Hydrate prevention method during deep well drilling period

A technology for hydrate and deep water wells, which is applied to drilling compositions, chemical instruments and methods, and earth-moving drilling and mining, etc., can solve the problems of easy formation of hydrates, etc., and achieves high pollution resistance, convenient operation and simple method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

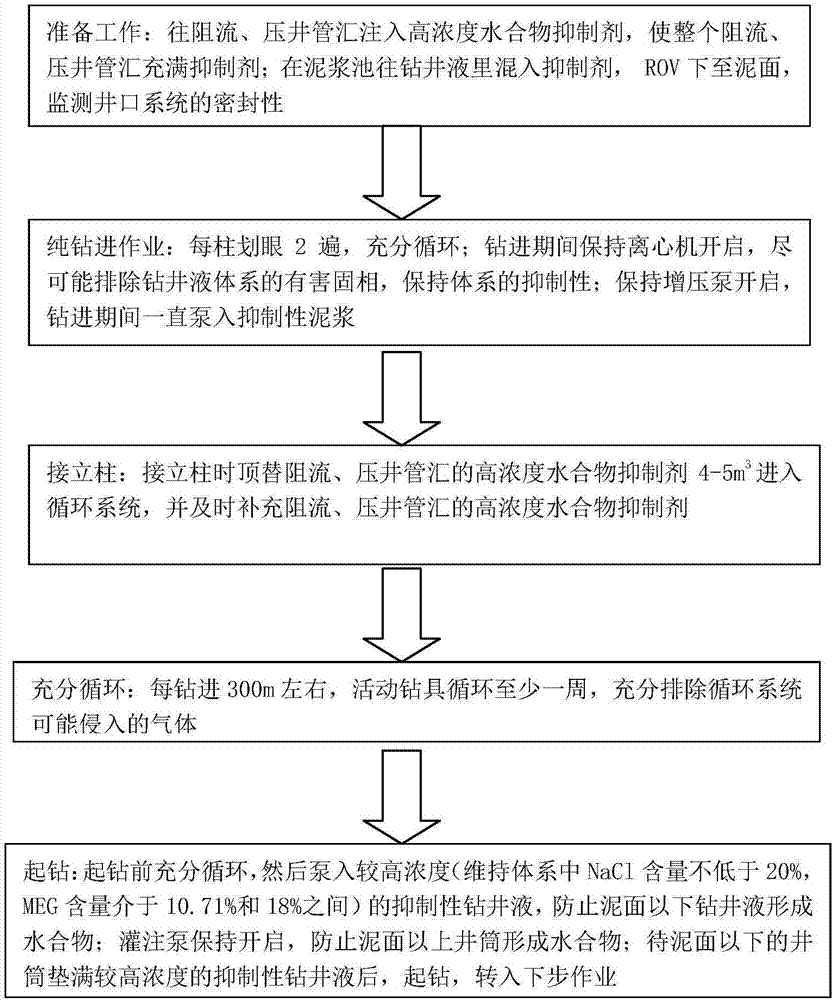

[0025] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. And the features in the embodiments can be combined with each other.

[0026] like figure 1 As shown, a method for preventing and controlling hydrates during deepwater well drilling provided by an embodiment of the present invention includes the following steps:

[0027] S1. Preparatory work: Inject high-concentration hydrate inhibitors into the choke and kill manifolds, so that the entire choke and kill manifolds are filled with high-concentration hydrate inhibitors. The formula of the high-concentration hydrate inhibitors is: 20.5% sodium chloride saline + 17.7% ethylene glycol. Inhibitors are mixed into the drilling fluid in the mud pool to form inhibitory drilling fluids. The inhibitor formula is: 12.2% sodium chloride...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com