Patents

Literature

46results about How to "Enhanced convective heat transfer intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

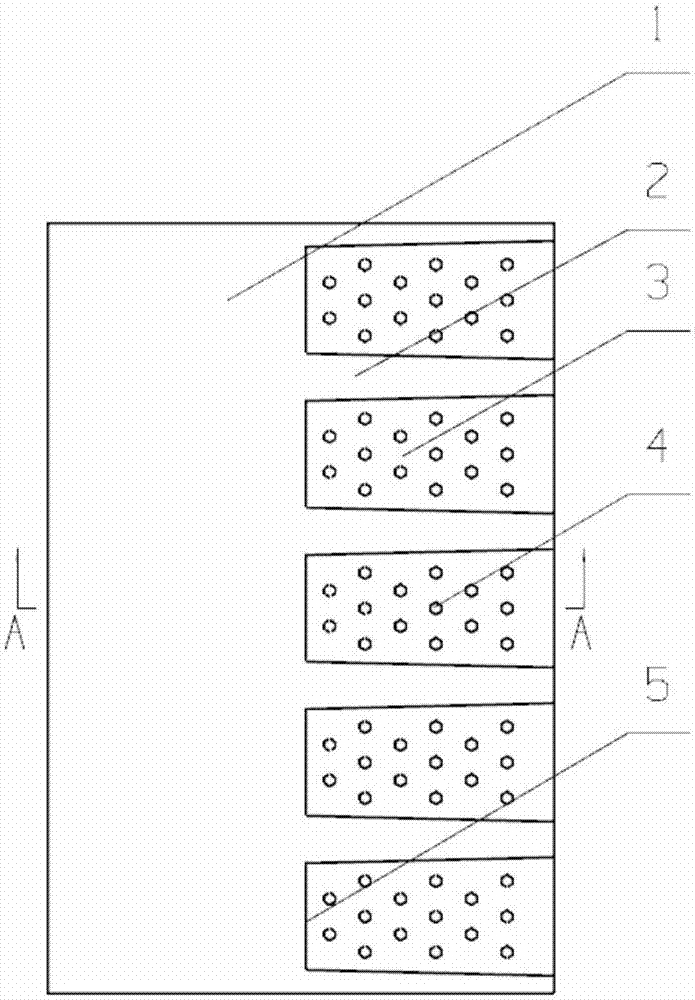

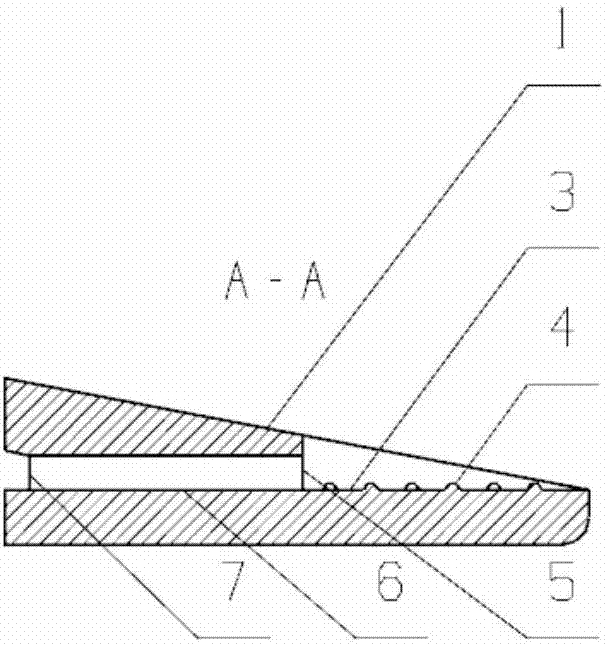

Turbine blade trailing edge turbulent flow half-wedge type seam cooling structure with array pin fins

InactiveCN107035421AImprove cooling effectImprove heat transfer effectBlade accessoriesMachines/enginesTurbine bladeCooling effect

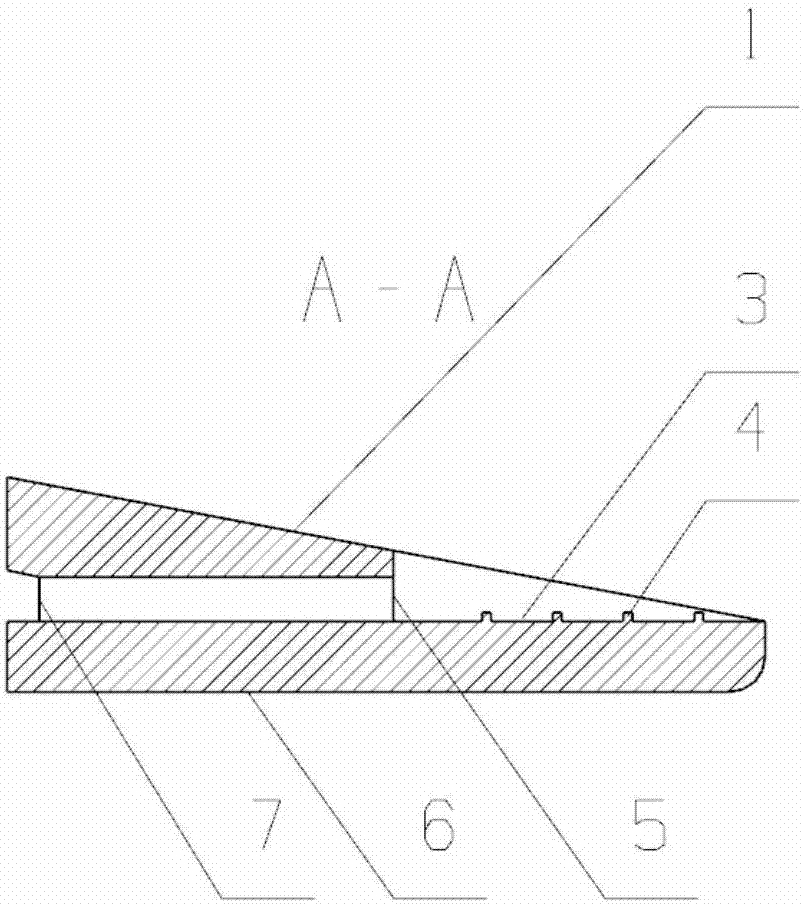

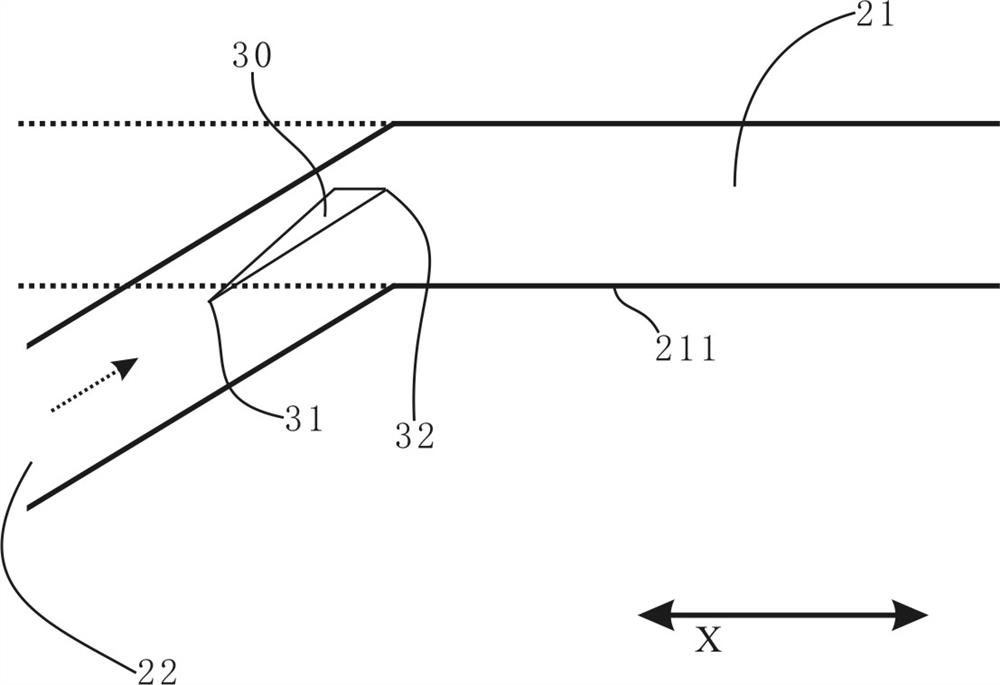

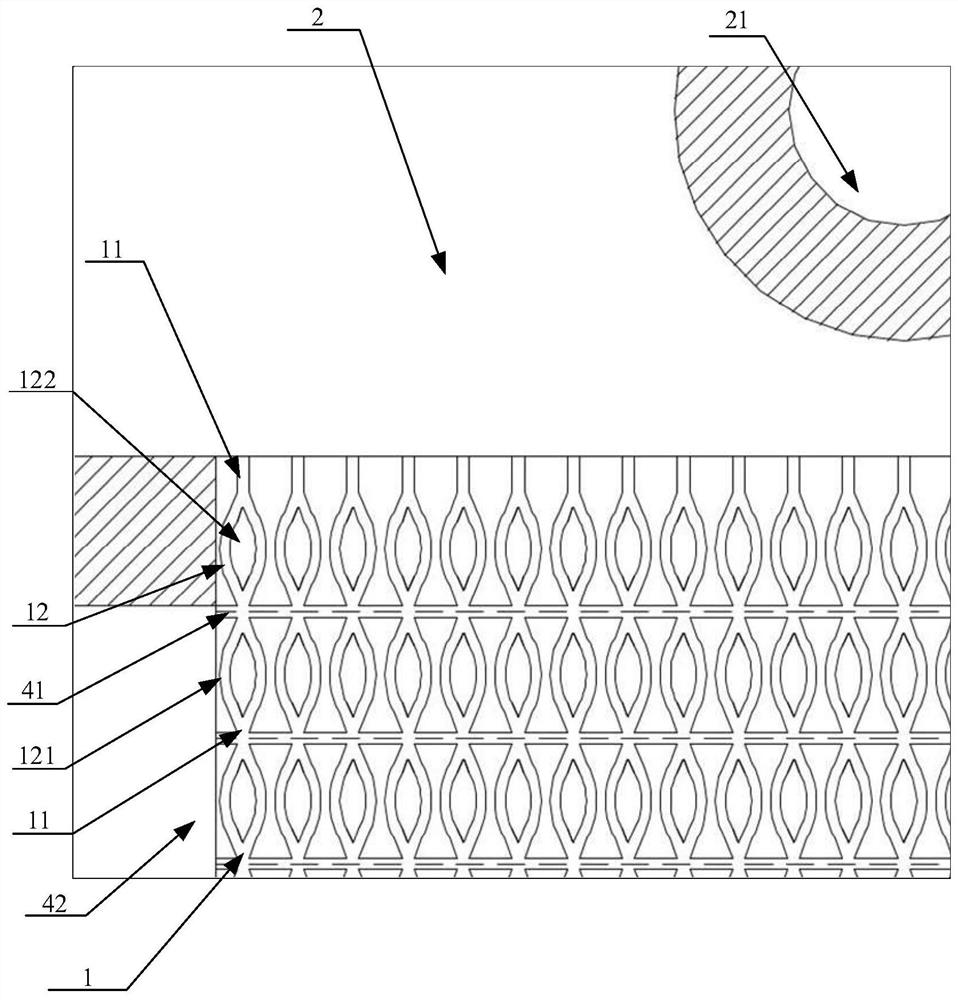

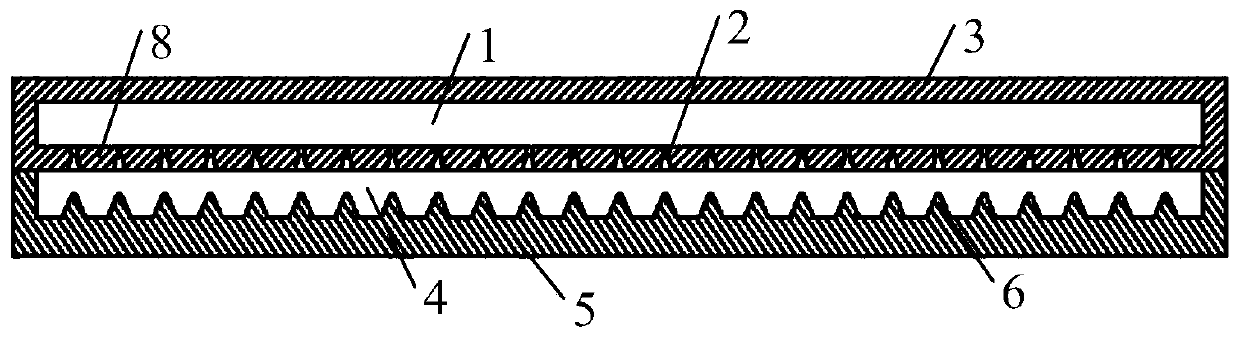

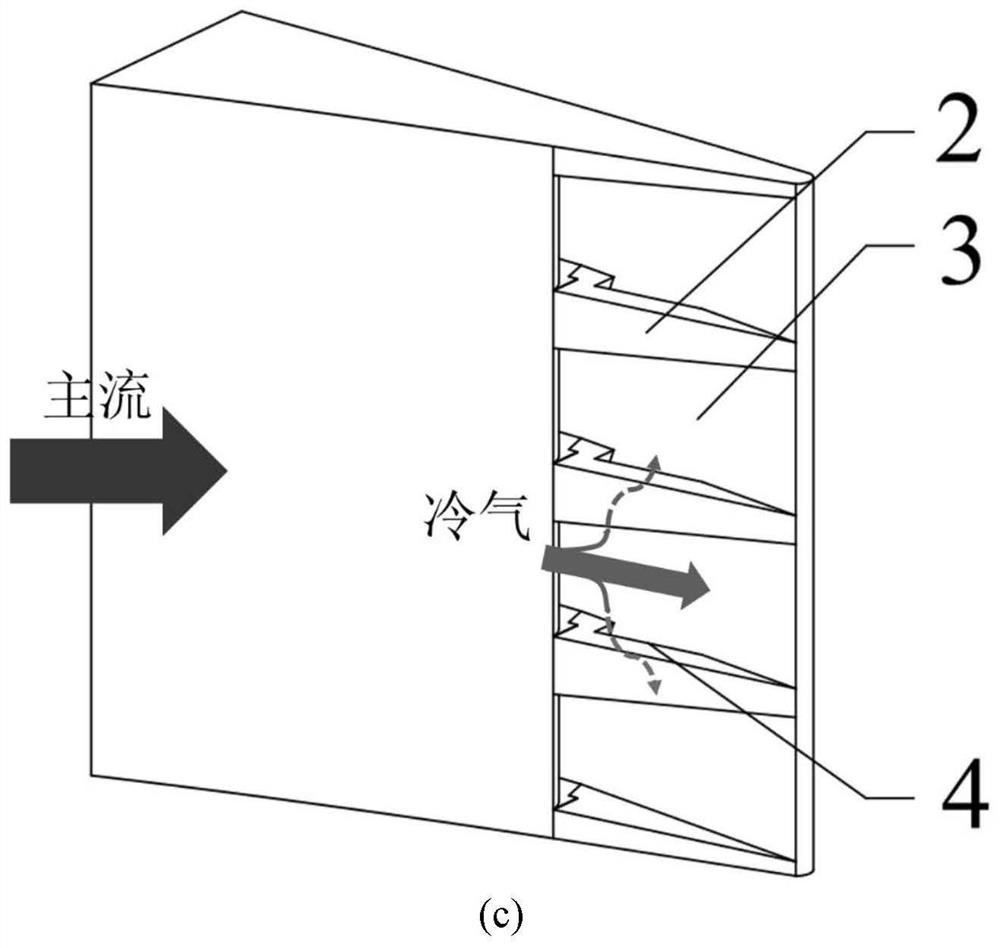

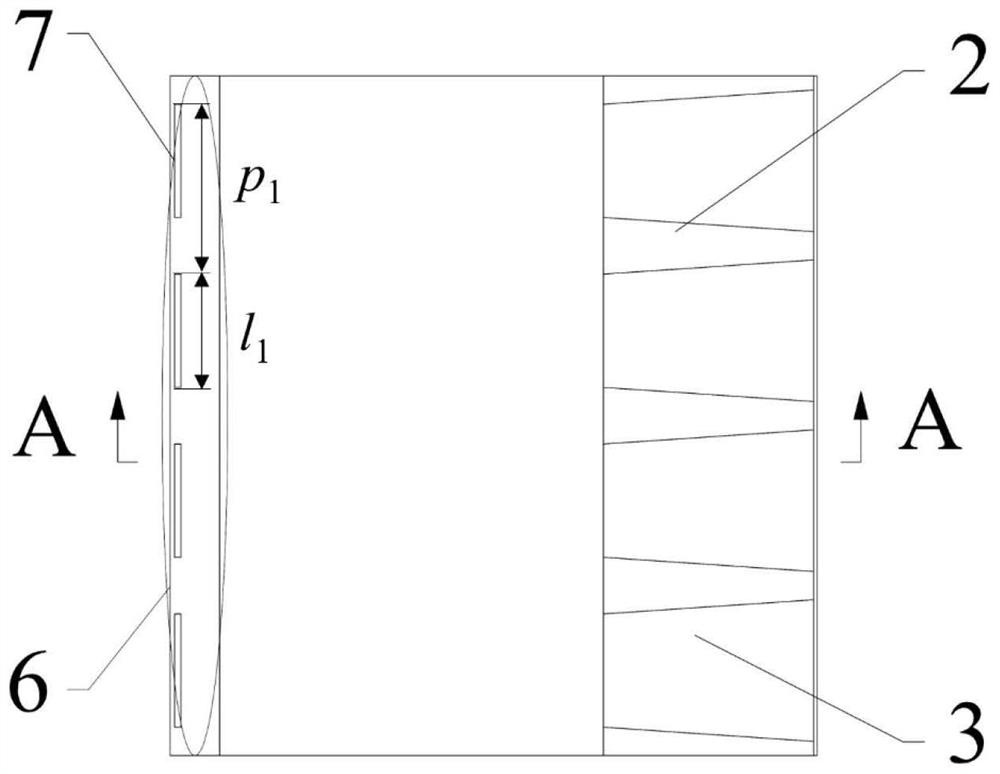

The invention discloses a turbine blade trailing edge turbulence half-slit cooling structure with an array of pin ribs. The array of pin ribs is applied to the half-slit wall surface, and the flow turbulence structure is passed without increasing the outflow of the gas film. Improve the convective heat transfer coefficient and heat transfer area of the air film, and enhance the convective heat transfer intensity of the half-slit air film cooling, thereby improving the comprehensive cooling effect of the trailing edge of the blade. Turbine blade trailing edge turbulent half-split cooling structure with continuous array of needle ribs cuts off part of the wall on the pressure surface of the blade trailing edge, retains the wall on the suction side of the blade trailing edge and separates the partition ribs to form multiple half-splits Slit structure, the cooling air flow is ejected from the cold flow outlet and covers the split wall of the trailing edge to form a cooling air film. The structure is simple; the maximum temperature and average temperature of the suction surface can be effectively reduced, and high-temperature ablation of the suction surface of the turbine blade can be avoided. The straight rib structure is arranged on the half-slit wall surface, which has good heat transfer characteristics and good processing feasibility.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Turbine blade tail edge turbulence half-crack cooling structure with spherical surface convex block

InactiveCN107013254AAvoid high temperature ablationImprove cooling effectEngine fuctionsBlade accessoriesCold airSuction stress

The invention discloses a turbine blade tail edge turbulence half-crack cooling structure with a spherical surface convex block; the spherical surface convex block structure is applied to a half-crack wall surface; and under the precondition of not increasing the outlet flow of an air film, the convection heat exchange coefficient and the heat exchange area of the air film are increased through a turbulence structure, and the convection heat exchange strength in self-crack air film cooling is reinforced, so that the comprehensive cooling effect of blade tail edges is improved. The turbine blade tail edge turbulence half-crack cooling structure with the spherical surface convex block is to cut off one part of the wall surface on a blade tail edge pressure surface; the wall surface for retaining one side of a blade tail edge suction surface and spaced separation ribs form multiple half-crack structures; cooling air currents are sprayed out from a cold current outlet to cover the self-crack wall surface to form a cooling air film, so that the structure is simple, the highest temperature and the average temperature of the suction surface are effectively lowered, and the high-temperature ablation of the suction furnace of turbine blades is prevented; and the spherical surface convex block structure is arranged on the half-crack wall surface to achieve excellent heat transfer characteristic and machining exploitativeness.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Turbine blade tail edge turbulence half-crack cooling structure with continuous straight ribs

InactiveCN107013255AAvoid high temperature ablationImprove cooling effectEngine fuctionsBlade accessoriesTurbine bladeCooling effect

The invention discloses a turbine blade trailing edge turbulence semi-slit cooling structure with continuous straight ribs. The straight rib structure is applied to the wall surface of the trailing edge half-slit. The flow structure improves the convective heat transfer coefficient and heat transfer area of the air film, and enhances the convective heat transfer intensity of the half-slit air film cooling, thereby improving the comprehensive cooling effect of the trailing edge of the blade. The turbulent half-split cooling structure is to cut off part of the wall surface on the pressure surface of the blade trailing edge, and retain the wall surface on the side of the suction side of the blade trailing edge and the spaced partition ribs to form a plurality of half-slit structures. The design is reasonable and the structure is simple; its characteristics are The cooling air flow is ejected from the cold flow outlet and covers the half-slit wall surface to form a cooling air film, which can effectively reduce the maximum and average temperature of the suction surface and avoid high-temperature ablation of the suction surface of the turbine blade. A simple straight rib structure is arranged on the half-slit wall surface, which has good heat transfer characteristics and good processability.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

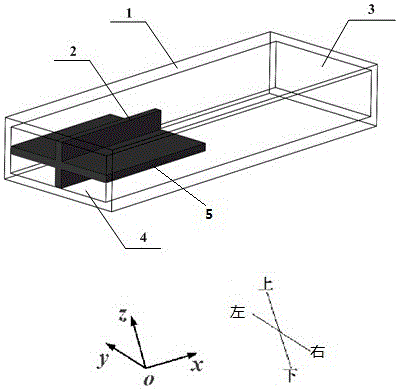

Micro combustor with built-in cross partition plate

InactiveCN105066127AUniform temperature distributionImprove thermal conductivityGaseous fuel burnerCombustorRadiation temperature

The invention relates to a micro combustor with a built-in cross partition plate and belongs to the field of energy combustion and utilization. The combustor comprises a combustor outer wall, the cross heat-conduction partition plate, a gas inlet and a gas outlet. The combustor outer wall comprises an upper wall, a lower wall, a left wall and a right wall. According to the combustor, by the adoption of the mode that the cross heat-conduction partition plate is arranged, turbulence of incoming flow gas is enhanced, and detention time is prolonged to a certain degree. Meanwhile, due to the fact that a channel becomes narrow in the partition plate area, the convective heat exchange strength of the inner wall surface and the mixed gas is improved, and rapid transfer of heat is achieved. The high-temperature gas flow is divided into four streams along the cross partition plate, so that temperature distribution of the wall surface is more uniform. Due to the design mode of the built-in cross heat-conduction partition plate, the micro-scale combustion process in the channel is more sufficient and stable, the radiation temperature of the wall surface can be increased, temperature distribution of the wall surface is more uniform, and thus a positive effect is achieved on improvement to the output performance of a miniature thermo photovoltaic system.

Owner:JIANGSU UNIV

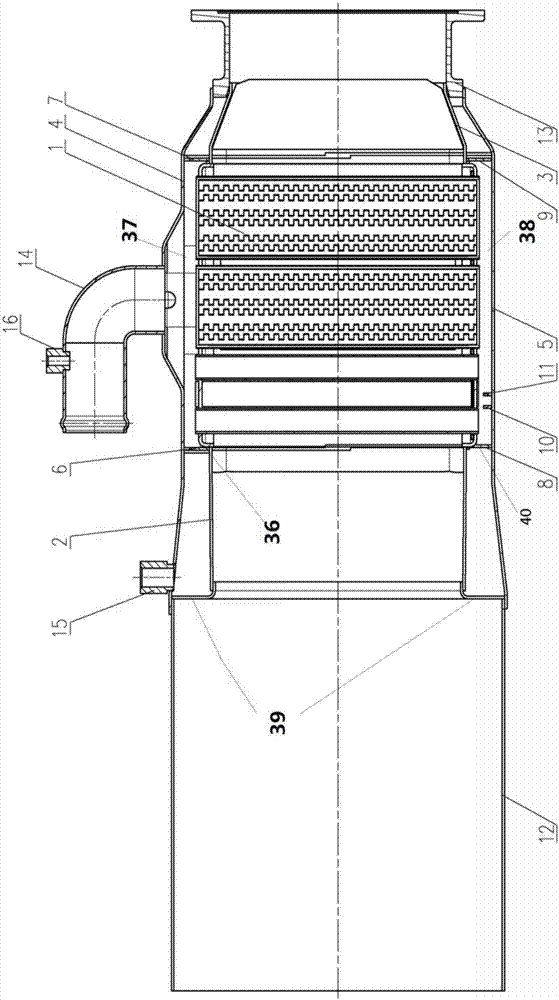

Heat exchange device utilizing combustion waste heat with variable distances of heat exchange structures

InactiveCN107270747AReduce film boilingReduce heat loadHeat exchanger casingsStationary tubular conduit assembliesCombustionEngineering

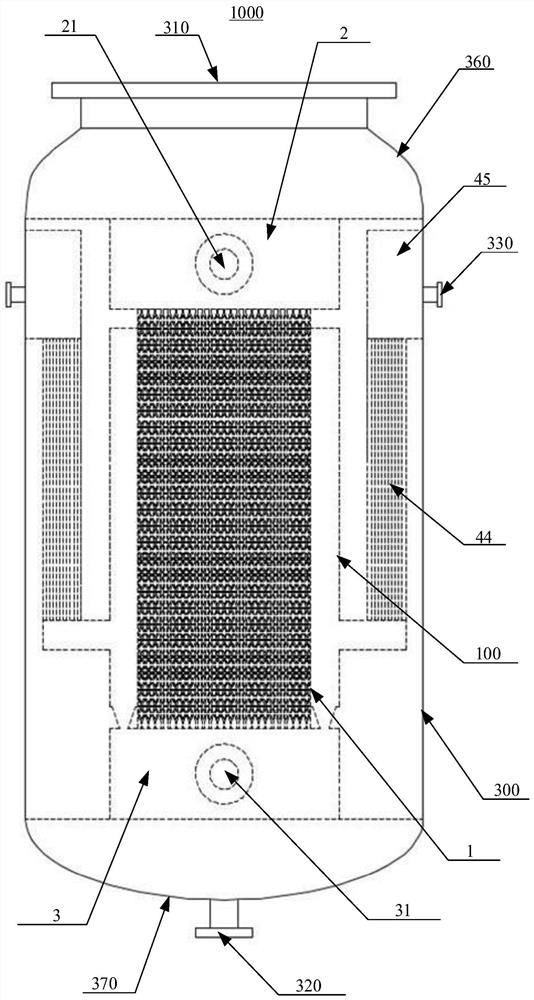

The invention provides a heat exchange device utilizing combustion waste heat. The heat exchange device comprises a heat exchange core; the heat exchange core is arranged in a waste gas flue and comprises circular tubes; the circular tubes are arranged perpendicular to the flowing direction of waste gas; a plurality of scattered heat exchange structures are arranged in the round tube at intervals; a plurality of dispersion heat exchange structures are arranged in the circular tubes in a segmented mode in the flow direction of fluid in the circular tubes; the distances between every two adjacent dispersion heat exchange structures become smaller and smaller from inlets of the circular tubes to outlets of the circular tubes. The heat exchange device has the advantages that the distances of the dispersion heat exchange structures in the circular tubes is continuously decreased along with the distance from the inlets of the circular tubes, and therefore the film boiling phenomenon on the water side can be effectively reduced, the convective heat exchange intensity of the water side can be increased, the heat load of the heat exchange core can be reduced, and the heat exchange efficiency can be improved.

