A biogas digester and its heat exchange tube setting method

A heat exchange tube and biogas digester technology, which is applied in biological sludge treatment, waste fuel and other directions, can solve the problem that the biogas digester cannot produce gas normally, and achieve the effect of improving the heat energy utilization efficiency, reducing the amount of pipe materials and increasing the heat exchange intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

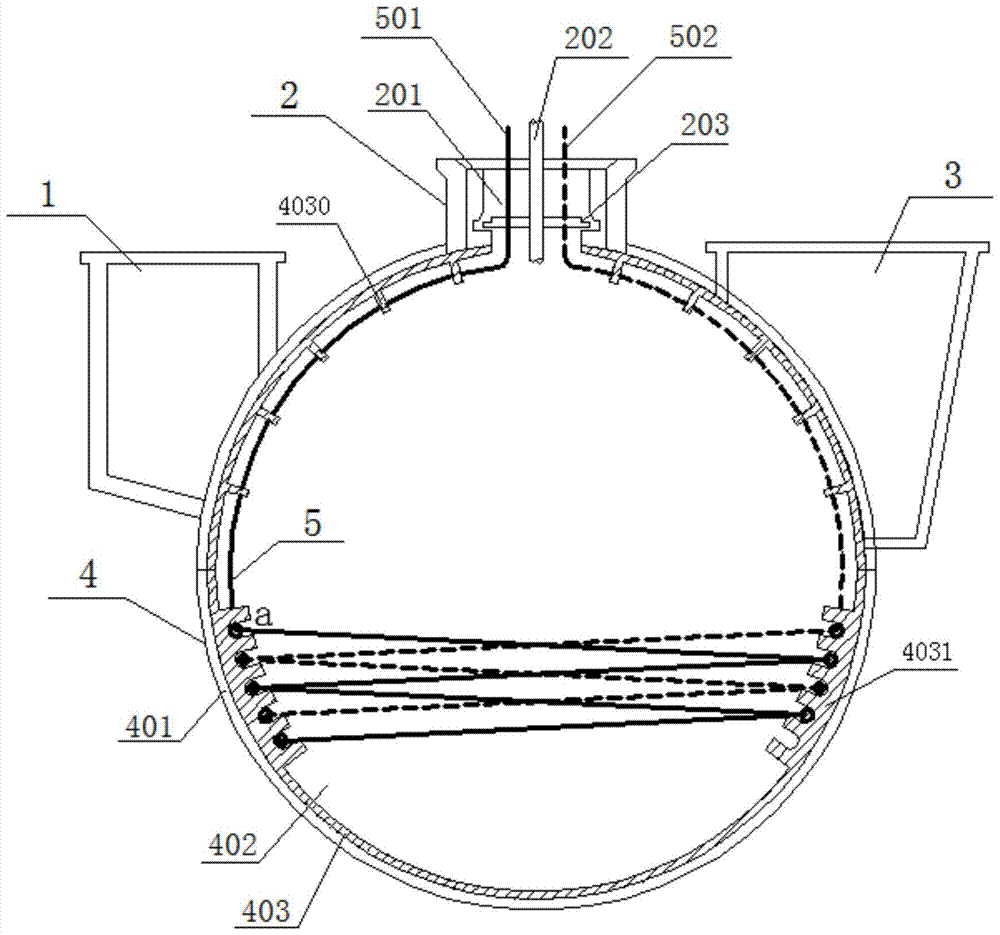

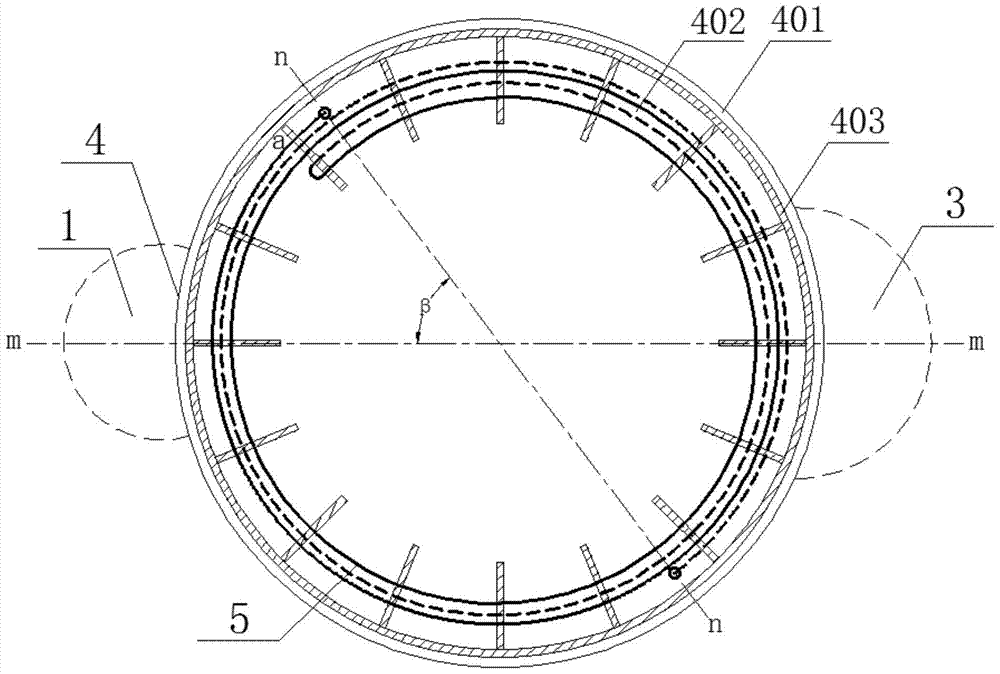

[0036] Example 1: Digester structure

[0037] to combine figure 1 , 2 , 3 and 4, the biogas digester of the present embodiment is a fiberglass biogas digester, which is spherical in shape as a whole, divided into two parts, the upper and lower hemispheres, without a stirring device, and belongs to static fermentation;

