Tubular falling film spraying device

A spray device and falling film technology, applied in evaporator accessories, evaporation, chemical instruments and methods, etc., can solve the problem of uneven spray density, achieve high heat transfer characteristics, good flow pattern, and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

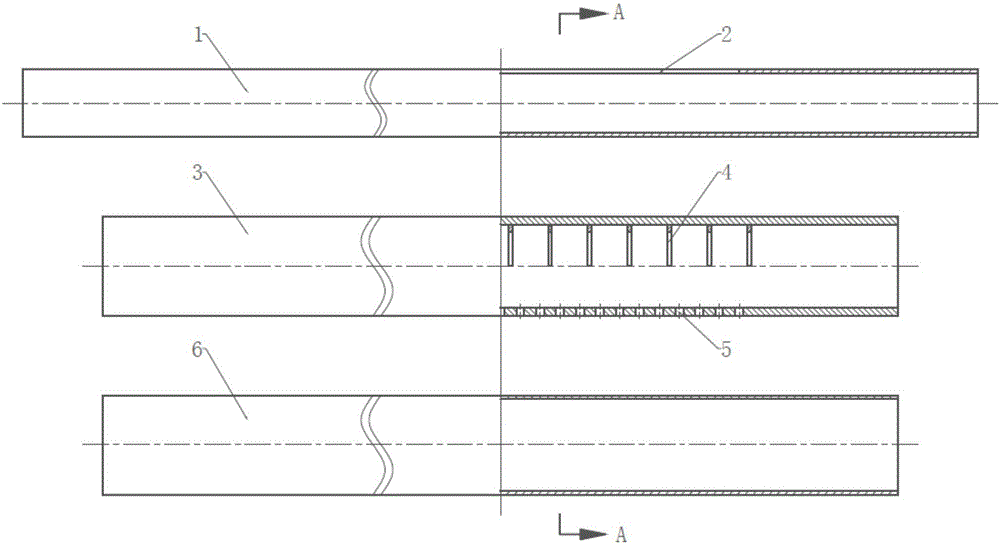

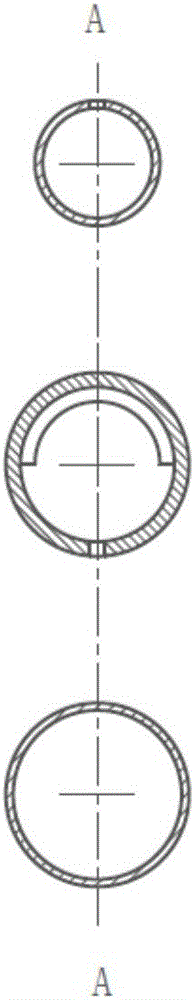

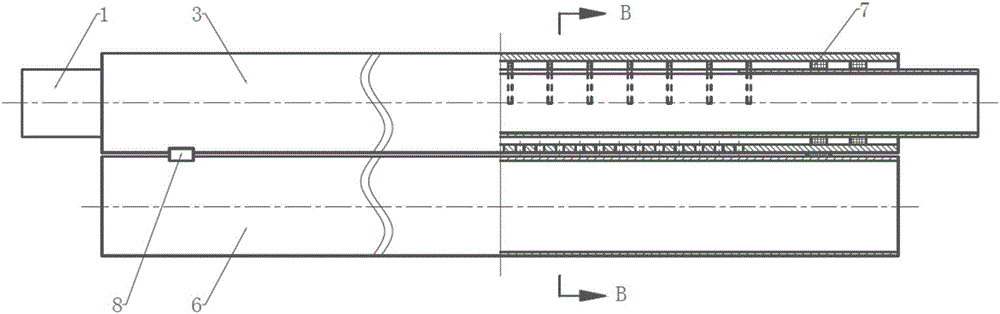

[0023] plan 1:

[0024] The working tube of the falling film evaporator is a DN20 tube (the outer diameter is 19mm). The outer diameter of both the cannula and the drainage tube is 19mm; the wall thickness of the cannula is 1mm; the outer diameter of the inner tube is 13mm, and the wall thickness is 1.5mm; there is a 2mm wide opening at the top of the inner tube; The diameter of the outflow hole is 1mm, and the center distance of the hole is 2mm; the inner tube is placed inside the sleeve, and the axis of the inner tube coincides with the axis of the sleeve; the top of the inner wall of the sleeve is embedded with a semi-annular spacer, and the thickness of the semi-annular spacer is The center point of the semi-annulus spacer and the center point of the distance between any two outlet holes at the bottom of the casing are on a vertical line; the center line of the opening of the inner pipe, the inner The axis of the tube is in the same vertical plane as the center line of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com