Refined honey processing process

A processing technology and honey technology, applied in the field of refined honey processing technology, can solve the problems of honey crystallization, crystallized product discarding, waste and the like, and achieve the effects of stable quality, low processing cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

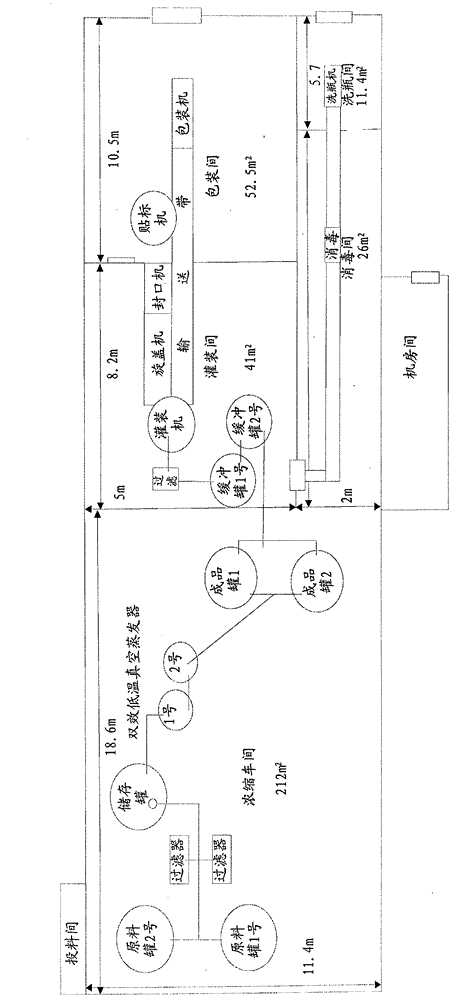

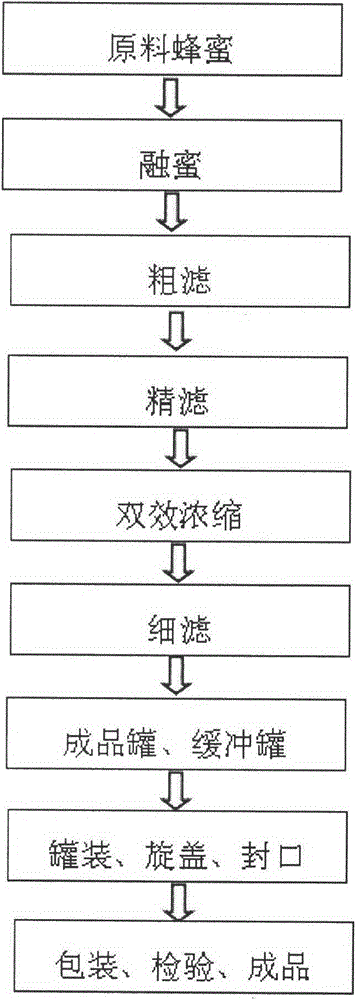

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: Take 50Kg of raw honey after inspection, and the processing method is as follows: 1) Put the honey in a preheating tank and heat the honey in a water bath, stir during the heating process, so that the honey is heated evenly, and the temperature is controlled at 55°C ; 2) filter the preheated honey with a filter, and first filter with a 500mm*60 mesh filter; filter with a SL-300 type duplex filter to remove impurities and a small amount of larger particle crystals. After coarse filtration, perform fine filtration, use a 500mm*120 mesh filter to filter, and replace the filter once an hour; 3) Pump the filtered honey to the concentration tank of the concentration equipment, supply heat for concentration, and control the heating temperature at At the same time, adjust the concentration equipment to a vacuum degree of 0.090Mpa or more, and when the water content of the dehydrated and concentrated honey is below 16%, it will be processed into concentrated honey. ...

Embodiment 2

[0022] Example 2: Take 120Kg of raw honey after inspection, and the processing method is as follows: 1) Put the honey in a preheating tank and heat the honey in a water bath, stir during the heating process, so that the honey is heated evenly, and the temperature is controlled at 50°C ; 2) filter the preheated honey with a filter, and first filter with a 500mm*60 mesh filter; filter with a SL-300 type duplex filter to remove impurities and a small amount of larger particle crystals. After coarse filtration, perform fine filtration, use a 500mm*120 mesh filter to filter, and replace the filter once an hour; 3) Pump the filtered honey to the concentration tank of the concentration equipment, supply heat for concentration, and control the heating temperature at At the same time, adjust the concentration equipment to a vacuum degree of 0.090Mpa or more, and when the water content of the dehydrated and concentrated honey is below 16%, it will be processed into concentrated honey. 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com