Patents

Literature

40results about How to "Improve condensation heat transfer efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

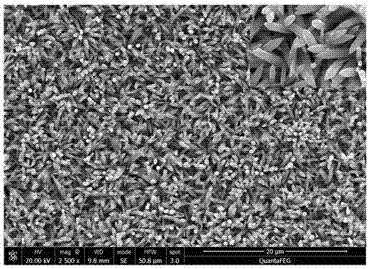

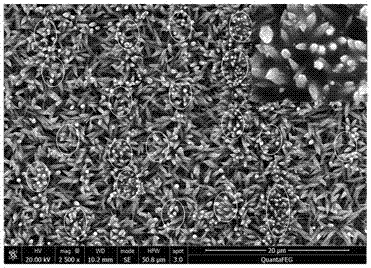

Method for preparing super-hydrophilic and hydrophobic composite nano array interface material

ActiveCN104846369AEfficient condensation nucleation is goodGood fast growth effectPretreated surfacesNanotechnologyPolyvinyl alcoholUltrasonic atomization

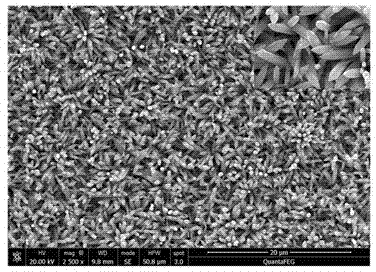

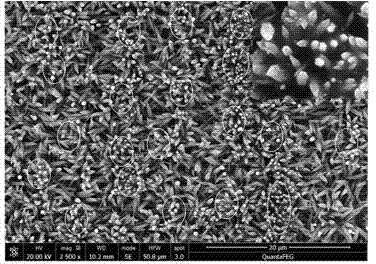

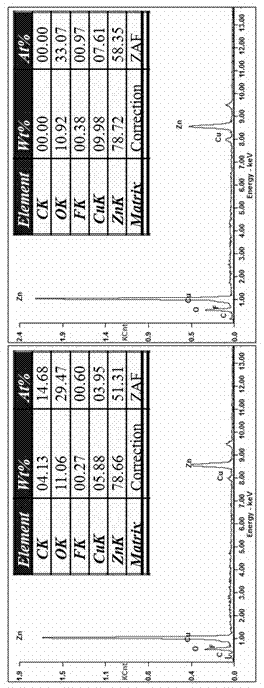

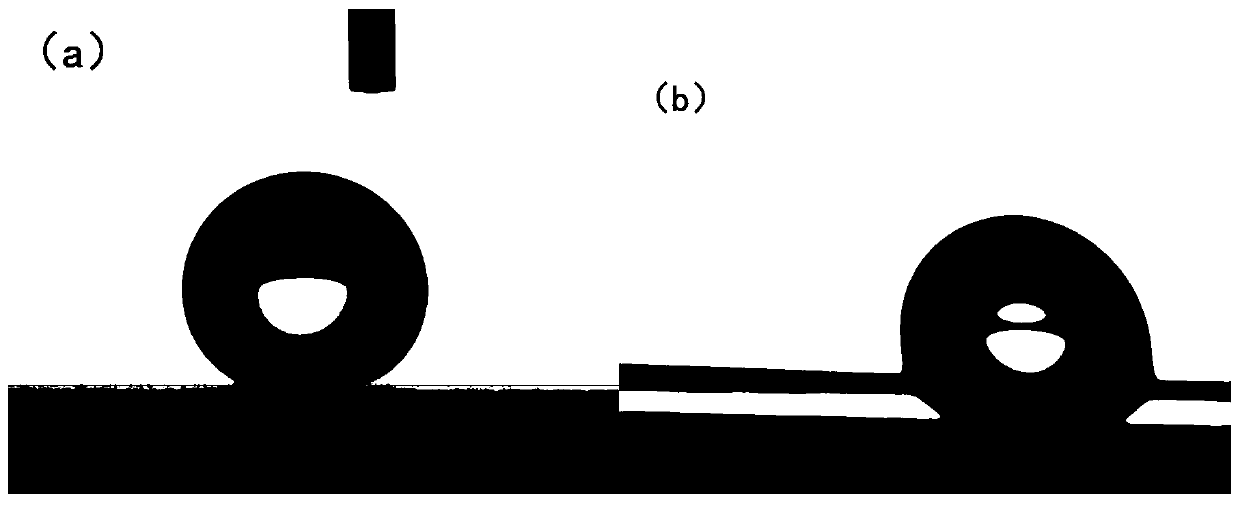

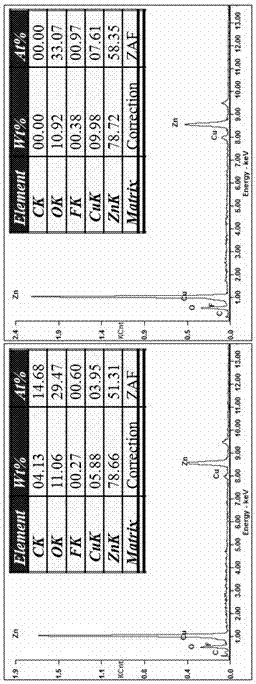

The invention relates to a method for preparing a super-hydrophilic and hydrophobic composite nano array interface material, which comprises the following steps: 1)taking a copper sheet as a base material, preparing a zinc oxide nano conical fascia by a chemical bath sedimentation method in hot bath; 2)using seventeen perfluorinated silane for modifying the oxidative nano conical fascia at 120 DEG C by a vapour deposition method; 3)preparing a polyvinyl alcohol low-solid content aqueous solution; 4)establishing an ultrasonic atomization and condensation platform, atomizing the polyvinyl alcohol aqueous solution with concentration being 0.1-0.2%, reducing the temperature of the surface of the copper-based zinc oxide nano conical fascia to 1-5 DEG C through the condensation platform, uniformly condensing the surface of the super-hydrophobic zinc oxide nano conical fascia by the polyvinyl alcohol dispersion liquid dispersed in air, performing spray deposition under observation of a high power CCD imaging system; and 5)rapidly transferring to a constant temperature heating stage, solidifying at constant temperature, after solvent moisture is completely volatilized, solidifying polyvinyl alcohol and absorbing on the surface of the zinc oxide nano conical fascia to form a hydrophilic and hydrophobic composite nano array interface. The method has the advantages of simple process and low cost, and the material has high anti-condensation frosting performance.

