir for 3min to obtain a uniform powdery mixture;

[0035] (2) Put the mixture in a corundum porcelain boat, put it into a horizontal tube furnace and feed nitrogen gas, raise the temperature in the horizontal tube furnace to 700 °C at a rate of 15 °C / min and maintain it for 90 min, After the temperature in the horizontal tube furnace is naturally cooled to room temperature, take out the reaction product; put the product into a beaker and add 1L of water for stirring, while continuously adding concentrated hydrochloric acid and measuring the pH value of the solution at any time until the pH value is 2. Stop Hydrochloric acid was added dropwise, and finally washed with water until neutral, and placed in an oven, dried at 90°C to obtain a natural mineral / activated carbon composite.

Embodiment 3

[0037] (1) Weigh 10g vacuum residue, 20g ZnCl 2 powder and 5g vermiculite, placed in a pulverizer and stirred for 5min to obtain a uniform powdery mixture;

[0038] (2) Put the mixture in a corundum porcelain boat, put it into a horizontal tube furnace and pass nitrogen gas, raise the temperature in the horizontal tube furnace to 900 °C at a rate of 20 °C / min and maintain it for 100 min, After the temperature in the horizontal tube furnace is naturally cooled to room temperature, take out the reaction product; put the product into a beaker and add 1L of water for stirring, while continuously adding concentrated hydrochloric acid and measuring the pH value of the solution at any time until the pH value is 2. Stop Hydrochloric acid was added dropwise, and finally washed with water until neutral, and placed in an oven, dried at 100°C to obtain a natural mineral / activated carbon composite.