Owner:CHINA NORTH VEHICLE RES INST

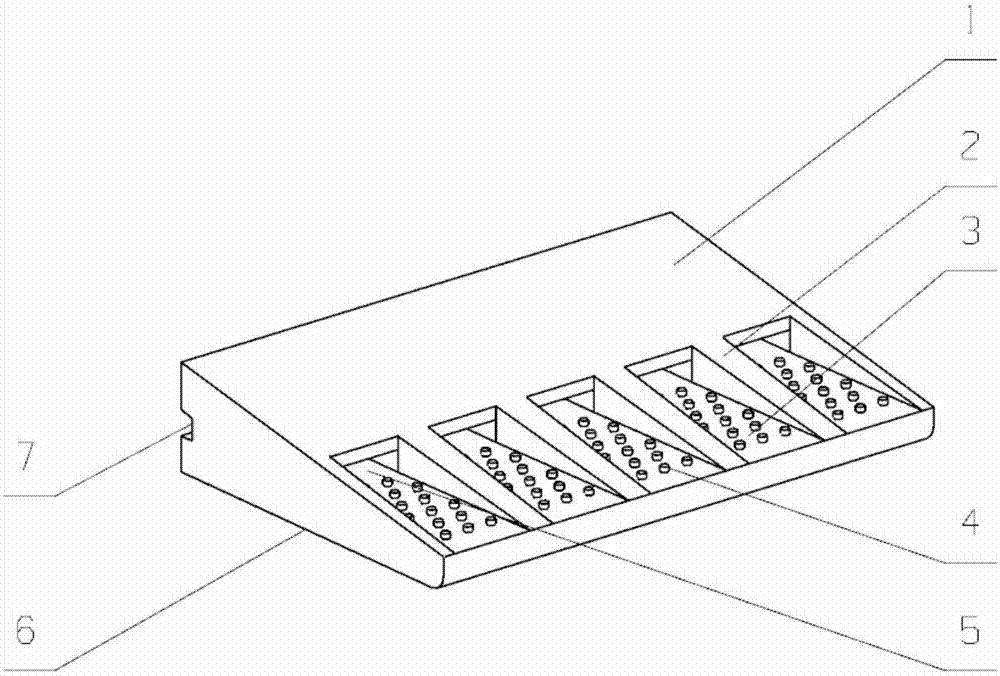

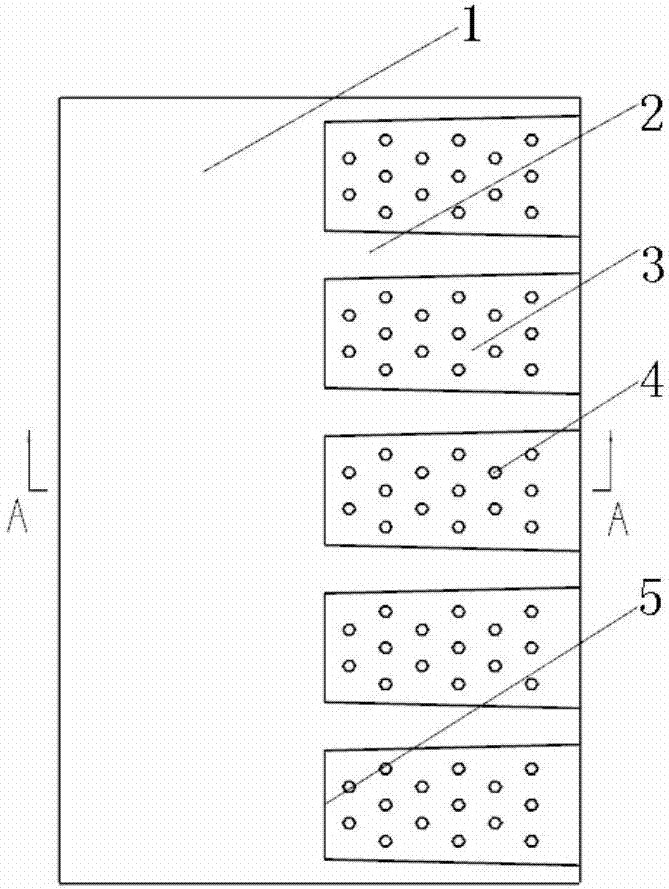

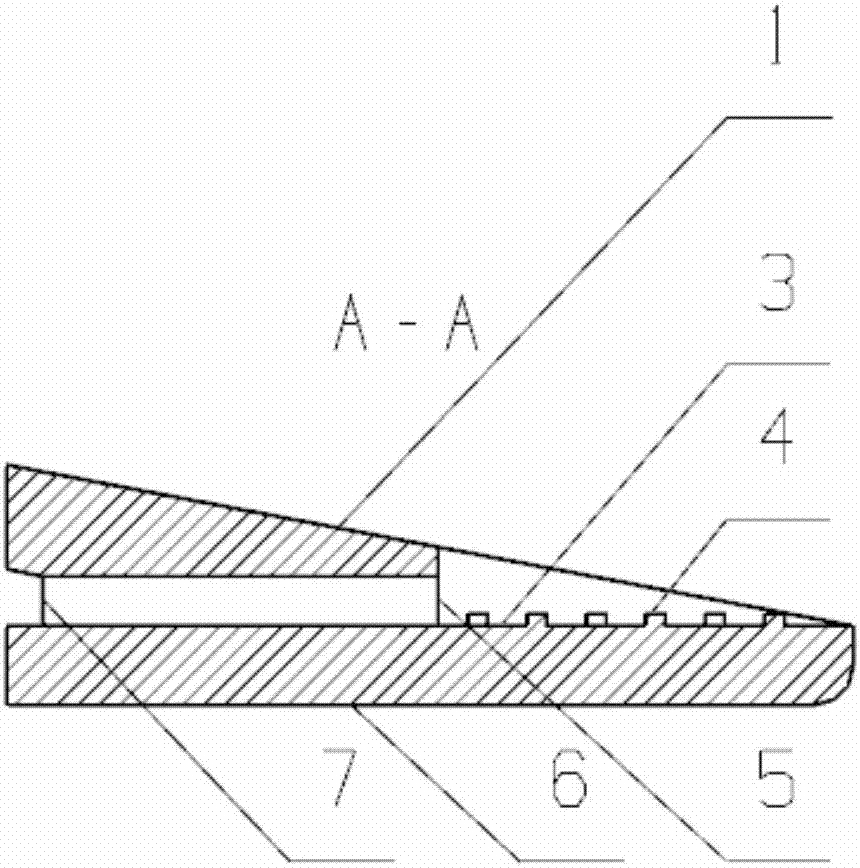

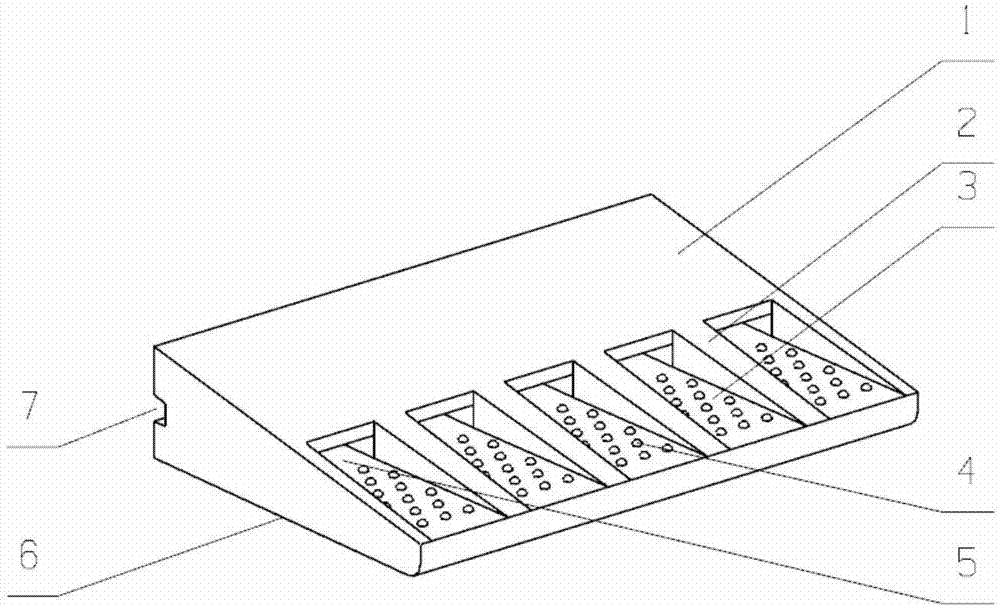

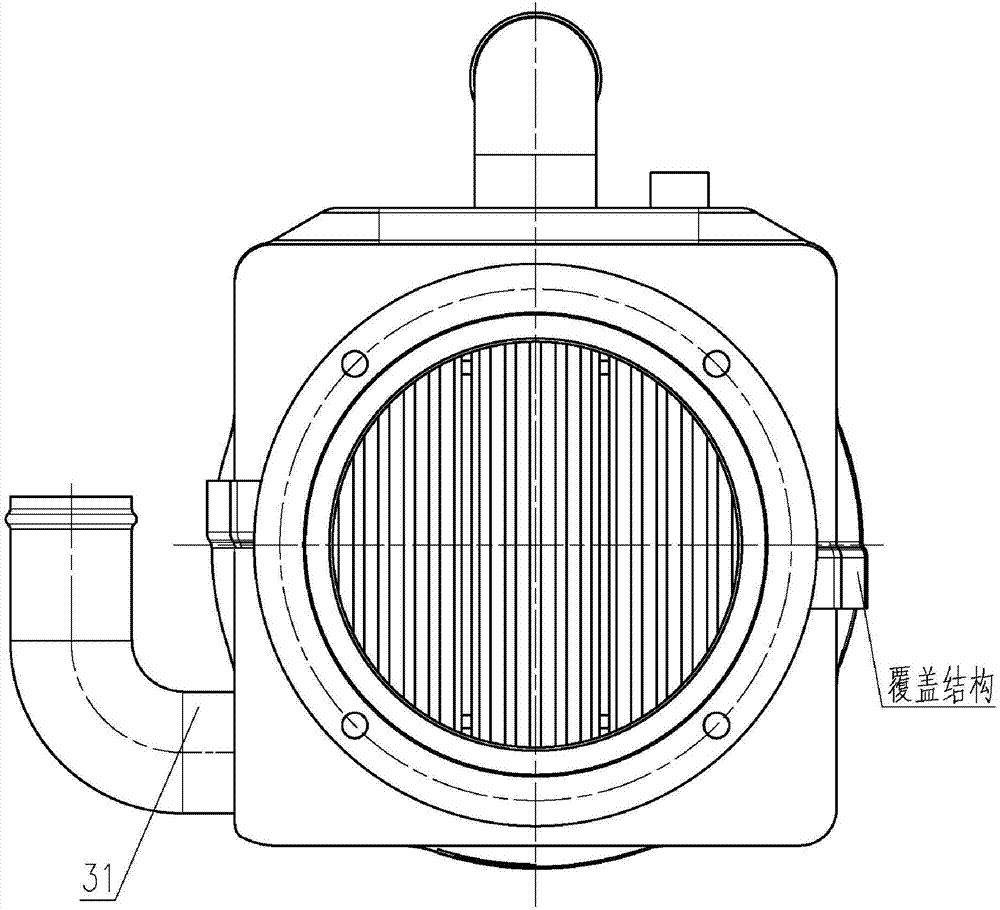

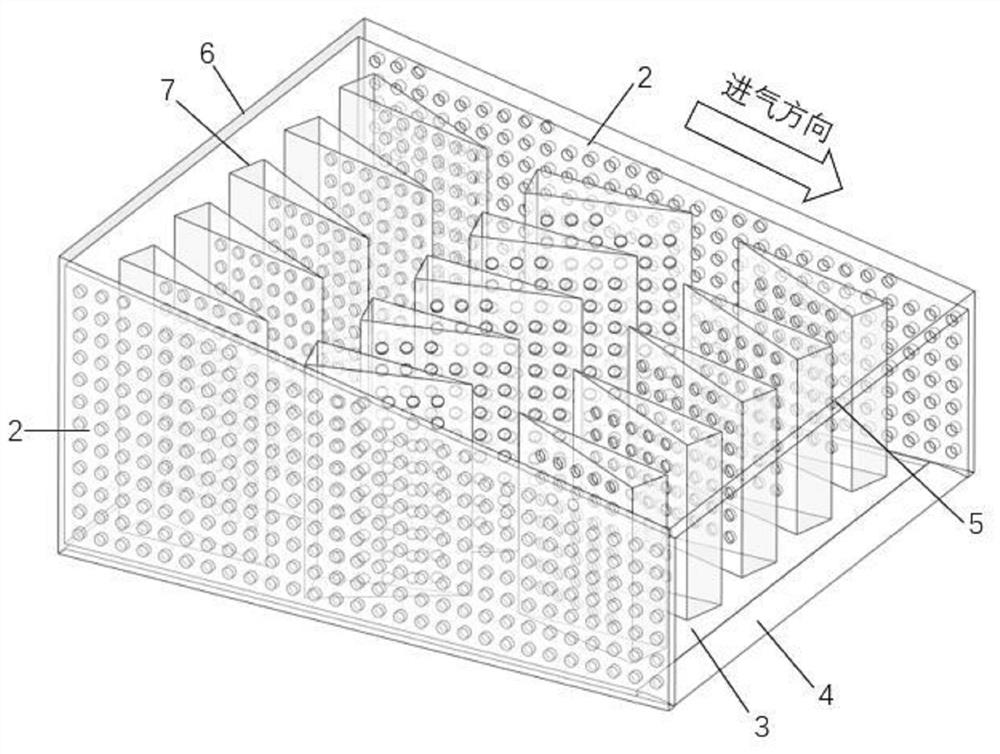

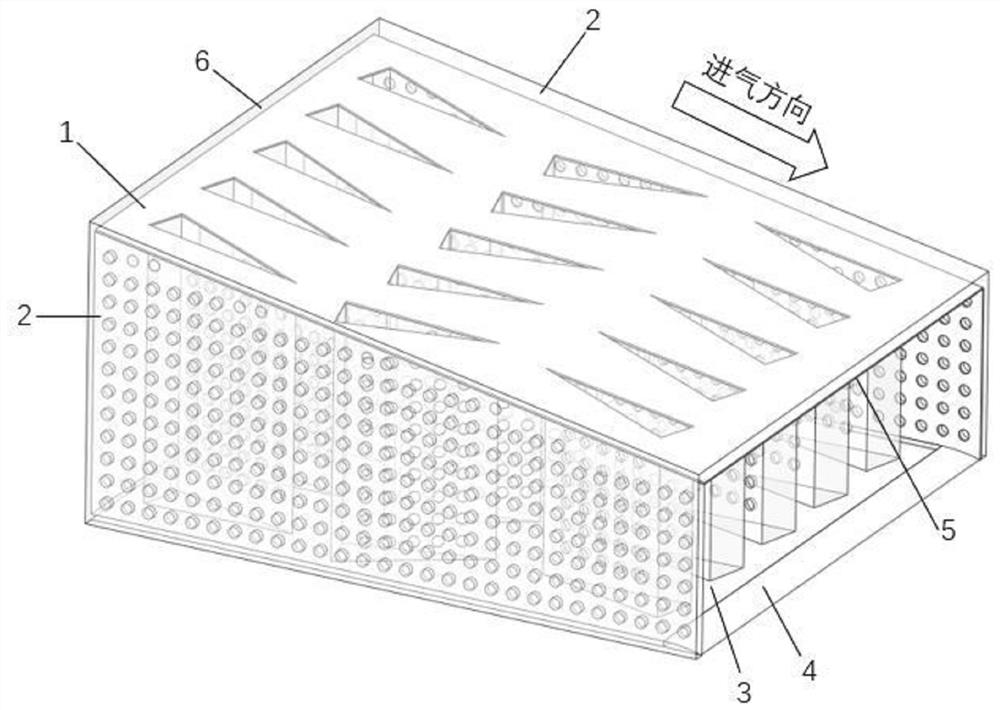

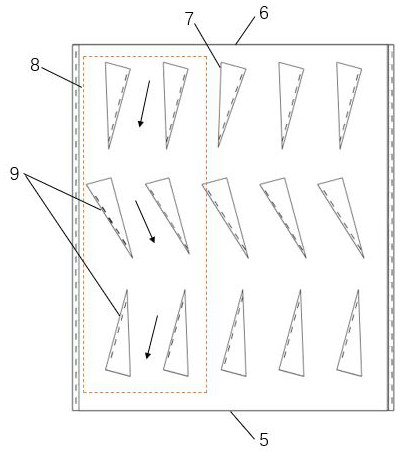

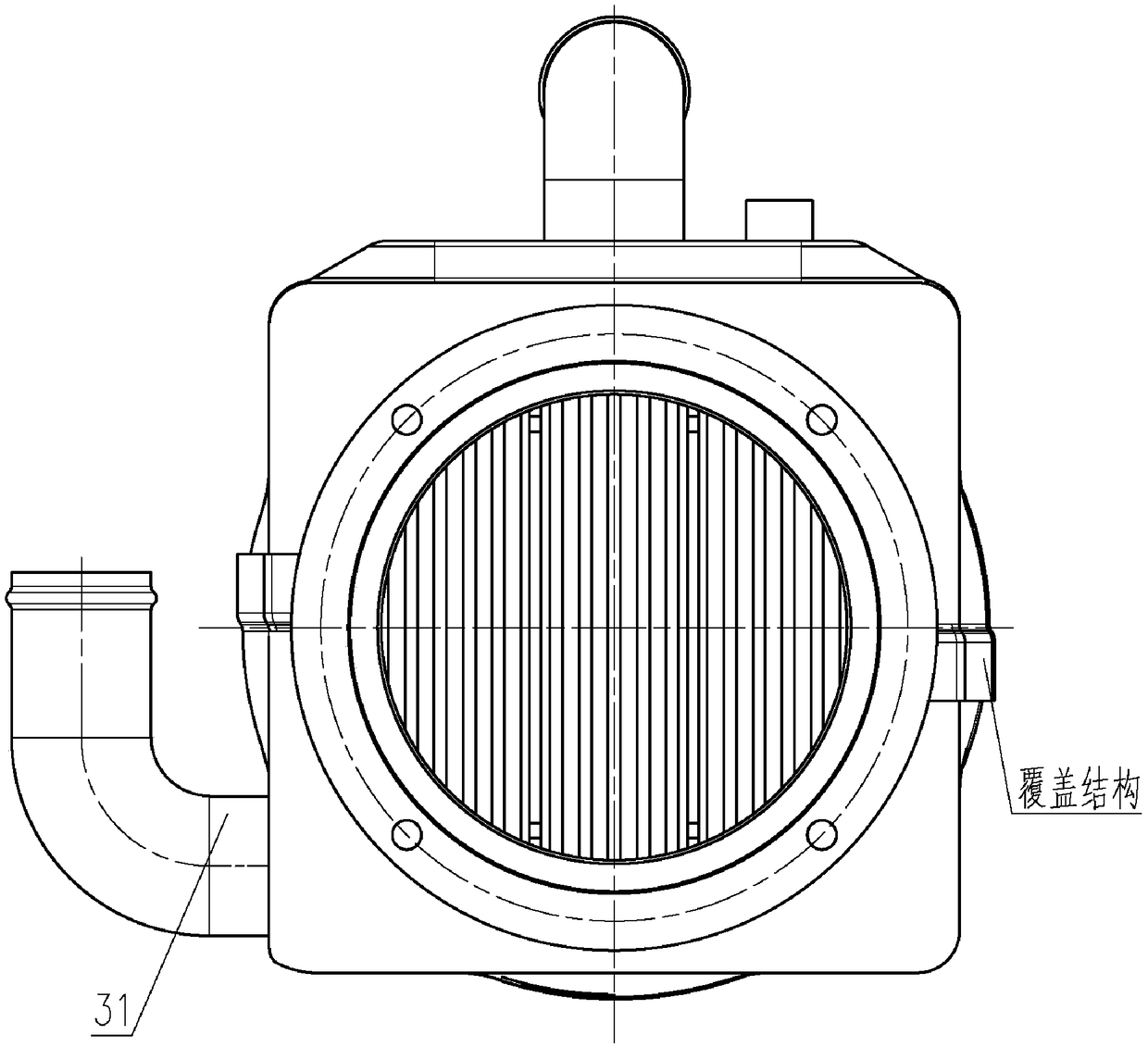

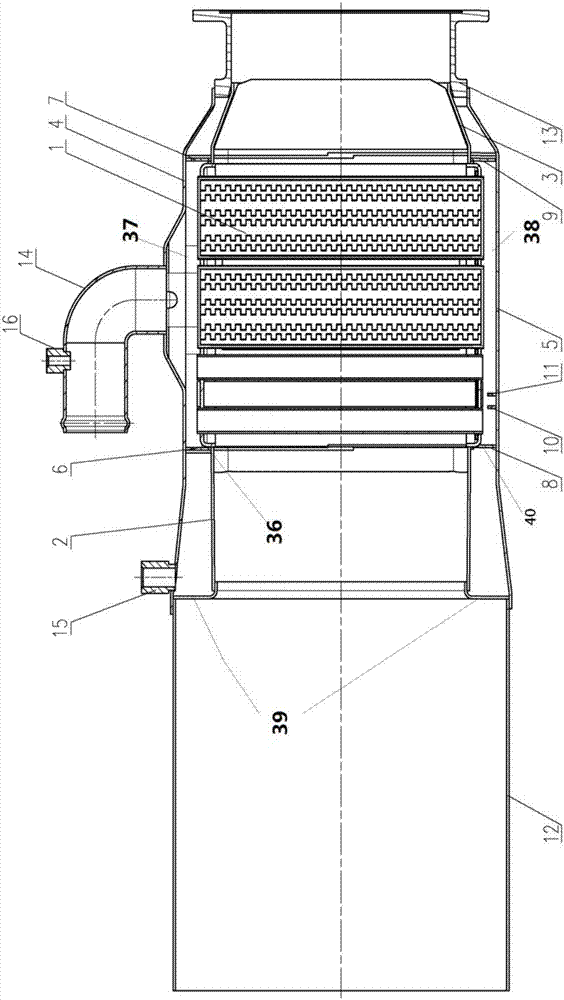

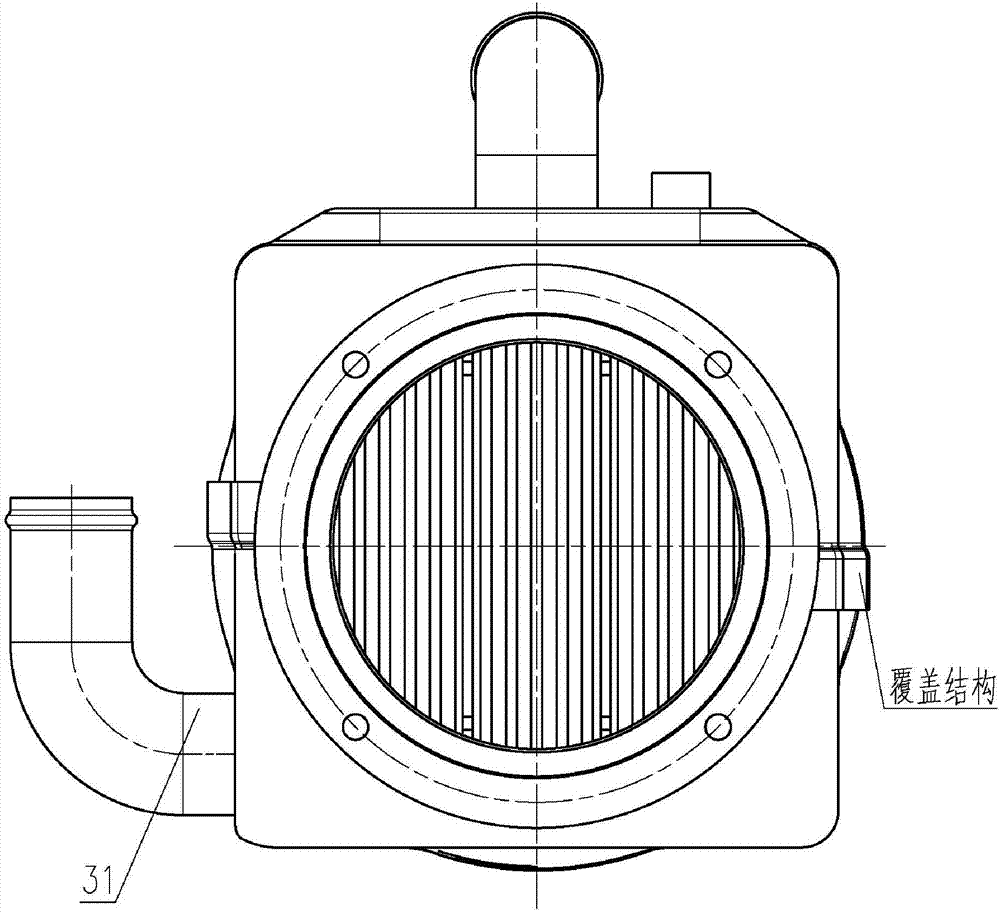

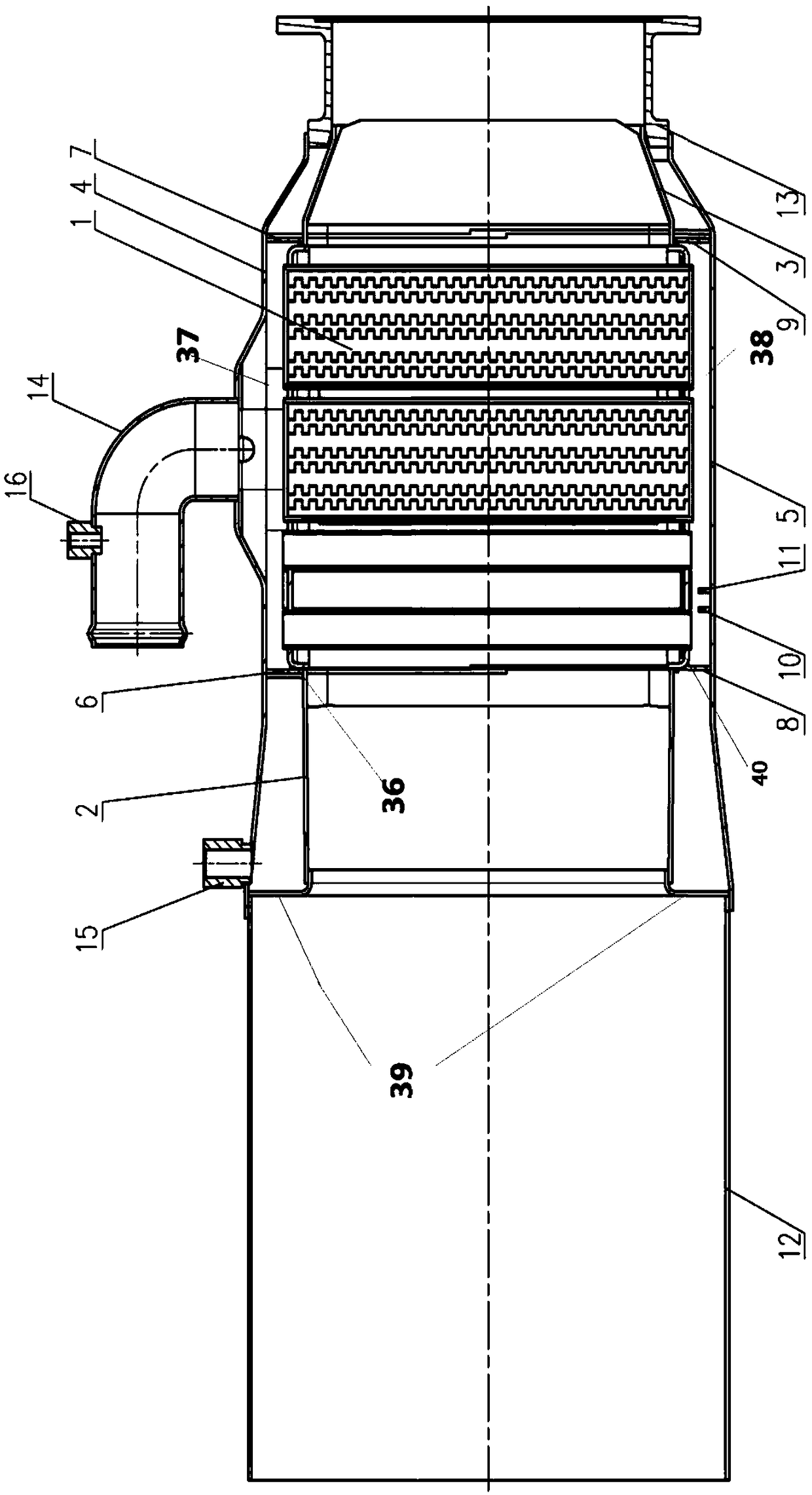

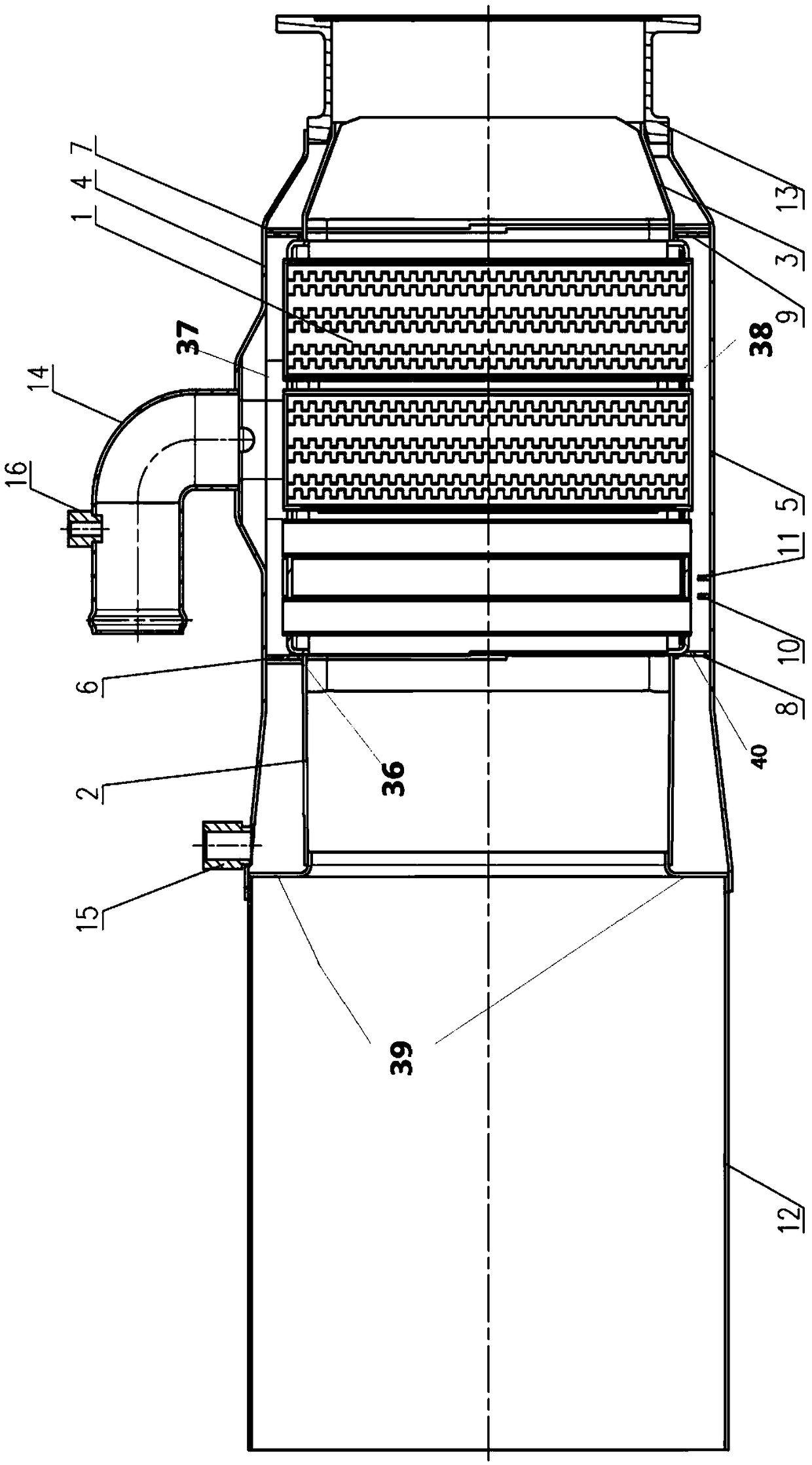

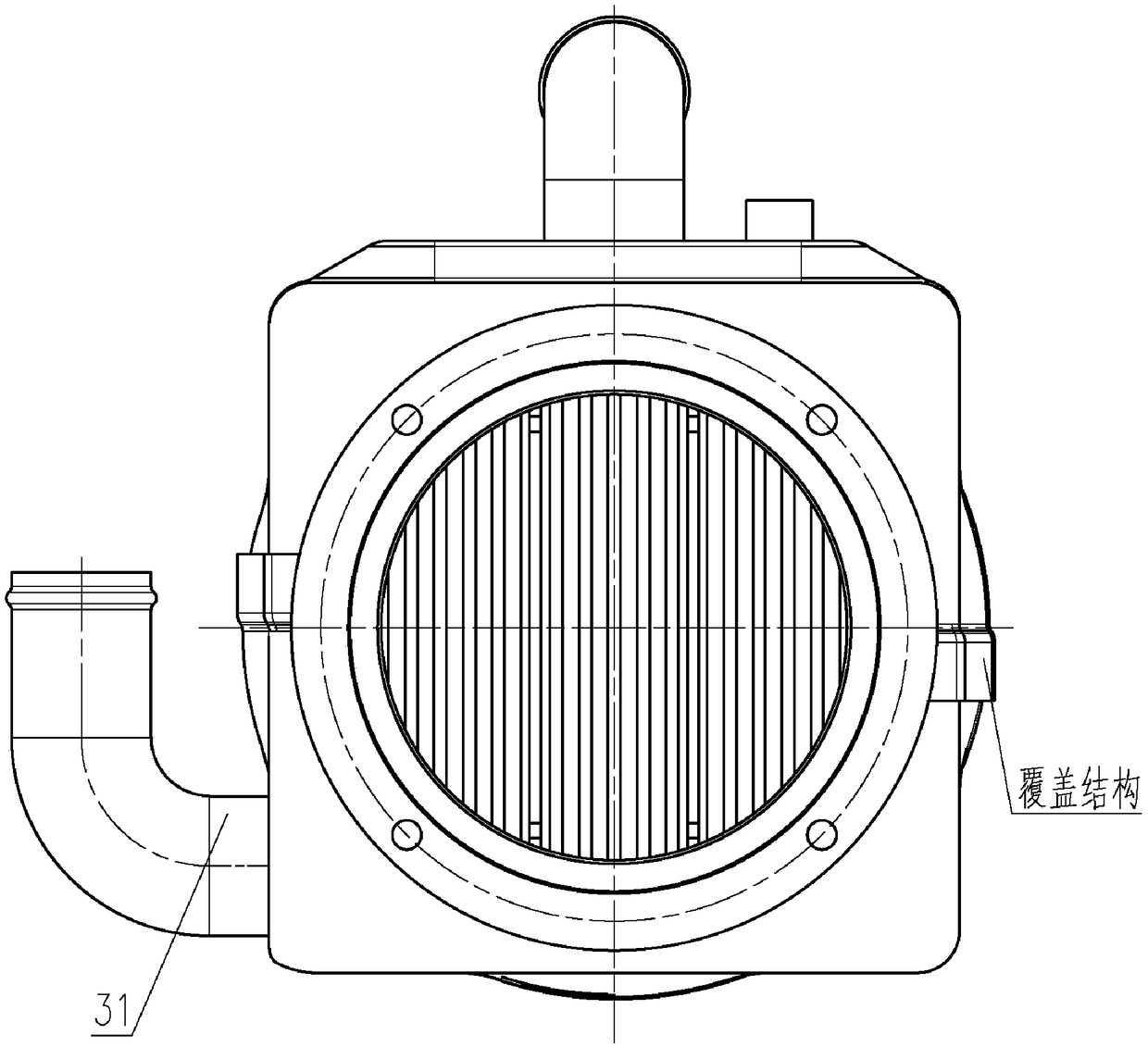

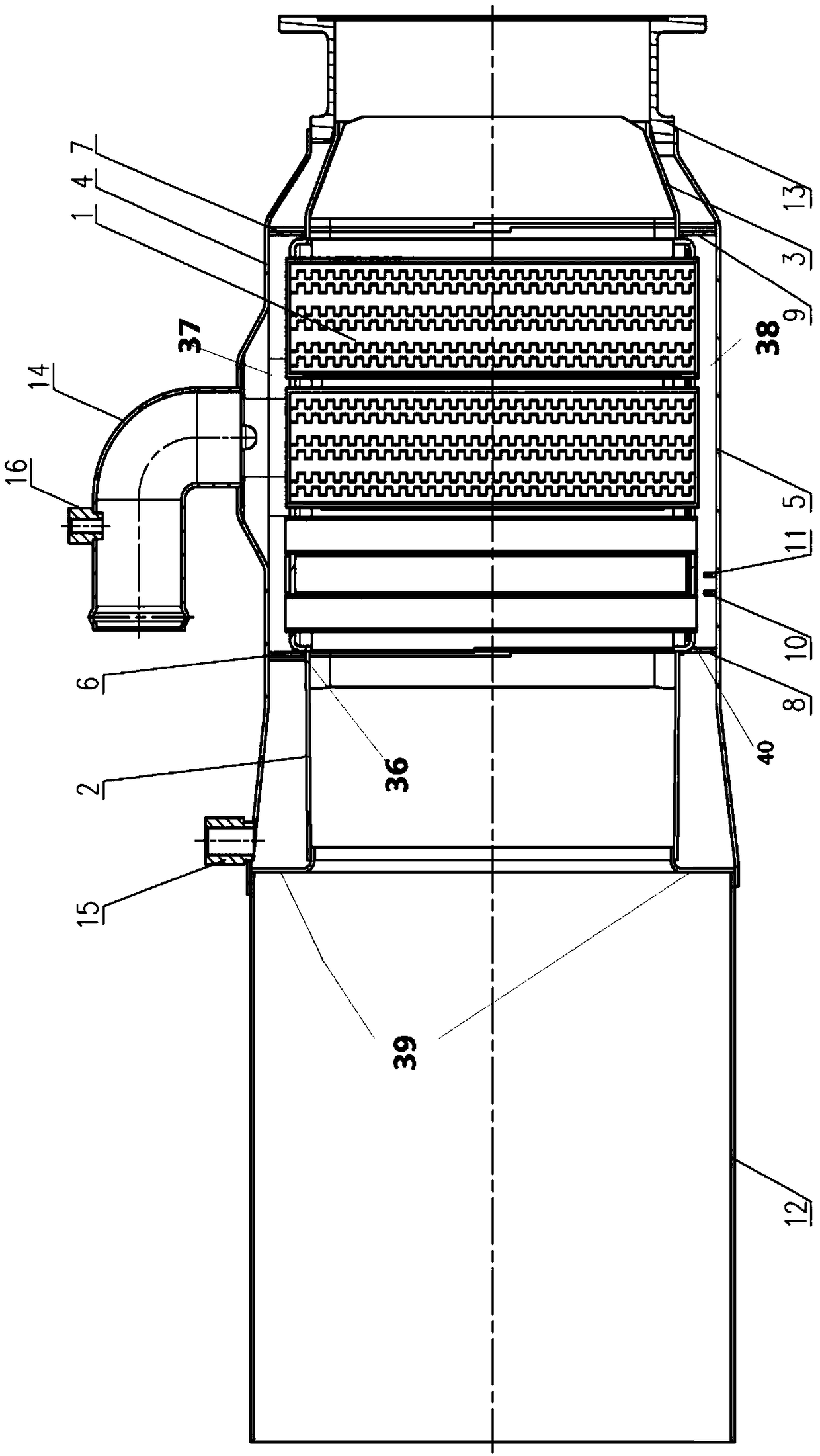

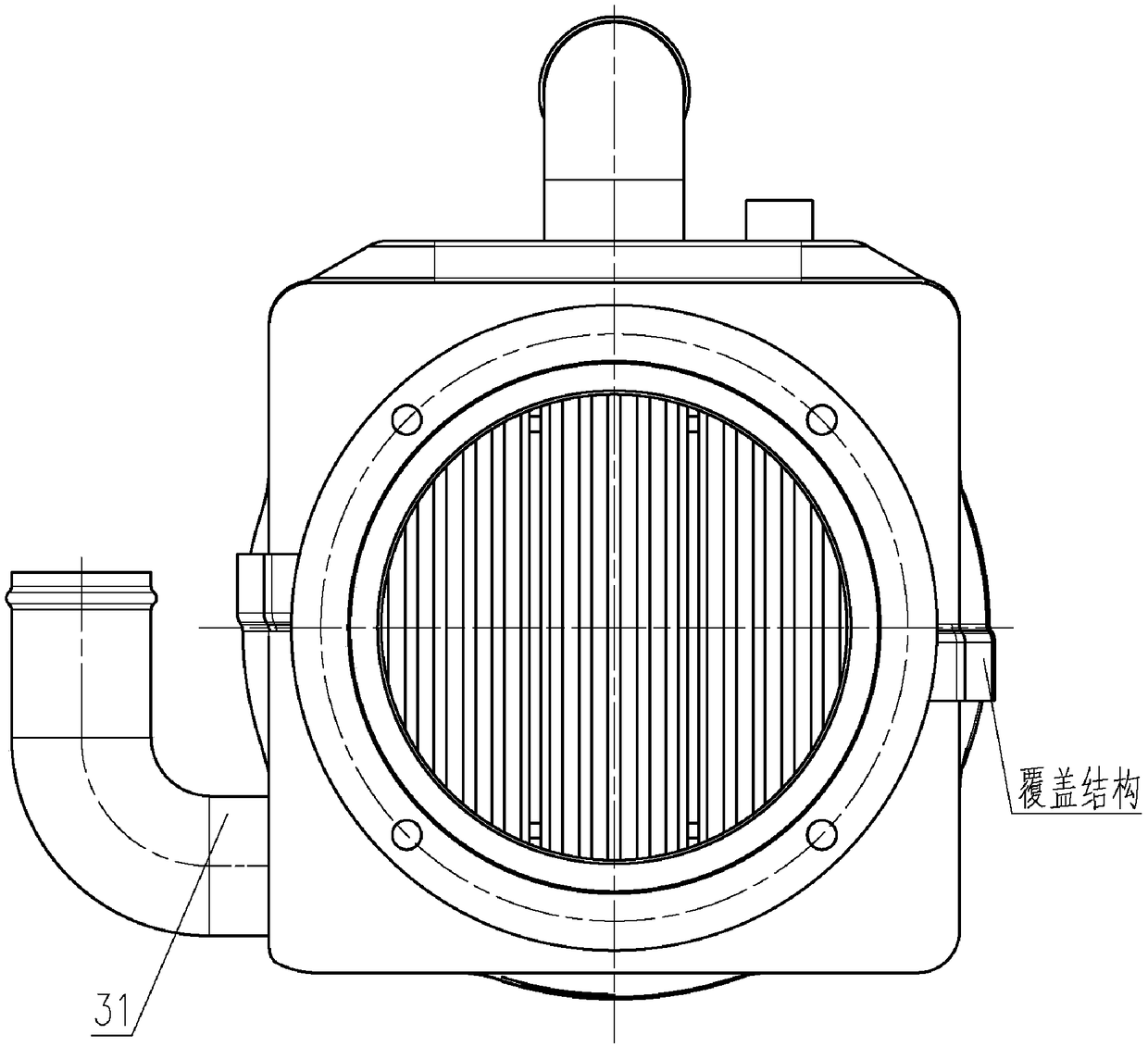

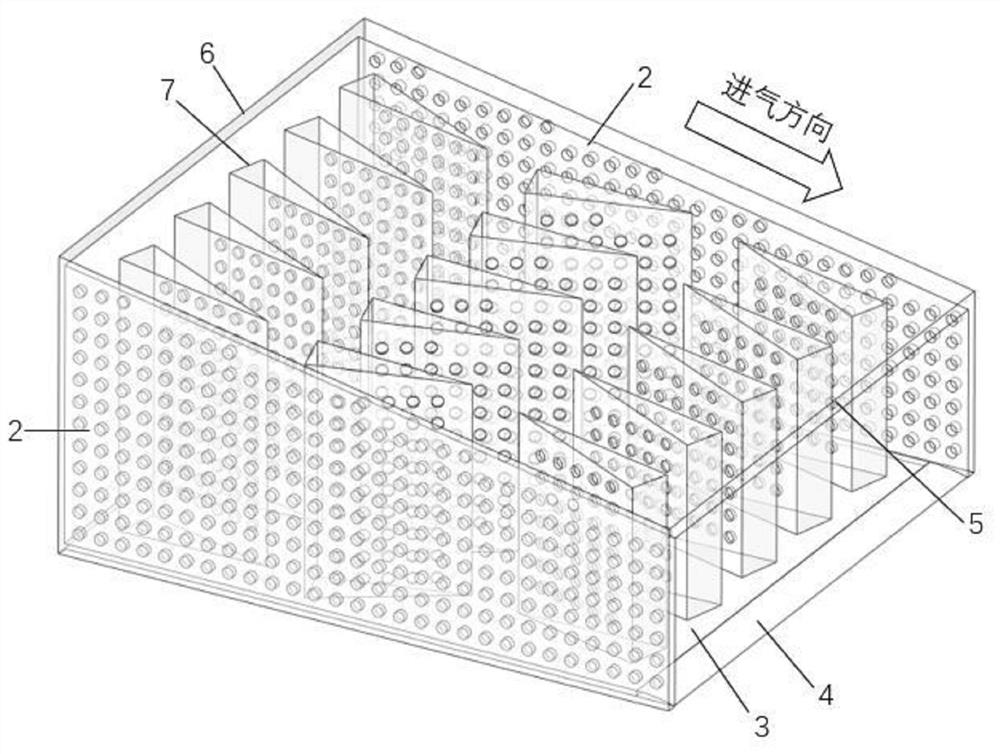

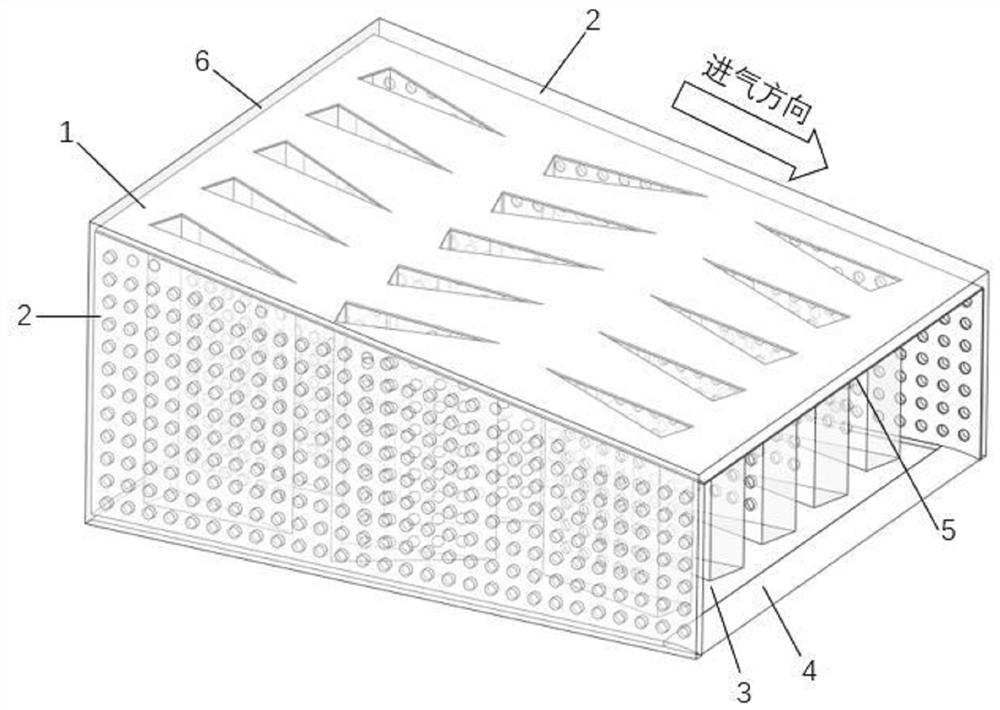

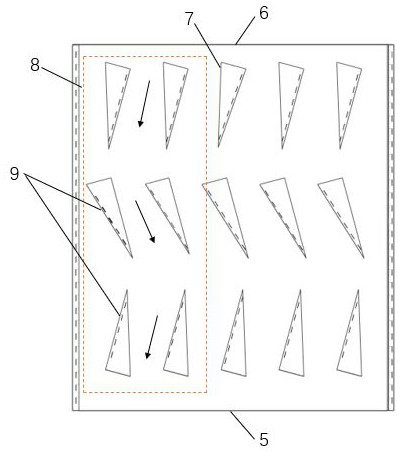

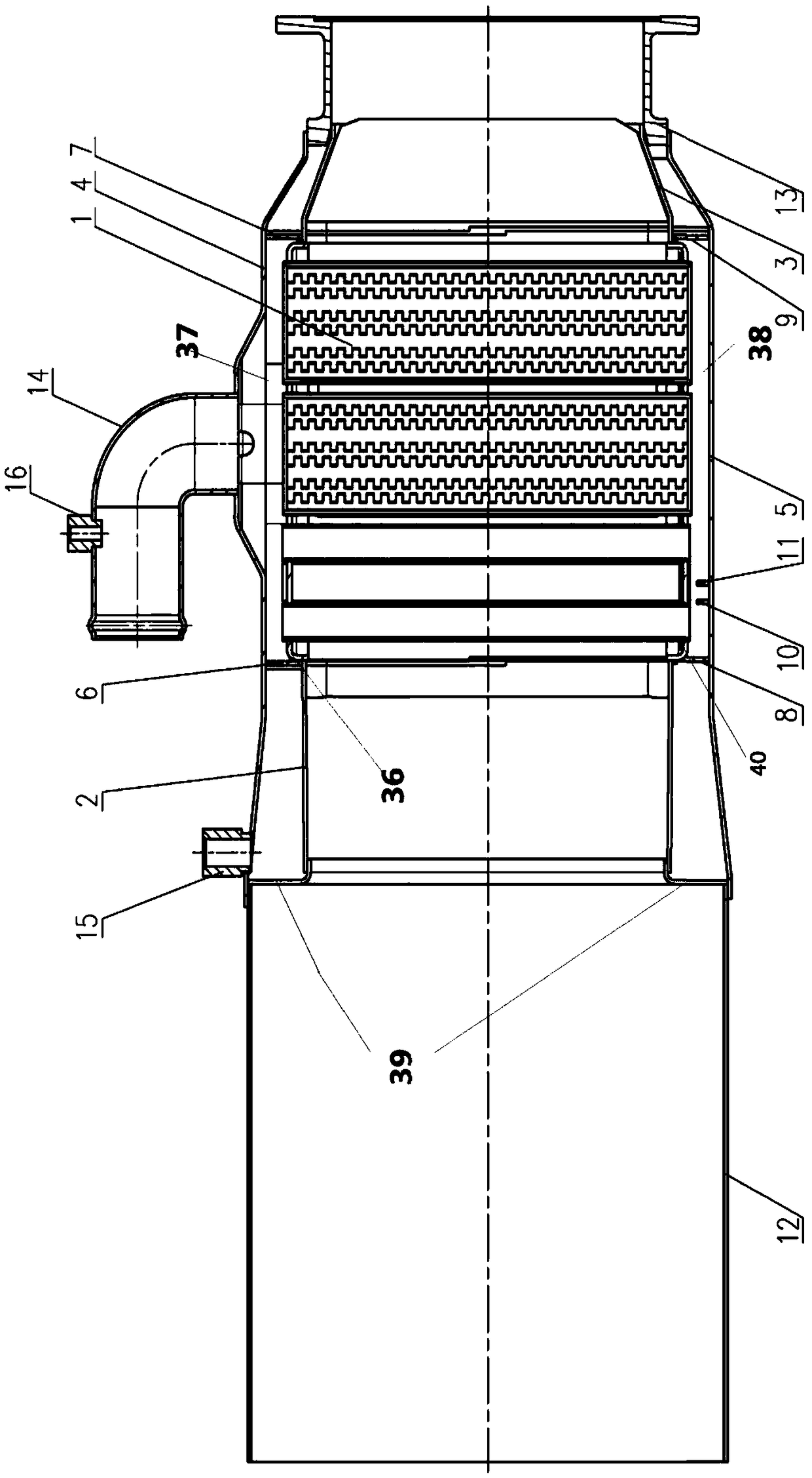

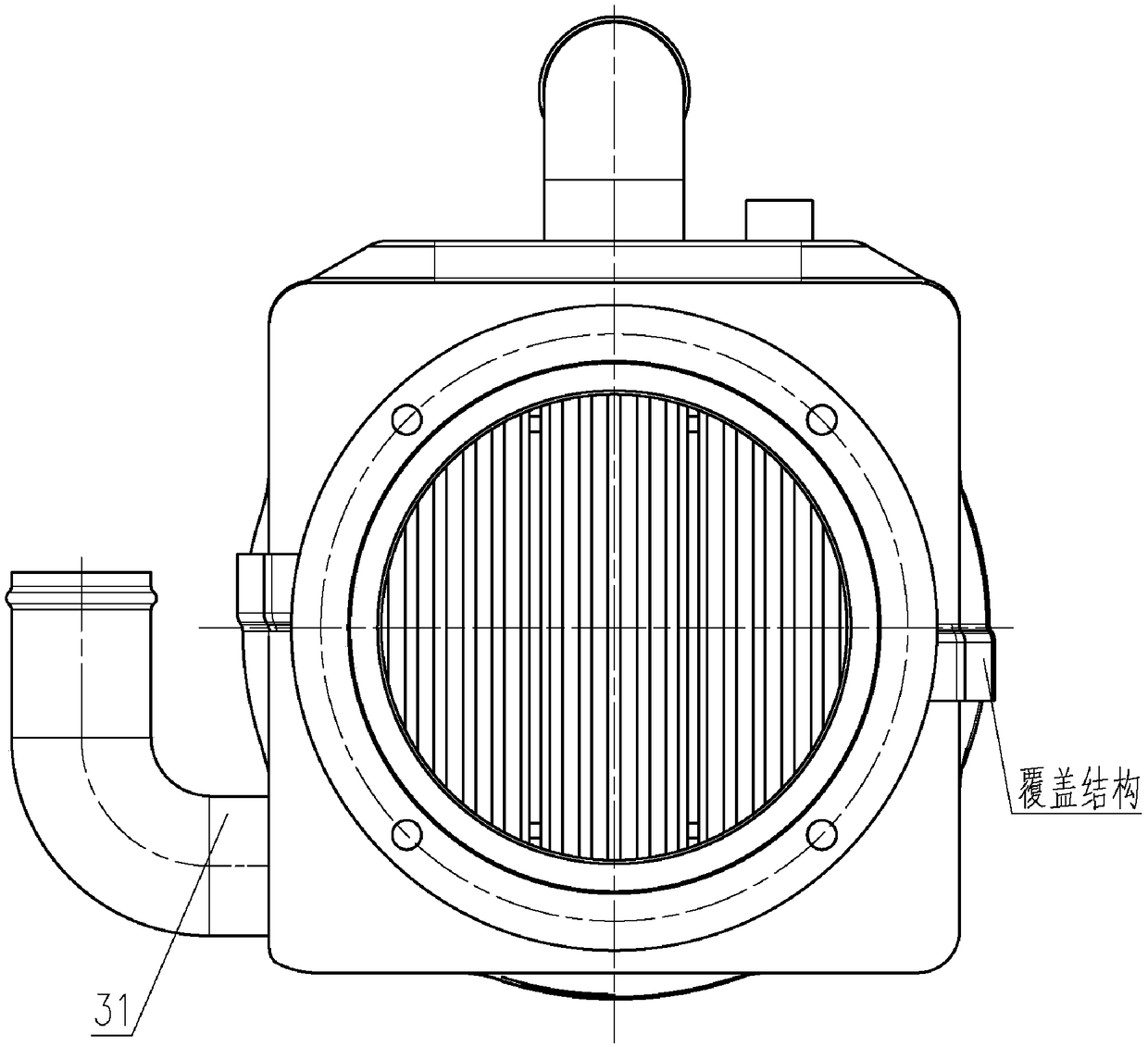

Intake silencer for acoustic enclosure of compressor unit

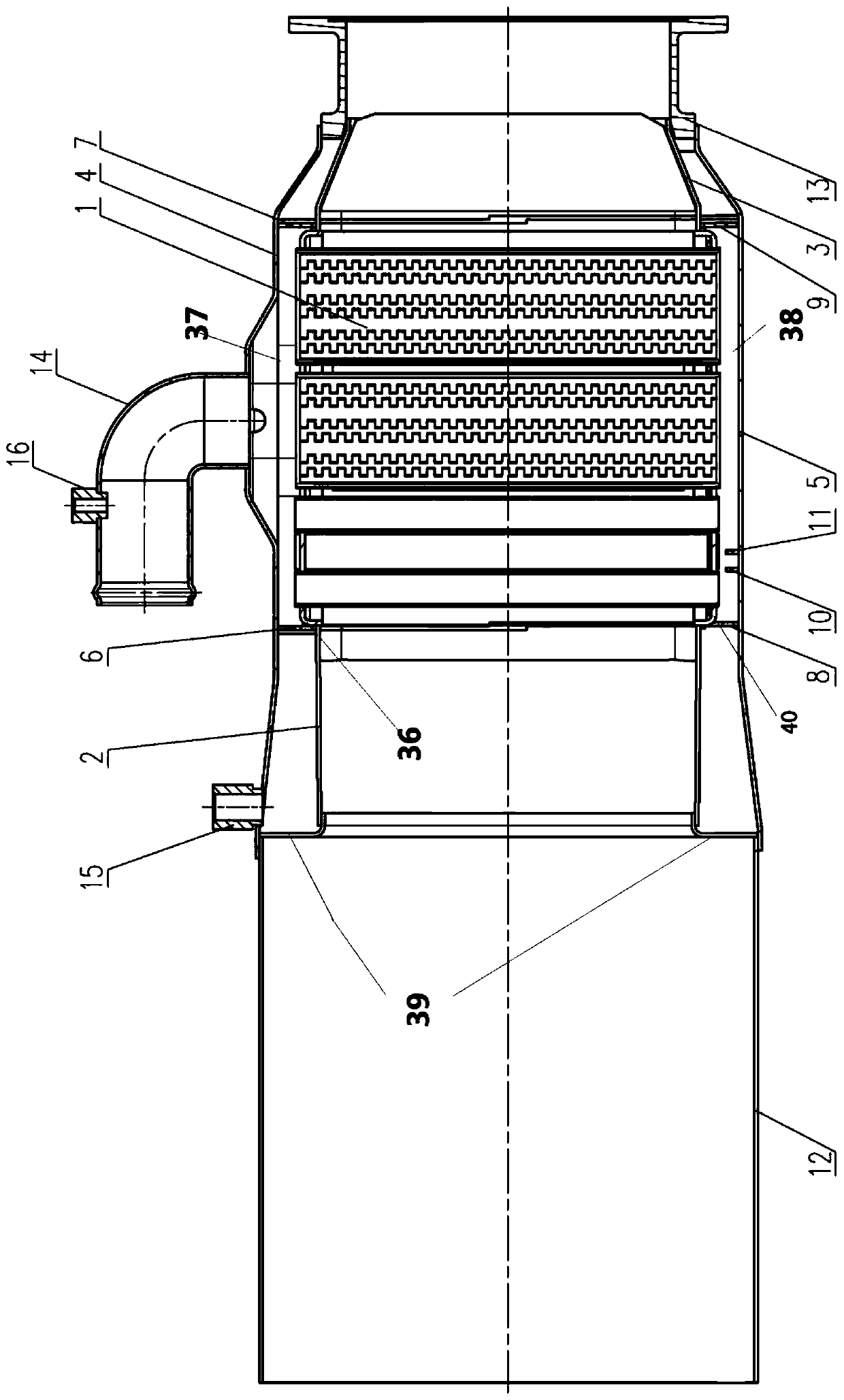

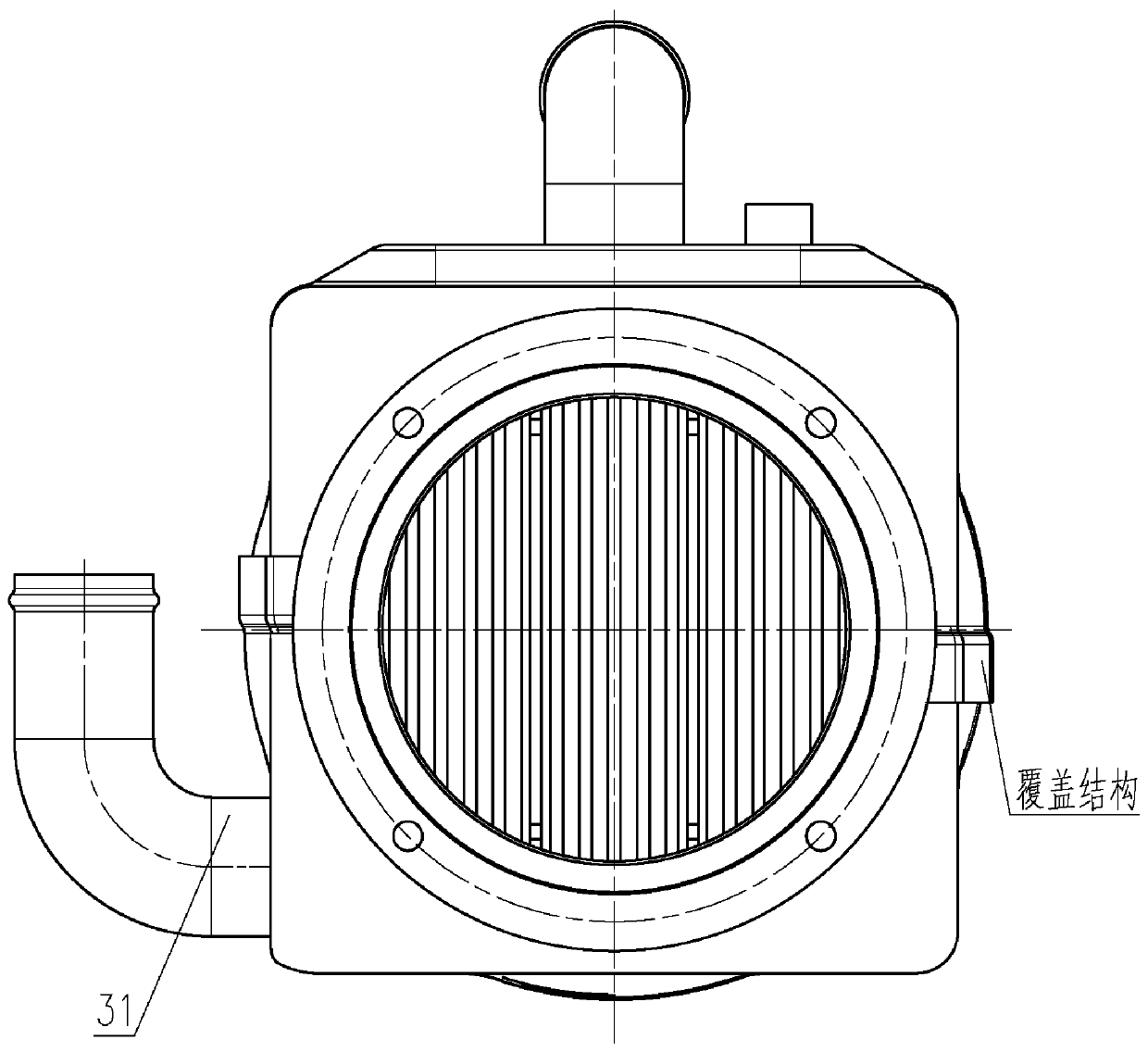

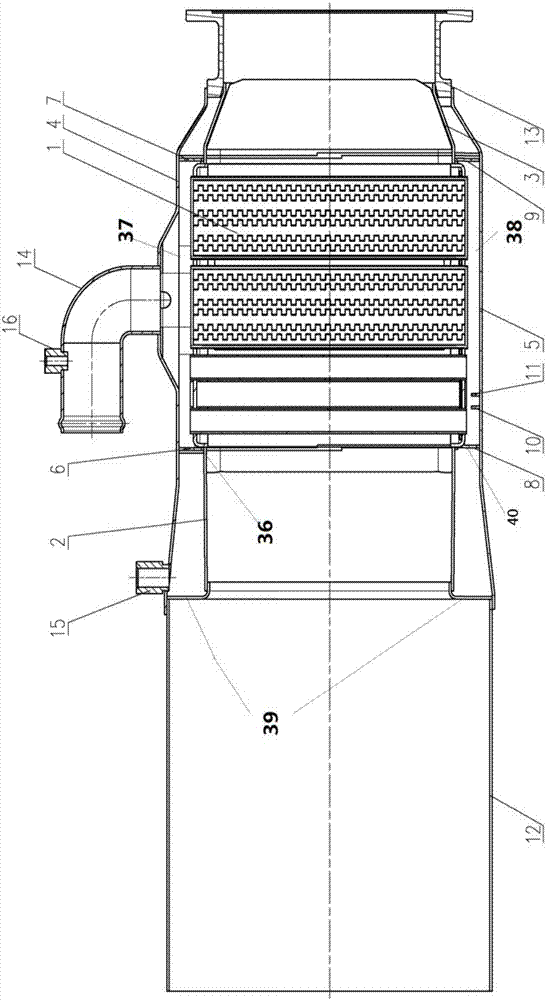

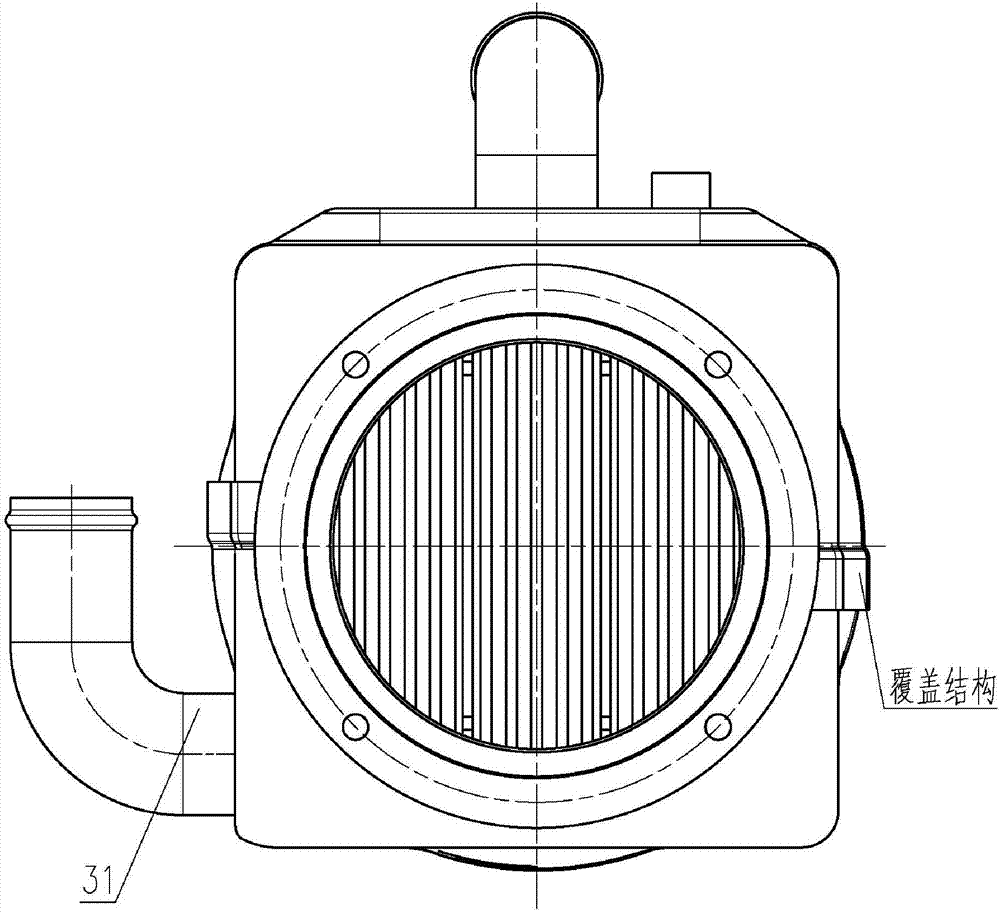

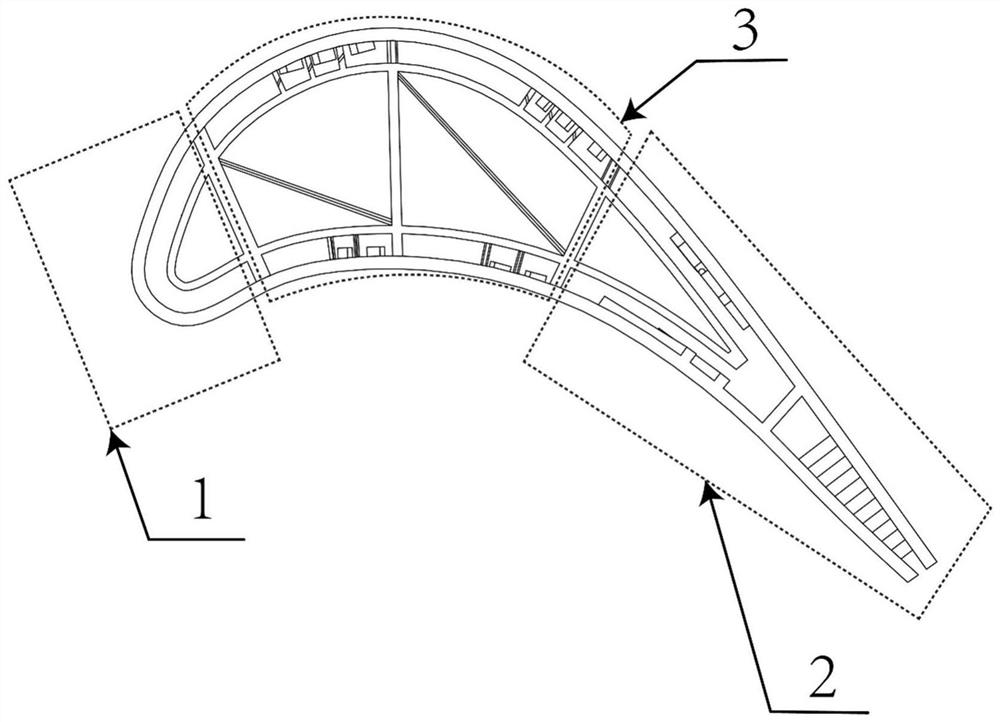

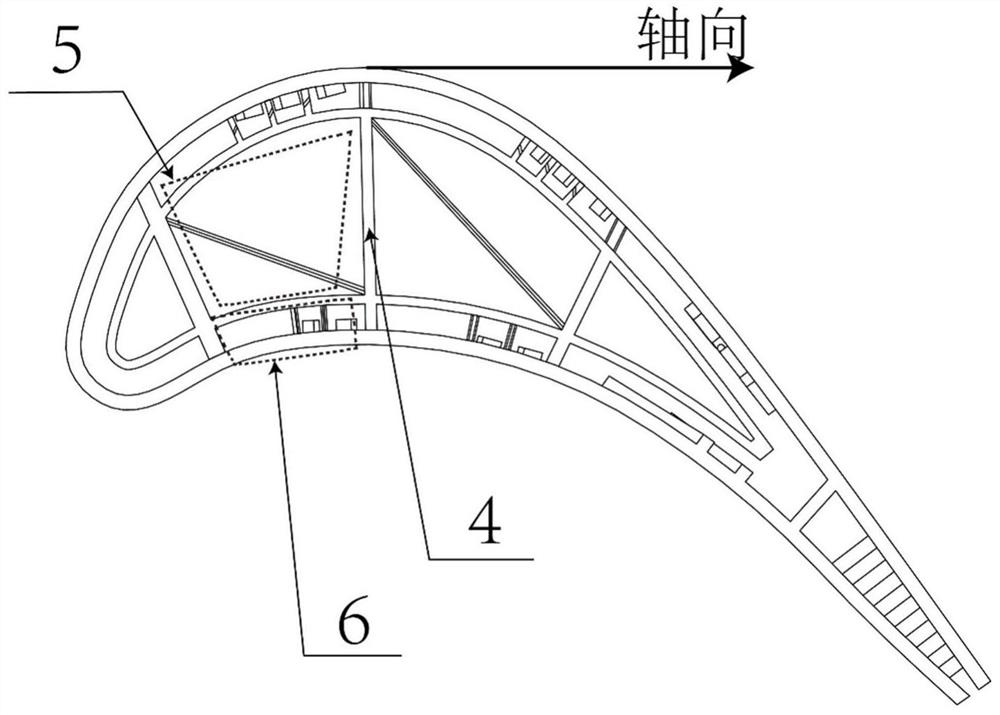

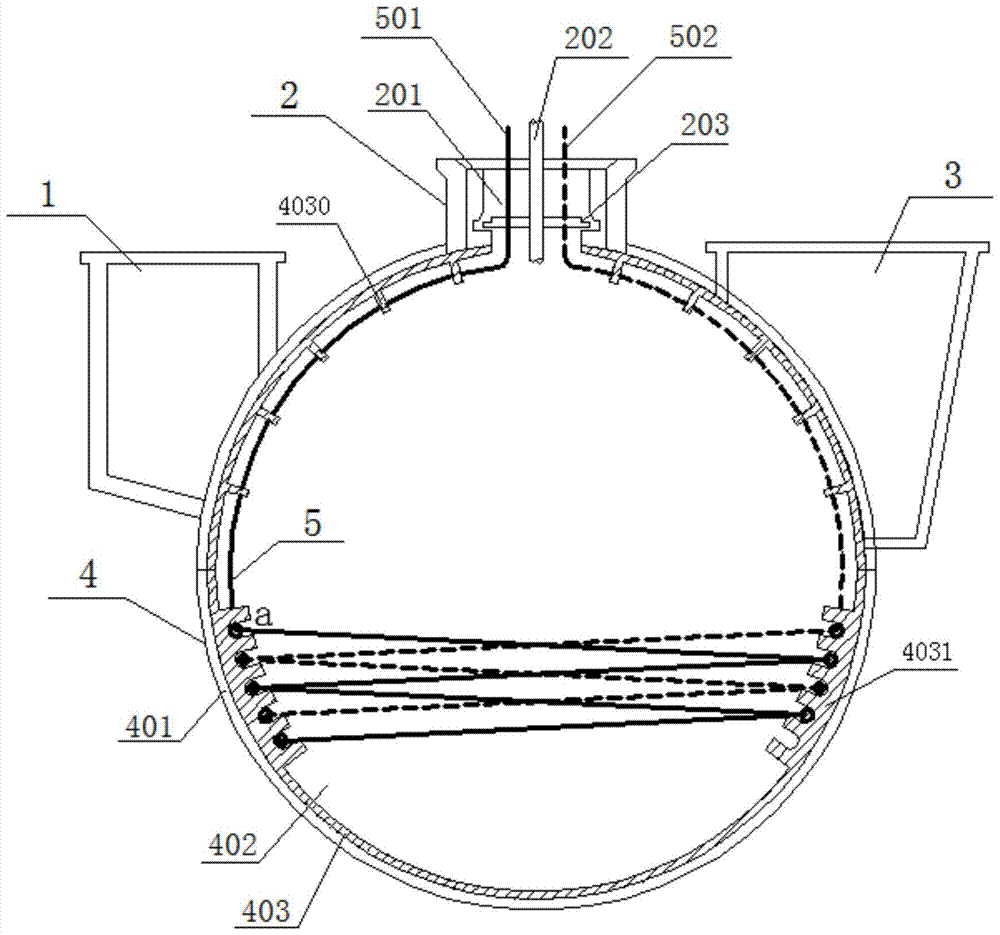

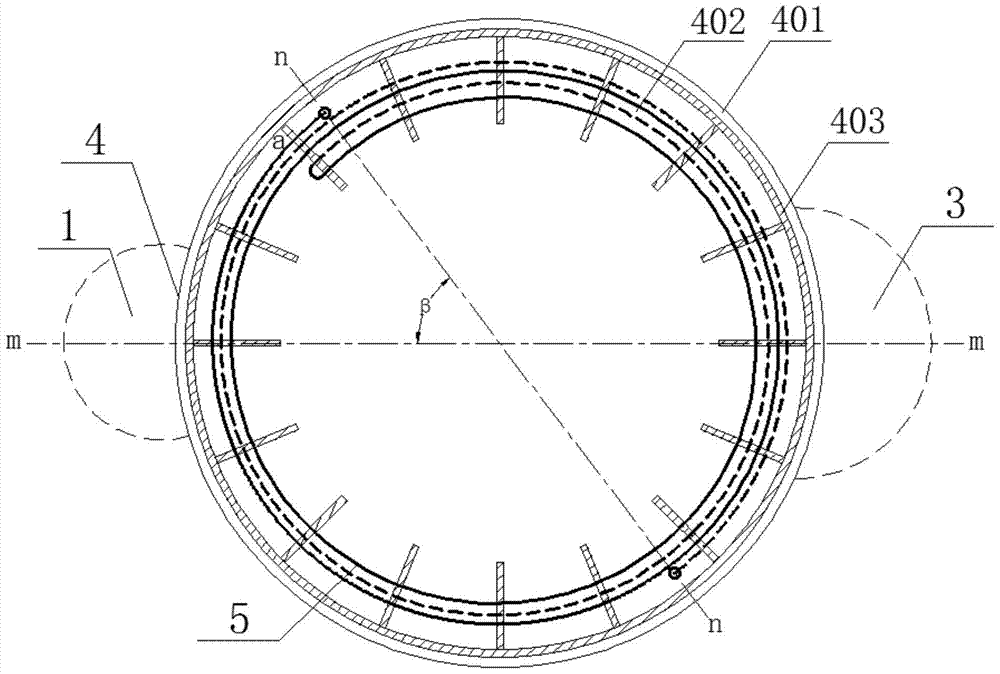