Owner:SHAANXI UNIV OF SCI & TECH

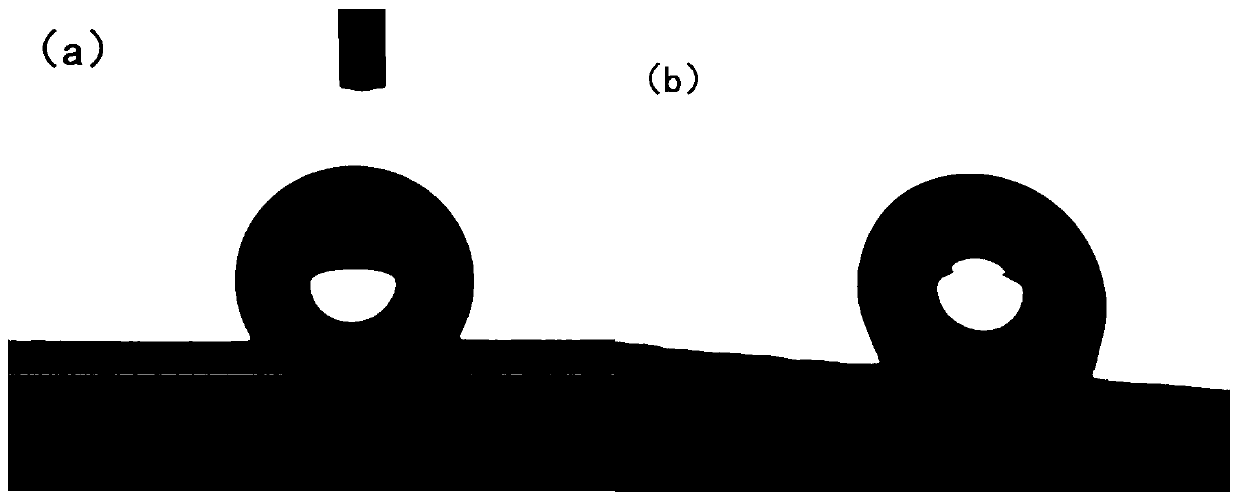

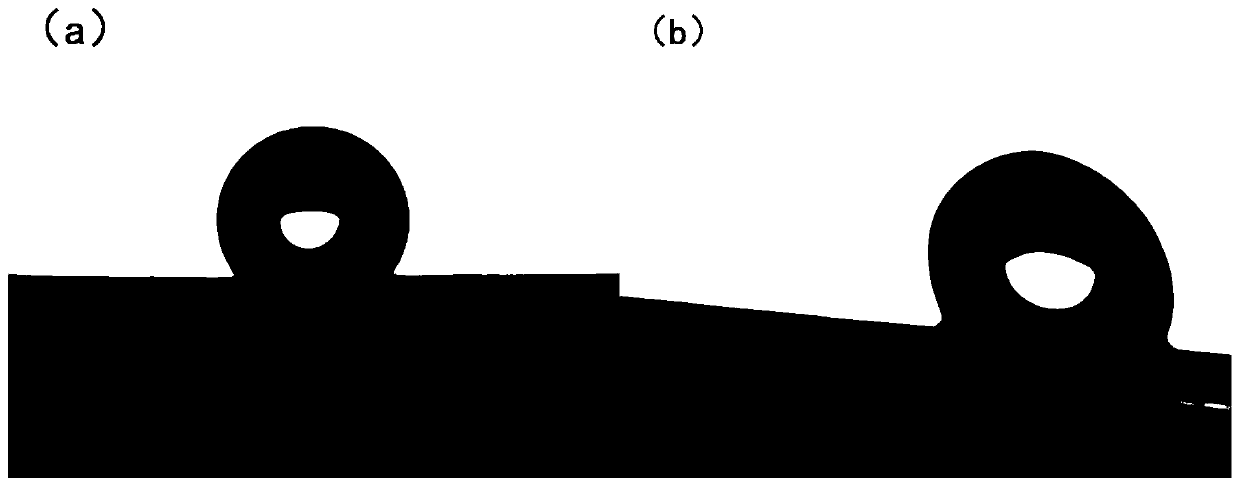

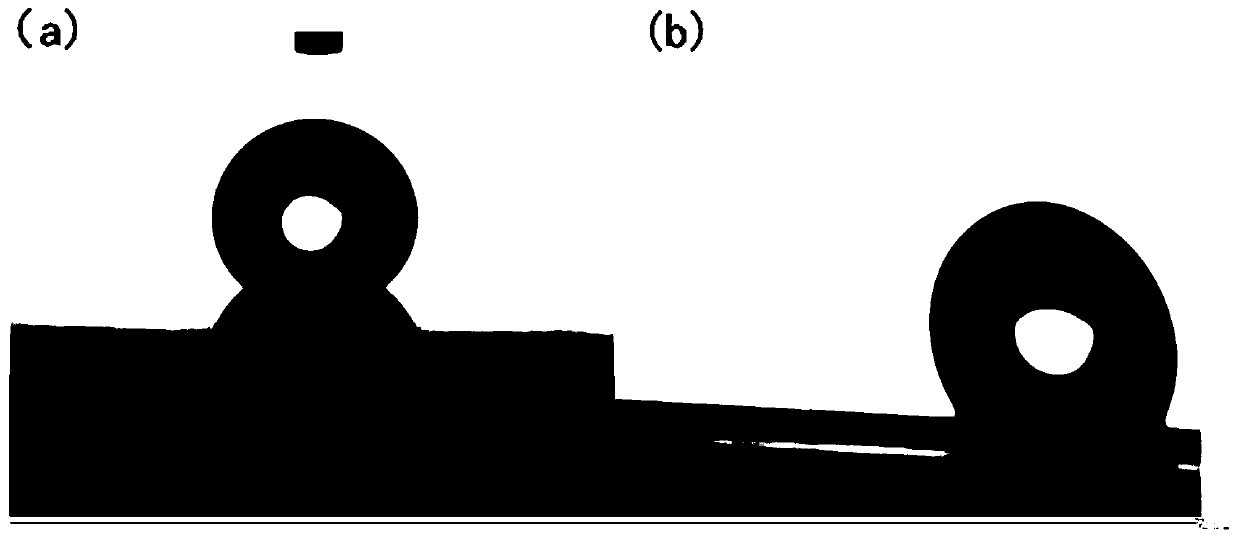

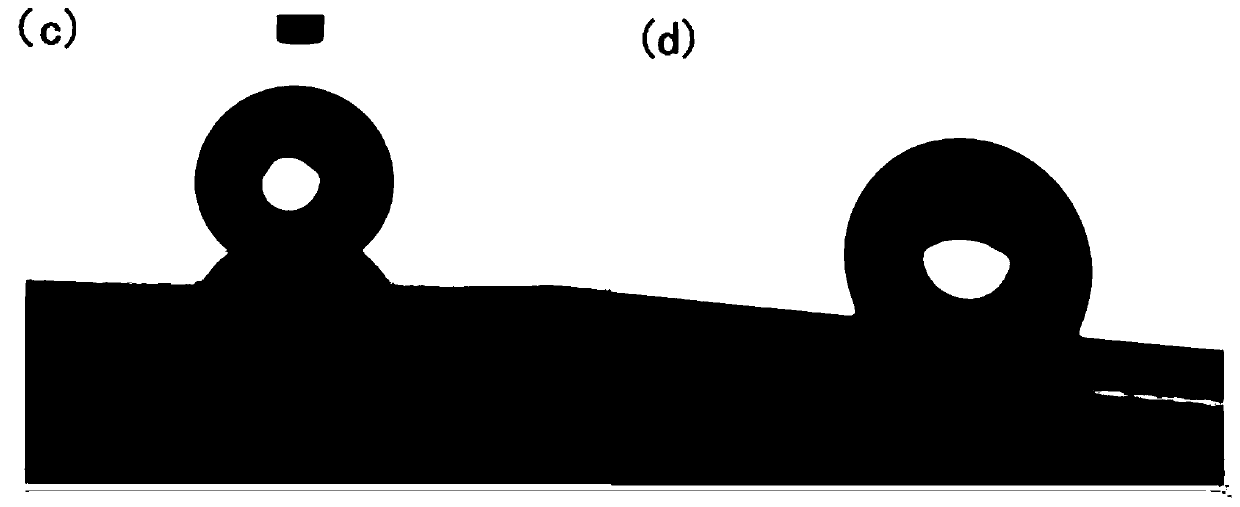

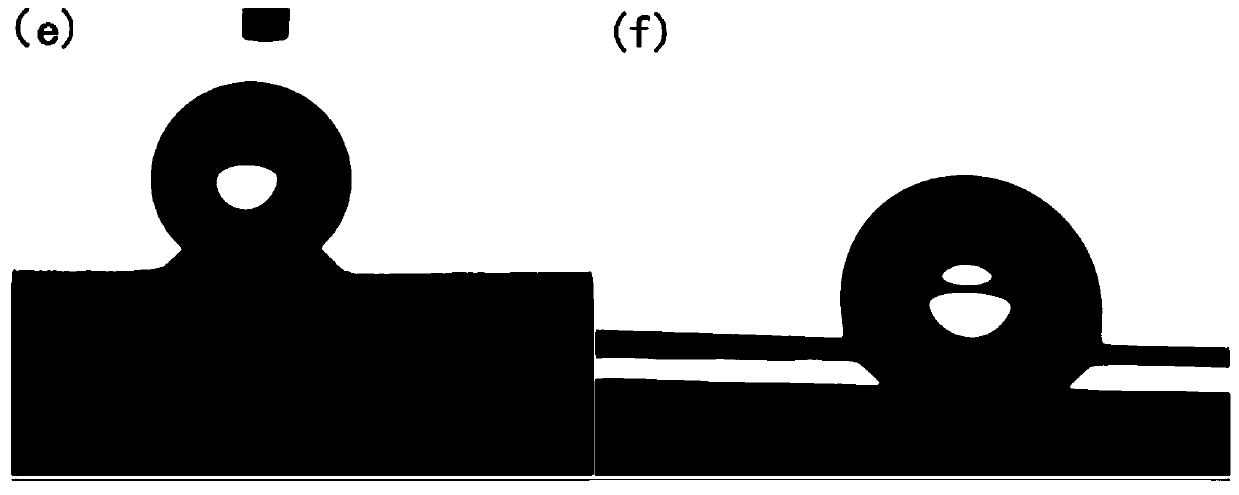

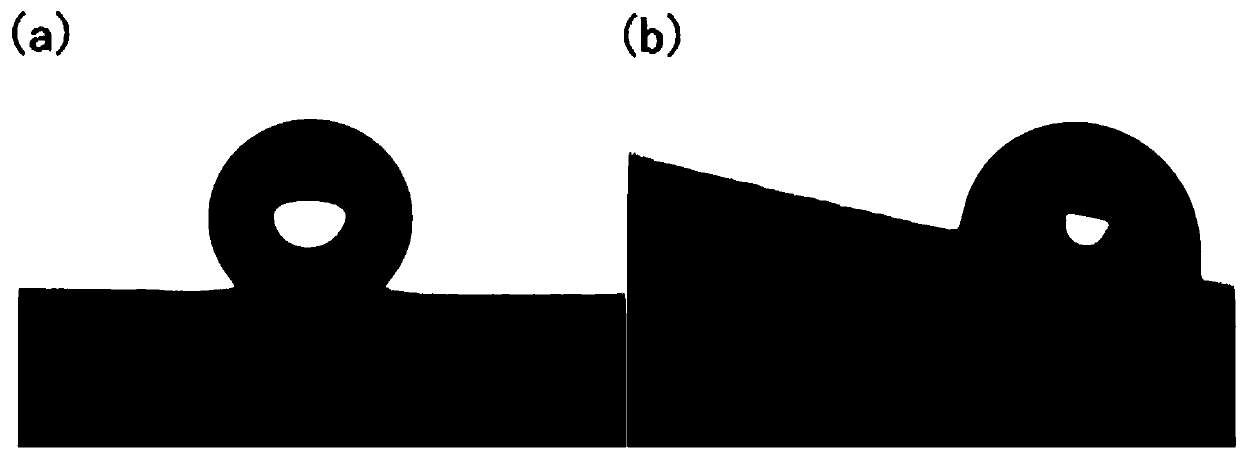

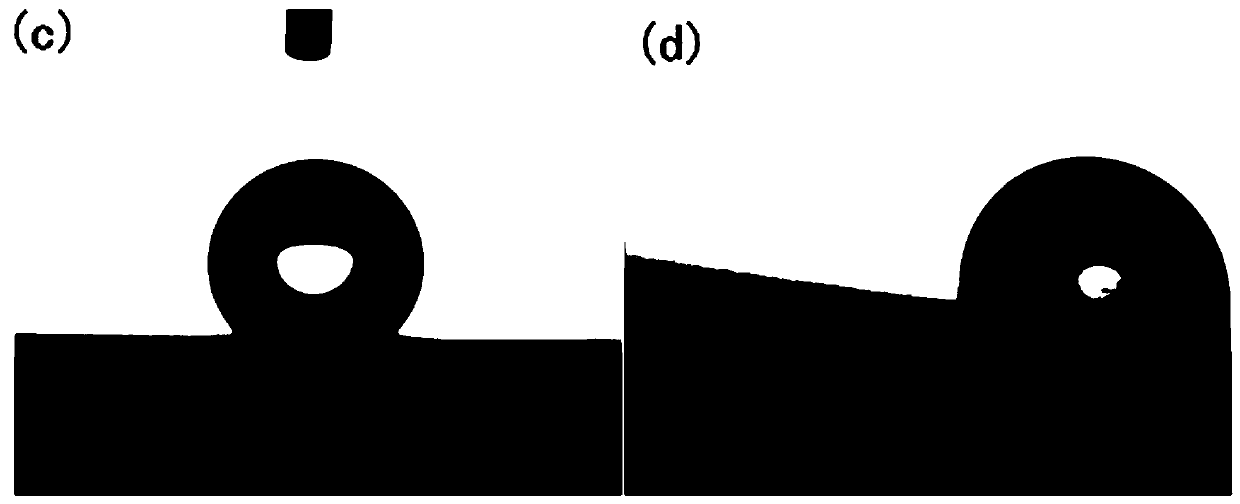

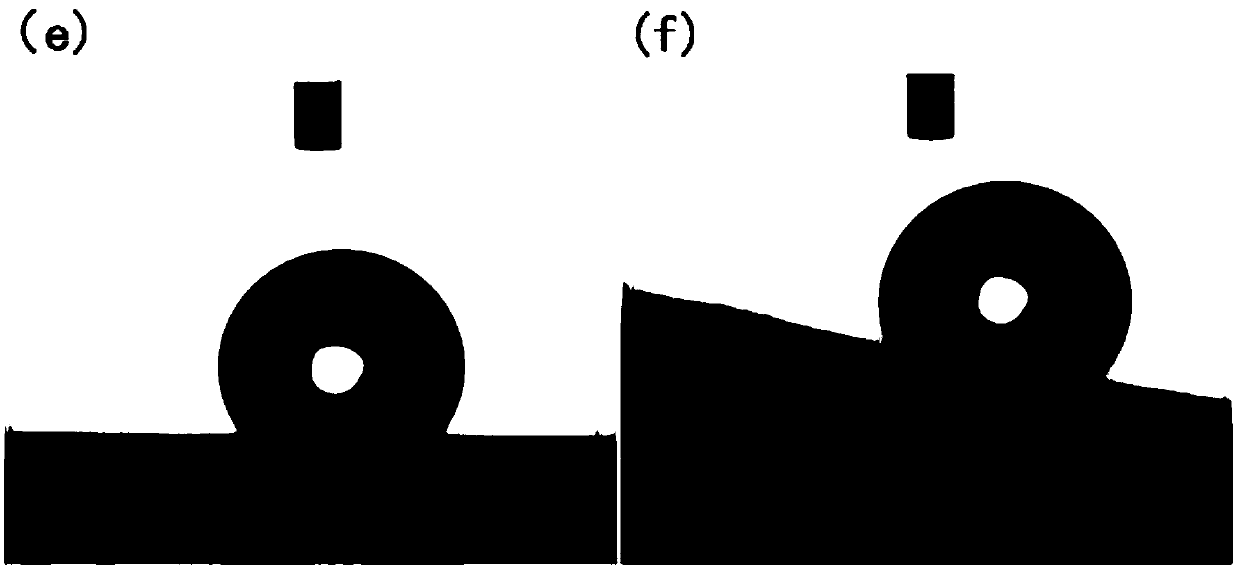

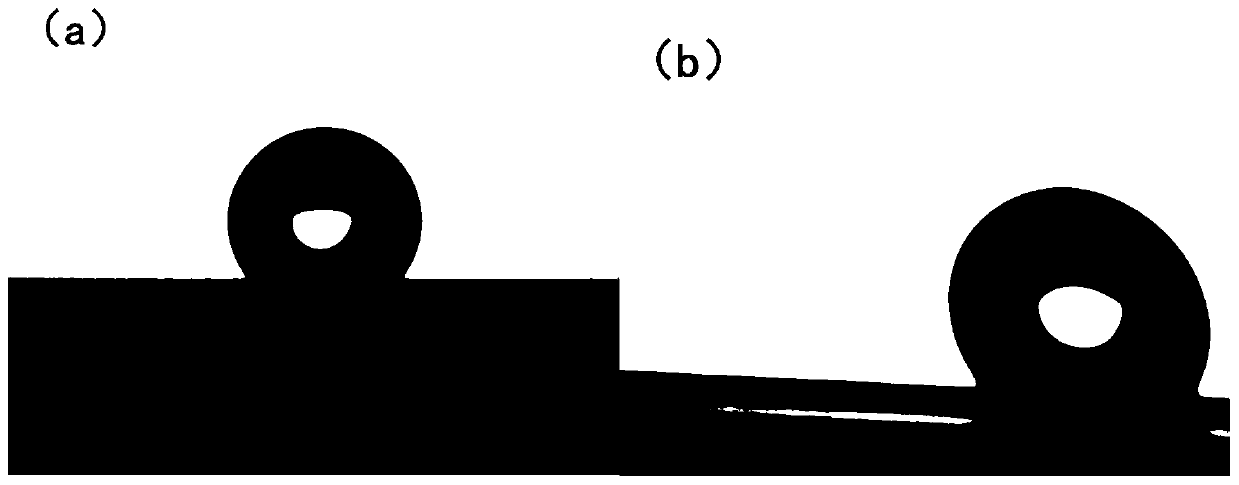

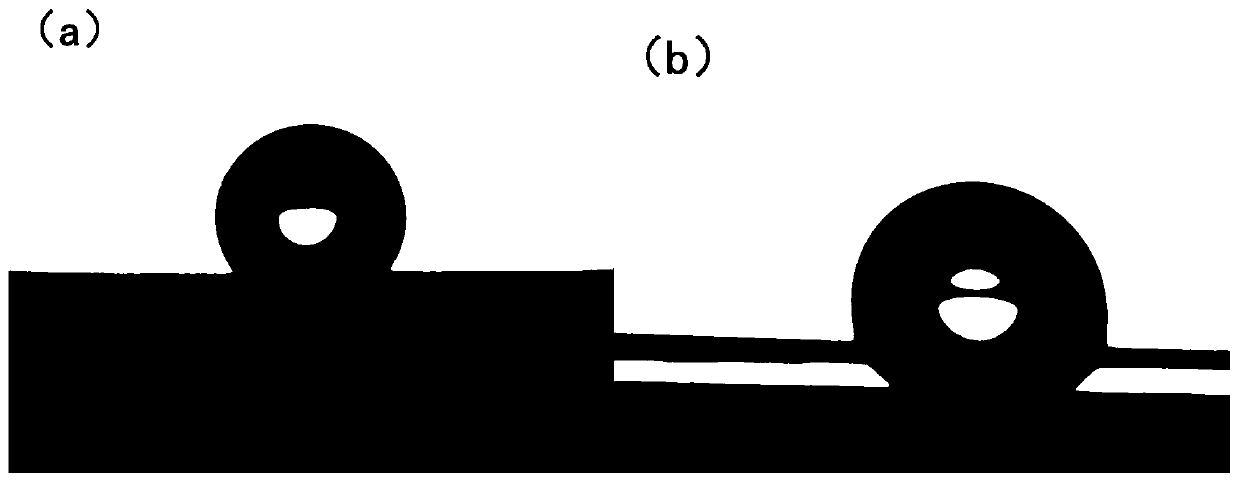

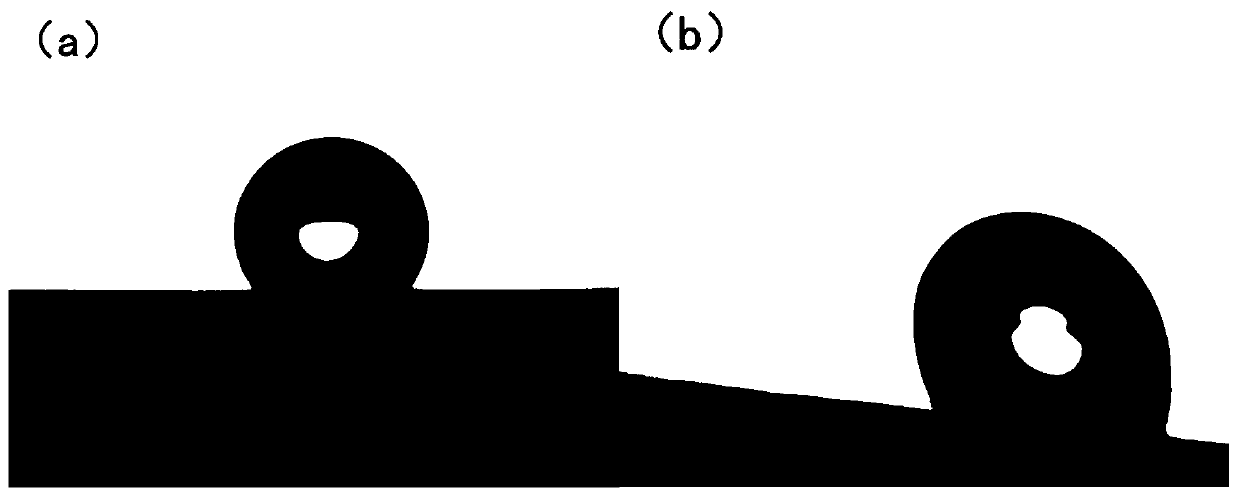

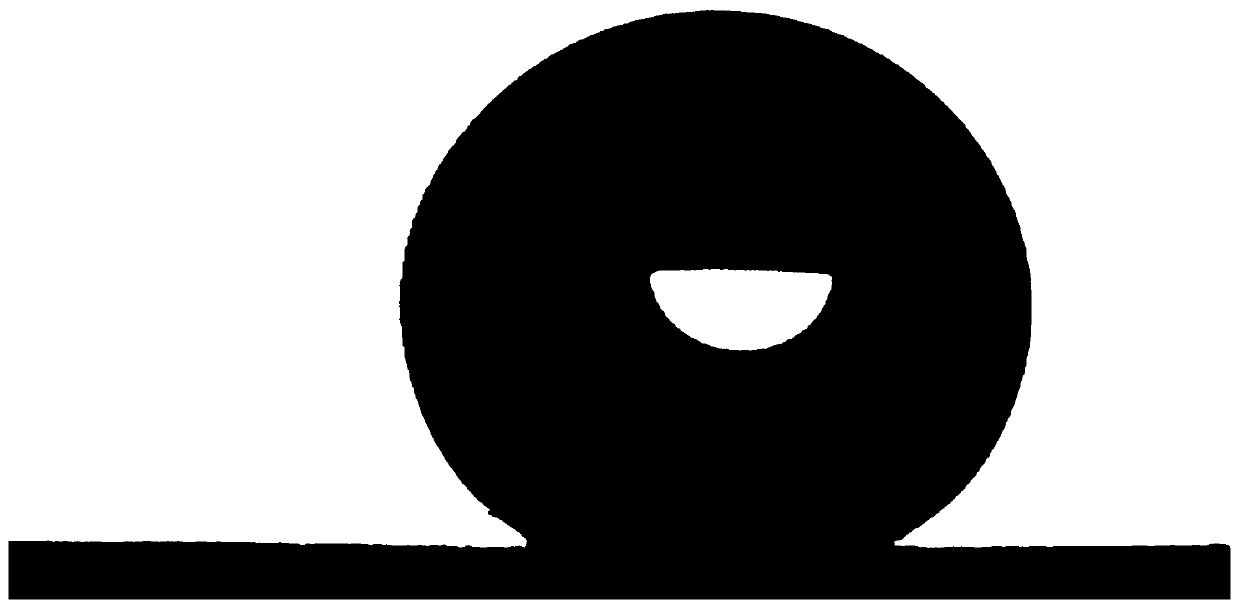

Titanium alloy super hydrophobic-super hydrophilic surface and preparing method and application of titanium alloy super hydrophobic-super hydrophilic surface

InactiveCN109732195AExcellent superhydrophobic propertiesReduce adhesionHeat exchange apparatusLaser beam welding apparatusHigh concentrationCondensation heat transfer

The invention discloses a titanium alloy super hydrophobic-super hydrophilic surface. Multiple sub arrays are distributed on the surface of a titanium alloy. Multiple super hydrophobic areas and multiple super hydrophilic areas in each sub array are arranged alternately in a wedge shape or a triangular shape, and super hydrophilic gathering areas are distributed between the sub arrays. The super hydrophobic surface has the good super hydrophobic performance, drop adhesion is very little, and rolling is extremely easy; drops can be adsorbed by the super hydrophilic areas, the drops at the top ends of the super hydrophilic areas in the wedge shape or the triangular shape can rapidly move towards the bottom of the wedge shape or the triangular shape under the drive of Plath pressure generatedby the wedge shape or the triangular shape, the super hydrophilic areas arranged alternately with the super hydrophilic areas can repel directional transportation of the drops, under the synergisticeffect of the super hydrophobic areas and the super hydrophilic areas, the condensation small drops can be gathered into the hydrophilic gathering area constantly, high-concentration-ratio self-driving water gathering is achieved, disengaging of the drops is accelerated, and therefore the condensation heat transfer efficiency is improved. The invention provides a preparing method and application of the titanium alloy super hydrophobic-super hydrophilic surface.

