Glue spreading method of soundproof cotton glue spreader

一种棉涂胶、涂胶的技术,应用在涂胶机领域,能够解决胶水易粘结在胶辊两端、不易清理、废胶回收率不高等问题,达到消除胶水失效现象、提高涂胶效率、减少缺胶现象的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

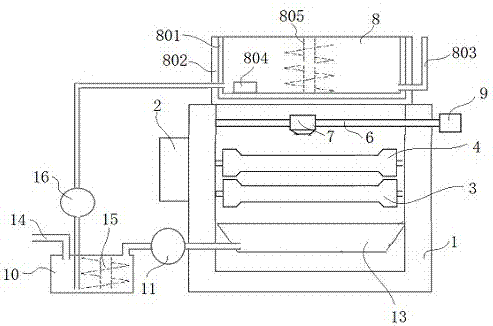

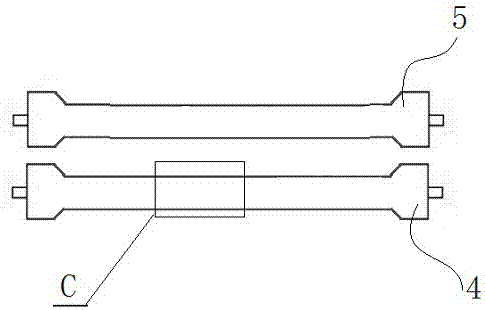

[0060] Such as figure 1 As shown, the soundproof cotton gluing machine of the present embodiment includes a frame 1, and a gluing mechanism is provided on the frame 1, and the gluing mechanism includes a gluing roller 3, a gluing roller 4 and a gluing roller arranged in parallel to each other. Roller 5, the glue-coating roller 3 is located below the gap between the top glue roller 4 and the glue-adjusting roller 5; the glue-coating roller 3, the top glue roller 4 and the glue-adjusting roller 5 are driven to rotate by different driving motors 2; A rubber storage barrel 8 is arranged above the upper rubber roller 4 and the rubber adjustment roller 5 .

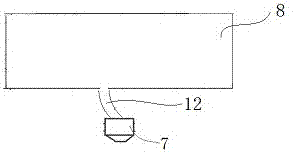

[0061] The outer side of the glue storage barrel 8 wraps the heating layer 801 and the insulation layer 802 respectively from the inside to the outside. The heating layer 801 is provided with a thermal resistor, which can heat the glue in the glue storage barrel 8 through the heat release of the thermal resistor; the insulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com