ActiveCN113007070AReduced opening sizeImprove sound absorptionPositive displacement pump componentsPositive-displacement liquid enginesNoiseEngineering

The invention relates to an intake silencer for an acoustic enclosure of a compressor unit. The intake silencer is mainly composed of an intake silencer box body, a plurality of broken line type intake silencing channels and a right-angle triangular prism sound absorption structures, wherein the intake silencer box body is of a quadrangular prism structure with trapezoidal side plates, and the broken line type intake silencing channels formed by arranging the right-angle triangular prism sound absorption structures side by side in a broken line form are arranged in the intake silencer box body; and each right-angle triangular prism sound absorption structure is composed of a right-angle triangular prism sound absorption structure inclined face, a right-angle triangular prism sound absorption structure long right-angle face, a right-angle triangular prism sound absorption structure short right-angle face and an unequal-thickness cavity structure. The intake silencer has the advantages of being simple in structure, accelerating the intake speed, increasing the effective ventilation quantity, effectively controlling the noise transmission path, remarkably improving the noise reduction effect and the like.

Owner:SOUTHWEST PETROLEUM UNIV

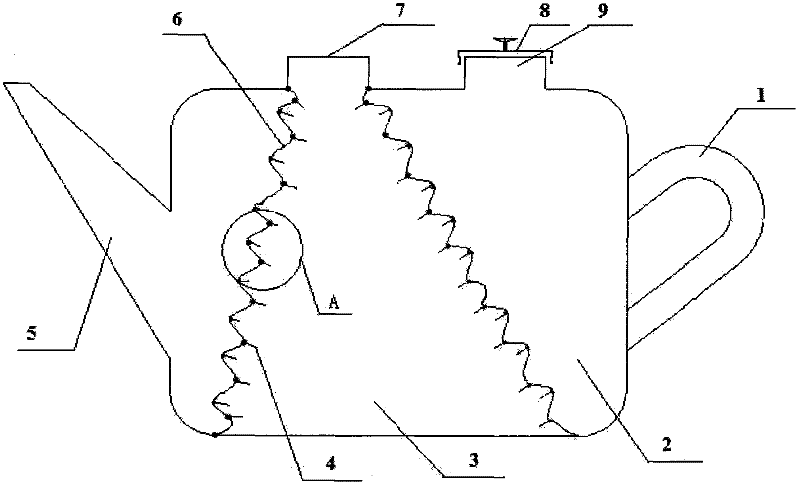

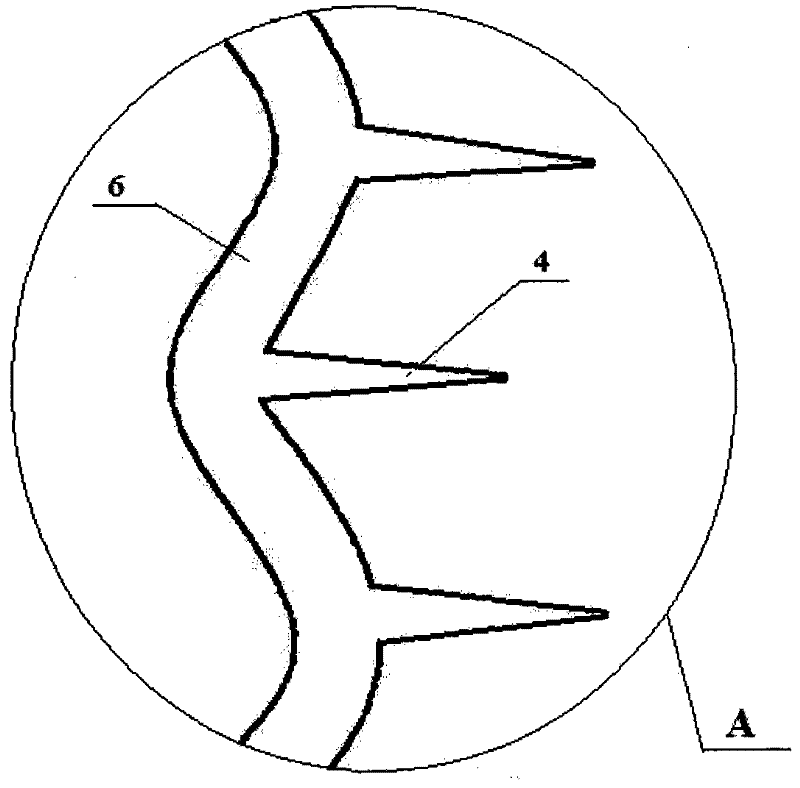

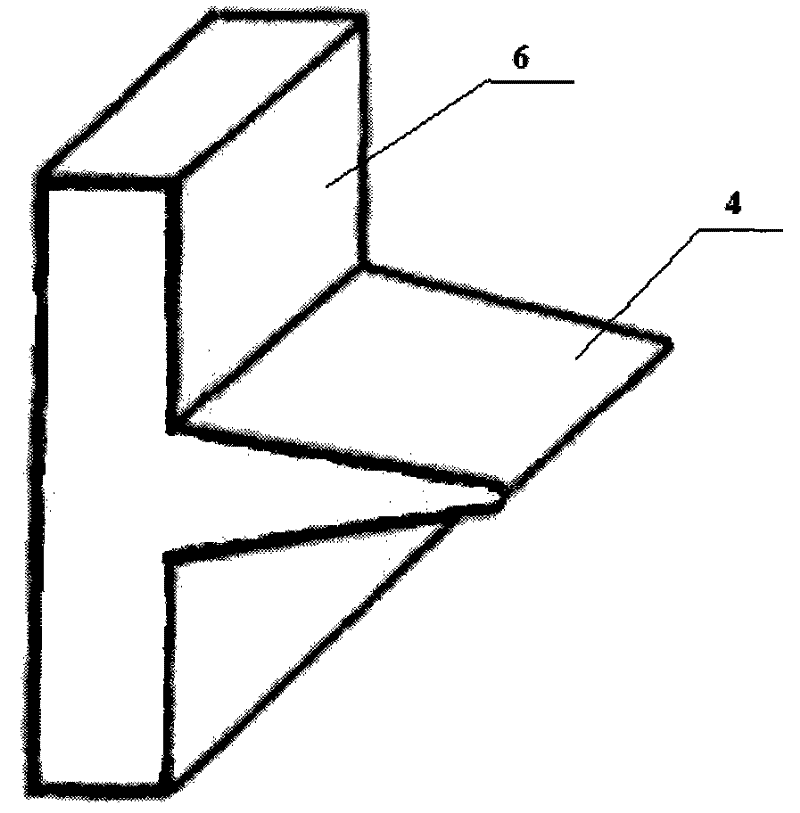

A kind of internal combustion type kettle

InactiveCN102293587AExtended stayLimit free developmentWater-boiling vesselsCombustion chamberEngineering

The invention discloses an internal combustion type kettle. It includes an annular water cavity surrounded by the outer wall and an internal combustion chamber surrounded by the inner wall, as well as curved walls, fins, water injection ports, exhaust ports, etc.; in the structural design, the knowledge of heat transfer and fluid mechanics is used. Reasonably optimize the heat transfer process, significantly increase the contact area between the flame and the wall of the kettle, reduce heat transfer resistance, and reduce heat energy loss. The flat conical internal combustion chamber used not only blocks the direct contact between the flame and the air, but also increases the residence time of the high-temperature flue gas; the curved wall and fins significantly increase the heat transfer area and enhance the The convective heat transfer intensity on the gas side. It not only improves the thermal efficiency, but also achieves the effect of energy saving and environmental protection.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