Owner:HUBEI UNIV OF TECH

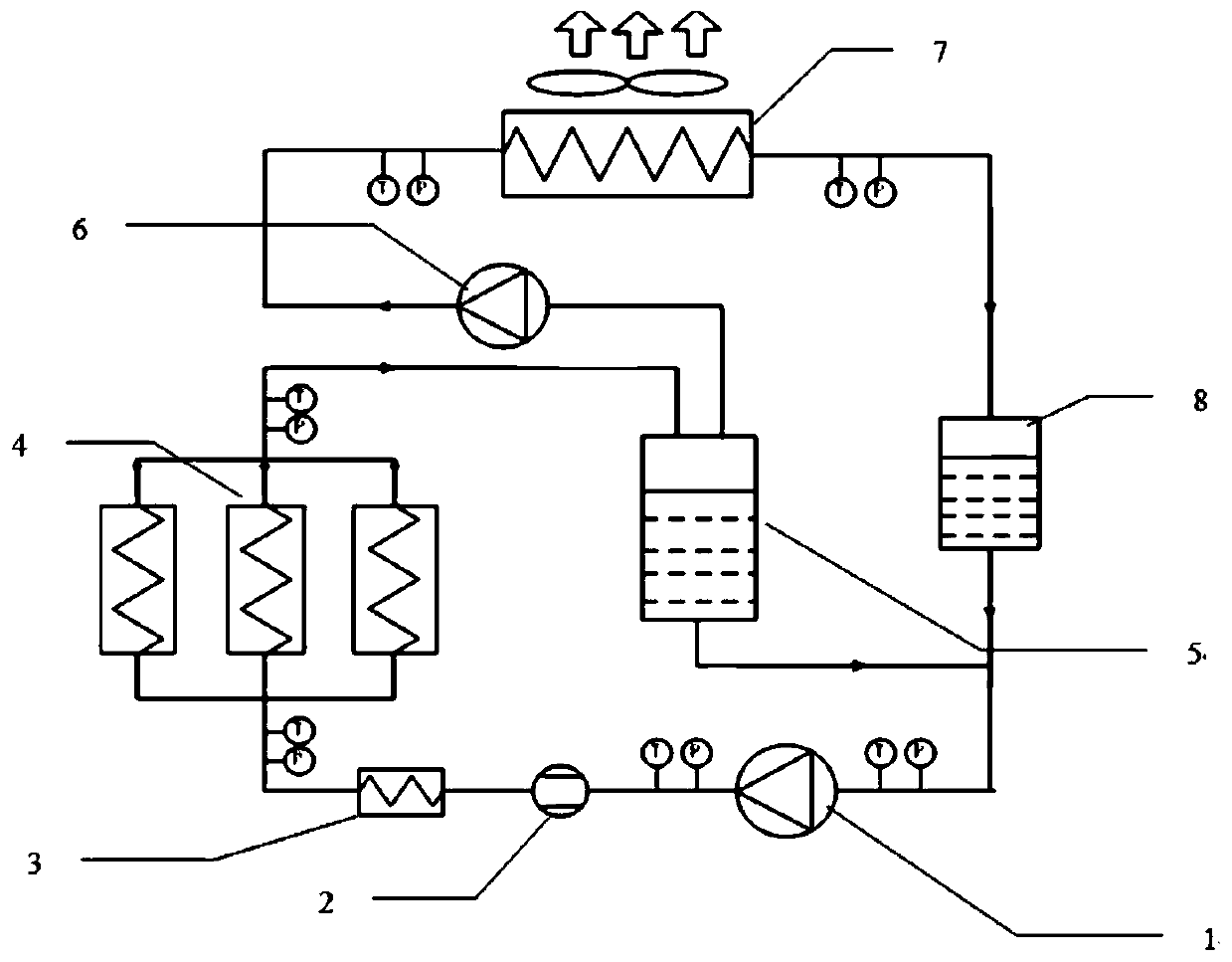

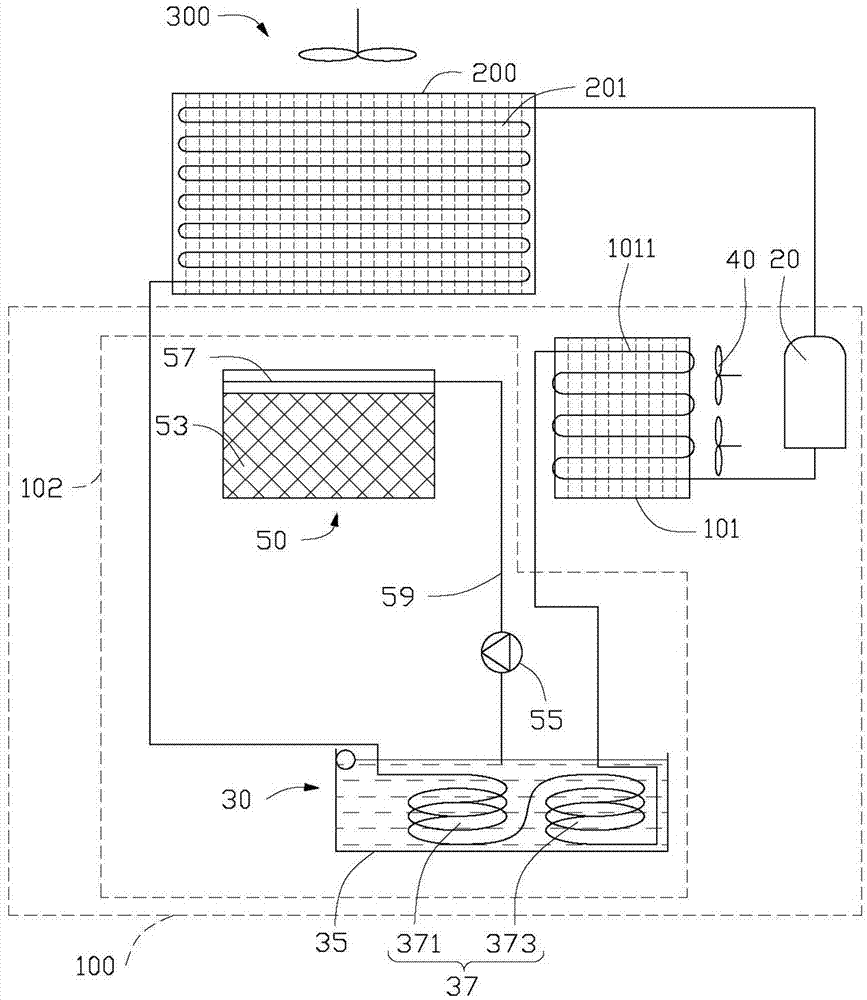

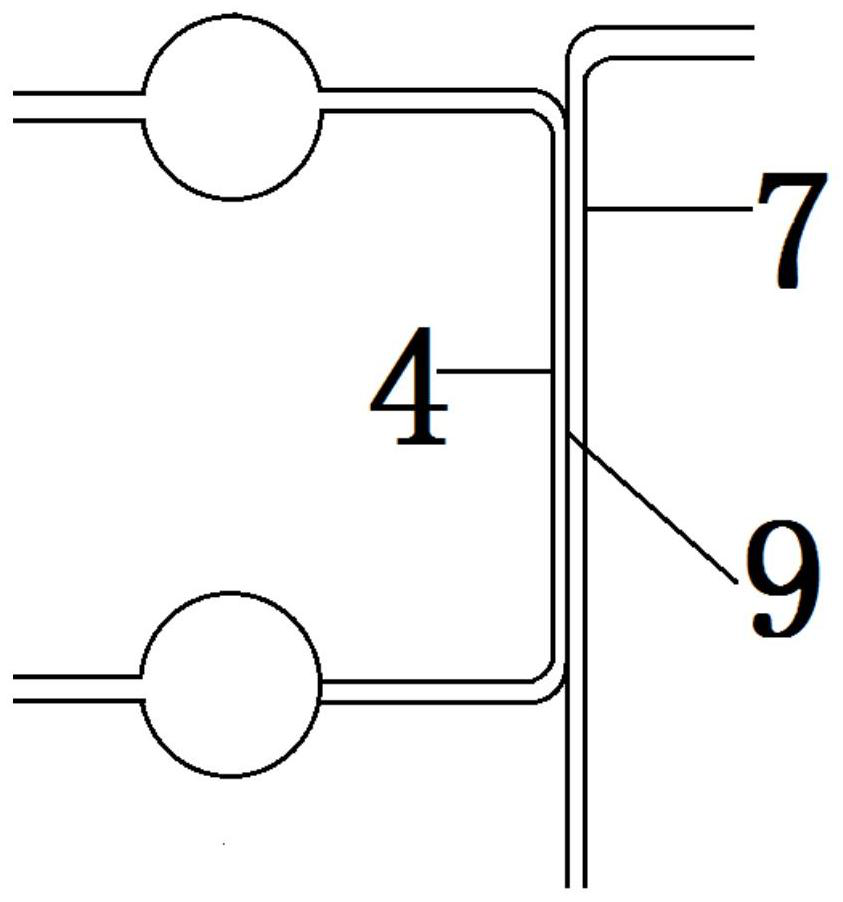

Phase change cooling system

InactiveCN110536592AReduce pressure pulseImprove condensation heat transfer efficiencyModifications using liquid coolingVapor liquidPressure rise

The invention discloses a phase change cooling system. The system comprises a liquid pump, a flow meter, an evaporator, a condenser, a preheater, a vapor-liquid separator, a liquid storage tank, a gaspump and a connecting pipeline. The system provided by the invention has the advantages that the vapor-liquid separator and the liquid storage tank are arranged in the system, reducing pressure pulses during the startup process of the system and improving the operation stability of the system; the gas pump arranged in the system can quickly separate vapor and liquid of a vapor-liquid two-phase working fluid flowing from the evaporator through the vapor-liquid separator, and then suck the working fluid into the condenser to condense and release heat; the condensation heat transfer efficiency can be improved; pressure rise and fluctuation caused by boiling heat transfer in the system are alleviated; and stable operation of the system is ensured.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

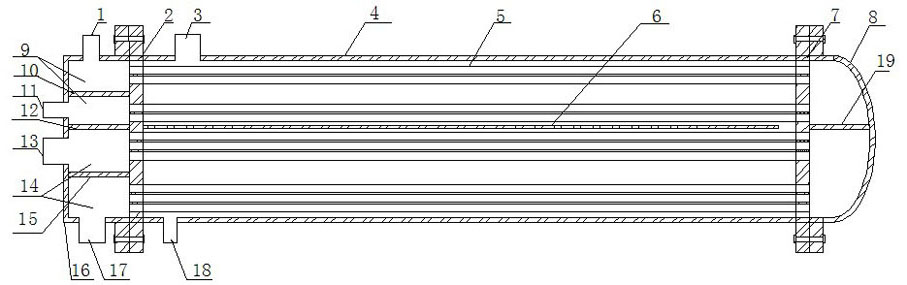

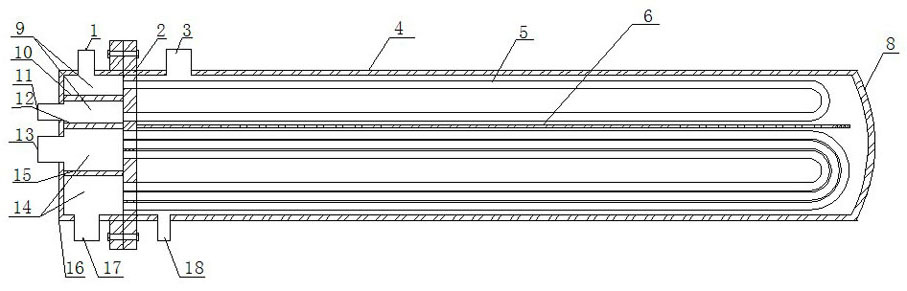

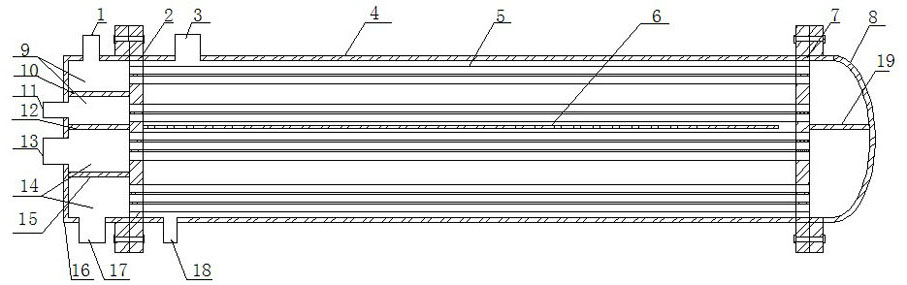

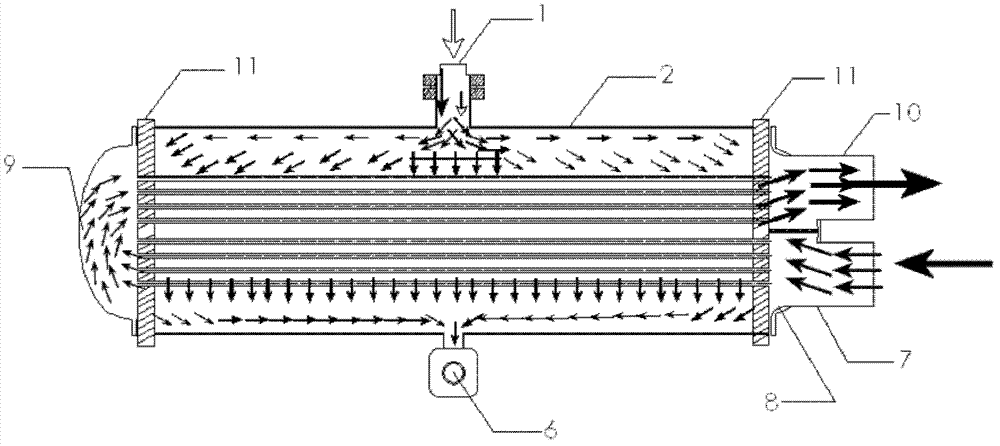

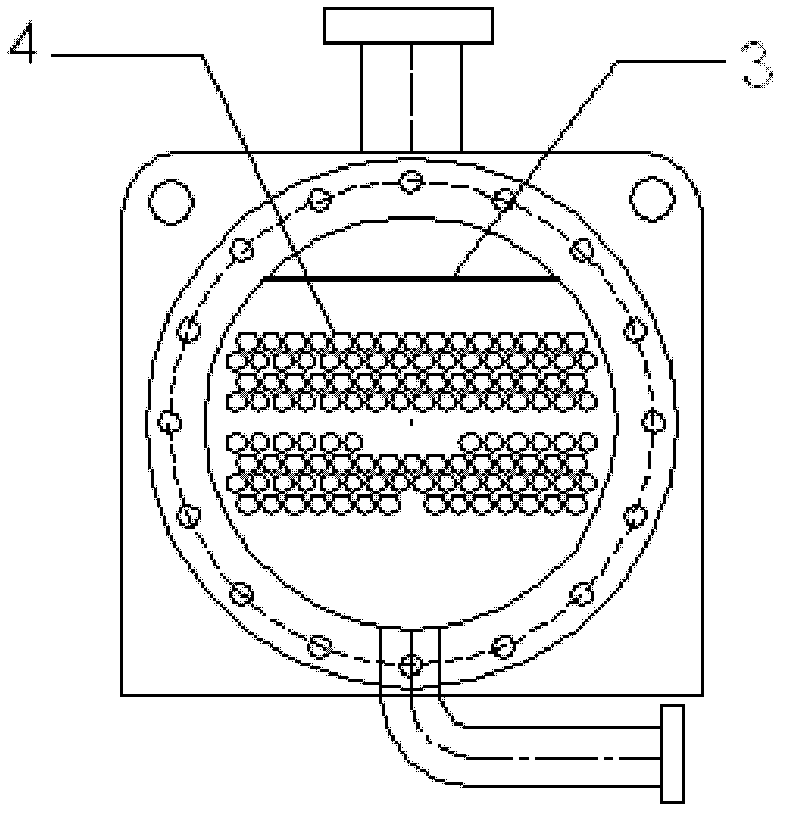

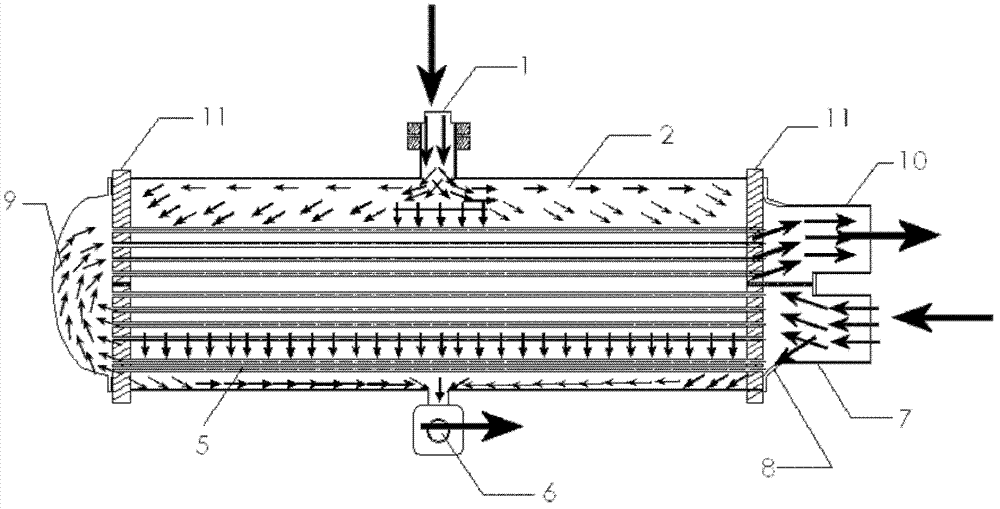

Multi-shell tube-shell-and-tube -type condenser with heat recoverer

InactiveCN101936628AReduce heat transfer temperature difference lossImprove condensation heat transfer efficiencyEvaporators/condensersHeat exchanger casingsEngineeringSuperheated steam

The invention relates to a multi-shell shell-and-tube-shell- type condenser with a heat recoverer. The condenser comprises a channel (16), tube plates (2 and 7), a shell (4) and an end cover (8). The tube plates are respectively arranged at both ends of the shell, the channel (16) is connected with the outer side of the tube plates (2) and internally provided with a separator to divide the channel into a heat recovery area (9) and a condensing area (14), the shell is provided with the end cover (8) at the other end and internally provided with a heat exchange pipe (5) which penetrates through the tube plates (2 and 7) and are communicated the channel and the end cover, and the shell is internally provided with a longitudinal deflectorflow-guiding plate (6) to divide the interior of the shell into the overheat steam heat recovery area and the condensing area. The heat exchanger of the invention can recover overheat steam through the separation of the overheat steam heat recovery area and the condensing area.