[0038] The biogas digester includes a feed port 1, a working port 2, a discharge port 3, a tank body 4 and a heat exchange tube 5, wherein the working port 2 is set at the top center of the spherical tank body, and the feed port 1 and the discharge port 3 are located on the tank body on both sides of the working port 2. The cylindrical interface of the working port 2 communicates with the tank body 4, and the water storage chamber 201, the air guide tube 202 and the movable cover 203 are arranged in the working port 2, and the movable cover 203 is set At the junction of the working port 2 and the tank body 4, the space from the movable cover 203 to the top ed...

Embodiment 2

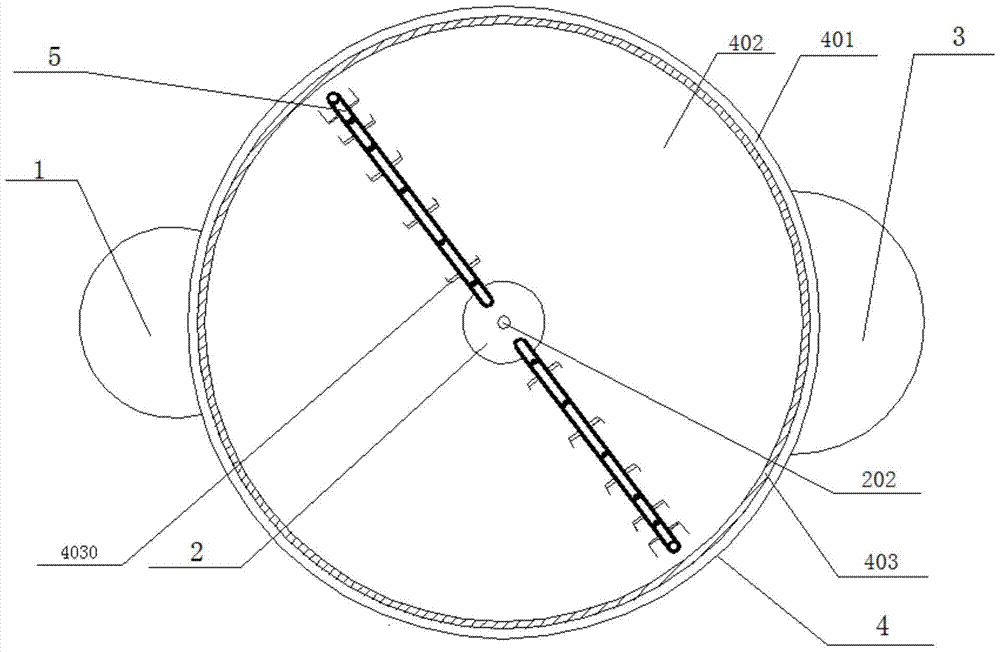

[0043] Embodiment 2: Setting method of heat exchange tube

[0044] The heat exchange tubes in the biogas digester in Example 1 are set, and the setting method is as follows:

[0045] The helix in this embodiment refers to the axis of the heat exchange tube, which is in the form of a spherical helix;

[0046] Pitch refers to the distance between the axes of two adjacent heat exchange tubes in the vertical direction;

[0047] The radius of the spherical surface refers to the distance from any point on the axis of the heat exchange tube to the center of the spherical surface;

[0048] Azimuth refers to the angle between a line connecting a point and the origin of coordinates in the plane Cartesian coordinate system and the axis of coordinates. When calculating the azimuth angle of the spherical helix in three-dimensional space, project all the points on the helix and the center of the sphere onto the same horizontal plane, establish a plane coordinate system with the center of ...

Embodiment 3

[0186] Embodiment Three: Application Example

[0187] The volume of the spherical fiberglass digester in embodiment one is 6m 3 , the diameter is about 2.2m, the pool wall is 10mm thick, and the outer wall of the pool is laid with a 30mm thick insulation layer, installed in a 3m deep pit under the ground, and the average temperature of the 0-3m soil in winter is 7.6°C.

[0188] According to relevant data, biogas fermentation bacteria can carry out normal growth activities and produce biogas in the range of 8-65 °C, and between 30-40 °C is medium-temperature fermentation, and around 35 °C is the peak of gas production. Therefore, the design The biogas slurry temperature was 35°C.

[0189] If the water temperature of the heat exchange tube is too high, the fermentation bacteria around the tube will be scalded to death. If the temperature is too low, the designed biogas slurry temperature cannot be maintained. Therefore, the temperature of the water entering the heat exchange tu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| Prandtl Number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com