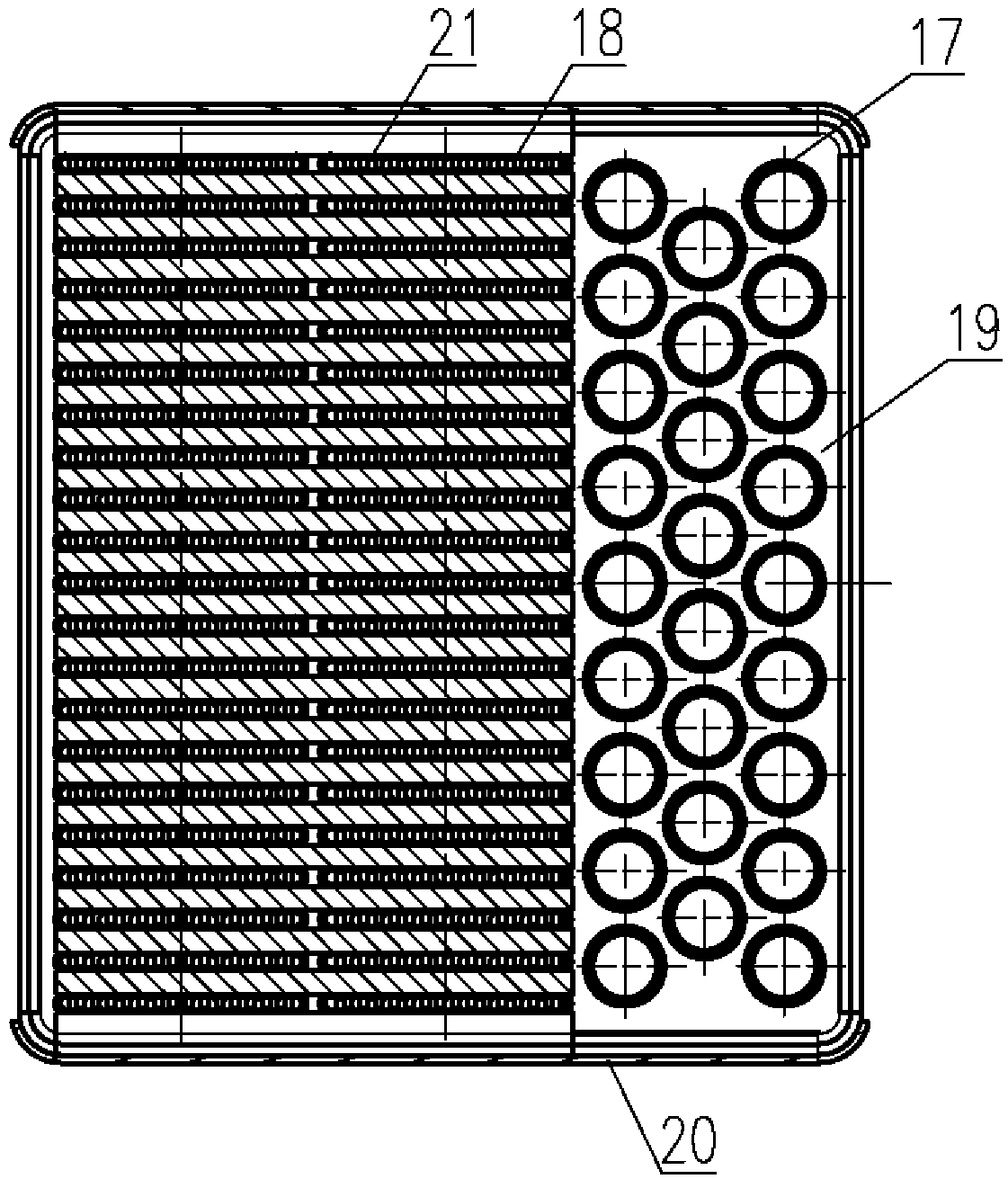

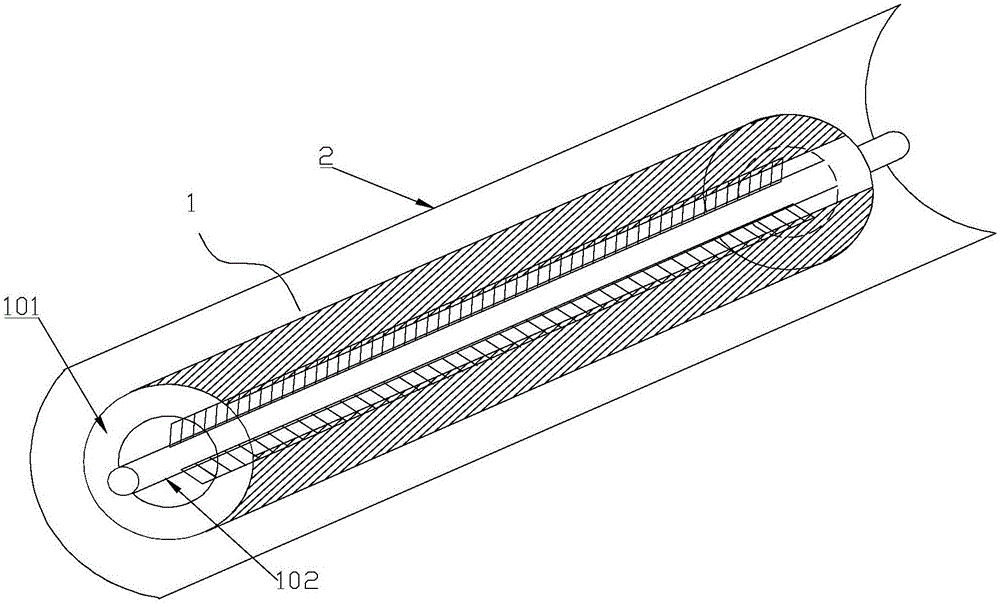

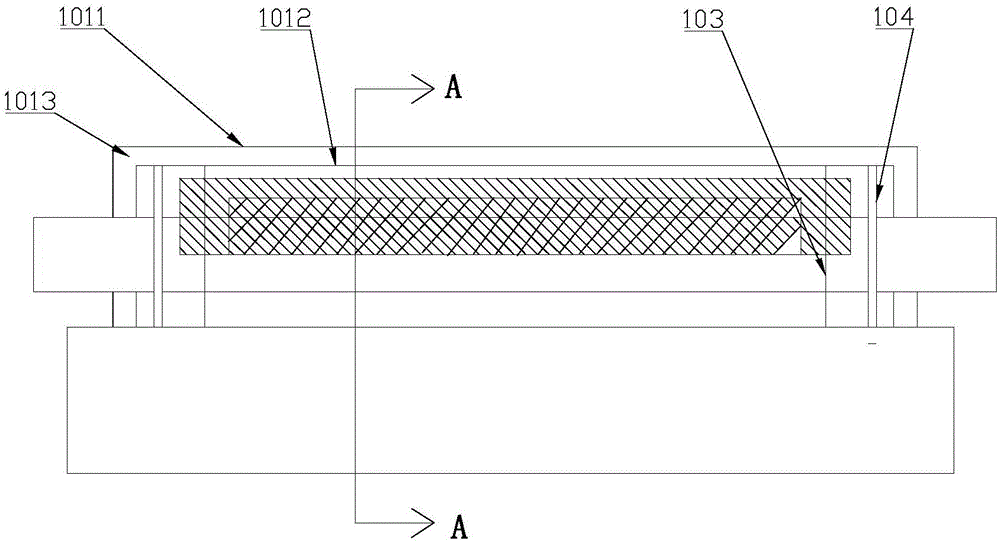

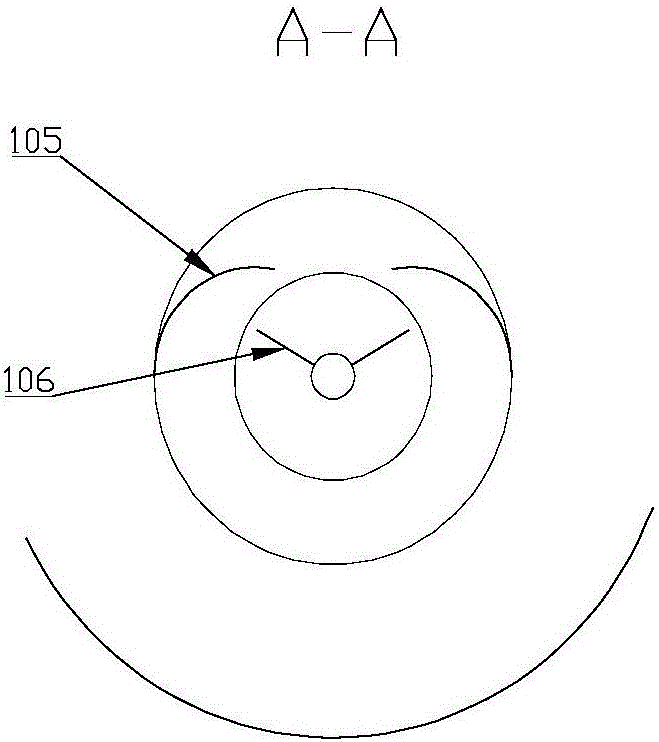

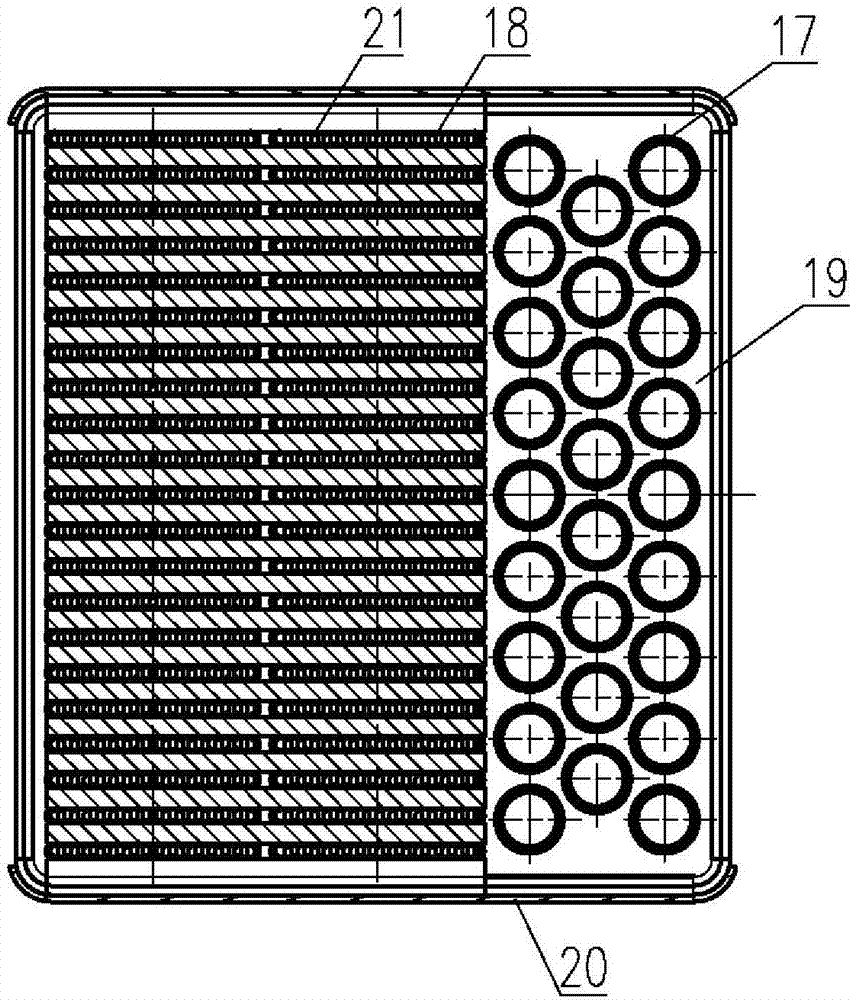

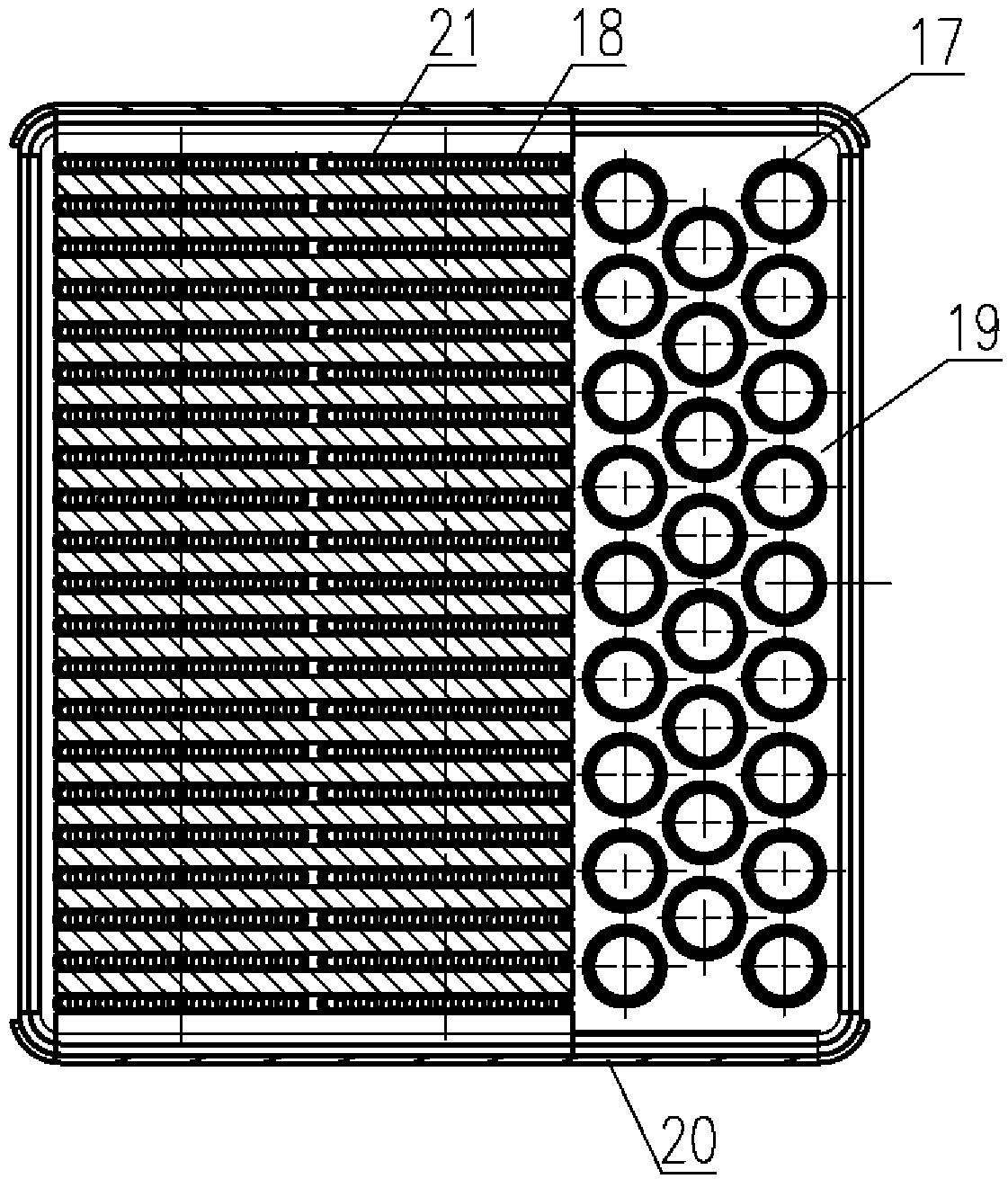

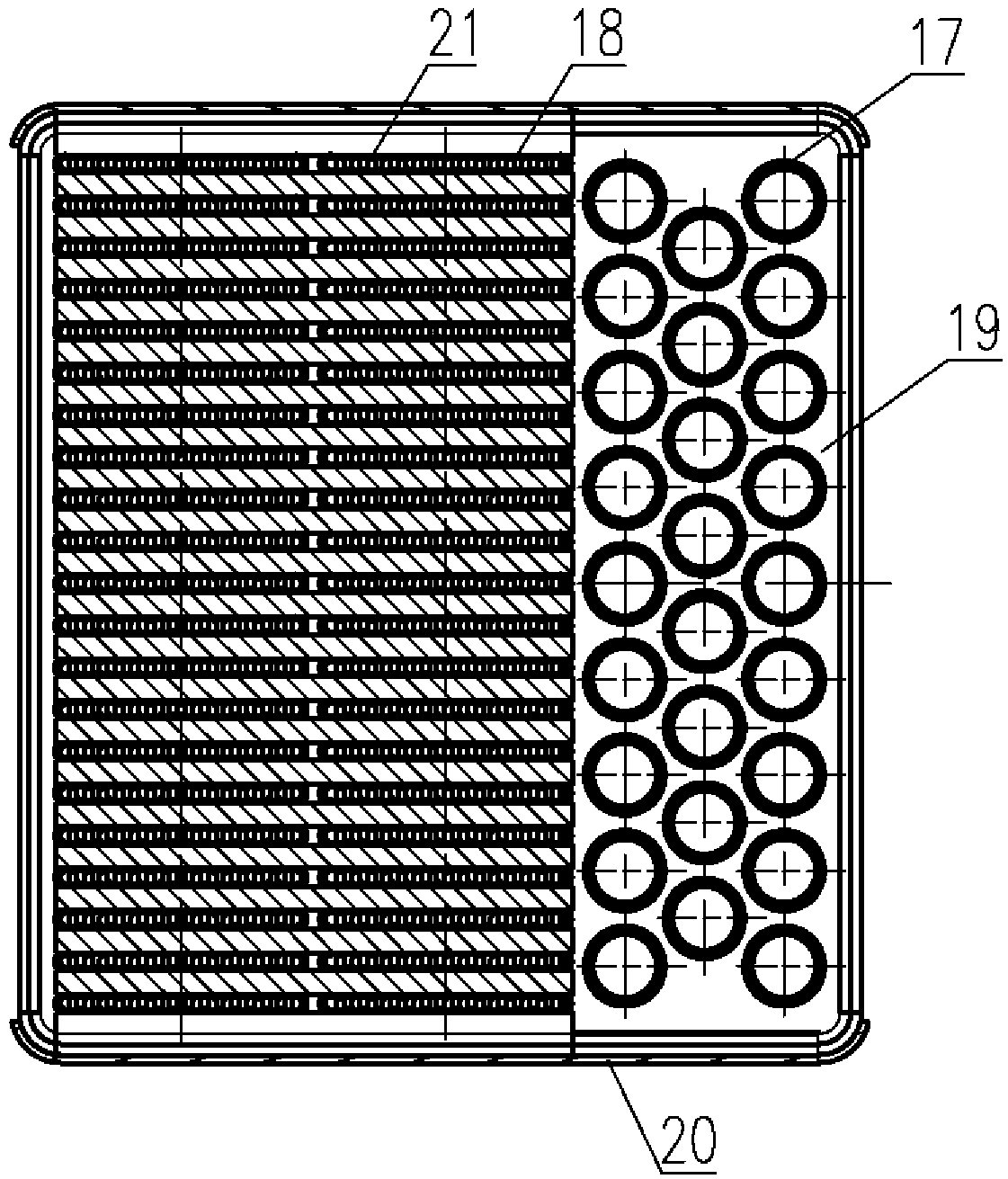

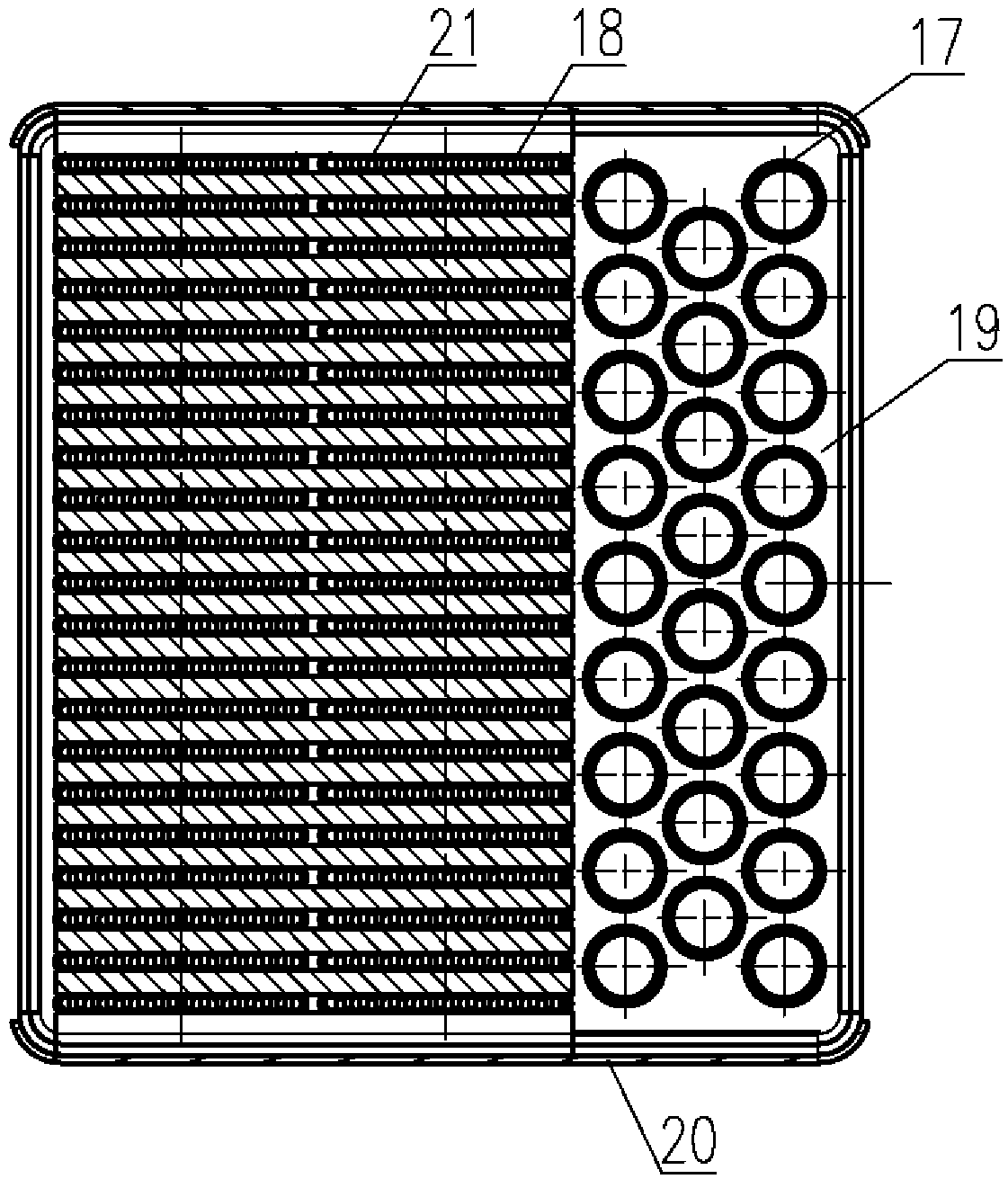

A heat exchange device for utilization of combustion waste heat with grid-distributed heat exchange structure

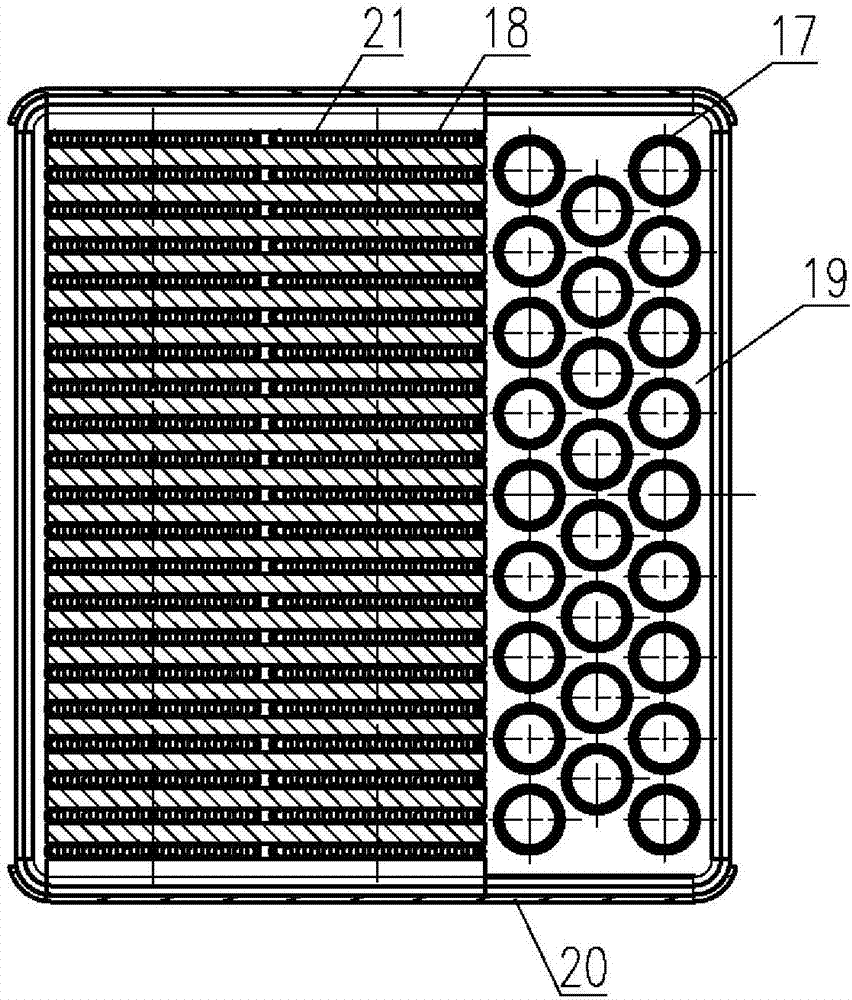

InactiveCN107270746BReduce film boilingReduce heat loadHeat exchanger casingsStationary tubular conduit assembliesGratingCombustion

The invention provides a heat exchange device utilizing combustion waste heat. The heat exchange device comprises a heat exchange core; the heat exchange core is arranged in a waste gas flue and comprises circular tubes; the circular tubes are arranged perpendicular to the flowing direction of waste gas; a plurality of dispersion heat exchange structures are arranged in the circular tubes in a segmented mode; each dispersion heat exchange structure comprises a core and a shell, wherein the core is arranged in the shell; the shells are fixedly connected to the inner walls of heat exchange tubes; each core is formed by arranging and combining a plurality of grating sheets; and the grating sheets are mutually connected to form grating holes. The heat exchange device has the advantages that the grating type dispersion heat exchange structures are arranged in the heat exchange tubes so as to separate a steam-water mixture in the heat exchange tubes, and therefore the film boiling phenomenon on the water side can be effectively reduced, the convective heat exchange intensity of the water side can be increased, the heat load of the heat exchange core can be reduced, and the heat exchange efficiency can be improved.

Owner:CHINA NORTH VEHICLE RES INST

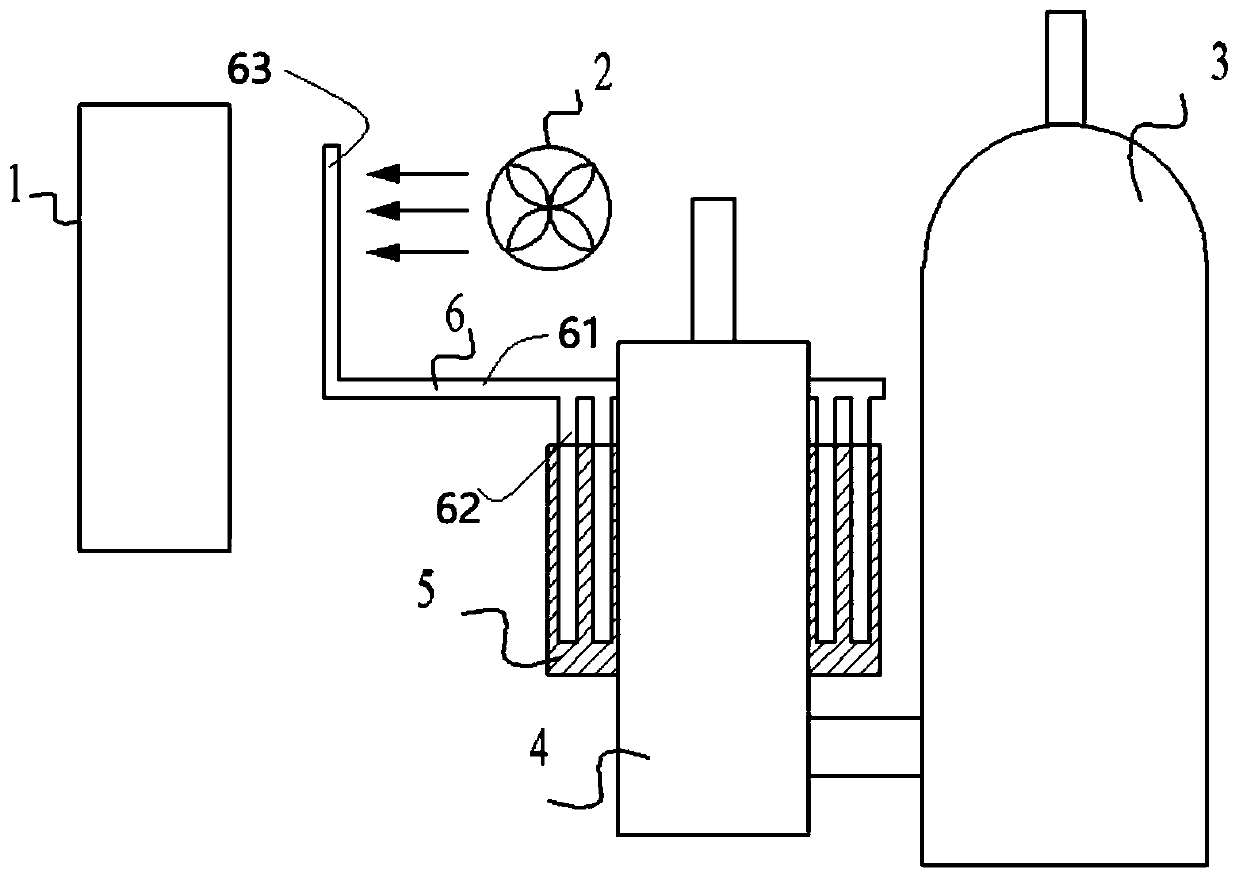

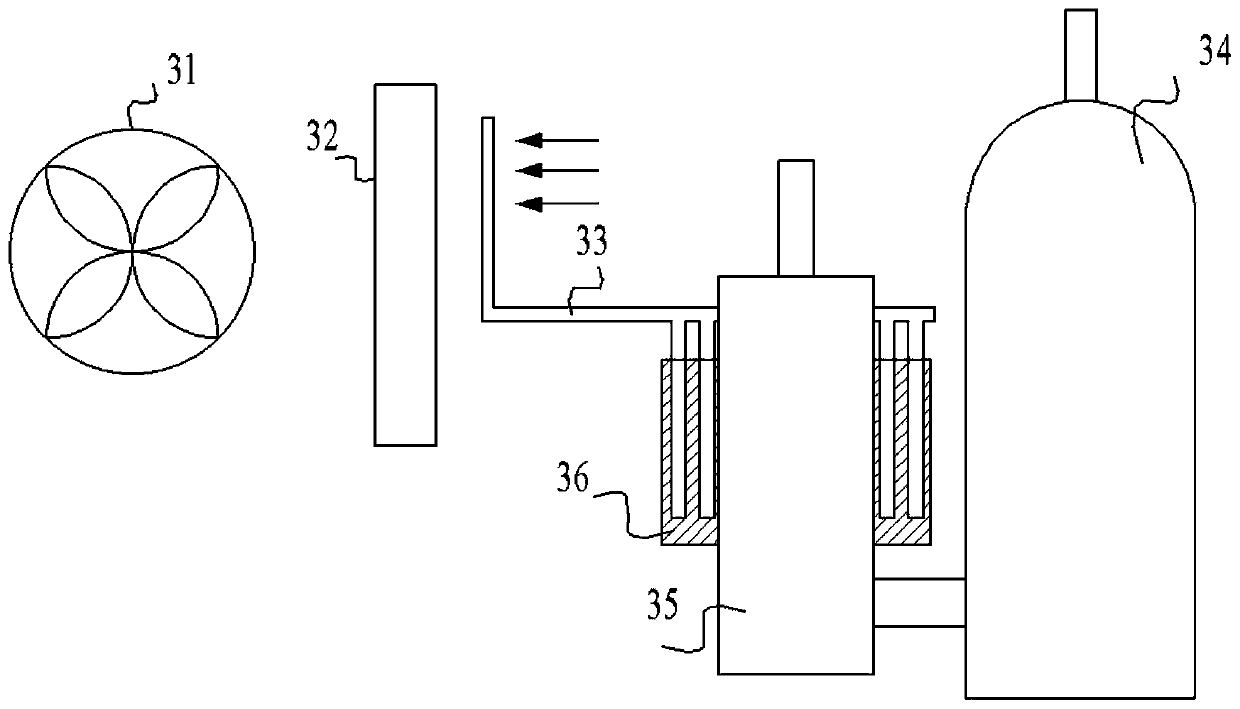

Electric appliance box heat dissipation device and air conditioner outdoor unit and air conditioner comprising same

InactiveCN110986192AGuaranteed uptimeEnhanced convective heat transfer intensityIndirect heat exchangersAir conditioning systemsLiquid storage tankHeat pipe

The invention relates to the technical field of air conditioners, and discloses an electric appliance box heat dissipation device. The device comprises an electric appliance box, a fan, a compressor,a liquid storage tank, a liquid storage tank pipe sleeve and a heat pipe bundle, and is characterized in that the compressor is connected with the liquid storage tank; the liquid storage tank pipe sleeve is disposed outside the liquid storage tank in a sleeved manner; one end of the heat pipe bundle is wrapped in the liquid storage tank pipe sleeve, and the electric appliance box, the fan and theheat pipe bundle are arranged at intervals. Due to the fact that the electric appliance box and the heat pipe bundle are arranged at intervals, the condensate water cannot be generated in the electricappliance box any more and is generated on the surface of the heat pipe bundle, thereby guaranteeing that the electric appliance box cannot be short-circuited, and safe and stable operation can be achieved.