Owner:ZHONGYUAN ENGINEERING COLLEGE

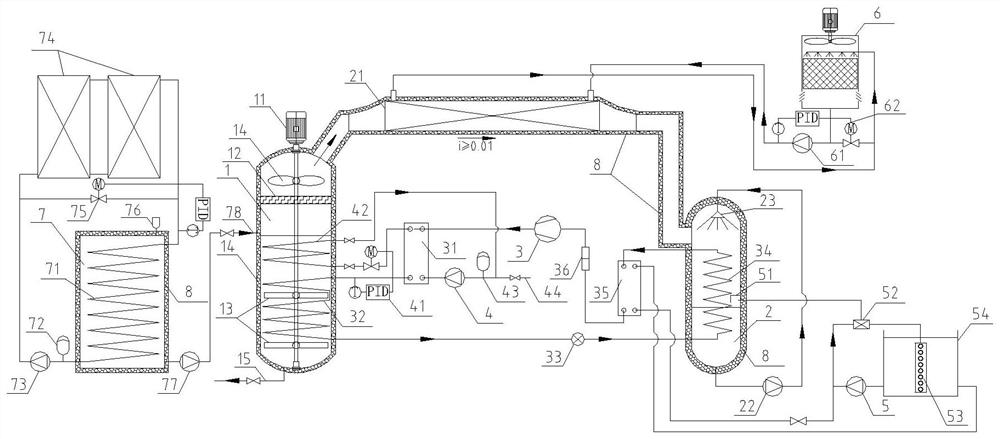

Multi-energy gradient utilization heat pump low-temperature evaporation and concentration system capable of accurately controlling temperature

PendingCN114100165AImprove system energy efficiencyReduce processing timeEvaporator accessoriesEvaporation by sprayingWater circulationRefrigerant

The invention belongs to the field of industrial processes, energy and environmental protection, and particularly relates to a multi-energy gradient utilization heat pump low-temperature evaporation and concentration system capable of accurately controlling temperature. The multi-energy gradient utilization heat pump low-temperature evaporation and concentration system capable of accurately controlling the temperature comprises a heating tank, a steam cooling and condensing system, a heat pump circulating system, a vacuumizing and re-condensing system, a water circulating temperature adjusting system, a heat dissipation system and a material preheating system. According to the system, efficient heat exchange on the refrigerant side can be achieved, the pressure environment of the material heating coil is improved, the adverse problems caused by heating materials through a high-temperature refrigerant are effectively solved, the material treatment quality is improved, meanwhile, the superheat degree of secondary steam can be reduced, and the heat exchange environment on the evaporator side during initial starting is improved. The system can accurately control the boiling evaporation temperature of the materials and efficiently utilize the materials in a gradient manner according to energy grades, so that the purposes of saving energy and reducing carbon are achieved, and the system is very significant.

Owner:李爱松

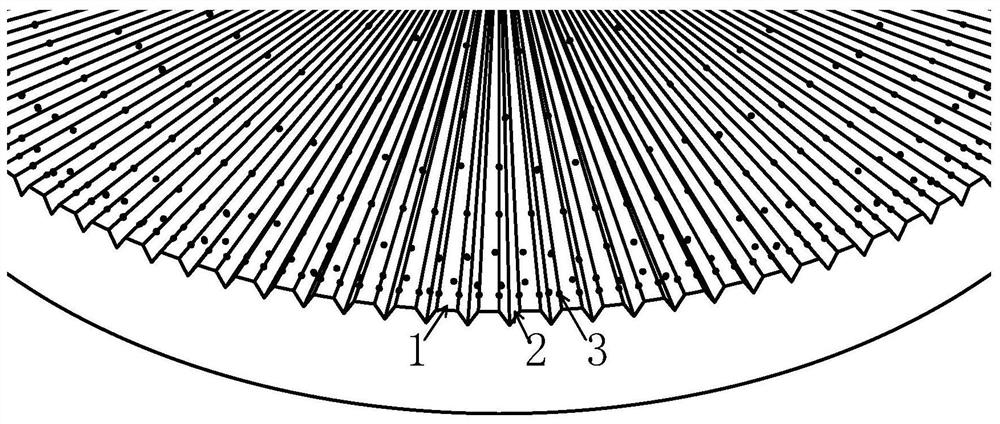

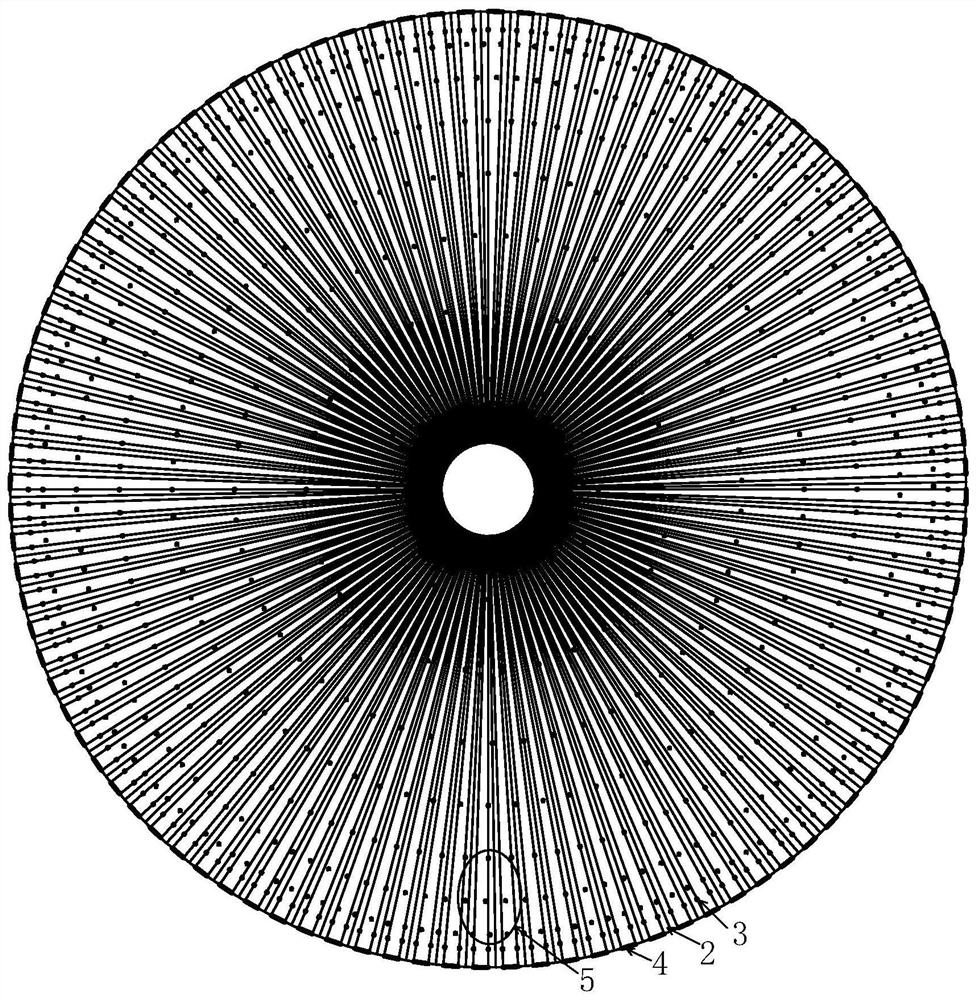

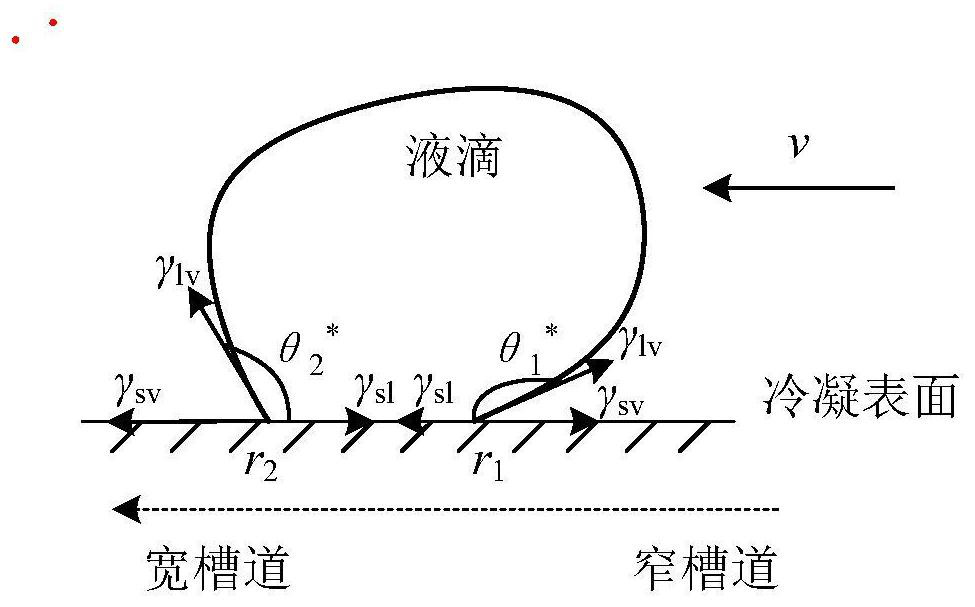

Bionic condensation enhanced heat transfer surface

InactiveCN112229234AEasy dischargeAccelerates the draining processSteam/vapor condensersHeat transfer modificationCondensation processFree energies

The invention discloses a bionic condensation enhanced heat transfer surface. The bionic condensation enhanced heat transfer surface comprises a substrate, micro-channels and hydrophilic nucleation points, wherein the substrate has hydrophobicity; the micro-channels are dispersed on the substrate at the same central angle in the radial direction of a circle center, and the circle center is locatedon the substrate or not located on the substrate; the hydrophilic nucleation points are distributed on the substrate; and the width between the adjacent micro-channels is increased in a gradient manner in the length direction. According to the condensation heat transfer surface, the surface free energy gradient is used for generating driving force on condensed liquid drops, liquid discharging ofa condensation surface is accelerated, nucleation of the condensed liquid drops on the condensation surface is accelerated through the hydrophilic nucleation points distributed on the surface of a hydrophobic substrate, a more stable bead-shaped condensation process is formed on the condensation surface, and smooth conduction of condensation circulation is guaranteed. The bionic condensation enhanced heat transfer surface can effectively improve the nucleation and updating rate of the condensed liquid drops, ensure continuous and stable bead-shaped condensation behaviors and enhance the condensation phase change heat transfer performance.

Owner:SOUTHEAST UNIV

Modified brass surface and preparation method and application thereof

InactiveCN109732196ANo chemical modificationSimple processLaser beam welding apparatusCondensation processLaser processing

The invention provides a modified brass surface and a preparation method and application of the modified brass surface. The method comprises the steps that 1, a brass surface to be treated is polishedfor pretreatment, cleaned and dried to obtain a clean surface-polished brass sample; 2, laser scanning treatment is carried out on the surface of the brass sample through a pulse laser device, multiple micro-nano structures are machined on the surface of the sample, the brass surface is placed into an electric heating vacuum drying box to be baked, and the brass super-hydrophobic surface is obtained; 3, a wedged or triangular parallel-connected super-hydrophilic surface is obtained on the obtained brass super-hydrophobic condensed surface through laser processing treatment, and the super-hydrophobic super-hydrophilic wedged or triangular interphase surface is obtained. Chemical modification is avoided, the process is simple, operation is convenient, the cost is low, the prepared super-hydrophobic super-hydrophilic wedged or triangular interphase surface is quite beneficial to realization and continuous conducting of the droplet condensation process and has the excellent condensation performance, the brass heat exchange efficiency is improved, and condensation efficiency of a condensation pipe is improved.

Owner:HUBEI UNIV OF TECH

Modified aluminum substrate surface and preparation method and application thereof

InactiveCN109590691ANo chemical modificationSimple processHeat transfer modificationMicro nanoCondensation process

The invention provides a modified aluminum substrate surface and a preparation method and application thereof. The method comprises the following steps that (1) polishing pretreatment is carried out on the aluminum surface to be treated, and a clean aluminum sample with the polished surface is obtained after washing and drying are carried out; (2) a pulsed laser is adopted for conducting laser scanning treatment on the surface of the obtained aluminum sample, a plurality of micro-nano structures are machined on the surface of the sample, the micro-nano structures are placed in an electric vacuum drying oven to be baked, and an aluminum superhydrophobic surface is obtained; and (3) the wedge-shaped or triangular parallel connection superhydrophilic surface is obtained on the obtained aluminum superhydrophobic surface through laser processing treatment, and the superhydrophobic-superhydrophilic wedge-shaped or triangular phase alternative surface is obtained. The method has no chemical modification and is simple in process, convenient to operate and low in cost, and the prepared aluminum substrate surface is the superhydrophobic-superhydrophilic wedge-shaped or triangular phase alternative surface, realization and continuous operation of the droplet condensation process are facilitated, the excellent condensation performance is achieved, the aluminum heat exchange rate is greatlyincreased, and the condensation efficiency of a condenser pipe is improved.

Owner:HUBEI UNIV OF TECH

Zinc alloy superhydrophobic-superhydrophilic surface as well as preparation method and application thereof

InactiveCN109702318AExcellent superhydrophobic propertiesReduce adhesionLaser beam welding apparatusHigh concentrationSuperhydrophobe

The invention discloses a zinc alloy superhydrophobic-superhydrophilic surface. A plurality of sub-arrays are distributed on the surface of a zinc alloy; a plurality of superhydrophobic areas and a plurality of superhydrophilic areas in each of the sub-arrays can be alternately arranged in a wedge or triangular shape; and a superhydrophilic collecting area is distributed between every two sub-arrays. The superhydrophobic surface disclosed by the invention has the excellent superhydrophobic performance, the adhesiveness of liquid droplets is very small and the liquid droplets are extremely andeasily rolled off; however, the superhydrophilic areas can absorb the liquid droplets, the liquid droplets formed in the top ends of the wedged or triangular superhydrophilic areas are driven by Plathpressure produced by the wedge or triangular shape and can be automatically and quickly moved toward the bottom part of the wedge or triangular shape, the superhydrophobic areas which alternate withthe superhydrophilic areas reject oriented transportation of the liquid droplets; and due to a mutual coordination effect of the superhydrophobic areas and the superhydrophilic areas, small condensedliquid droplets are continuously collected to a hydrophilic collecting area, so that self-driven water collection with the high concentration ratio can be realized, and dropping of the liquid dropletsis quickened, and thus, the condensation and heat transfer efficiency can be accelerated. The invention provides a preparation method and application of the zinc alloy superhydrophobic-superhydrophilic surface.