PUM

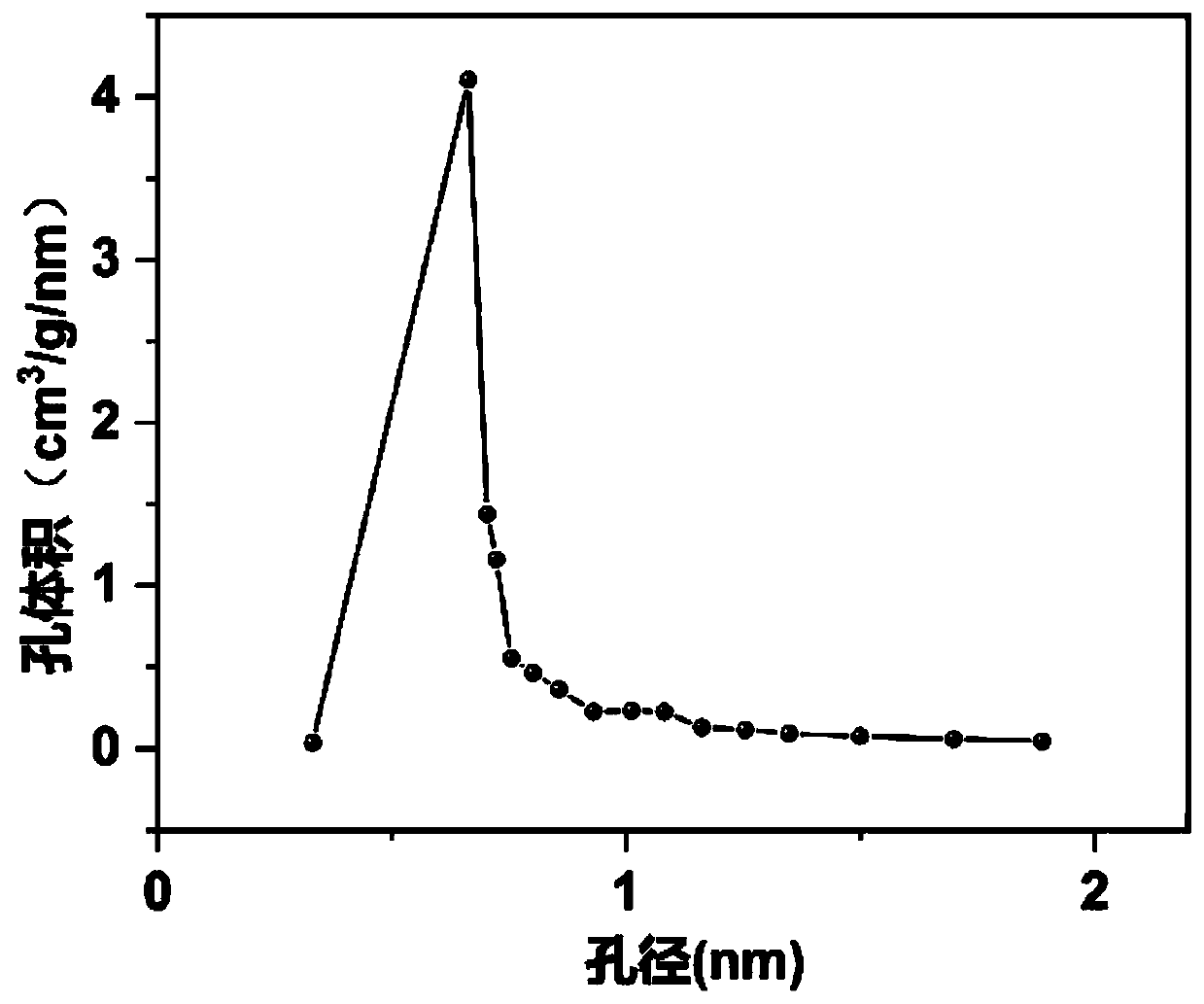

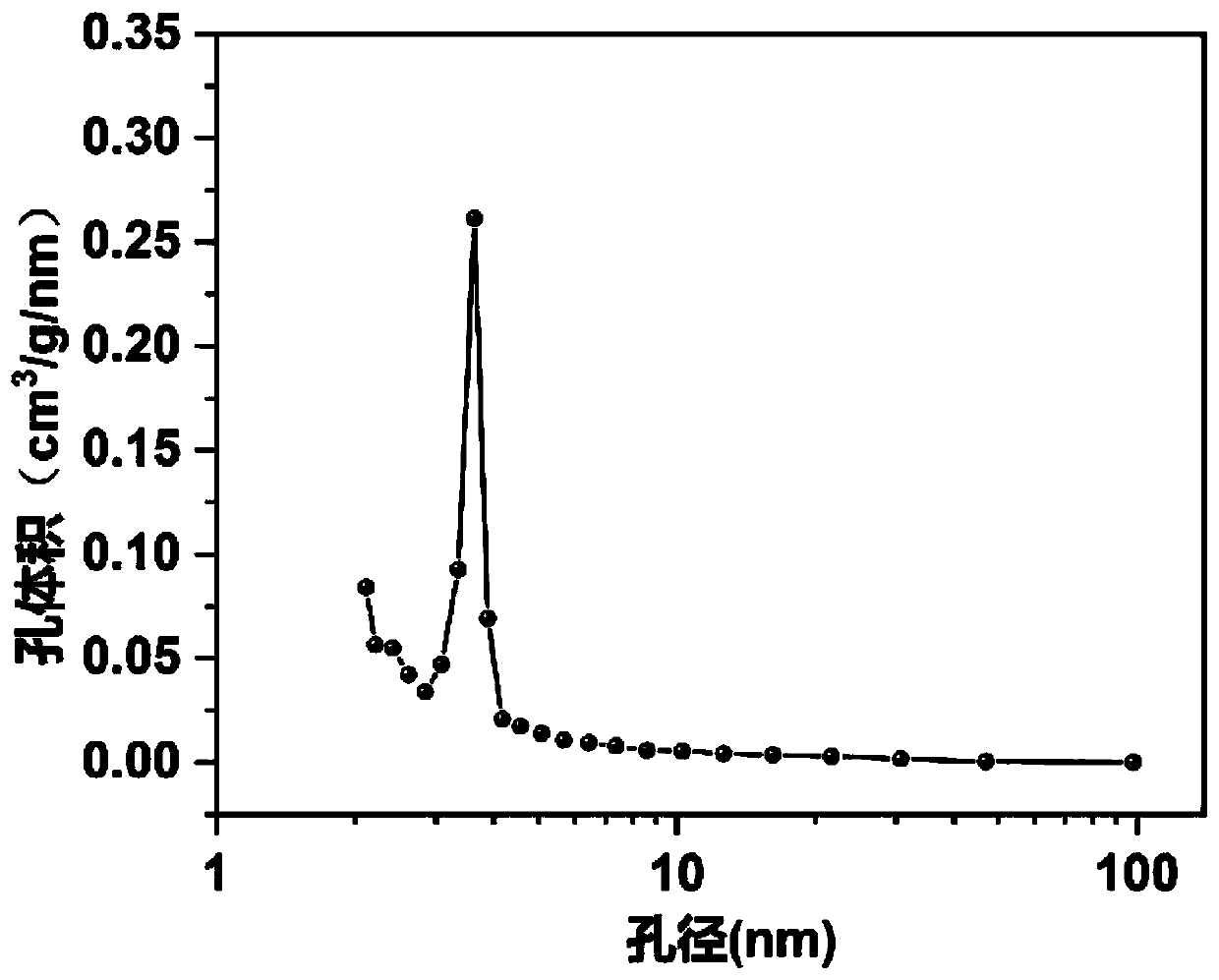

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com