Owner:GREE ELECTRIC APPLIANCES INC

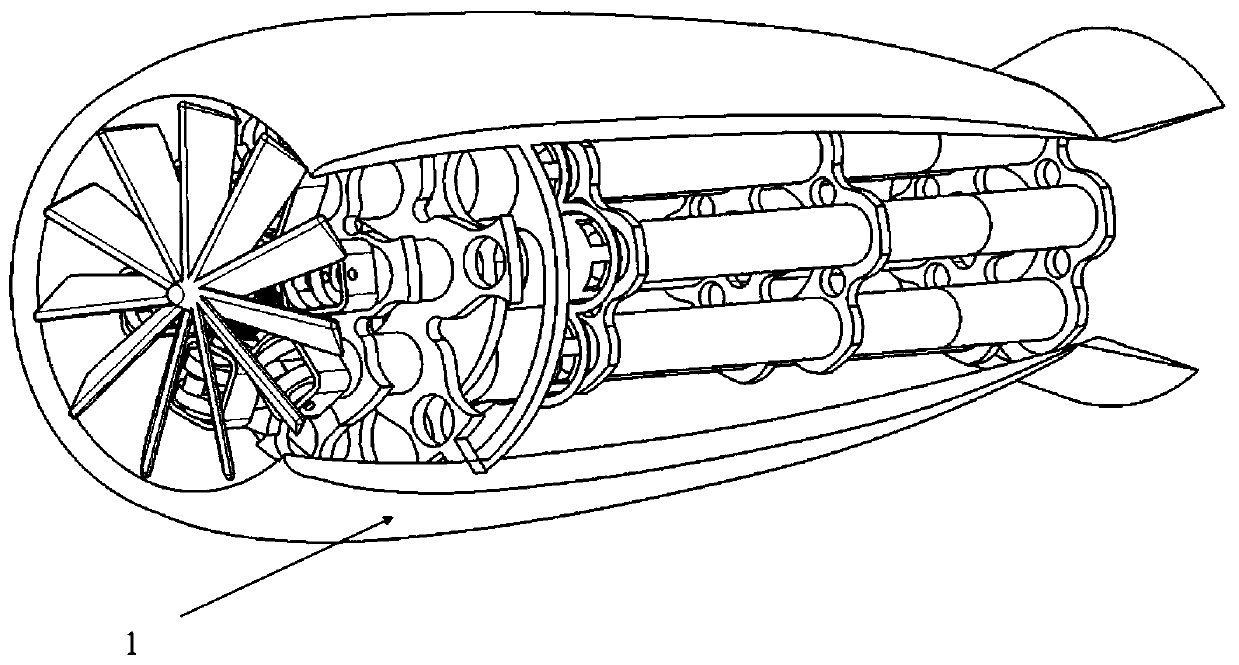

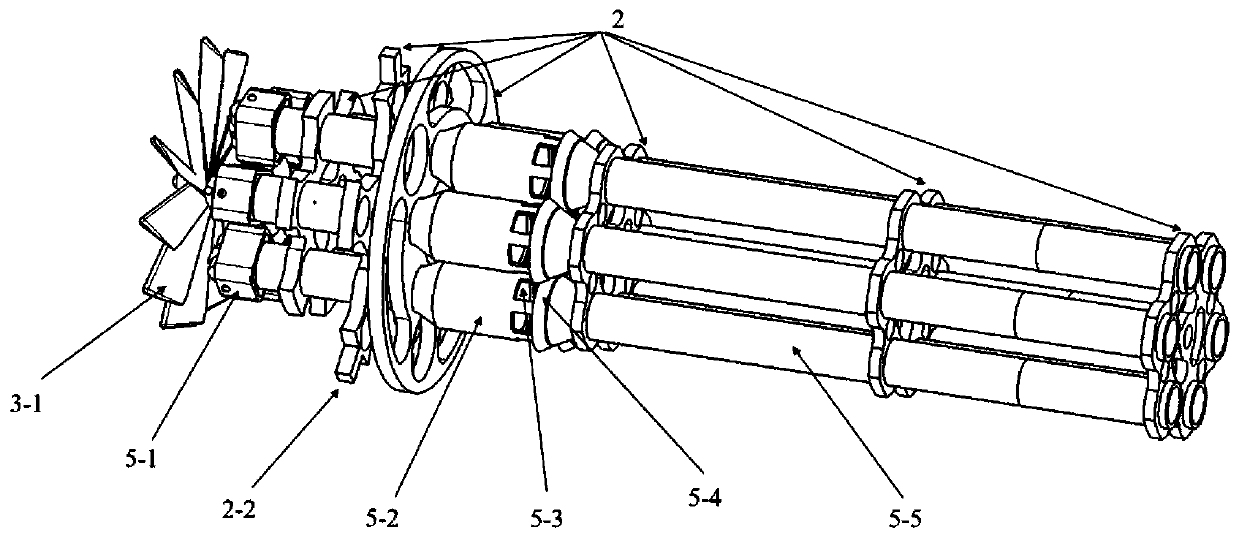

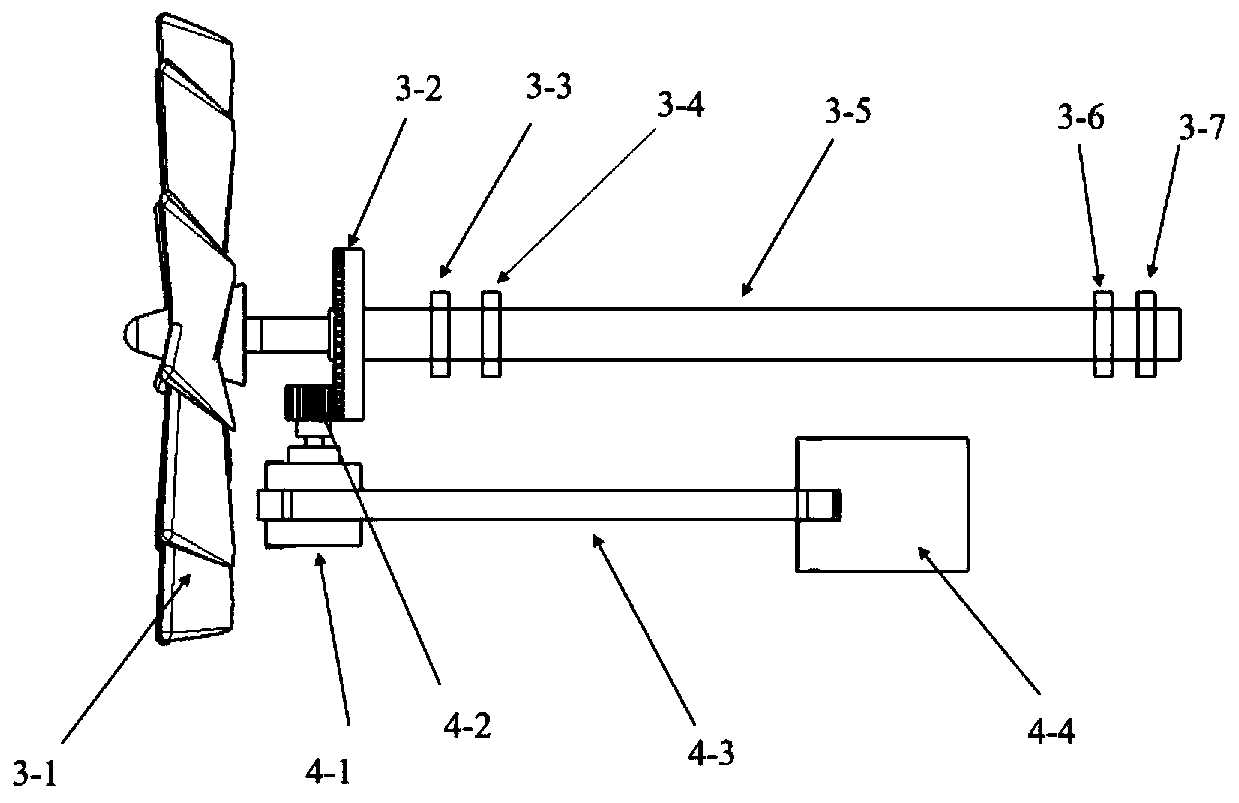

Piston type pulse detonation engine

InactiveCN110017220AControl accessIncrease intake pressureIntermittent jet plantsCombustionMechanical energy

The invention provides a piston type pulse detonation engine. The piston type pulse detonation engine comprises a fairing, a detonation combustion device, a fan assembly, a transmission mechanism anda supporting structure, wherein one part of energy generated by the detonation combustion device is transmitted downstream to form thrust, and the other part of the energy is transmitted upstream to act on a transmission device; the transmission device drives a fan in the fan assembly to rapidly rotate to produce mechanical energy, the energy utilization rate and thrust of a whole engine system are increased, and energy back transmission during detonation combustion is effectively inhibited. The supporting structure achieves the fixing and constraint effects on the detonation combustion device, the fan assembly and the transmission mechanism. The fairing achieves the rectifying and external duct forming effects. Through the piston type pulse detonation engine, a series of problems existingin pressure back transmission, energy utilization and the like of an existing self-priming pulse detonation engine are effectively solved. The piston type pulse detonation engine is suitable for thefield of detonation propulsion.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

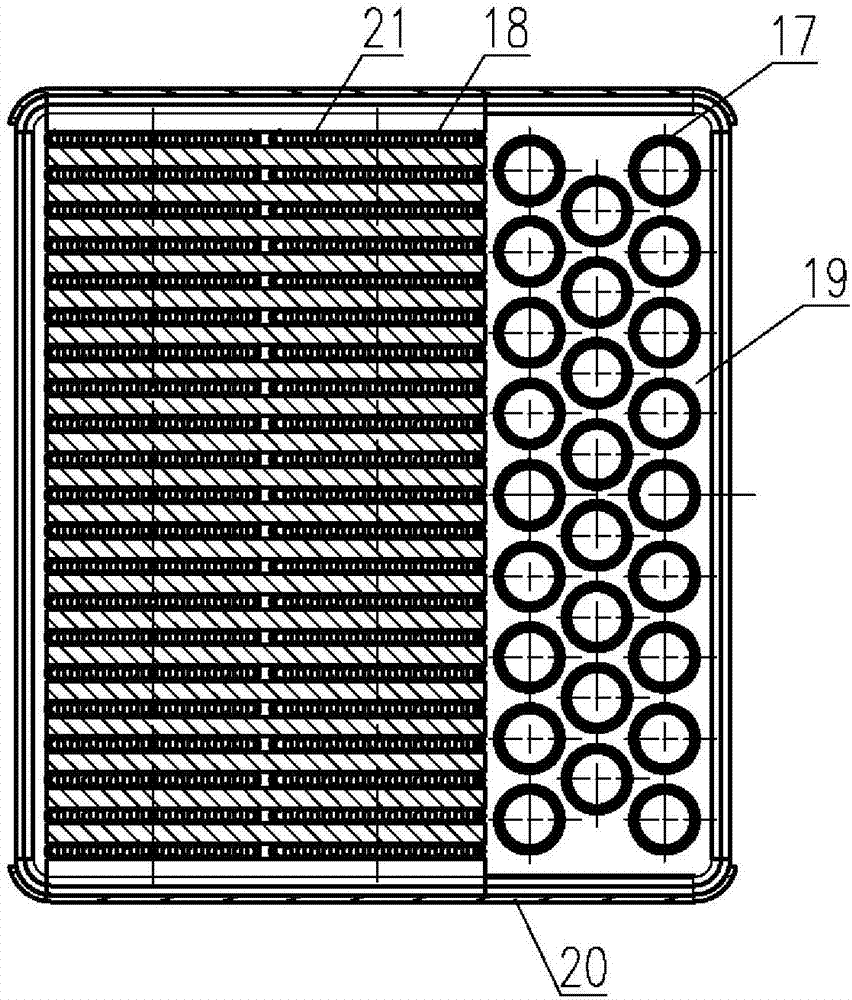

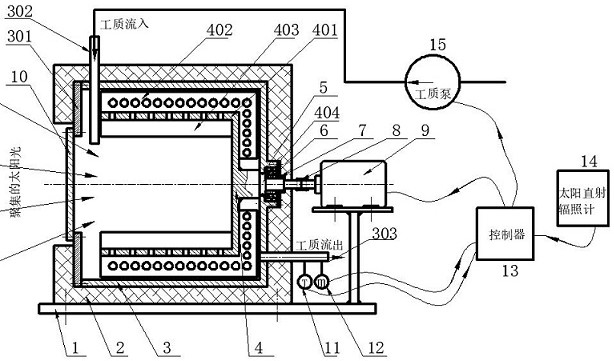

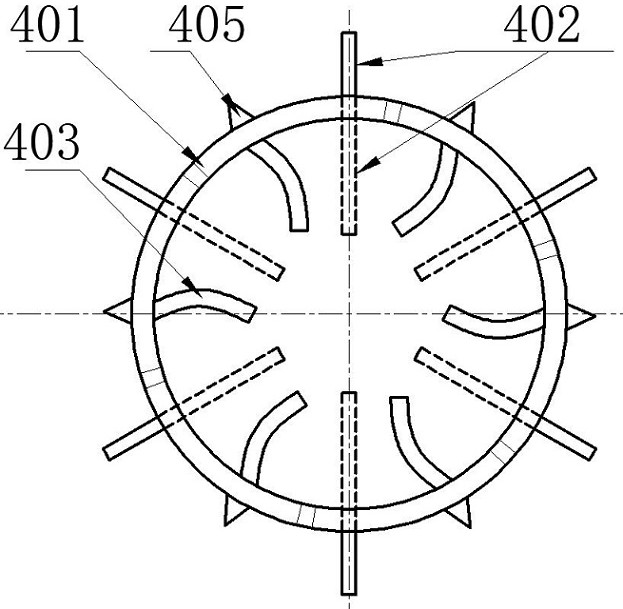

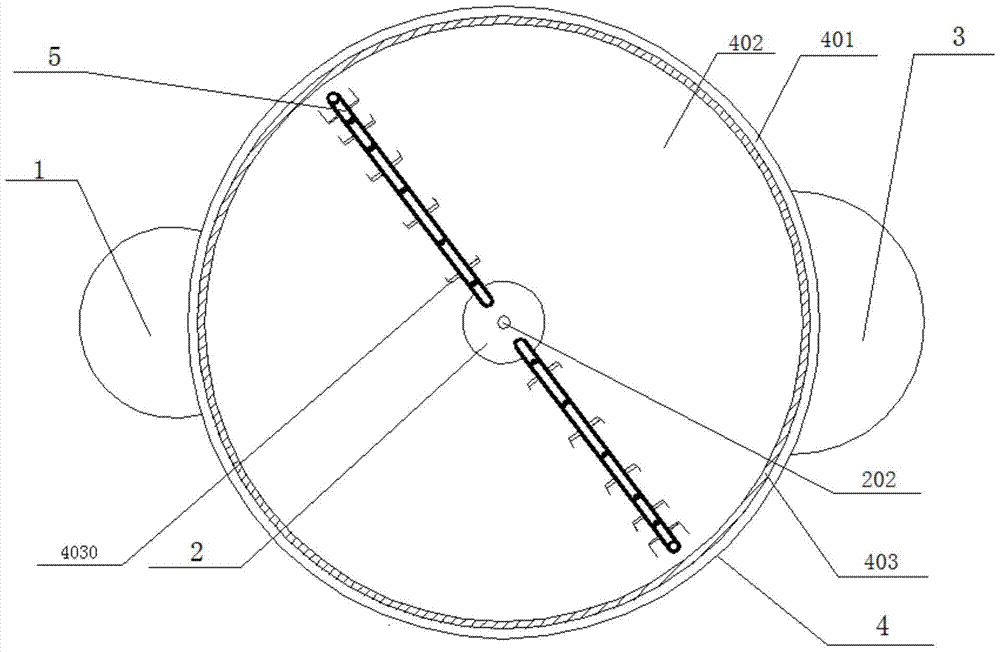

Volumetric solar cavity heat absorber with rotary heat absorbing body

InactiveCN113294919AImprove temperature distribution uniformityEnhanced convective heat transfer intensitySolar heating energySolar heat collector controllersGlass coverDrive shaft

The invention discloses a volumetric solar cavity heat absorber with a rotary heat absorbing body. The volumetric solar cavity heat absorber is composed of an outer barrel, the heat absorbing body, a glass cover plate, a motor, a controller, a temperature sensor and the like, wherein the heat absorbing body is composed of a heat absorbing main body in a concave cavity shape, a plurality of outer fins arranged on the outer side surface and the outer bottom surface of the heat absorbing main body, a plurality of inner fins arranged on the inner side surface of the heat absorbing main body and a transmission shaft arranged at the bottom of the heat absorbing main body; the inner surface of a concave cavity of the heat absorbing main body absorbs sunlight; a plurality of through holes are formed in the side wall and the bottom of the heat absorbing main body and the outer fins; and the transmission shaft is matched with a stepped hole in the bottom of the outer barrel through the shaft surface of the transmission shaft and an installed bearing, and the tail end of the transmission shaft is fixedly connected with an output shaft of the motor through a connecting sleeve. The motor is controlled to drive the heat absorbing body to rotate, so that the convective heat exchange intensity of the heat absorbing body and a heat transfer working medium is improved, the working temperature distribution of the heat absorbing body and the distribution uniformity of absorbed solar energy are improved, and safe, reliable and efficient operation of the solar heat absorber achieved.

Owner:HUNAN UNIV OF SCI & TECH

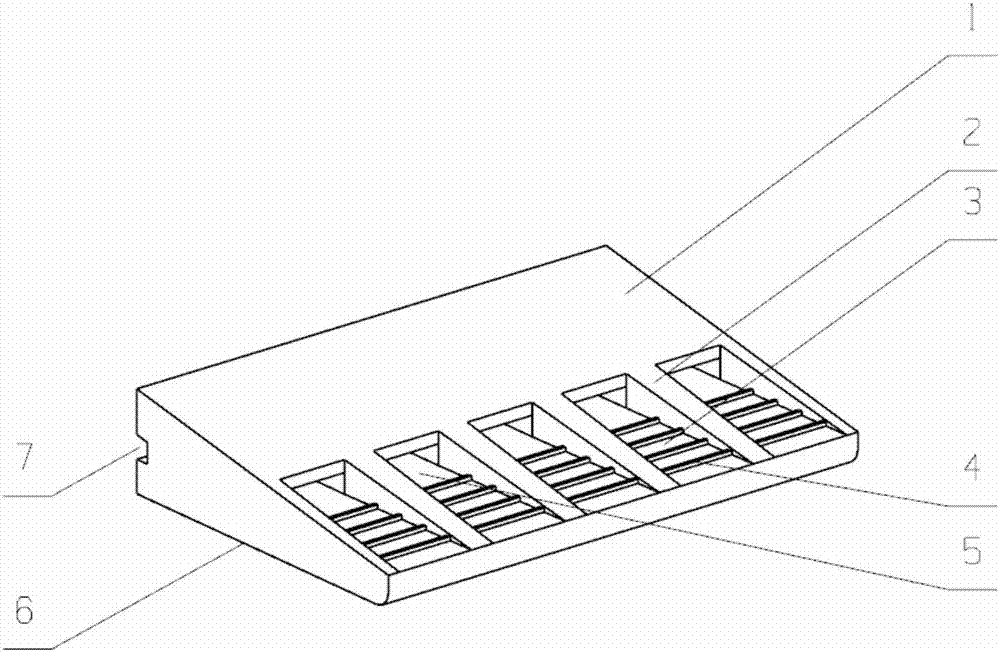

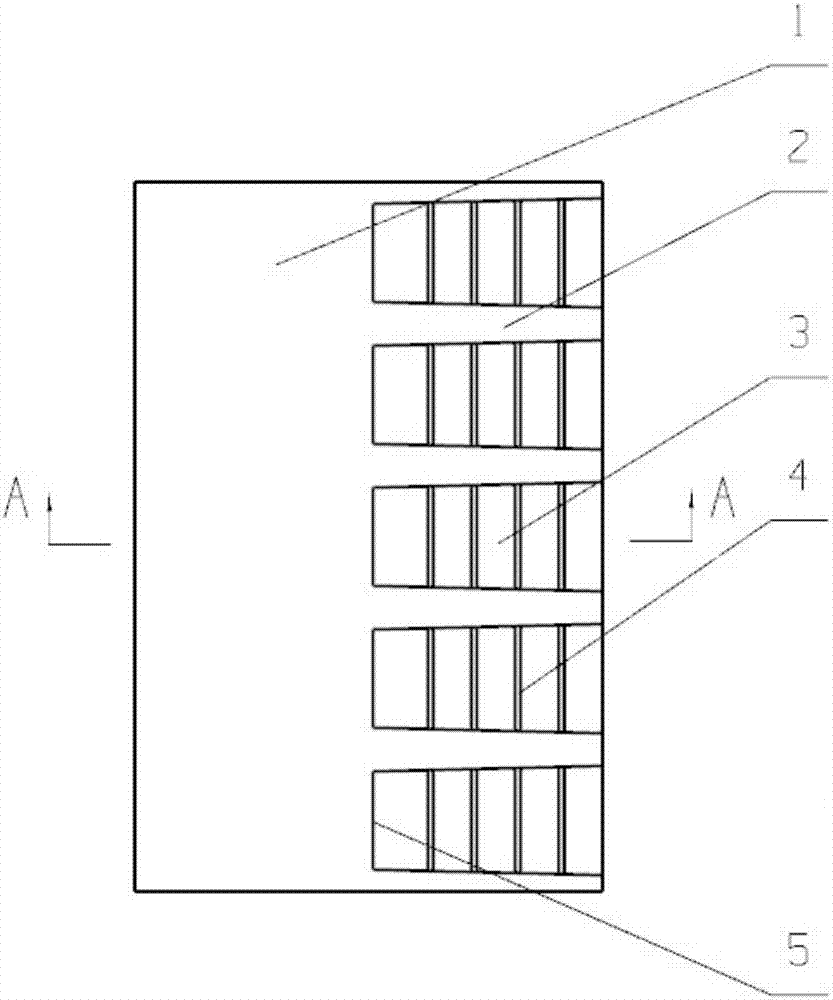

Liquid cooling plate radiator

ActiveCN113365485AIncrease disturbanceIncrease cooling areaStationary conduit assembliesCooling/ventilation/heating modificationsEngineeringCooling fluid

Owner:SHENZHEN MICROBT ELECTRONICS TECH CO LTD

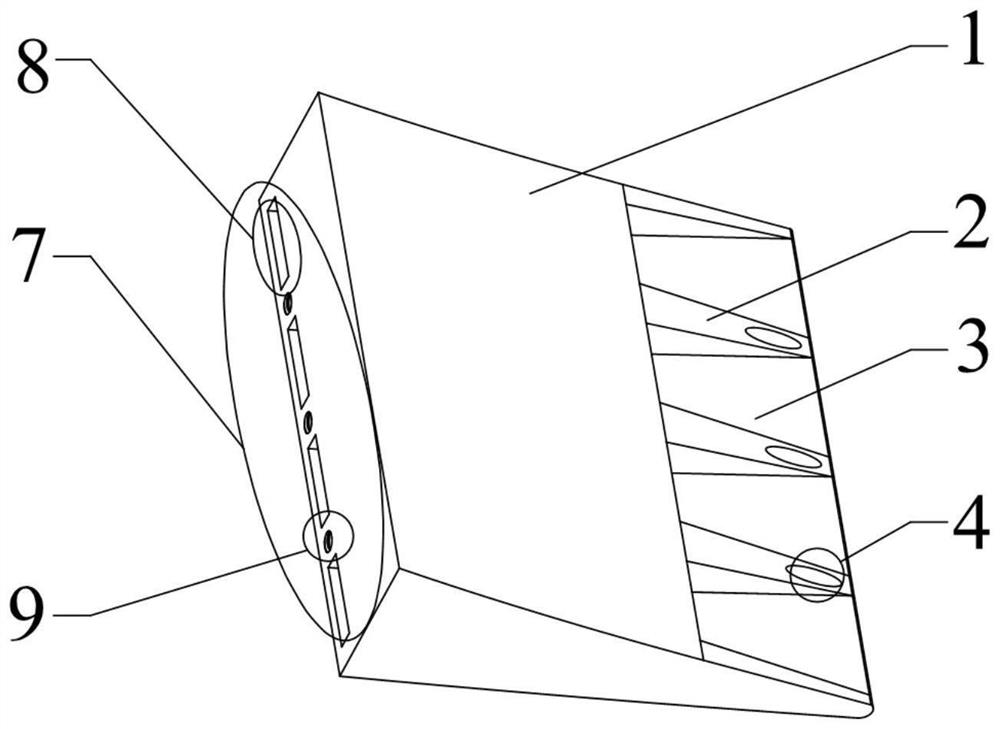

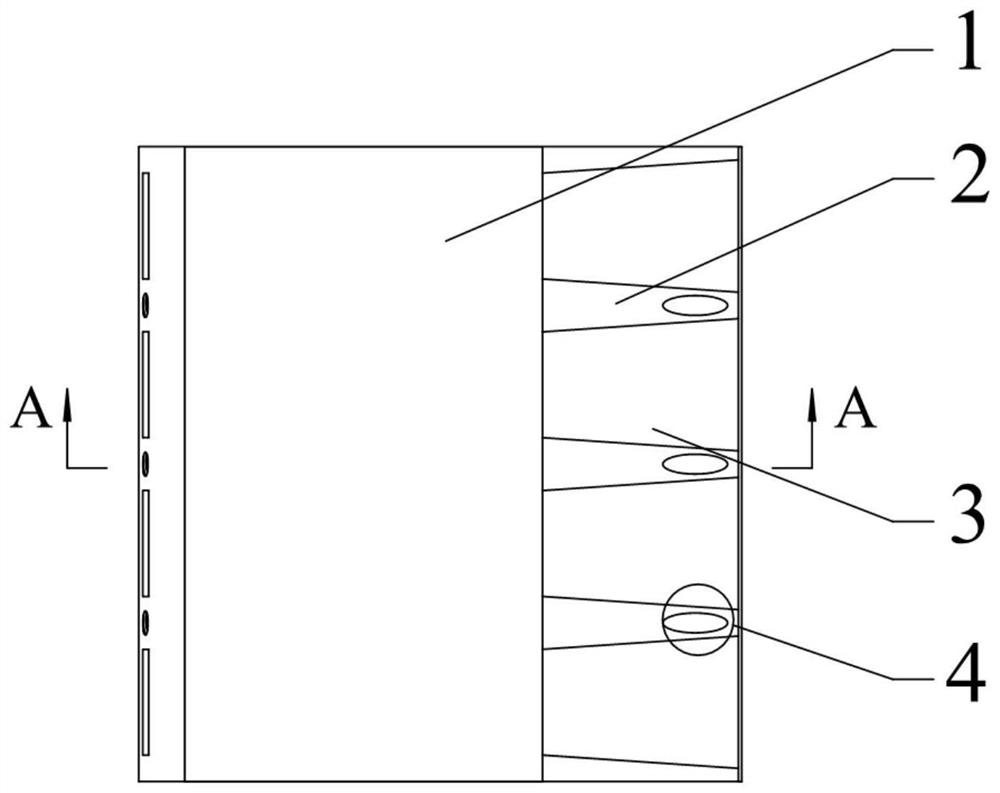

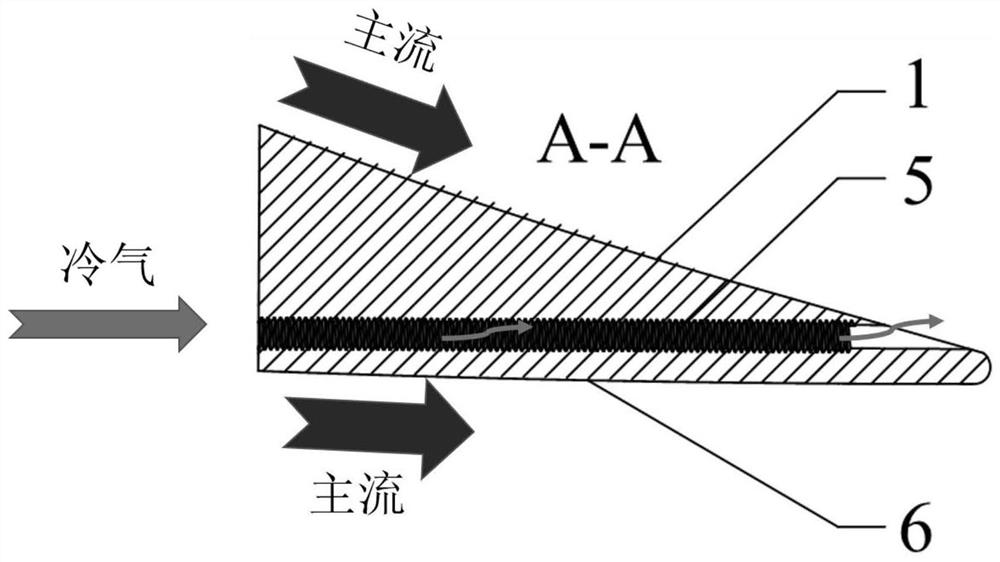

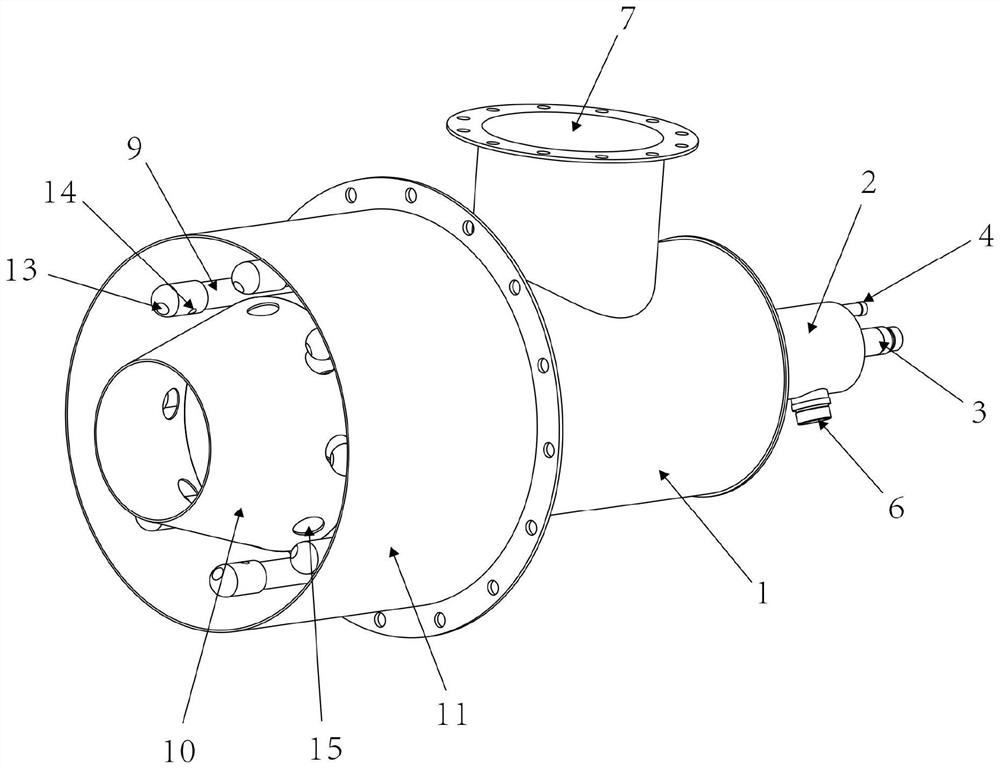

Turbulent flow threaded hole cooling structure for trailing edge of turbine blade and turbine blade

ActiveCN113107608AImprove cooling effectEnhanced convective heat transfer intensityBlade accessoriesMachines/enginesCold airThermodynamics

The invention provides a turbulent flow threaded hole cooling structure for a trailing edge of a turbine blade, which is arranged in the trailing edge area of the turbine blade, and is formed by cutting off part of the wall surface of a pressure surface of the trailing edge of the turbine blade, only reserving the wall surface on one side of a suction surface and arranging a plurality of separation ribs. Cylindrical cooling holes which penetrate through the separation ribs along the flow direction of cooling air flow are formed in the separation ribs; the center line of the cylindrical cooling hole is parallel to the center line of a trailing edge cold air inlet cavity; and turbulent flow threads are arranged in the cylindrical cooling holes. Cooling airflow in the threaded holes can generate a remarkable cooling effect on the inner and outer surfaces of the separation ribs, the heat exchange area is increased through the turbulent flow threaded structures in the holes, and the convective heat exchange strength of the inner surfaces of the separation ribs is enhanced; meanwhile, the internal heat exchange of the wall surface of the suction surface can be enhanced, the blank of the split seam separation rib cooling design is filled up, and the comprehensive cooling effect of the trailing edge is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Straight ribbed pipe fin inserting trough-type condensation vacuum solar heat collector

InactiveCN106679196AUniform heat fluxNot easy to scalePhotovoltaic supportsSolar heating energyConnection typeHeat flow

The invention discloses a straight ribbed pipe fin inserting trough-type condensation vacuum solar heat collector which comprises a vacuum heat collector body and a trough-type condenser; the vacuum heat collector body is arranged in a condensation position of the trough-type condenser, and comprises a direct connection type glass vacuum casing pipe; a vacuum layer is formed between an outer glass pipe and an inner glass pipe; a straight ribbed pipe is arranged in the inner glass pipe in a penetrating manner, and is fixed through springs; two arc-shaped heat insulating plates are arranged in the vacuum layer; and two fins are arranged on the outer side of the straight ribbed pipe. The straight ribbed pipe fin inserting trough-type condensation vacuum solar heat collector has the advantages that the condensation heat collection efficiency is high, the heat flux density received by a heat collection pipe is uniform, the external radiation heat loss of the inner glass pipe is little, the heat collection pipe is not prone to scaling, and the service life is long.