Owner:HUBEI UNIV OF TECH

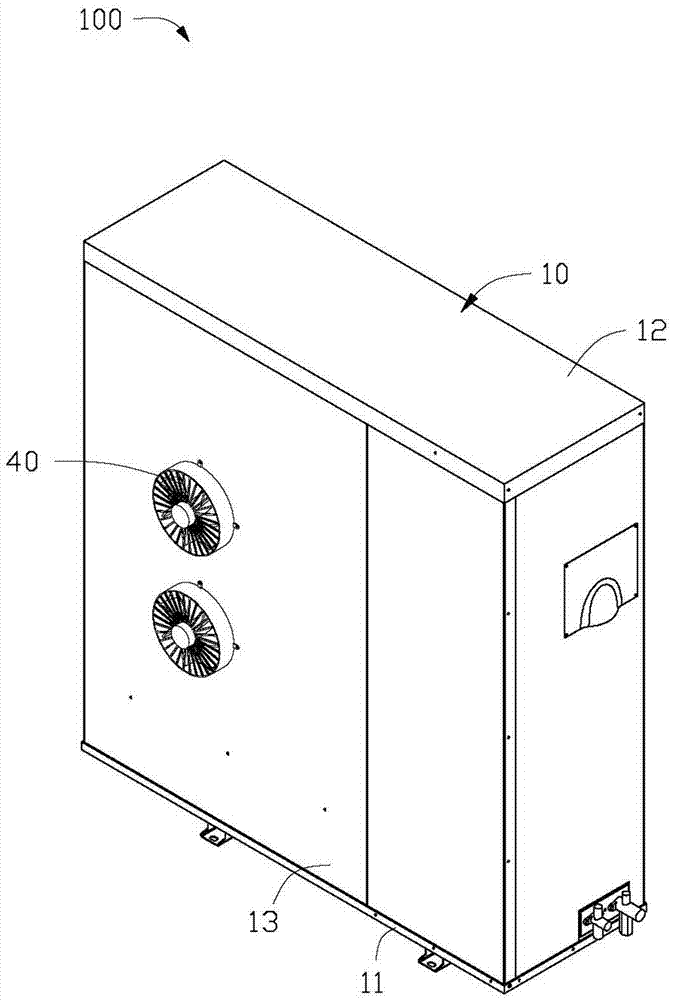

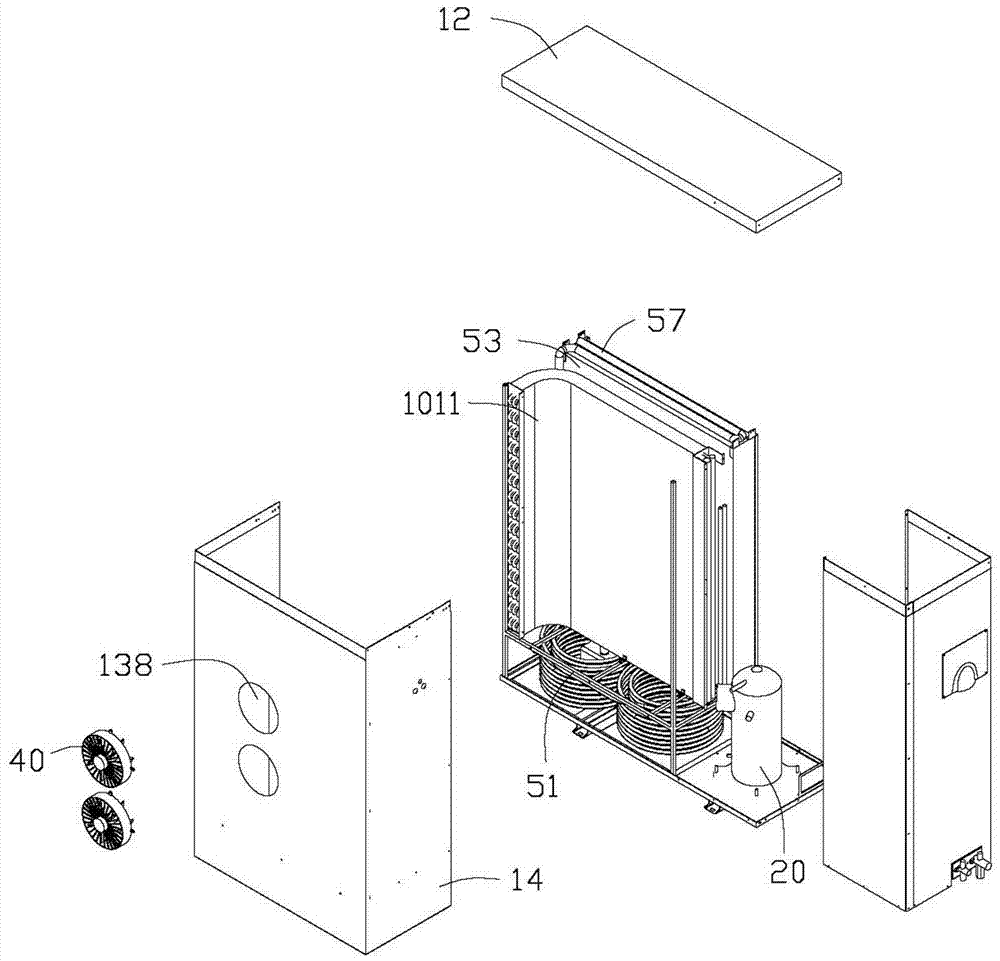

Cooling device and air conditioner with same

InactiveCN106931565APromote the development of miniaturizationReduce lossLighting and heating apparatusSpace heating and ventilation detailsEvaporationEngineering

The invention relates to a cooling device which comprises a housing, a fan, a compressor, a first heat exchange system accommodated in the housing and a second heat exchange system communicated with the first heat exchange system, wherein the housing is provided with an air inlet and an air outlet which are communicated; a heat dissipation air duct is formed between the air inlet and the air outlet; the fan is arranged at the air inlet or air outlet; the first heat exchange system comprises an air-cooled condenser communicated with the compressor; the second heat exchange system comprises a first heat exchange subsystem and a second heat exchange subsystem; the first heat exchange subsystem comprises a collecting part and a water cooled condenser; the collecting part is used for accommodating water; the water cooled condenser is communicated with the air-cooled condenser; the water cooled condenser is submerged in water during use; the second heat exchange subsystem comprises an evaporation medium structure and a spray structure; the evaporation medium structure and the air-cooled condenser are positioned in the heat dissipation air duct; a refrigerant from the compressor is subjected to primary cooling by air when passing through the air-cooled condenser and then subjected to secondary cooling by water evaporation when flowing into the water cooled condenser. The invention further provides an air conditioner.

Owner:SHENZHEN LANYUN SCI & TECH CO LTD

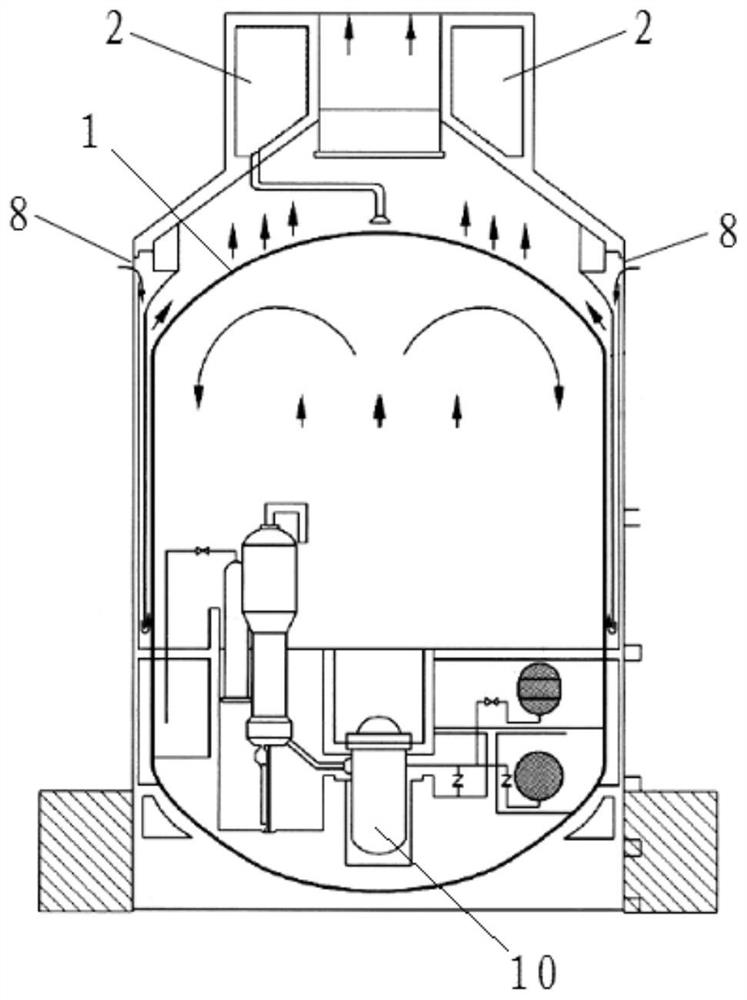

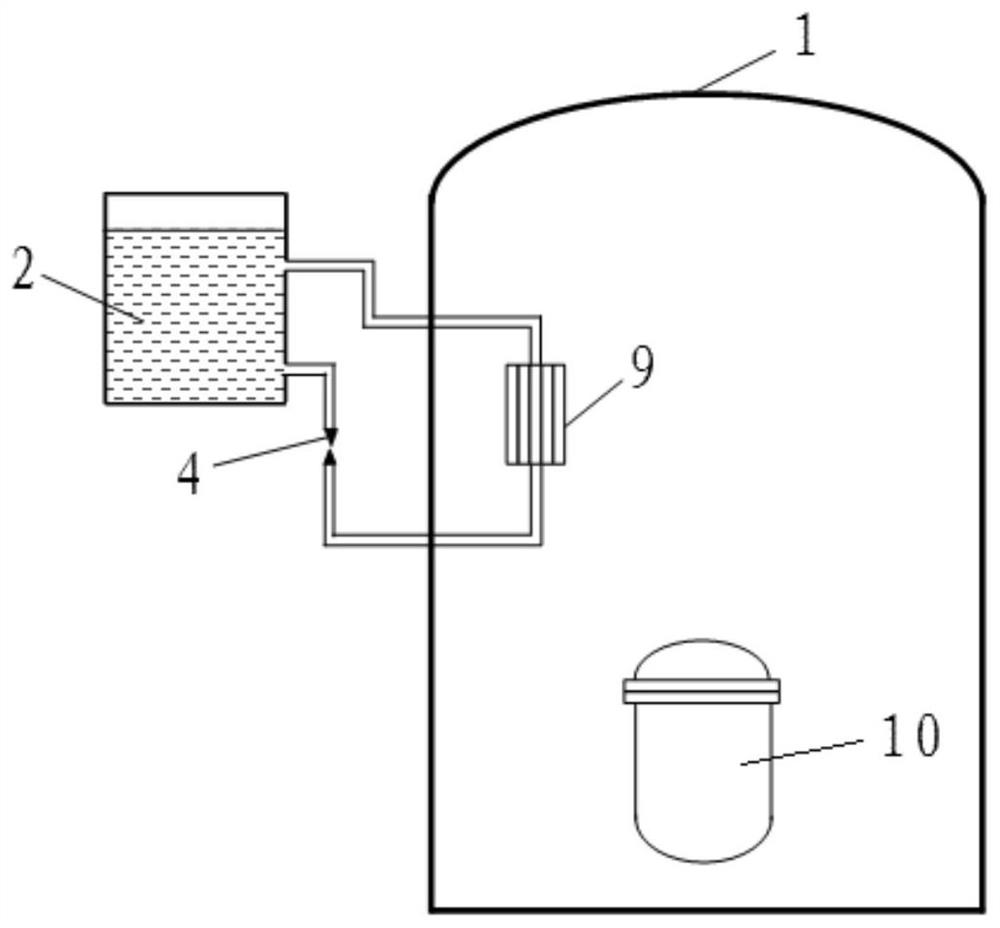

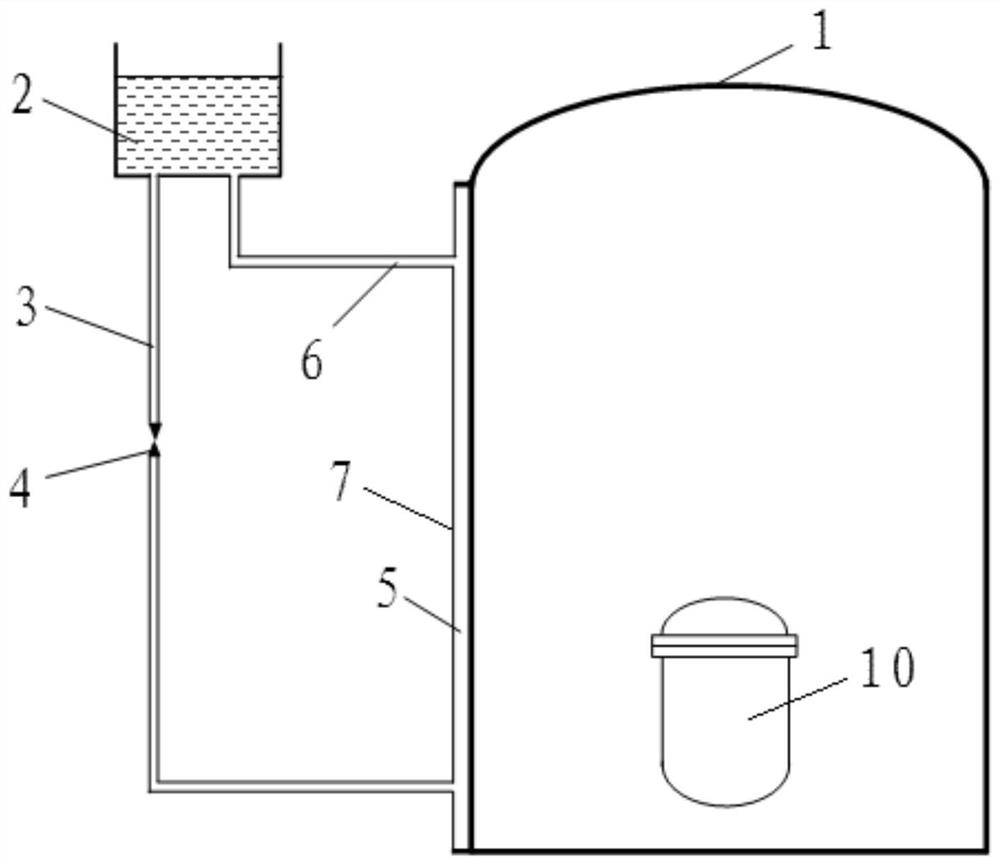

Passive containment heat export system with flow guide structure

ActiveCN113140336AImprove gas flowReduce the impact of deteriorationNuclear energy generationCooling arrangementNuclear reactorThermal efficiency

The invention relates to the field of nuclear reactor passive safety systems, in particular to a passive containment heat export system with a flow guide structure. The system is arranged on the inner side and the outer side of a containment and comprises a containment inner side part and a containment outer side part, the containment inner side part is positioned at the upper part of the inner side wall of the containment; the main body comprises an inner heat exchanger and a flow guide structure; the outer side part of the containment is positioned above the outer side wall of the containment, and the main body structure comprises an external cooling water tank and a steam-water separator; the containment inner side part and the containment outer side part are connected through a pipeline and a valve. According to the gas flow distribution characteristics in the containment vessel under the accident condition, the flow guide structure is arranged near the heat exchanger to effectively improve the gas flow condition near the heat exchanger in the PCS, the deterioration influence on condensation heat exchange caused by gathering of non-condensable gas near the internal heat exchanger is reduced, and the heat exchange efficiency of the PCS is improved.

