Catalyst stuffing and stuffing bed for seawater desulfurization process

A desulfurization process and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low separation efficiency, large pressure drop, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

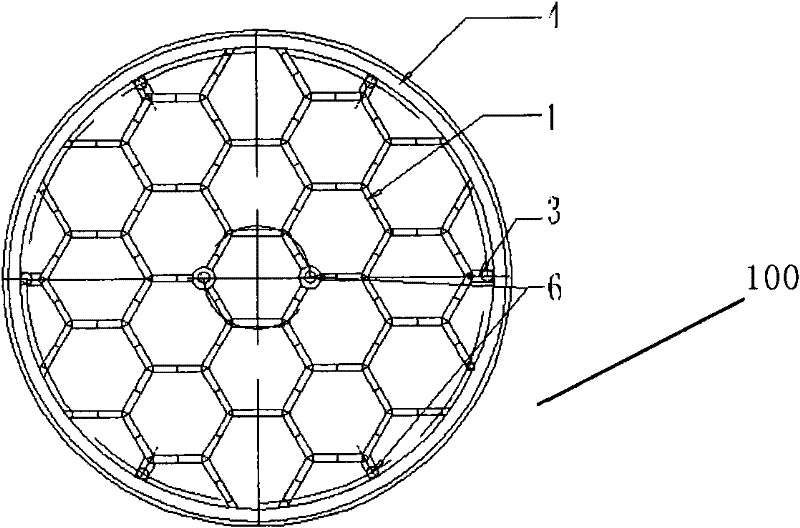

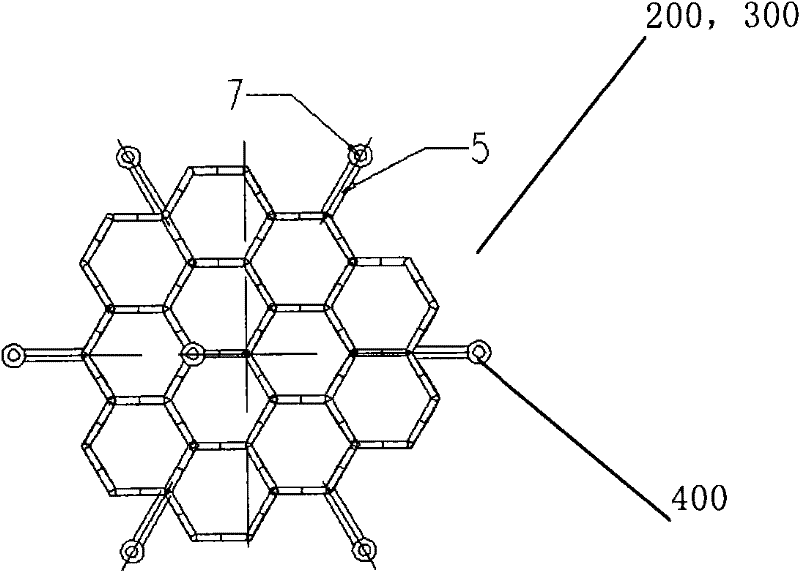

[0086] Such as Figure 1 to Figure 6 As shown, the catalyst packing of the seawater desulfurization process is composed of a three-layer honeycomb ring structure, including:

[0087] (a) intermediate layer honeycomb ring 100; described intermediate layer honeycomb ring 100 comprises:

[0088] - circumscribed ring 4;

[0089] - Nineteen honeycomb rings 1 are arranged on the outer ring 4, and a central honeycomb ring closely surrounding the center is evenly distributed by eighteen honeycomb rings;

[0090] (b) The upper surface honeycomb ring 200 and the lower surface honeycomb ring 300; the upper surface honeycomb ring 200 and the lower surface honeycomb ring 300 are respectively provided with twelve honeycomb rings, wherein,

[0091] The centers of the upper surface honeycomb ring 200 and the lower surface honeycomb ring 300 are on the same axis as the center of the middle layer honeycomb ring 100;

[0092] And the upper surface honeycomb ring 200 and the lower surface hone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com