Owner:FUJIAN UNIV OF TECH

Circular pipe and flat pipe combined combustion waste heat utilization heat exchange device

InactiveCN107192283AReduce heat loadReduce film boilingCombustion technology mitigationHeat exchanger casingsCombustionEngineering

The invention provides a combustion waste heat utilization heat exchange device. The combustion waste heat utilization heat exchange device comprises a heat exchange core arranged in a waste gas flue. The heat exchange core comprises circular pipes and flat pipes. The flowing direction of liquid in the circular pipes and the flat pipes is perpendicular to the flowing direction of waste gas. The circular pipes and the flat pipes are sequentially distributed in the waste gas flowing direction. The heat exchange core of the heat exchange device is of a circular pipe and flat pipe combined heat exchange structure. A thin-wall circular-pipe-shaped heat exchange structure is adopted at the front end of the heat exchange core, and a multi-row thin-wall flat pipe type heat exchange structure is adopted at the rear end of the heat exchange core. Different heat exchange structures are adopted at different positions according to different heat absorbing amounts, the phenomenon of film boiling on the water side is effectively reduced, the heat load of the heat exchange core is reduced, and the heat exchange efficiency is improved.

Owner:CHINA NORTH VEHICLE RES INST

Combustion waste heat utilization heat exchange device with regular change of circular tube diameter

InactiveCN107192281BReduce heat loadReduce film boilingStationary tubular conduit assembliesTubular elementsDifferential coefficientCombustion

The invention provides a heat exchange device utilizing combustion waste heat. The heat exchange device utilizing combustion waste heat comprises a heat exchange core body which is arranged in a waste gas flue. The heat exchange core body comprises round tubes, and the round tubes are arranged in the direction perpendicular to the waste gas flowing direction; suppose the distance between each round tube and a waste gas inlet is S, the inner diameter of each round tube is D; and suppose D=F(S), F'(S)<0, and F'(S) is the first-order differential coefficient of F(S). According to the heat exchange device, the round heat exchange tubes are adopted by the heat exchange core body, and the diameters of the heat exchange tubes become smaller gradually in the smoke flowing direction so that the probability of film boiling on the water side can be effectively lowered, the heat-convection heat exchange intensity of the water side is increased, the heat load of the heat exchange core body is reduced, and the heat exchange efficiency is improved.

Owner:CHINA NORTH VEHICLE RES INST

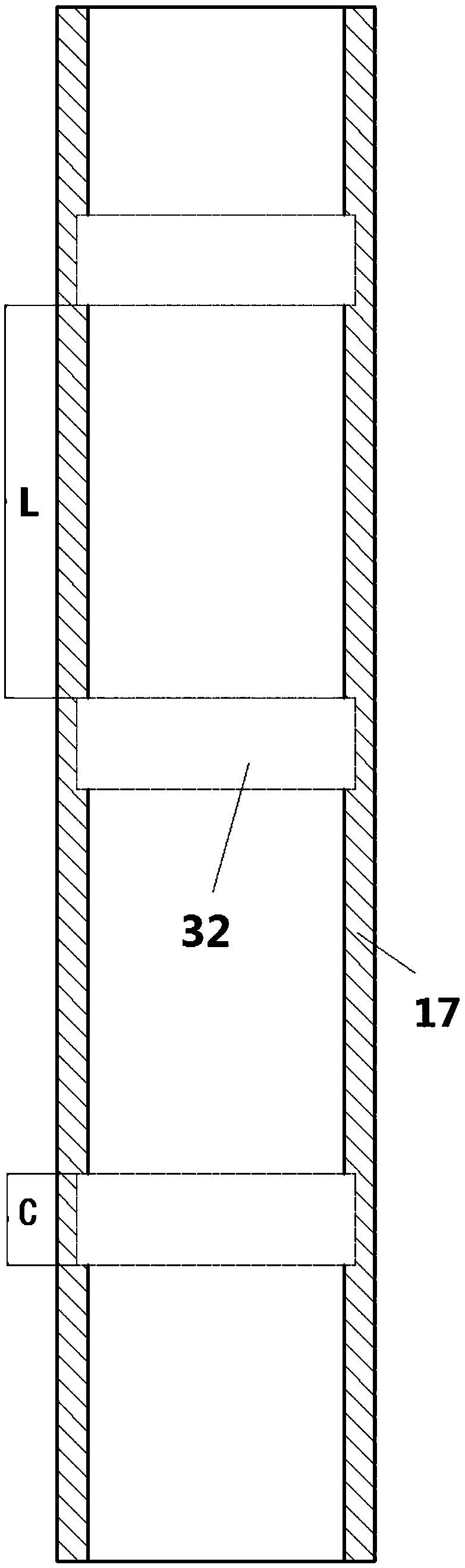

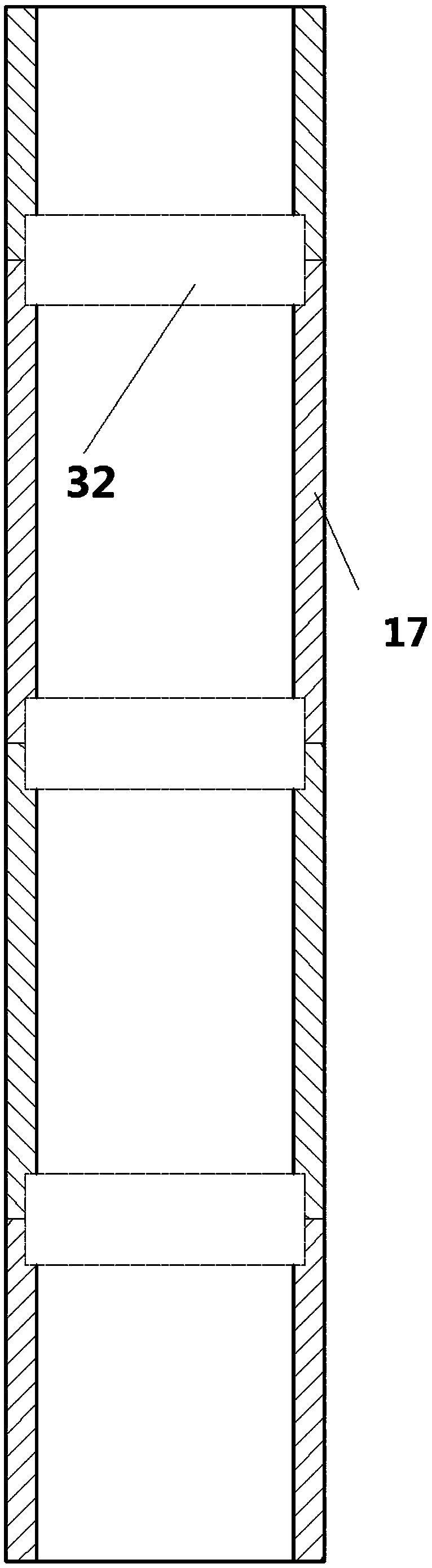

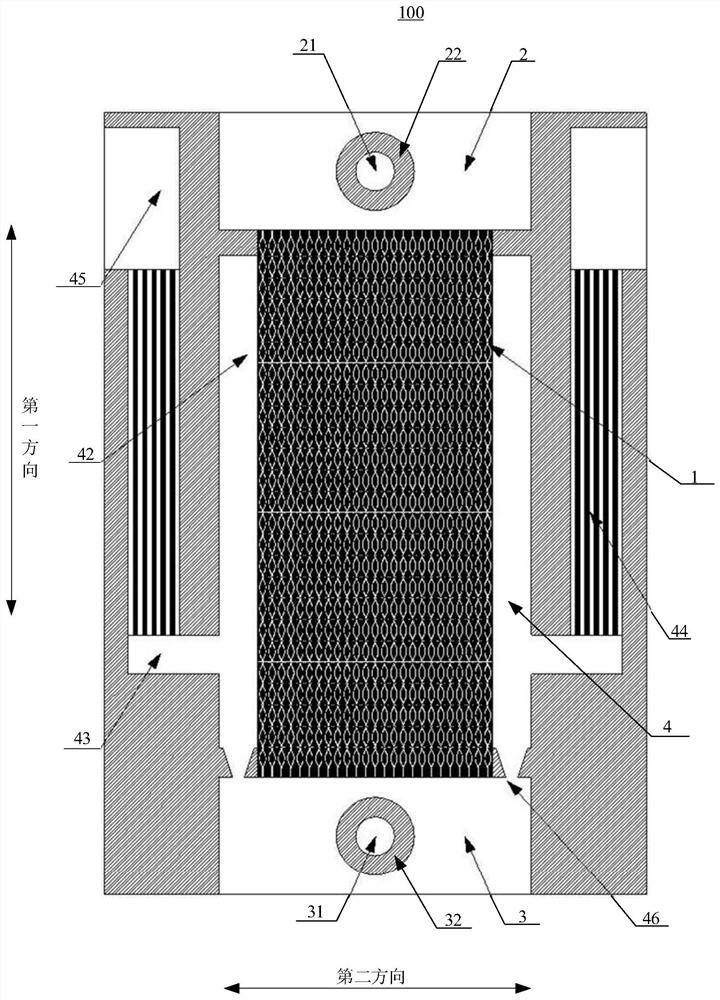

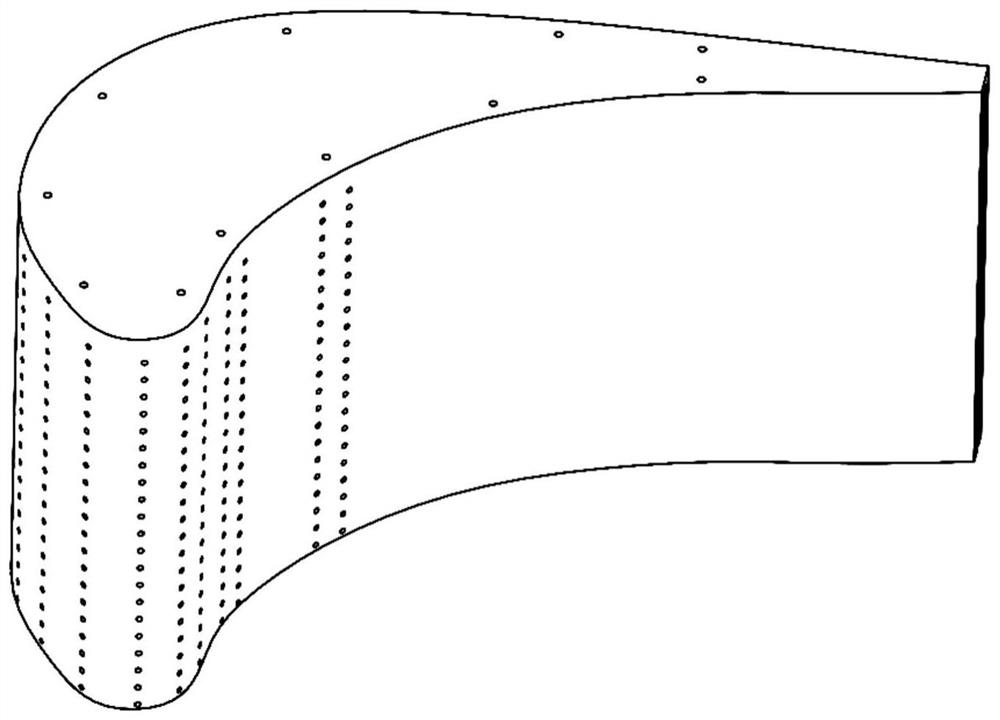

A combustion waste heat utilization heat exchange device with heat exchange structure length change

InactiveCN107191958BEnhanced convective heat transfer intensityReduce film boilingStationary conduit assembliesCombustion technology mitigationCombustionEngineering

The invention provides a heat exchange device utilizing combustion waste heat. The heat exchange device utilizing combustion waste heat comprises a heat exchange core body which is arranged in a waste gas flue. The heat exchange core body comprises round tubes, and the round tubes are arranged in the direction perpendicular to the waste gas flowing direction. The multiple dispersed heat exchange structures are arranged in the round tubes at intervals. The multiple dispersed heat exchange structures are arranged in the round tubes in the flowing direction of fluid in the round tubes, and the lengths of the dispersed heat exchange structures become larger gradually from inlets of the round tubes to outlets of the round tubes. According to the heat exchange device, the lengths of the dispersed heat exchange structures in the round tubes become large continuously in the direction away from the inlets of the round pipes so that the probability of film boiling on the water side can be effectively lowered, the heat-convection heat exchange intensity of the water side is increased, the heat load of the heat exchange core body is reduced, and the heat exchange efficiency is improved.

Owner:CHINA NORTH VEHICLE RES INST

A combustion waste heat utilization heat exchange device with variable heat exchange structure spacing

InactiveCN107270747BReduce film boilingReduce heat loadHeat exchanger casingsStationary tubular conduit assembliesCombustionEngineering

The invention provides a heat exchange device utilizing combustion waste heat. The heat exchange device comprises a heat exchange core; the heat exchange core is arranged in a waste gas flue and comprises circular tubes; the circular tubes are arranged perpendicular to the flowing direction of waste gas; a plurality of scattered heat exchange structures are arranged in the round tube at intervals; a plurality of dispersion heat exchange structures are arranged in the circular tubes in a segmented mode in the flow direction of fluid in the circular tubes; the distances between every two adjacent dispersion heat exchange structures become smaller and smaller from inlets of the circular tubes to outlets of the circular tubes. The heat exchange device has the advantages that the distances of the dispersion heat exchange structures in the circular tubes is continuously decreased along with the distance from the inlets of the circular tubes, and therefore the film boiling phenomenon on the water side can be effectively reduced, the convective heat exchange intensity of the water side can be increased, the heat load of the heat exchange core can be reduced, and the heat exchange efficiency can be improved.

Owner:CHINA NORTH VEHICLE RES INST

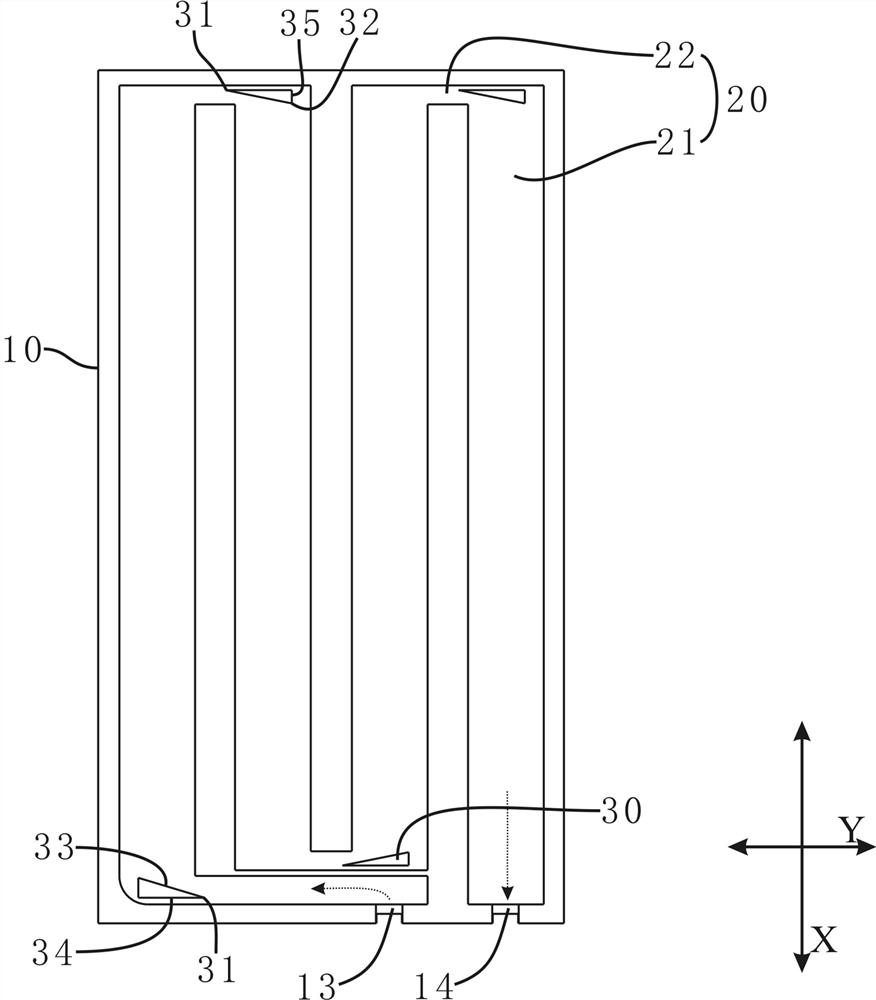

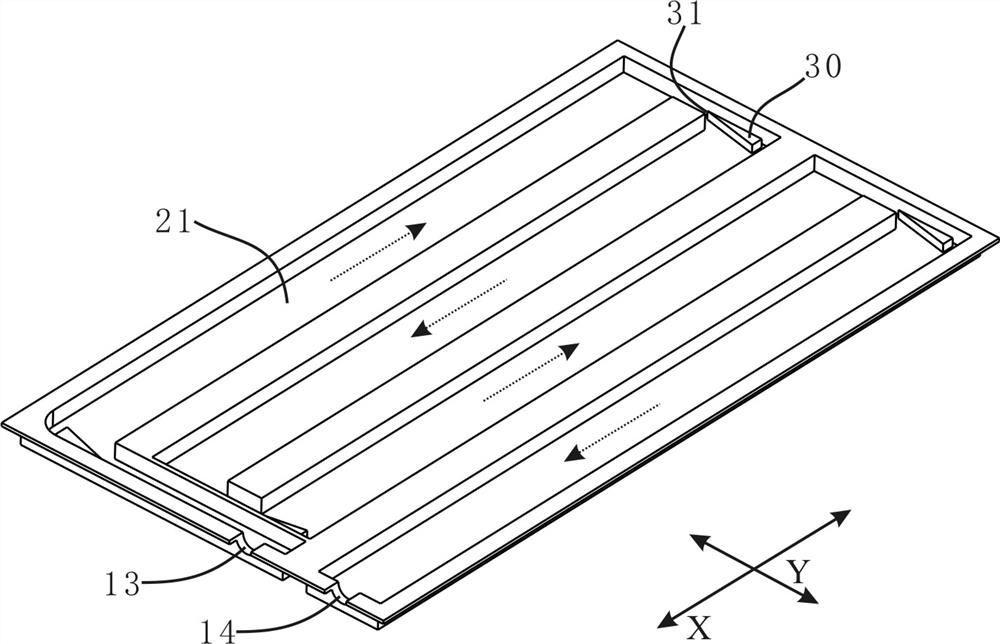

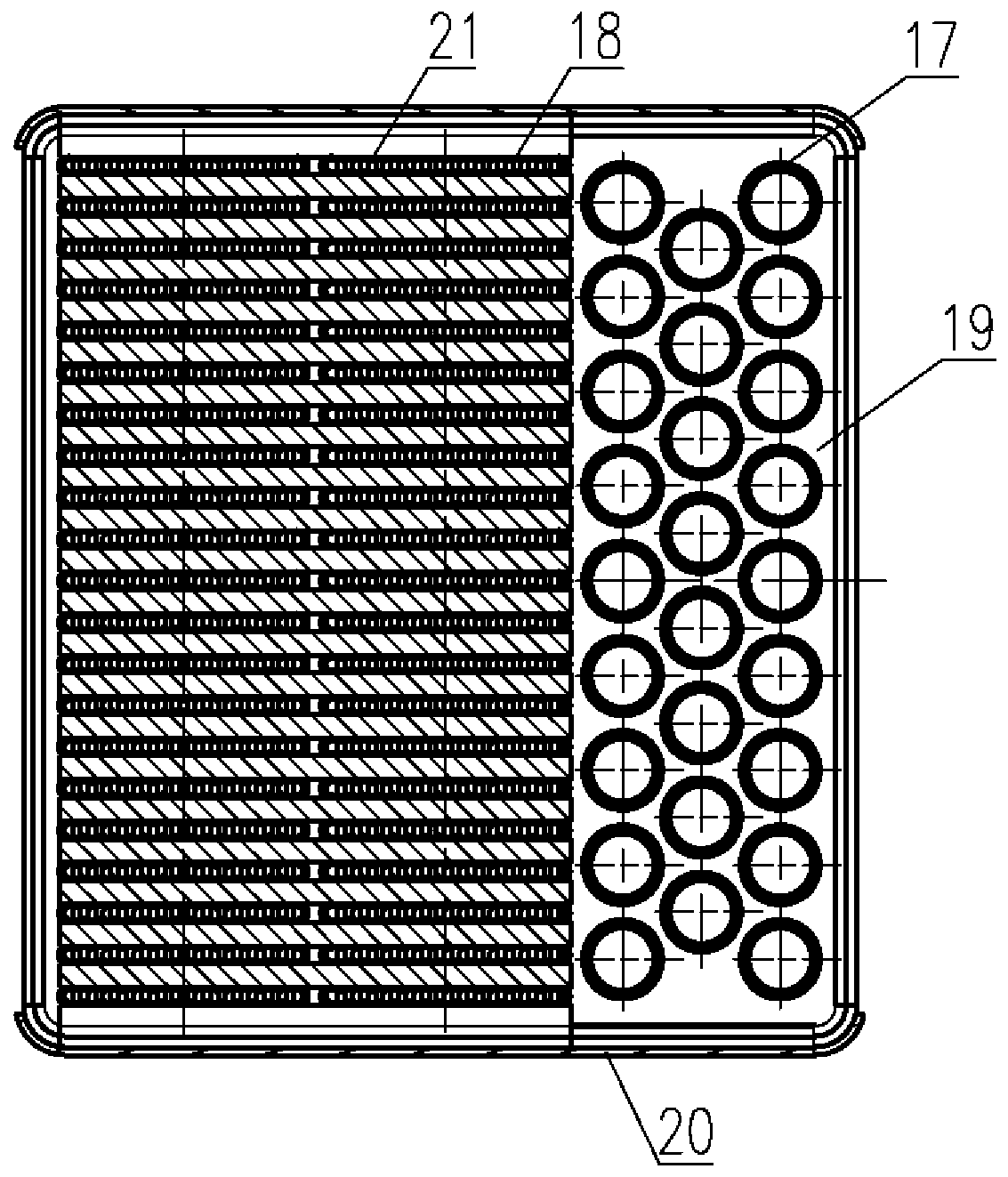

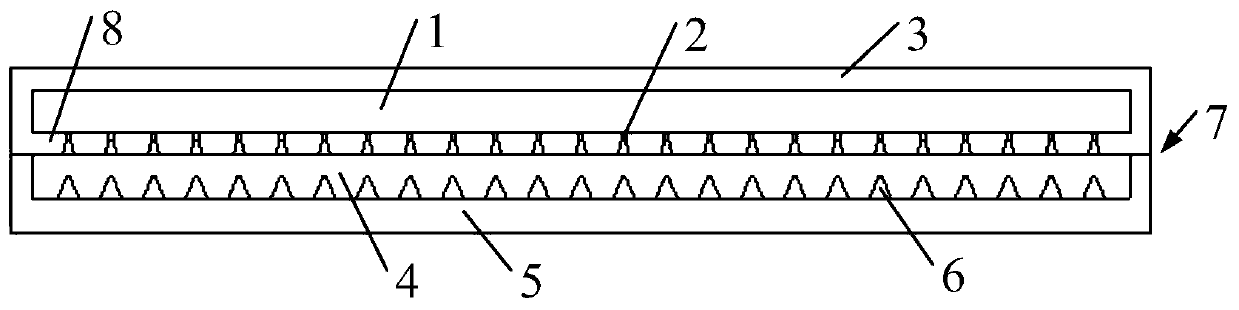

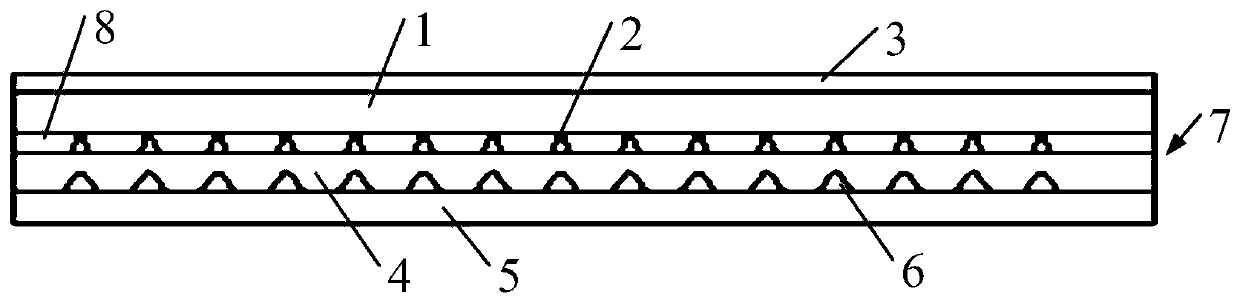

A first heat exchange plate and microchannel condenser

ActiveCN111780569BEnhanced convective heat transfer intensityImprove condensation heat transfer efficiencySteam/vapor condensersStationary plate conduit assembliesSteam condensationCondenser (heat transfer)

The invention relates to the technical field of heat exchange, and discloses a first heat exchange plate and a microchannel condenser. The first heat exchange plate is provided with a steam inlet and a water discharge port, and a plate surface of the first heat exchange plate is provided with a plurality of condensation channels, and the two ends of each condensation channel are respectively connected with the steam inlet and the water discharge port; each condensation The channels include a plurality of single-row channels connected in series and at least one multi-row channel, a multi-row channel is connected between two adjacent single-row channels, and the multi-row channels include a plurality of parallel branch channels. The condensation channel of the first heat exchange plate provided by the embodiment of the present invention includes single-row channels and multi-row channels connected in series. When the first heat exchange plate is used as a steam condensation plate, the steam will repeatedly gather and separate in the condensation channel, strengthening the The convective heat transfer intensity of the condenser is improved, and the condensation heat transfer efficiency of the condensation channel can be significantly improved, thereby relatively reducing the volume of the condenser.

Owner:WUHAN SECOND SHIP DESIGN & RES INST

Waste heat utilization heat exchange device with changeable dispersed heat exchange structure grid holes

InactiveCN110017496AReduce heat loadReduce film boilingCombustion technology mitigationHeat exchanger casingsVapor liquidEngineering

Owner:CHINA NORTH VEHICLE RES INST

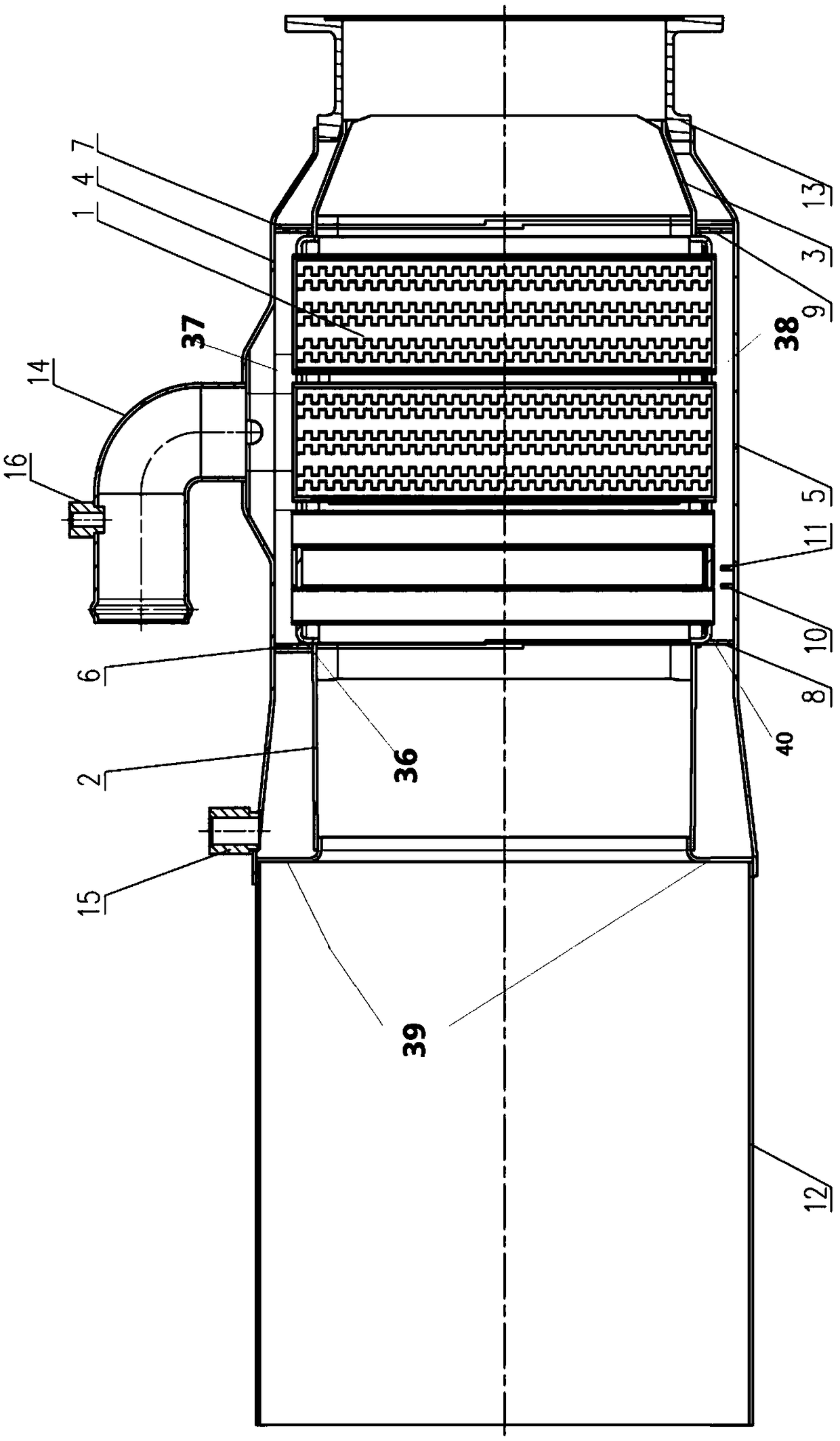

A kind of inlet muffler used in the sound insulation cover of compressor unit

ActiveCN113007070BReduced opening sizeImprove sound absorptionPositive displacement pump componentsPositive-displacement liquid enginesNoiseVentilation volume

The invention relates to an intake muffler used for a sound insulation cover of a compressor unit, which is mainly composed of an intake muffler box body, a zigzag type intake muffler channel and a right-angled triangular prism sound-absorbing structure. The air intake muffler box body is a quadrangular prism structure with trapezoidal side panels, and inside the box body is a plurality of broken-line air intake and muffler channels formed by arranging side-by-side right-angled triangular prism sound-absorbing structures in the form of broken lines; the right-angled The triangular prism sound-absorbing structure is composed of the inclined surface of the right-angled triangular prism sound-absorbing structure, the long right-angle surface of the right-angle triangular prism sound-absorbing structure, the short right-angle surface of the right-angle triangular prism sound-absorbing structure and the non-equal thickness cavity structure. The invention has the advantages of simple structure, quicker air intake speed, higher effective ventilation volume, effective control of noise transmission paths, significantly improved noise reduction effect, and the like.