Owner:CHINA NUCLEAR POWER ENG CO LTD

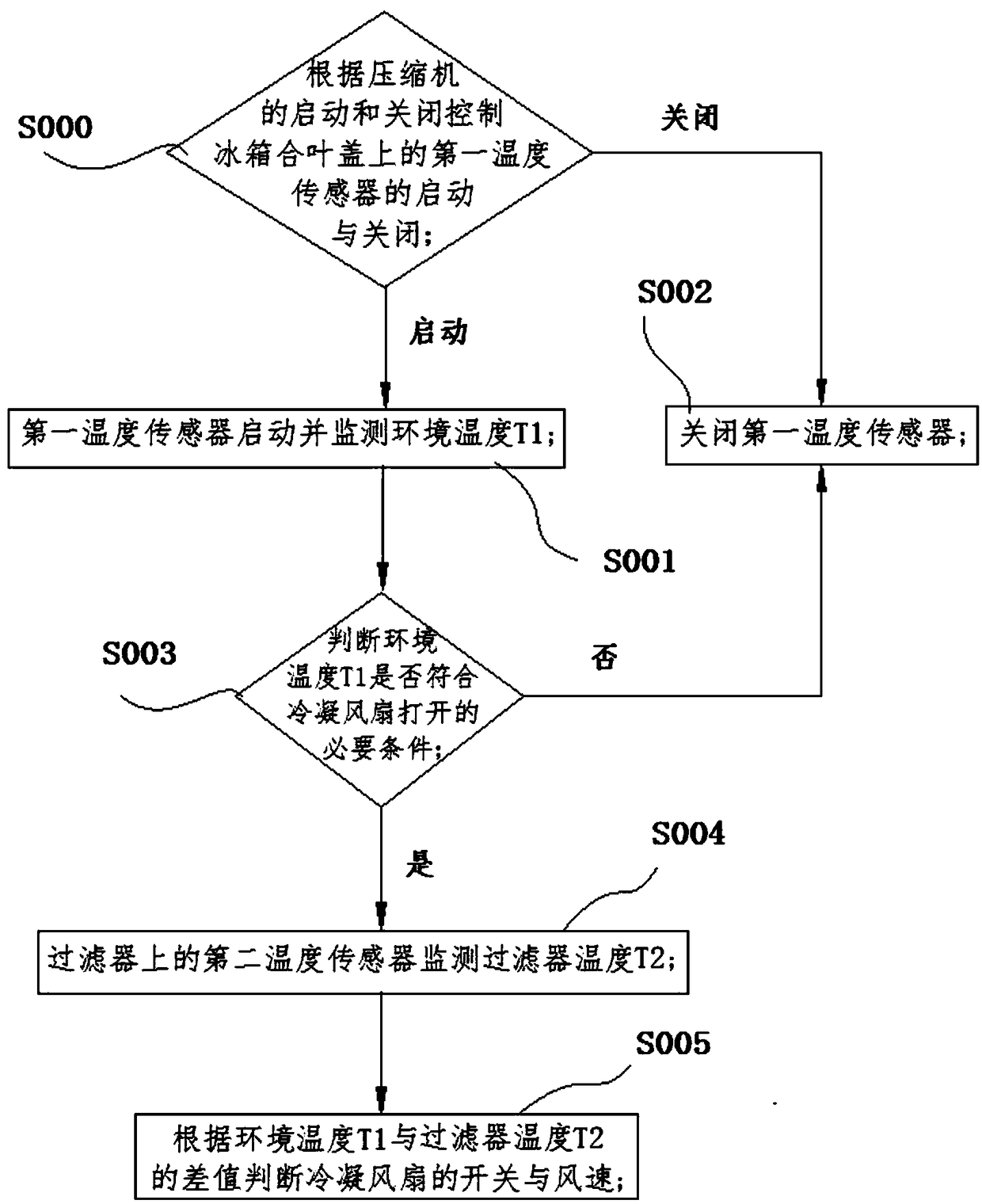

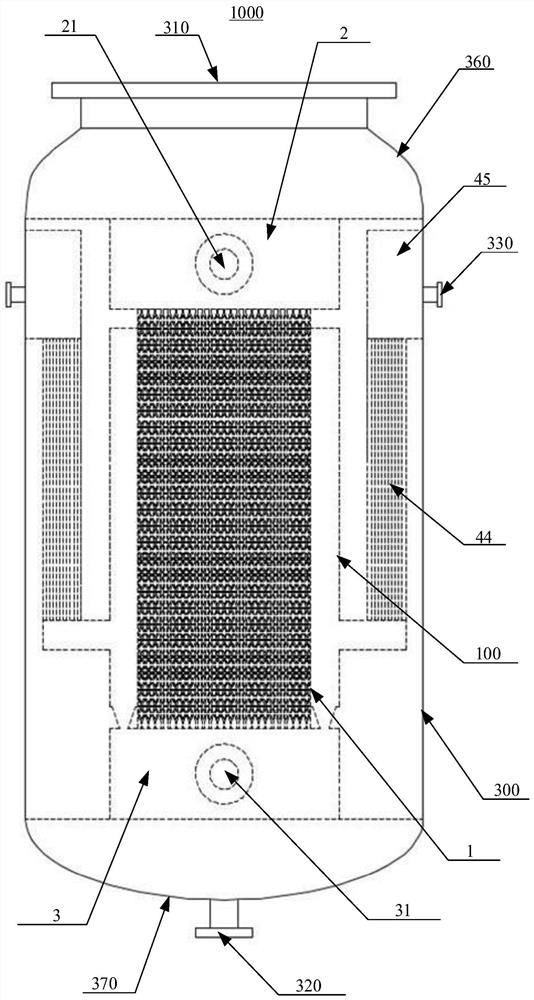

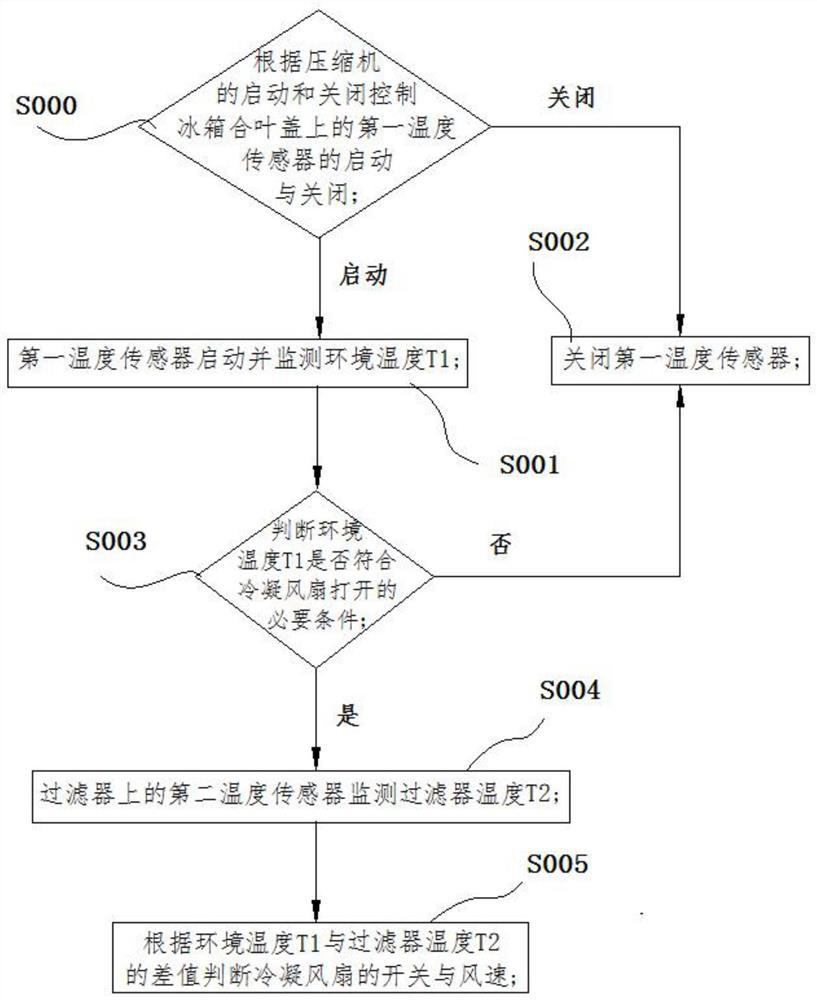

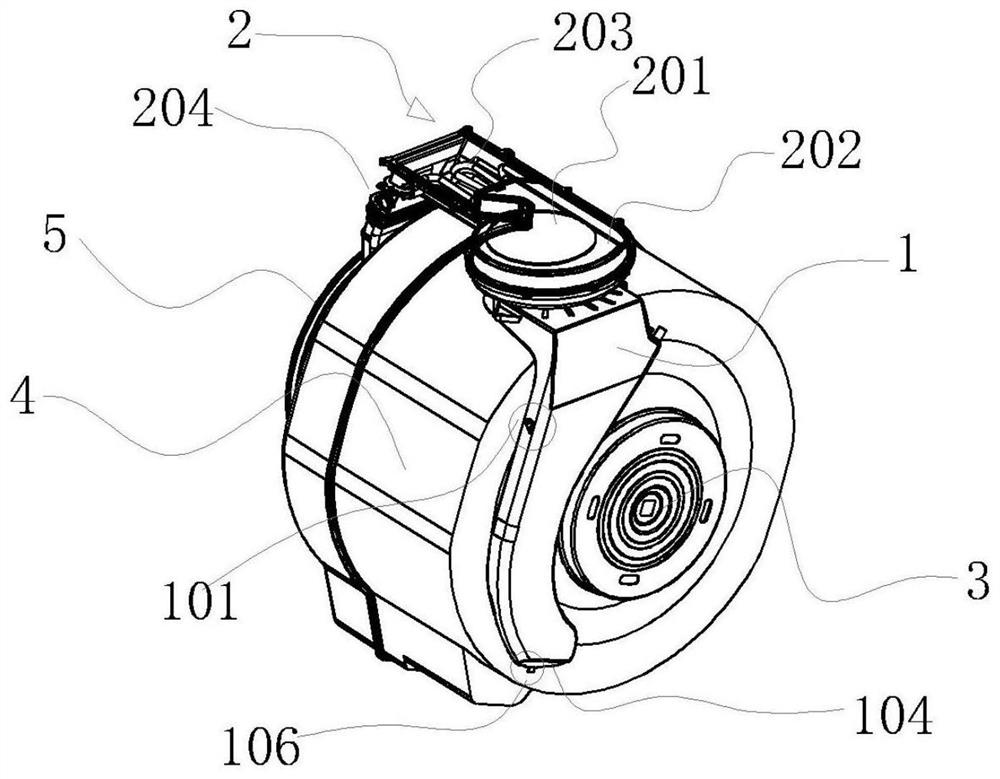

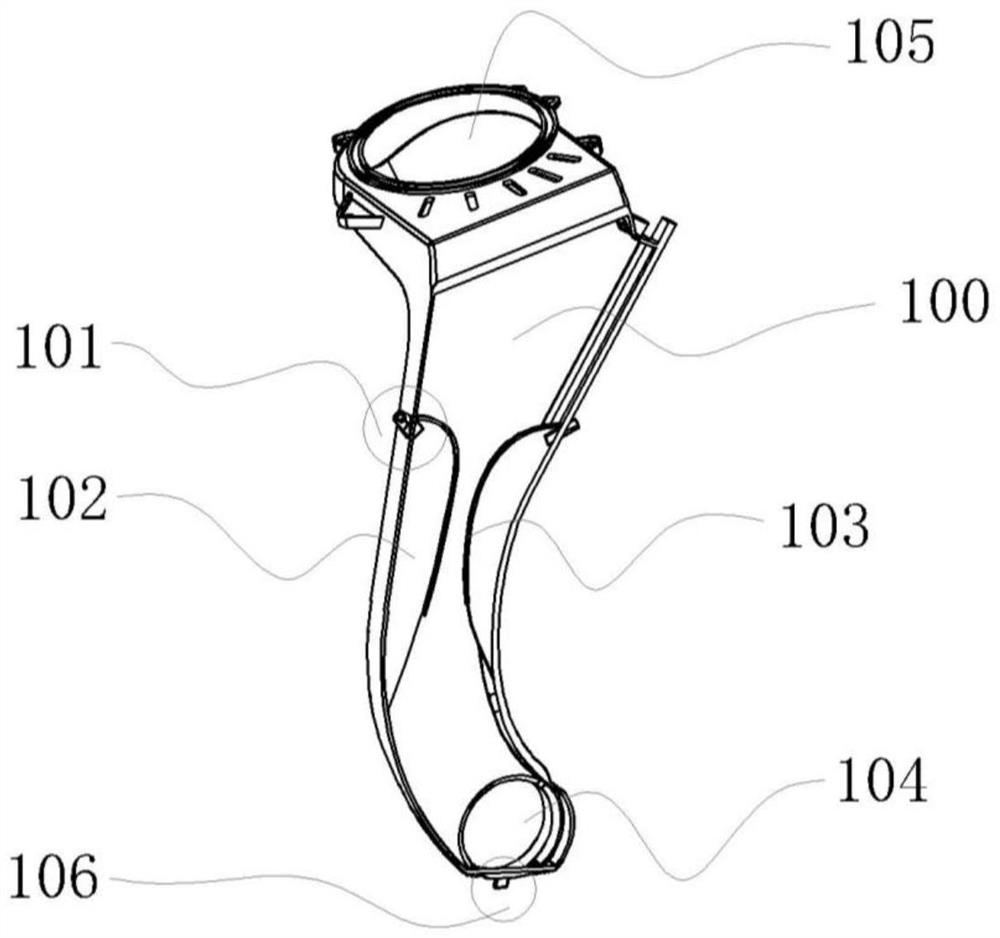

Embedded type refrigerator condensation and heat exchange control method

ActiveCN108444204AControl start and stopImprove condensation heat transfer efficiencyDomestic cooling apparatusRefrigeration safety arrangementEngineeringRefrigerated temperature

Owner:CHANGHONG MEILING CO LTD

A method for preparing super-hydrophobic composite nano-array interface material

A method for preparing a super-hydrophobic composite nano-array interface material, the preparation steps are: 1) using a copper sheet as a base material to prepare a zinc oxide nanocone film by chemical bath deposition in a hot water bath; 2) using a vapor phase deposition method on Use seventeen perfluorosilane to super-modify the oxidized nano-cone membrane at 120°C; 3) configure polyvinyl alcohol low-solid content aqueous solution; The aqueous solution is atomized through the condensation platform to reduce the surface temperature of the copper-based zinc oxide nano-cone film to 1°C to 5°C, so that the polyvinyl alcohol dispersion liquid dispersed in the air can condense the surface of the super-hydrophobic zinc oxide nano-cone film evenly, at high magnification Atomized deposition under the observation of the CCD imaging system; 5) Quickly transfer to a constant temperature hot stage, and cure at a constant temperature. After the solvent moisture is completely volatilized, the polyvinyl alcohol is cured and adsorbed and adhered to the surface of the zinc oxide nanocone to form a hydrophilic-hydrophobic composite nano-array interface; The process is simple, the cost is low, and the resistance to condensation and frosting is high.

Owner:SHAANXI UNIV OF SCI & TECH

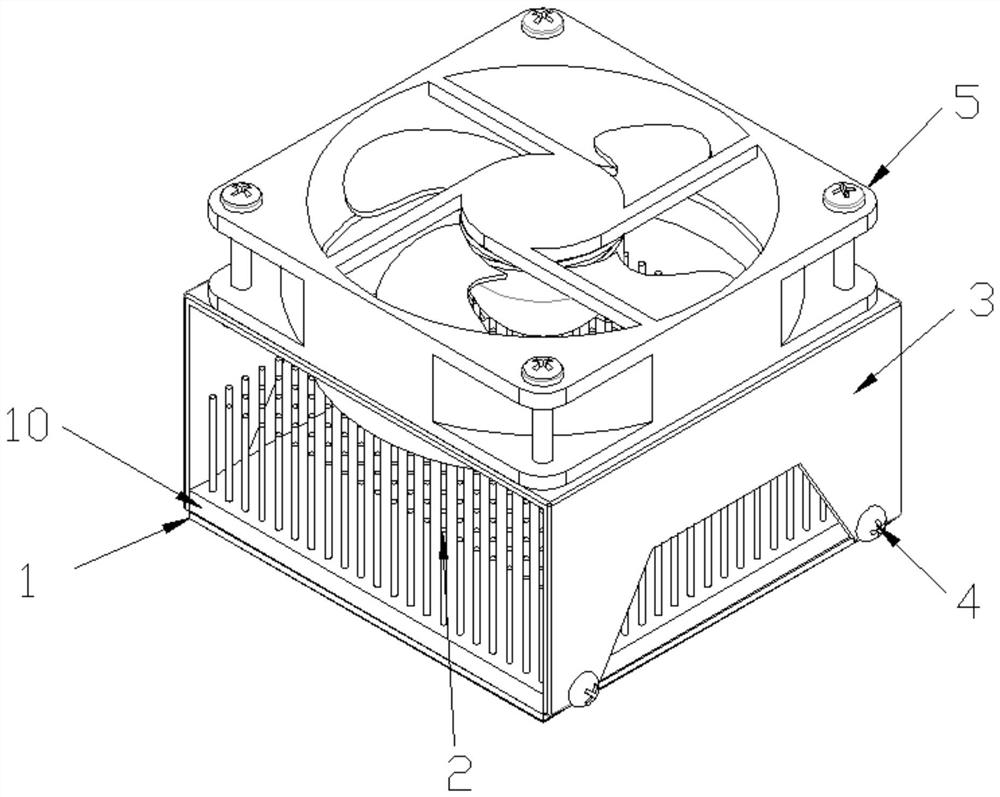

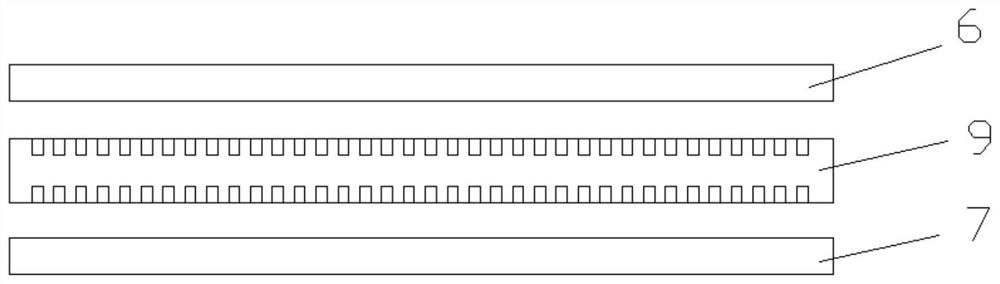

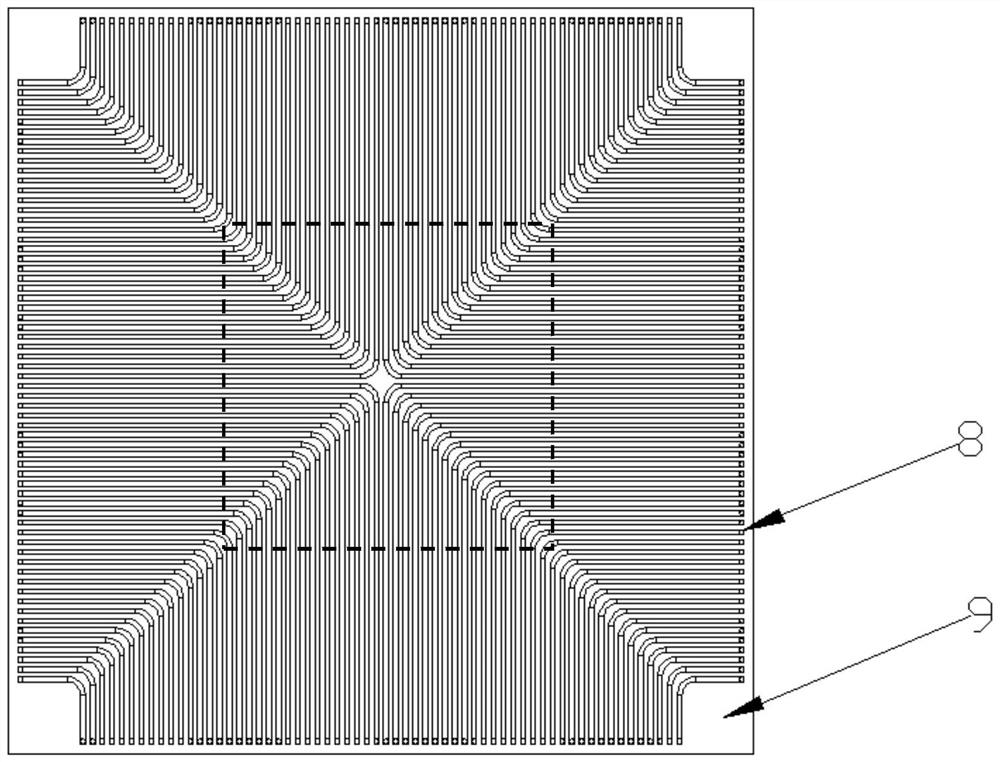

Preparation method of double-sided micro-channel flat pulsating heat pipe and application thereof to high-power chip heat dissipation device

