Turbine blade trailing edge turbulent flow half-wedge type seam cooling structure with array pin fins

A technology for turbine blades and cooling structures, applied in the directions of blade support elements, engine elements, machines/engines, etc., can solve problems such as tendency to limit, and achieve the effect of reducing the maximum temperature and average temperature, with reasonable design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

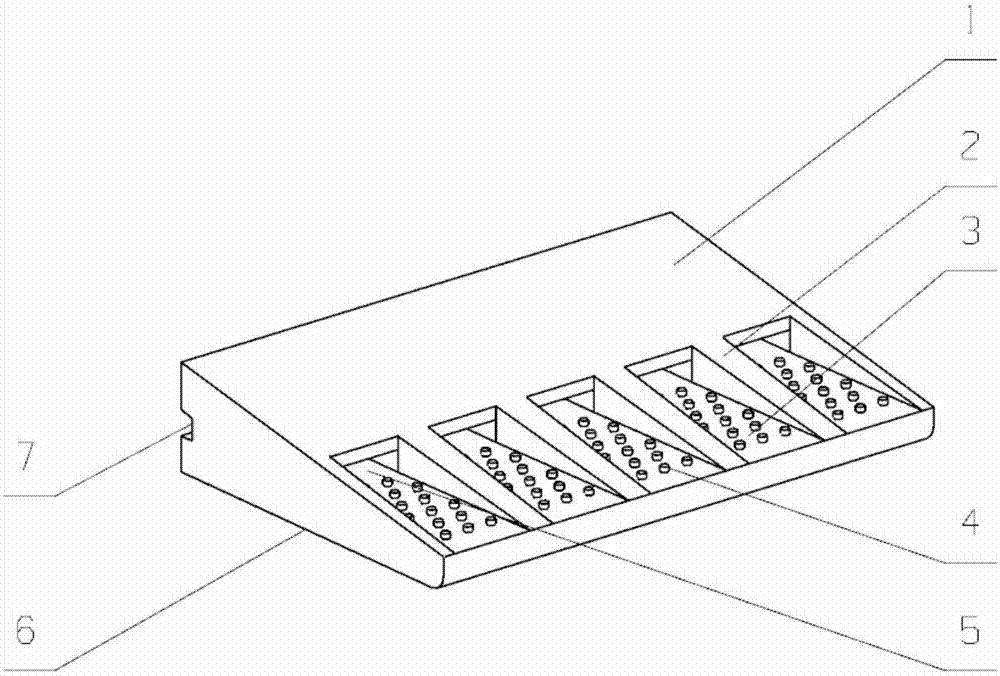

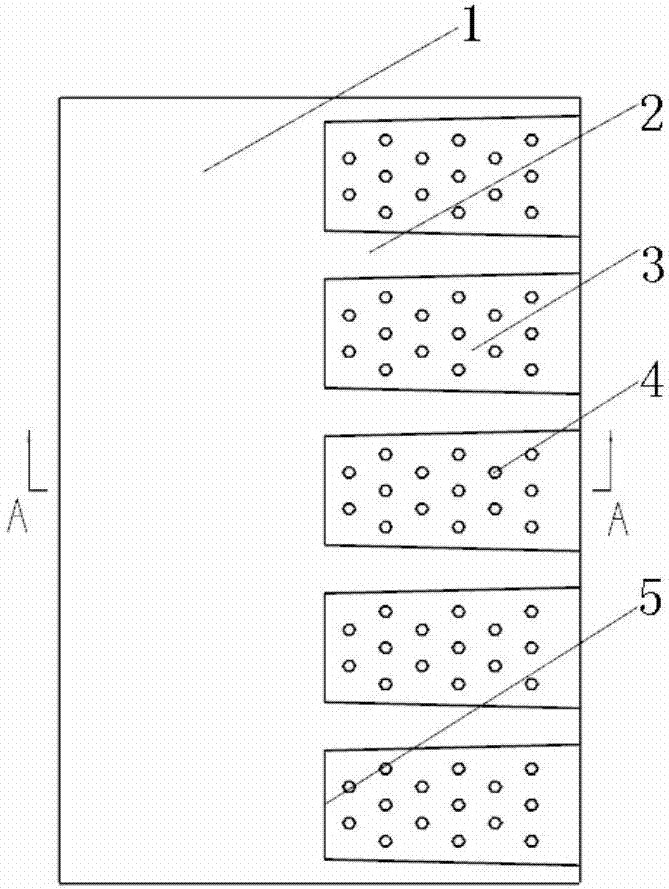

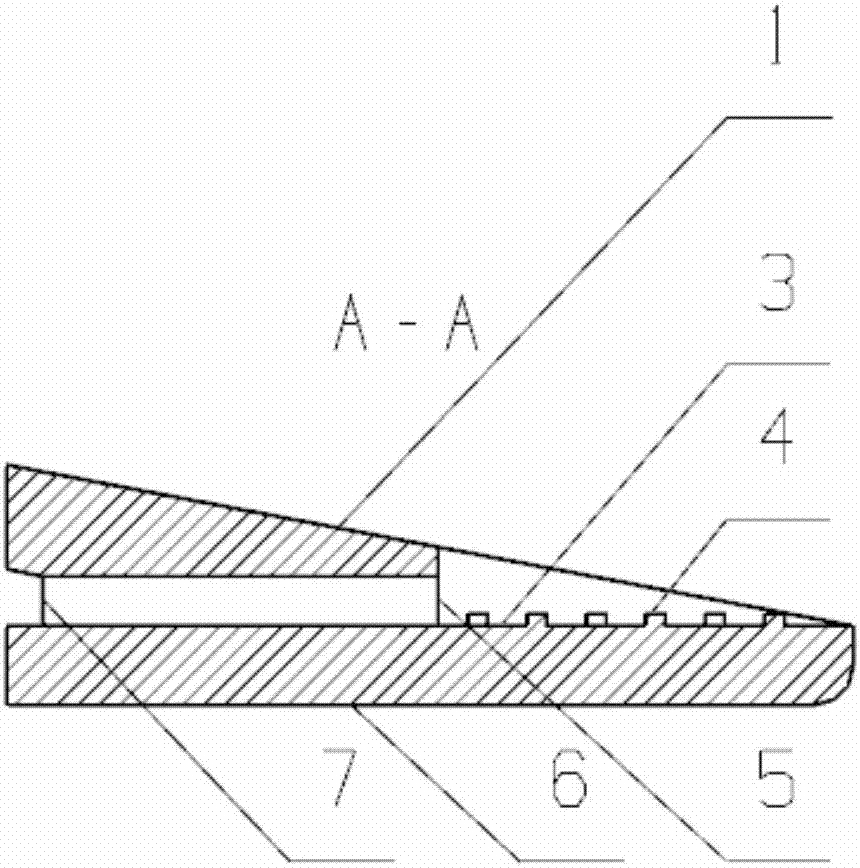

[0023] This embodiment is a turbine blade trailing edge turbulent half-slit cooling structure with array pin fins.

[0024] refer to Figure 1 to Figure 6 In this embodiment, the turbine blade trailing edge turbulent half-slit cooling structure with array pin ribs is applied to an aeroengine turbine blade, and the turbulent half-slit cooling structure is applied to the trailing edge region 8 of the turbine blade. edge suction surface 6, blade trailing edge pressure surface 1, trailing edge half-split wall surface 3, partition rib 2, array pin rib 4, cold flow outlet 5, and cold flow inlet 7; Part of the wall surface, the wall surface on the side that retains the suction surface 6 of the blade trailing edge and the spaced partition ribs 2 form a plurality of half-slit structures; the ratio of the thickness t of the lip plate of the half-slit structure to the height s of the cold air outlet slot is 0.2 to 1.5 , the inclination angle of the half-slit is 0-15°, and the cooling ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com