Owner:SOUTHWEST PETROLEUM UNIV

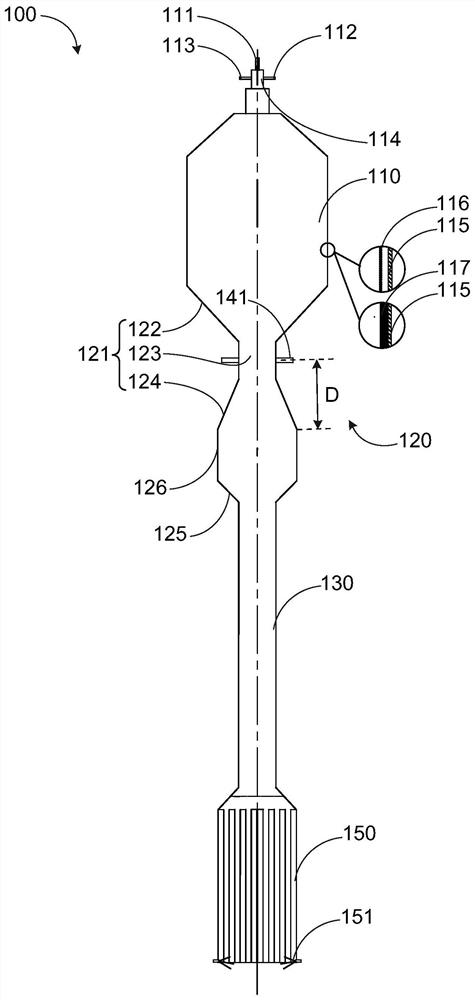

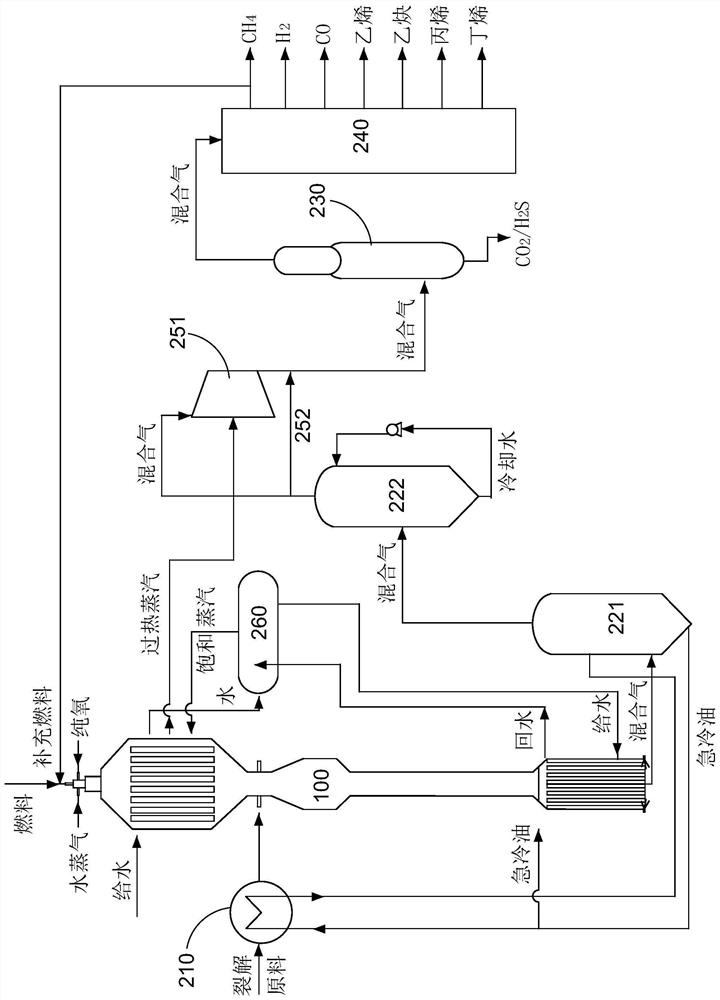

Reaction device, production system and production method for preparing low-carbon olefin

ActiveCN111826173AShorten the timeLow yieldDirect heating destructive distillationEnergy inputThermodynamicsCombustion chamber

The invention discloses a reaction device, a production system and a production method for preparing low-carbon olefin. The reaction device is a pressure reaction device and comprises a device body, the device body comprises a combustion chamber, a mixing chamber and a cracking chamber which are sequentially communicated, the mixing chamber comprises a Venturi section and a raw material inlet, andthe raw material inlet is formed in the lowest pressure position of the Venturi section. According to the reaction device, the independent mixing chamber is arranged, the raw materials are mixed withthe synthesis gas in the mixing chamber and directly exchange heat, and the cracking reaction is performed after the cracking temperature is reached so that the reaction time can be shortened, and the yield of the low-carbon olefin is increased; the mixing chamber is constructed to comprise the venturi section, and the raw material inlet is formed in the lowest pressure position of the venturi section so that turbulent flow with higher turbulence is formed, higher convective heat exchange strength is achieved, raw materials can be quickly mixed and subjected to heat exchange with synthesis gas, and shorter retention time can be achieved.

Owner:中国船舶集团有限公司第七一一研究所 +1

Device for enhancing heat dissipation efficiency of jet radiator, heat dissipation component and manufacturing method

ActiveCN108551750BIncrease disturbanceReduce thermal resistanceCooling/ventilation/heating modificationsHeat resistanceEngineering

Owner:SHANDONG CHAOYUE DATA CONTROL ELECTRONICS CO LTD

Heat exchange device capable of realizing combustion waste heat utilization and provided with flow guide structures

InactiveCN107238303AReduce heat loadIncrease profitHeat exchanger casingsStationary tubular conduit assembliesCombustionTemperature difference

The invention provides a heat exchange device capable of realizing combustion waste heat utilization. The heat exchange device comprises a heat exchange core and a casing; the heat exchange core is arranged in the casing; an upper header and a lower header are formed by the space between the heat exchange core and the casing; the casing comprises an upper casing and a lower casing; the upper casing comprises an upper casing front frame type baffle and an upper casing back frame type baffle which adopt identical structures; semi-circular holes penetrating through baffles are formed in middle areas of the upper parts of upper baffles; the upper baffle of the front frame type baffle is transversely placed at the front end of the heat exchange body upper casing and the front end of the heat exchange core and is fixed on the inner side of the heat exchange body upper casing; and side baffles of the front frame type baffle are located at the back part of the upper baffle of the front frame type baffle as well as the left side and the right side of the heat exchange core. With the heat exchange device, the baffles and flow guide plates are arranged on the heat exchange body upper casing and the heat exchange body lower casing, so that the thermal load of the heat exchange core is reduced while the heat exchange temperature difference is increased.

Owner:CHINA NORTH VEHICLE RES INST

A combustion waste heat utilization heat exchange device with a diversion structure

InactiveCN107238303BReduce heat loadIncrease profitHeat exchanger casingsStationary tubular conduit assembliesCombustionTemperature difference

The invention provides a heat exchange device capable of realizing combustion waste heat utilization. The heat exchange device comprises a heat exchange core and a casing; the heat exchange core is arranged in the casing; an upper header and a lower header are formed by the space between the heat exchange core and the casing; the casing comprises an upper casing and a lower casing; the upper casing comprises an upper casing front frame type baffle and an upper casing back frame type baffle which adopt identical structures; semi-circular holes penetrating through baffles are formed in middle areas of the upper parts of upper baffles; the upper baffle of the front frame type baffle is transversely placed at the front end of the heat exchange body upper casing and the front end of the heat exchange core and is fixed on the inner side of the heat exchange body upper casing; and side baffles of the front frame type baffle are located at the back part of the upper baffle of the front frame type baffle as well as the left side and the right side of the heat exchange core. With the heat exchange device, the baffles and flow guide plates are arranged on the heat exchange body upper casing and the heat exchange body lower casing, so that the thermal load of the heat exchange core is reduced while the heat exchange temperature difference is increased.

Owner:CHINA NORTH VEHICLE RES INST

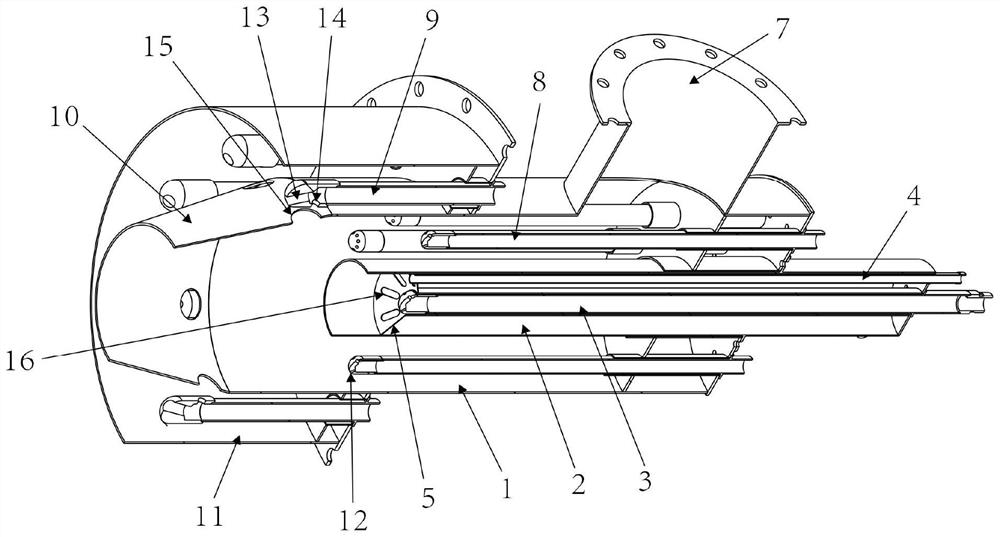

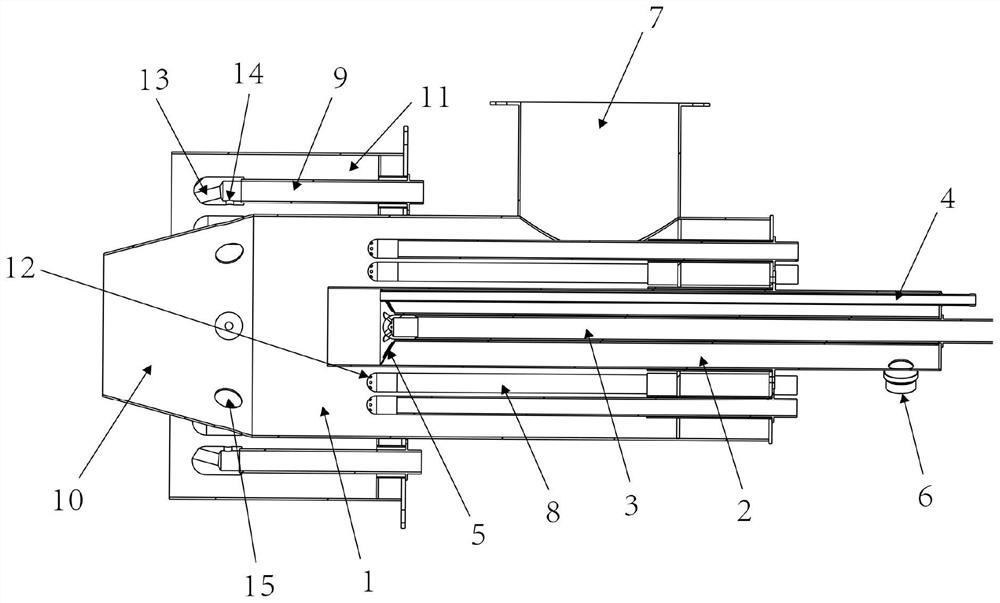

A supercharged cooling structure for gas turbine moving blades using the rotation effect

ActiveCN114017129BFacilitates horizontal vortexIncrease air supply pressureBlade accessoriesEfficient propulsion technologiesSuction forceEngineering

The invention discloses a supercharging cooling structure for a gas turbine moving blade by utilizing the rotation effect. The structure is specifically composed of a flow-to-intermediate partition plate, a multi-stage Z-shaped rotary booster cavity, and an impact-convection series cooling layer, all of which are located inside the gas turbine moving blades, and the Z-shaped rotary booster cavity passes through the separation pressure. The surface and suction surface supply air to the cavity and organize the radial flow direction in the air supply cavity, and use the rotating Coriolis force to increase the air supply pressure of the shock-convective series cooling layer and reduce the air supply pressure gradient between the suction and pressure surfaces; shock- The convection series cooling layer plate increases the Reynolds number by collecting the impinging cooling air flow, and adopts the radial guide baffle with the guide slit to enhance the transverse vortex formed by the rotating Coriolis force in the radial convection heat exchange chamber, which effectively improves the heat transfer rate. thermal coefficient. The invention can utilize the rotation effect to reduce the demand for the cooling air extraction pressure and air extraction volume, and effectively enhance the cooling performance.

Owner:XI AN JIAOTONG UNIV

A biogas digester and its heat exchange tube setting method

ActiveCN105198183BEnhanced convective heat transfer intensityReduce dosageWaste based fuelBiological sludge treatmentEngineeringFermentation

The invention discloses a biogas tank and a method for setting heat exchange tubes thereof. The heat exchange tubes are embedded on the fins with U-shaped slots integrated with the biogas tank, and the position of the slots is determined according to certain rules, so that the heat exchange tubes It is in the form of a spherical helix, and the water supply and return pipes are arranged at intervals. The method includes the installation arrangement method of the spherical spiral pipe, the determination method of the screw pitch, and the calculation method of the pipe length. First of all, according to the shape and material of the biogas digester, the layout form of the spiral heat exchange tubes, the type of installation components and the calculation of the slot position of the fixed heat exchange tubes are proposed. Then, the effect of tube spacing on heat transfer is analyzed, and the pitch of the helical tube is determined by numerical simulation method according to the heat transfer principle. Finally, in the case of determining the heat medium and biogas fermentation parameters, according to the principle of energy conservation, the length of the required spiral tube is obtained by trial calculation.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

High-speed low-nitrogen combustor for heating furnace and combustion method of high-speed low-nitrogen combustor

PendingCN114234187AReduce nitrogen oxidesFlame temperature and shape stabilityGaseous fuel burnerAutomotive engineeringNitrogen oxides

The high-speed low-nitrogen combustor comprises a lower straight barrel, a center gun is arranged in the lower straight barrel, a center fuel gun and an ignition gun are arranged in the center gun, the front end of the center fuel gun and the front end of the ignition gun are both arranged on a flame stabilizing device, and the flame stabilizing device is arranged at an opening in the front end of the center gun. A first air inlet is formed in the side face of the center gun, a second air inlet is formed in the side face of the lower straight barrel, a plurality of first fuel guns are arranged in the lower straight barrel and evenly and annularly distributed on the periphery of the center gun, and ports of the lower straight barrel, the center gun, the center fuel gun and the first fuel guns are located on the same side. According to the scheme, the nitrogen reduction strategy of staged combustion is adopted, combusted mixed gas is divided into three stages to be combusted in the axial direction, flames diverging from the center to the outer layer are formed, and therefore the combustor has the effects of reducing the oxidation burning loss rate, reducing generation of thermal nitrogen oxide and improving the steel billet yield.

Owner:北京瑞晨航宇能源科技有限公司

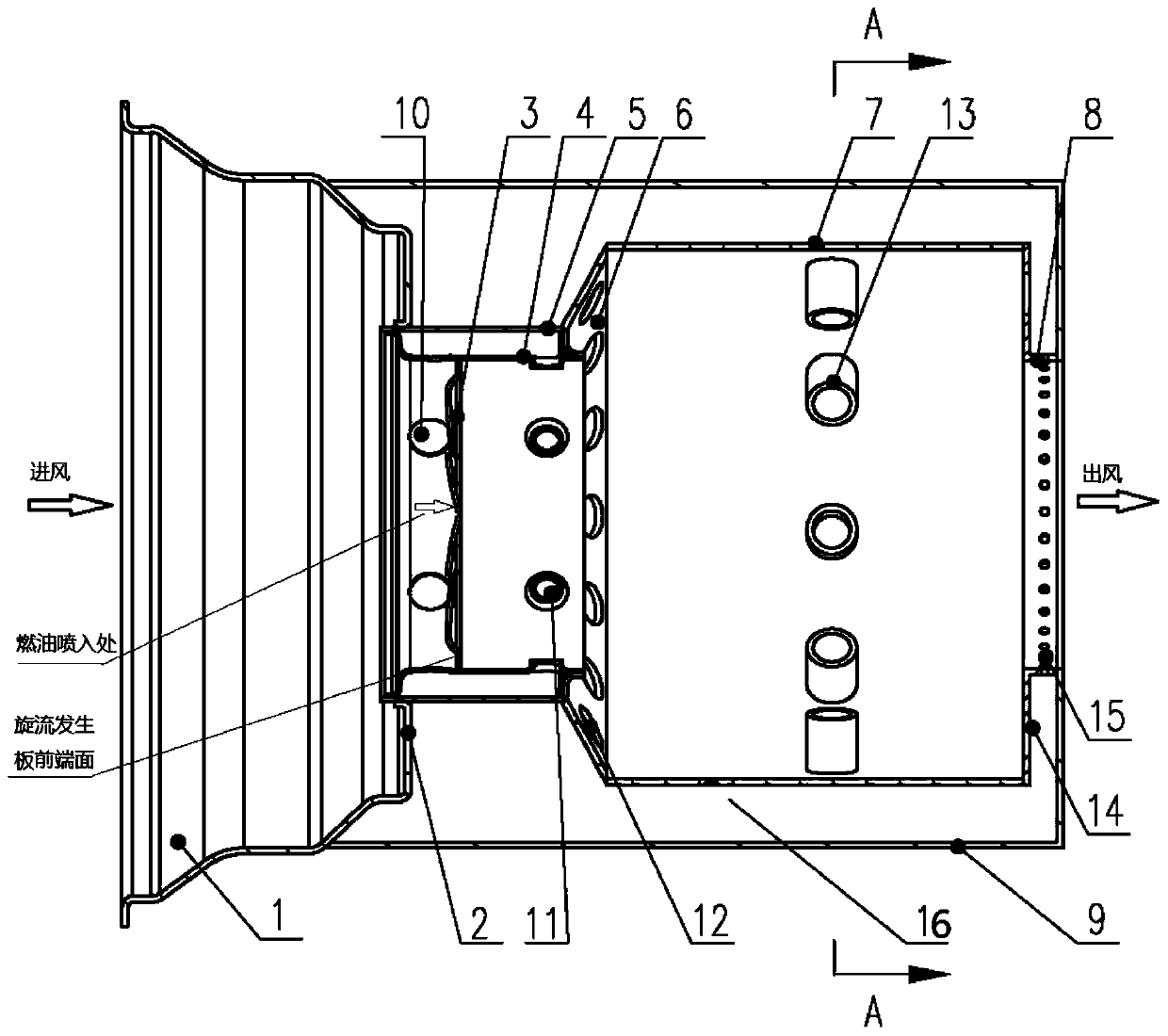

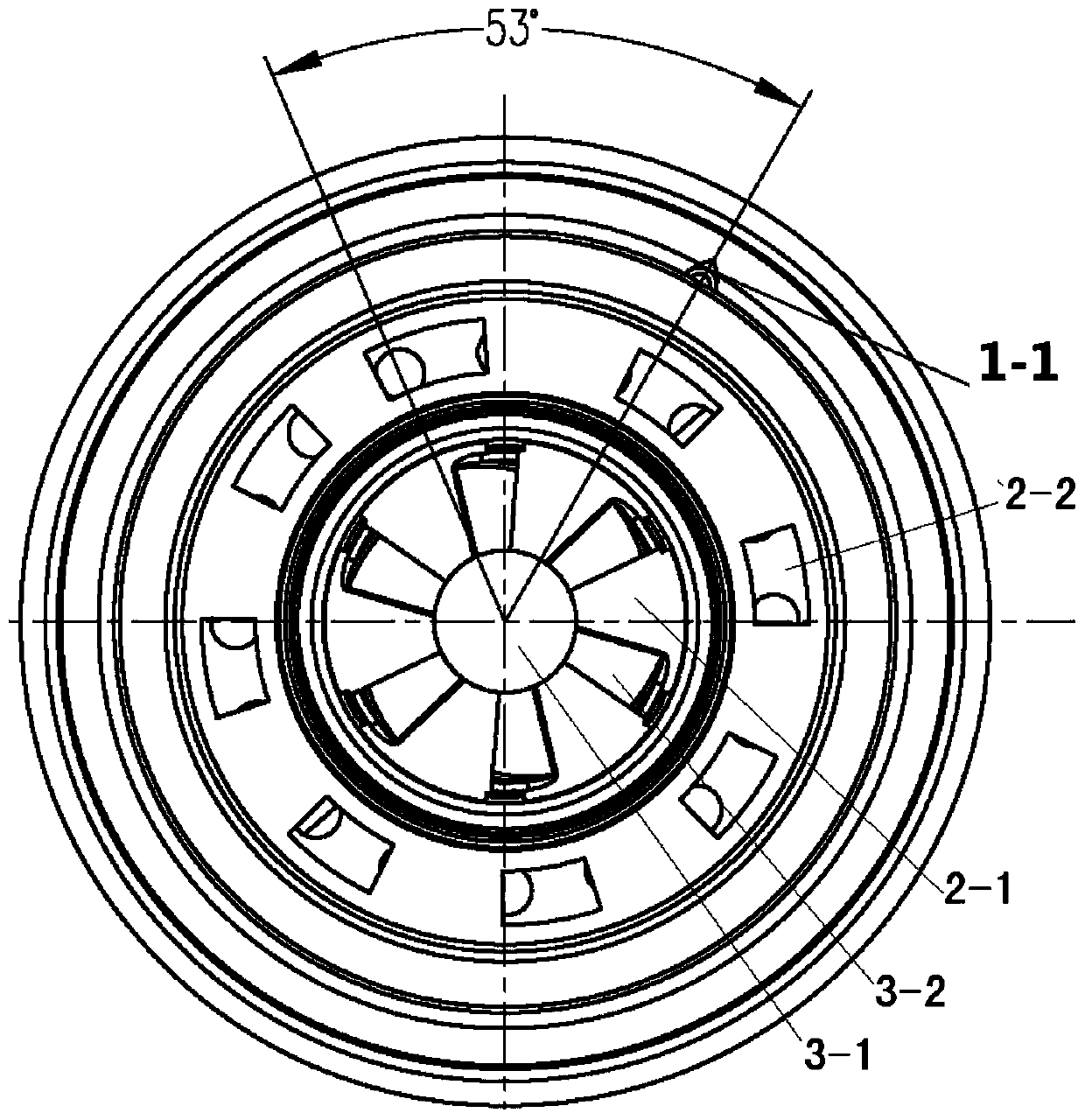

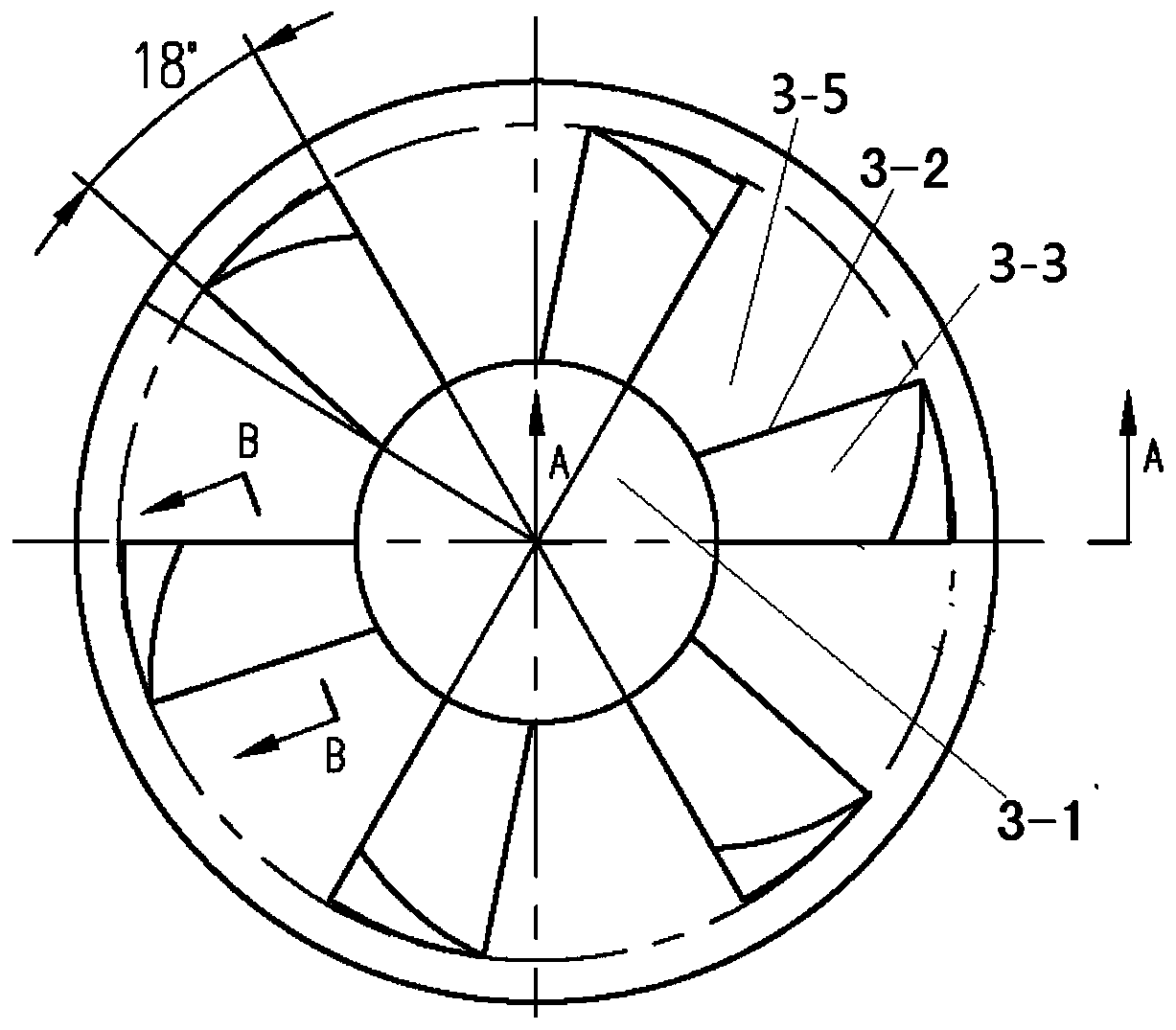

Design method of secondary air inlet barrel and combustor system thereof

InactiveCN110260304AAvoid extinctionImprove transmission efficiencyBurnersMachines/enginesCombustorPulp and paper industry

The invention provides a design method of a secondary air inlet barrel and a combustor system thereof. Two ends of a secondary air inlet cylinder are opened, one end of the secondary air inlet cylinder is connected to the large diameter end of a transitional barrel to form a diffused combustion space and the other end of the secondary air inlet cylinder is connected to the large diameter end of a third-time air inlet transitional ring to serve as a diffused combustion exhaust channel. The secondary air inlet barrel is characterized in that multiple rows of air inlet holes are formed in the secondary air inlet cylinder, and the inner diameters of the air inlet holes are increased and decreased successively in a direction from the transitional barrel to the third-time air inlet transitional ring. By means of change of the inner diameters of the air inlet holes, the flow of combustion air changes axially regularly according to the fuel combustion condition in the secondary air inlet cylinder, so that the combustor achieves the optimum combustion efficiency.

Owner:CHINA NORTH VEHICLE RES INST

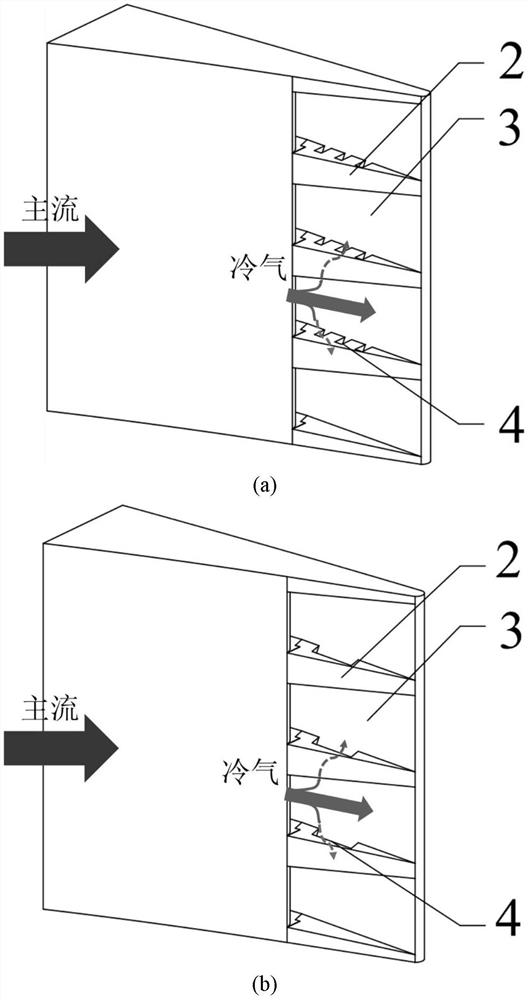

Turbine guide vane structure with rib upper through seam on trailing edge

PendingCN113107607AEnhanced convective heat transfer intensityImprove overall cooling effectBlade accessoriesMachines/enginesPhysicsCold air

The invention provides a turbine guide vane structure with a rib upper through seam on a trailing edge. The through seam is formed in a separation rib; after cooling airflow passes through an outflow seam, part of cooling air can cool the interiors of the separation rib through the through seam in the separation rib, so that under the condition that the cold air flow is not increased, the convection heat exchange intensity of the inner wall surface and the side wall surface of the separation rib is enhanced, and the comprehensive cooling effect of the trailing edge is improved; preferably, the through seam is an inclined seam, when cooling airflow passes through the separation rib, the strength of cold air vortexes generated under the influence of the separation rib can be weakened, so that the interaction between lip plate falling vortexes and the cold air vortexes can be weakened, and the air film cooling efficiency of the surface of the separation rib is improved. The structure is reasonable in design and simple in structure, and the inclined seam is formed in the side wall surface of the separation rib, so that the heat exchanger has good heat transfer and cooling characteristics, has good machining integrity and is more practicable.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com