High strength non-cement corundum castable material used in heating furnace

A castable, cement-free technology, applied in the field of high-strength cement-free corundum castables for heating furnaces, can solve problems such as no reports yet, achieve the effects of simple production process, improved sintering performance, and maintained continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

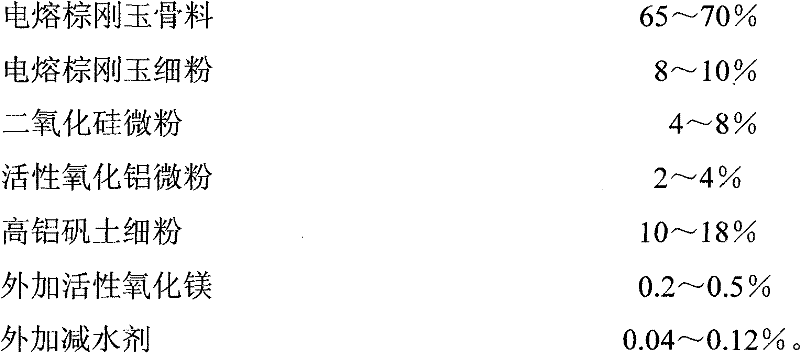

Method used

Image

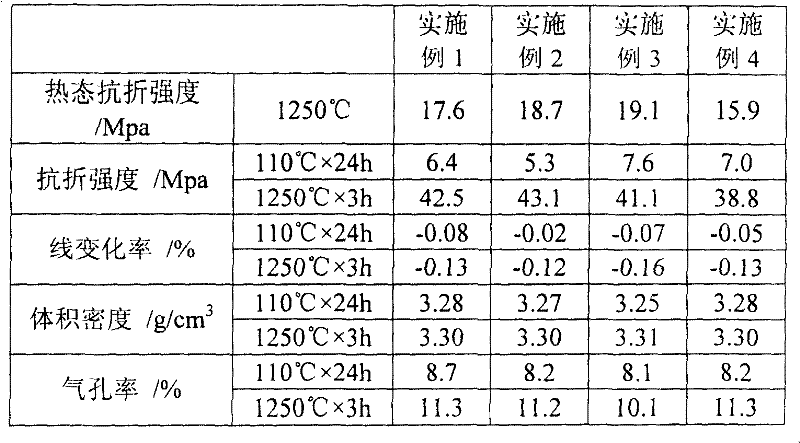

Examples

Embodiment 1

[0031] Example 1: The proportion of each component is (mass percentage) fused brown corundum particles 65%, fused brown corundum fine powder 9%, high alumina fine powder 18%, silica micropowder 4%, activated alumina Micropowder 4%, active magnesium oxide (additional) 0.2%, sodium citrate 0.04% (additional).

Embodiment 2

[0032] Example 2: The proportion of each component is (mass percentage): 67% of fused brown corundum particles, 10% of fused brown corundum fine powder, 16% of high alumina fine powder, 5% of silica micropowder, activated alumina Micropowder 2%, activated magnesium oxide (additional) 0.3%, citric acid 0.04% (additional).

Embodiment 3

[0033] Example 3: The proportion of each component is (mass percentage) fused brown corundum particles 68%, fused brown corundum fine powder 9%, high alumina fine powder 14%, silica micropowder 6%, activated alumina Micropowder 3%, active magnesium oxide (additional) 0.4%, ammonium citrate 0.08% (additional).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com