InactiveCN113008057AIncrease heat transfer limitIncrease the number ofSemiconductor/solid-state device detailsSolid-state devicesEngineeringMechanical engineering

The invention discloses a preparation method of a double-sided micro-channel flat plate pulsating heat pipe and application of the double-sided micro-channel flat plate pulsating heat pipe to a high-power chip heat dissipation device. The device comprises a method for preparing the double-sided micro-channel flat plate pulsating heat pipe, the two opposite surfaces of the double-sided micro-channel flat plate pulsating heat pipe are an evaporation end face and a condensation end face respectively, the evaporation end face and the condensation end face are both provided with identical micro-channels, the micro-channels on the two surfaces are communicated with each other, and the double-face micro-channel flat plate pulsating heat pipe is filled with working media in a sealed mode; a heat dissipation unit is fixedly connected to the upper portion of the evaporation end face of the double-face micro-channel flat plate pulsating heat pipe; and the chip is fixedly installed on the evaporation end face, and heat dissipation of the chip is achieved through circulation of a working medium on the evaporation end face and the condensation end face.

Owner:JIANGSU UNIV

High energy efficiency dry shell and tube condensing heat exchanger with tube for subcooling

InactiveCN103090599AIncreased condensing subcoolingLower condensation temperatureEvaporators/condensersSubcoolersHigh energyEngineering

The invention relates to a high energy efficiency dry shell and tube condensing heat exchanger with tube for subcooling. The high energy efficiency dry shell and tube condensing heat exchanger with tube for subcooling comprises a shell group and a tube core group for subcooling, wherein a heat exchange tube core group is fixedly disposed in the shell group, expanded joints at the two ends of the heat exchange tube core group are fixed on the end plates, a dispersion plate is disposed above the heat exchange tube core group, a refrigerant inlet is formed at the top end of the shell group, a refrigerant outlet is formed at the bottom end of the shell group, an end cover is arranged on one side of the shell group, a secondary refrigerant inlet is formed at the lower portion of the shell group, a secondary refrigerant outlet is formed at the upper portion of the shell group, an end cover without splitter plates is installed on the other side of the shell group, and the tube core group for subcooling is fixedly disposed in the shell group and under the heat exchange tube core group. The high energy efficiency dry shell and tube condensing heat exchanger with tube for subcooling has the advantages that because the tube core group for subcooling is installed in the heat exchanger, the degree of subcooling of refrigerants is improved, condensing temperature is decreased, the efficiency of condensing heat exchange is improved, the load of the secondary refrigerants is reduced, and negative factors of overall cyclicity is reduced.

Owner:SHANGHAI HANYE REFRIGERATION MACHINERY

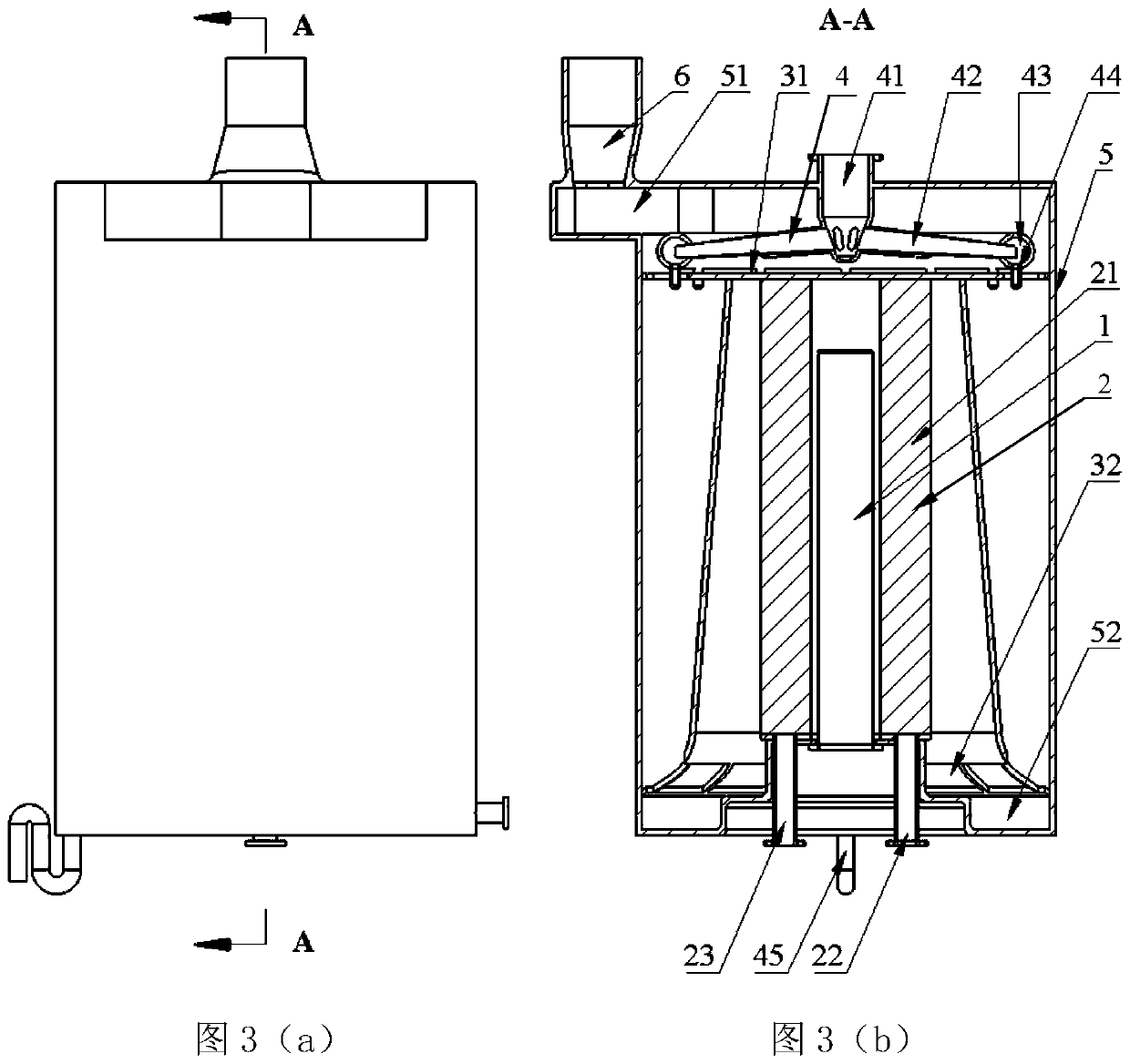

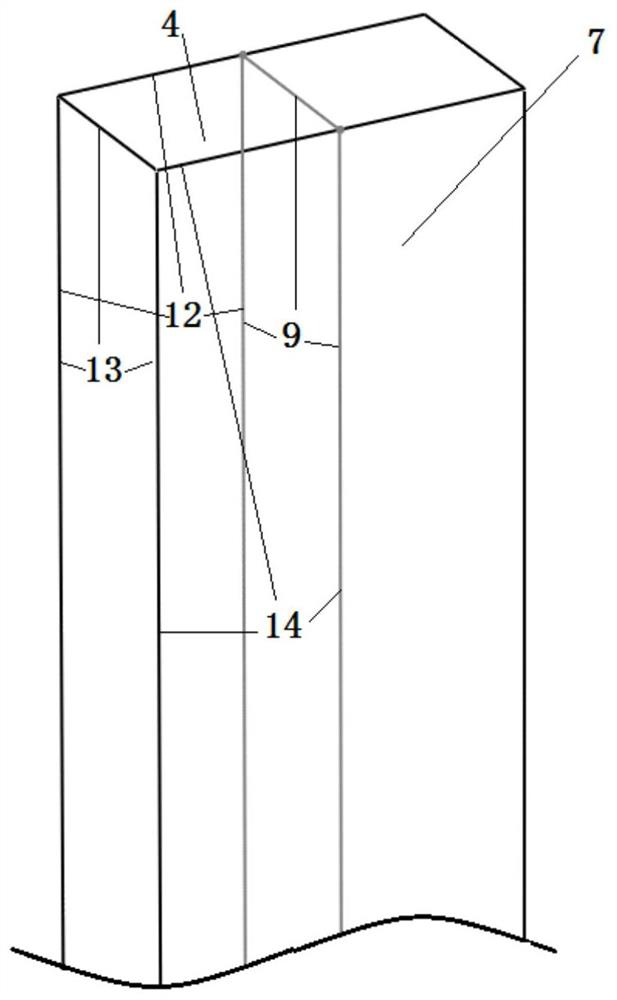

Passive steel containment heat export system

PendingCN113593733AEliminate dependenciesImprove securityNuclear energy generationCooling arrangementNuclear plantThermodynamics

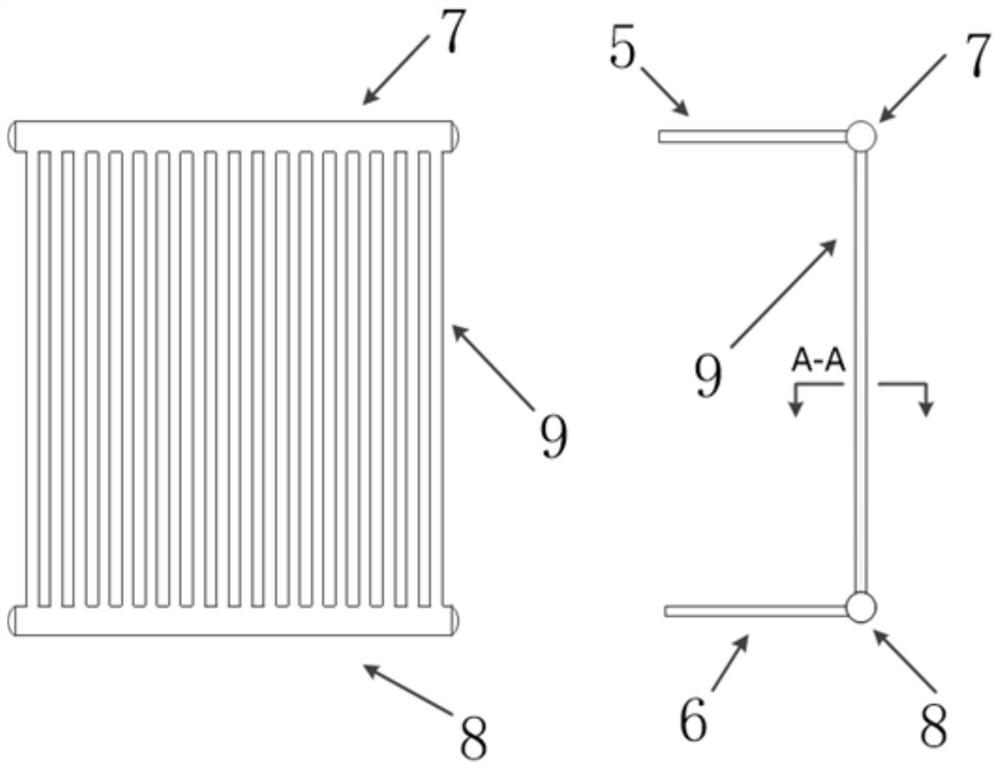

The invention belongs to the technical field of nuclear power plant reactor safety systems, and particularly relates to a passive steel containment heat export system, which is characterized in that a cooling cover (7) is arranged on the side wall of a containment (1) of a reactor and forms a closed annular cavity (5) with the containment (1), a cooling water loop is arranged on the cooling cover (7), the cooling water loop can inject cooling water into the annular cavity (5) from the bottom of the cooling cover (7) in a passive mode, the cooling water absorbing heat in the annular cavity (5) can flow back into the cooling water loop from the top of the cooling cover (7) in a passive mode, and the containment (1) is made of stainless steel. According to the invention, dependence of a traditional active safety system on a safety-level power supply is eliminated, high natural circulation capacity and heat removal capacity are achieved, and the capacity of relieving accident consequences for a long time without intervention after an accident is provided.

Owner:CHINA NUCLEAR POWER ENG CO LTD

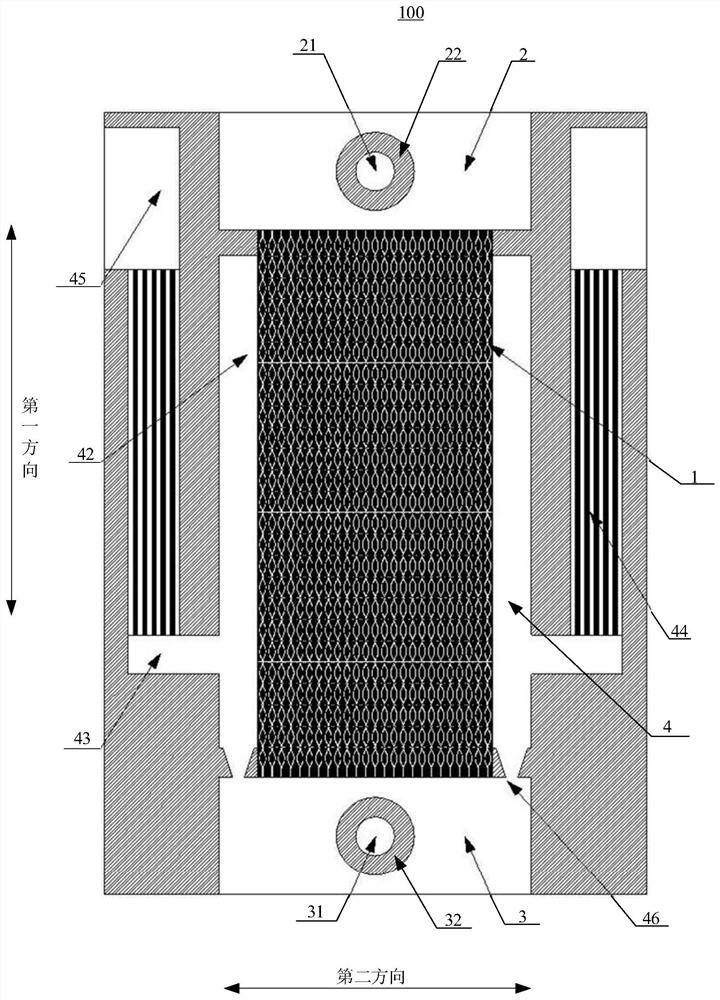

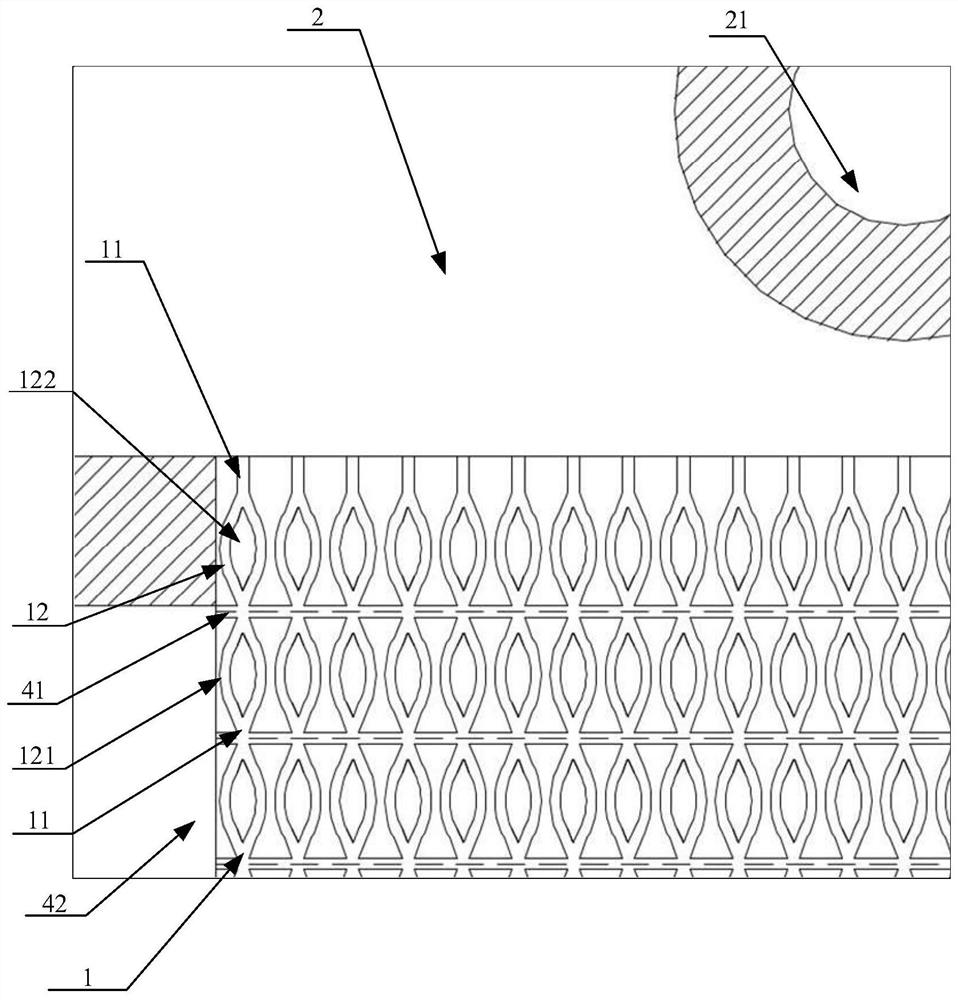

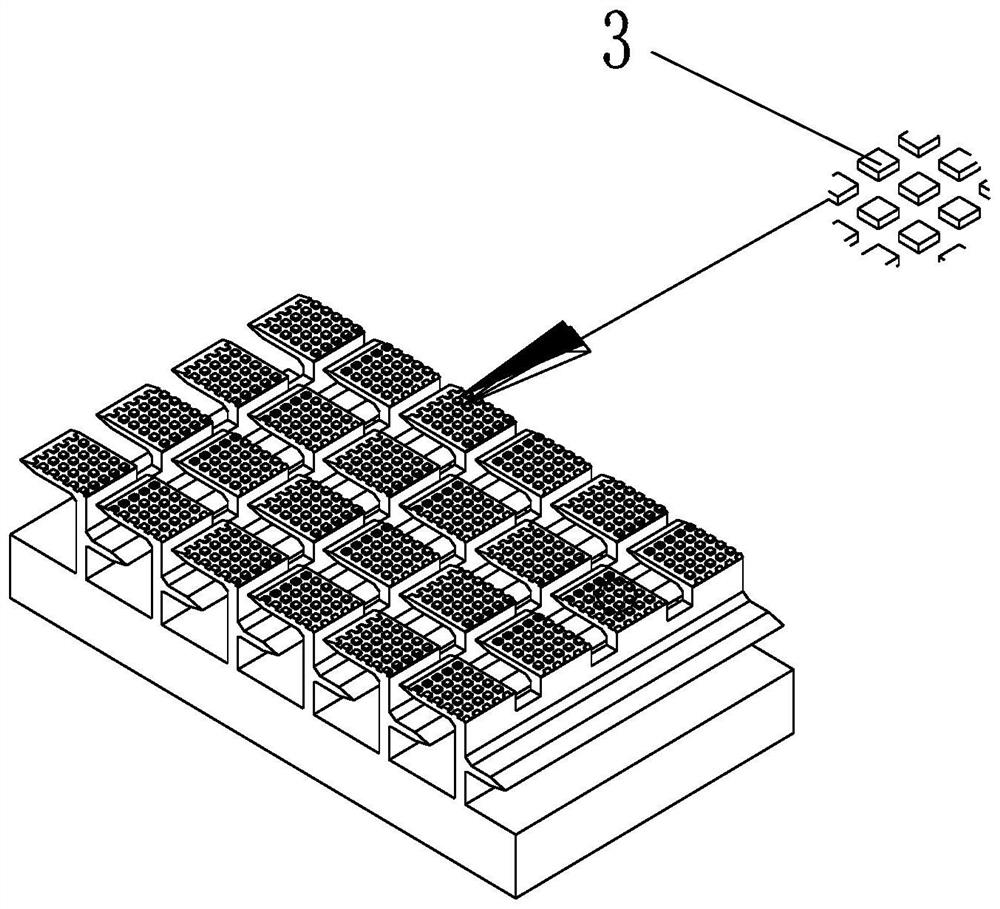

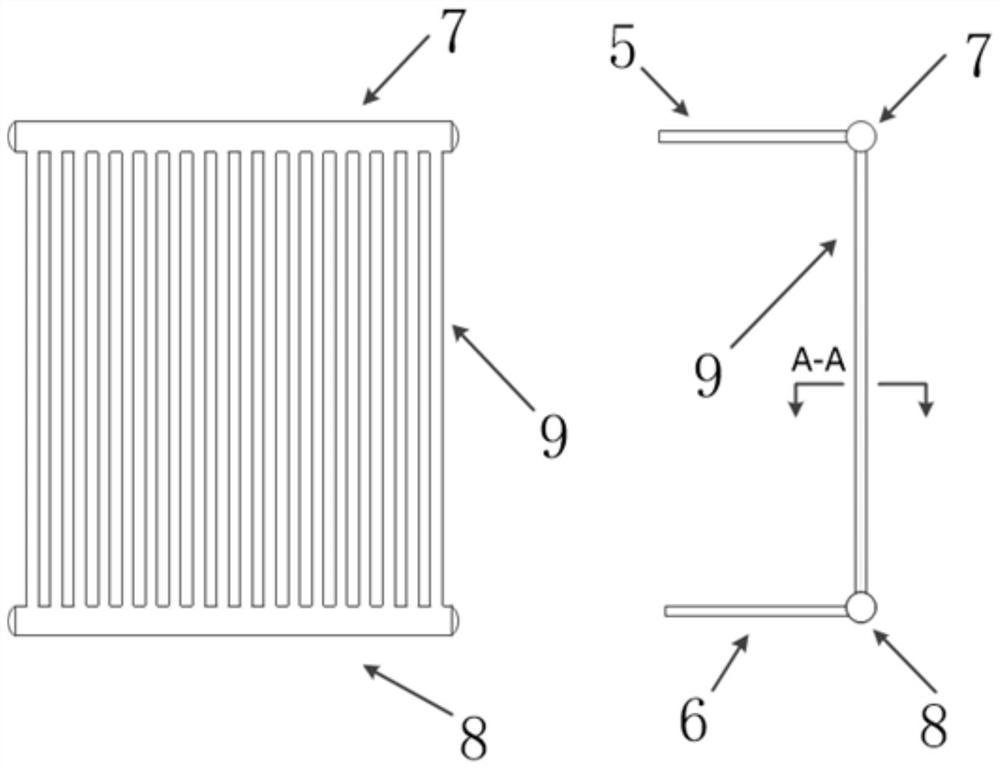

A first heat exchange plate and microchannel condenser

ActiveCN111780569BEnhanced convective heat transfer intensityImprove condensation heat transfer efficiencySteam/vapor condensersStationary plate conduit assembliesSteam condensationCondenser (heat transfer)

The invention relates to the technical field of heat exchange, and discloses a first heat exchange plate and a microchannel condenser. The first heat exchange plate is provided with a steam inlet and a water discharge port, and a plate surface of the first heat exchange plate is provided with a plurality of condensation channels, and the two ends of each condensation channel are respectively connected with the steam inlet and the water discharge port; each condensation The channels include a plurality of single-row channels connected in series and at least one multi-row channel, a multi-row channel is connected between two adjacent single-row channels, and the multi-row channels include a plurality of parallel branch channels. The condensation channel of the first heat exchange plate provided by the embodiment of the present invention includes single-row channels and multi-row channels connected in series. When the first heat exchange plate is used as a steam condensation plate, the steam will repeatedly gather and separate in the condensation channel, strengthening the The convective heat transfer intensity of the condenser is improved, and the condensation heat transfer efficiency of the condensation channel can be significantly improved, thereby relatively reducing the volume of the condenser.

Owner:WUHAN SECOND SHIP DESIGN & RES INST

A method for controlling condensation and heat exchange of an embedded refrigerator

ActiveCN108444204BControl start and stopImprove condensation heat transfer efficiencyDomestic cooling apparatusRefrigeration safety arrangementTemperature controlCondenser (heat transfer)

The invention discloses a method for controlling condensation heat exchange of an embedded refrigerator. The invention relates to the technical field of condensation heat exchange control of embedded refrigerators. The invention includes controlling the starting and rotating speed of the condensing fan according to the ambient temperature outside the refrigerator and the temperature of the filter. The invention timely and accurately controls the start and stop of the condensing fan through the difference between the ambient temperature and the surface temperature of the filter, and improves the condensation heat exchange efficiency of the refrigerator condenser with external condensers on the side and the back; The temperature difference is used to control the condensing fan using different speed control schemes, which can effectively control the condensing heat exchange in real time and dynamically, and save energy.

Owner:CHANGHONG MEILING CO LTD

A cooling and dehumidifying device

ActiveCN112553851BIncrease contact areaImprove condensation heat transfer efficiencyTextiles and paperLaundry driersWater flowCondensation heat transfer

The invention provides a cooling and dehumidifying device, which includes a shell, an air inlet, an air outlet, a cooling water inlet joint, a cooling water outlet and a partition plate. The partition plate is arranged in a part of the air duct of the cooling and dehumidification device, and divides the part of the air duct into a direct heat exchange area and an indirect heat exchange area; the cooling water inlet joint sprays cooling water to the partition plate and forms a wall-attached water flow, Scour the partition plate; hot and humid air enters from the bottom of the cooling and dehumidification device, and part of it directly contacts the cooling water in the direct heat exchange area to exchange heat; the other part realizes indirect heat exchange with the cooling water through the partition plate in the indirect heat exchange area. Through the cooling and dehumidification device, the contact area between the cooling water and the hot and humid air is increased without increasing the volume of the heat exchanger, thereby improving the comprehensive condensation heat exchange efficiency.

Owner:GREE ELECTRIC APPLIANCES INC

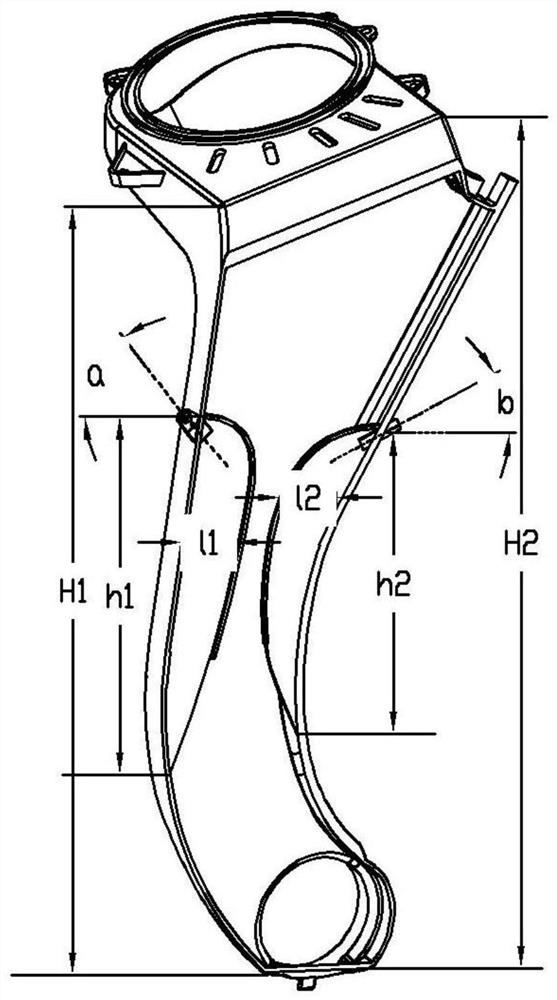

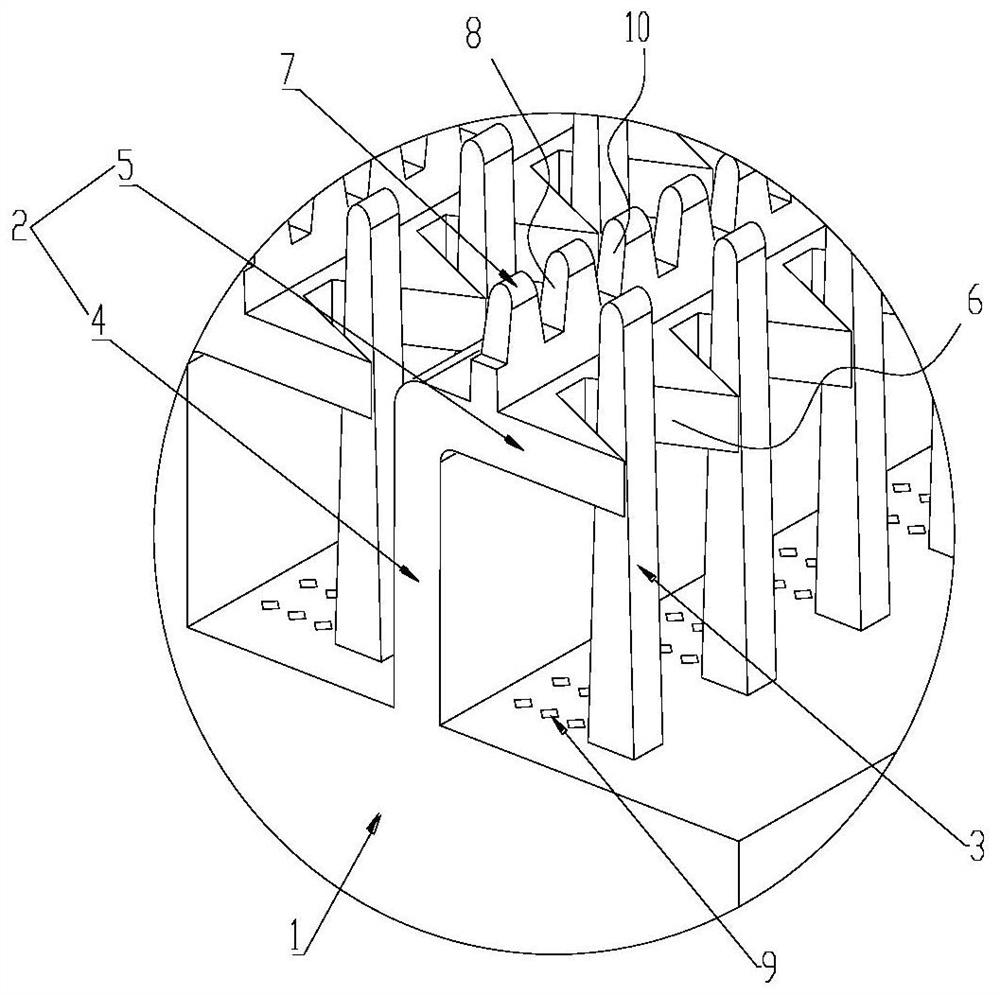

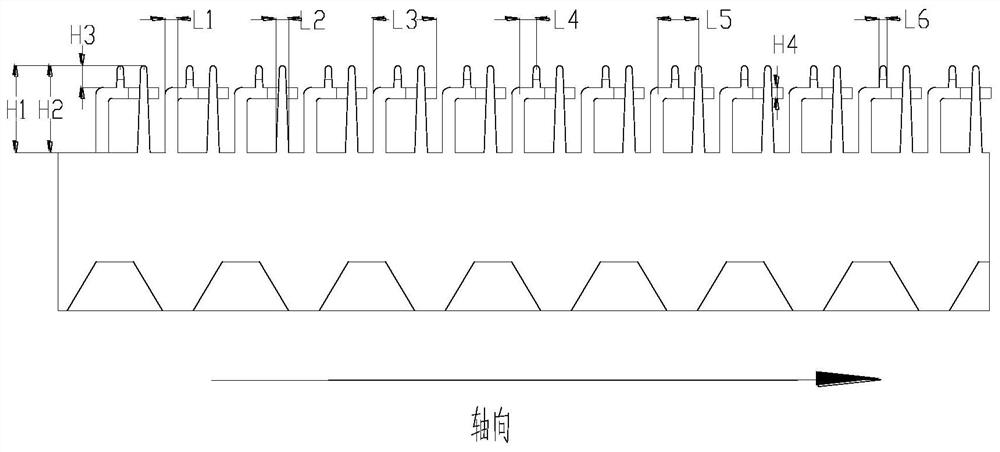

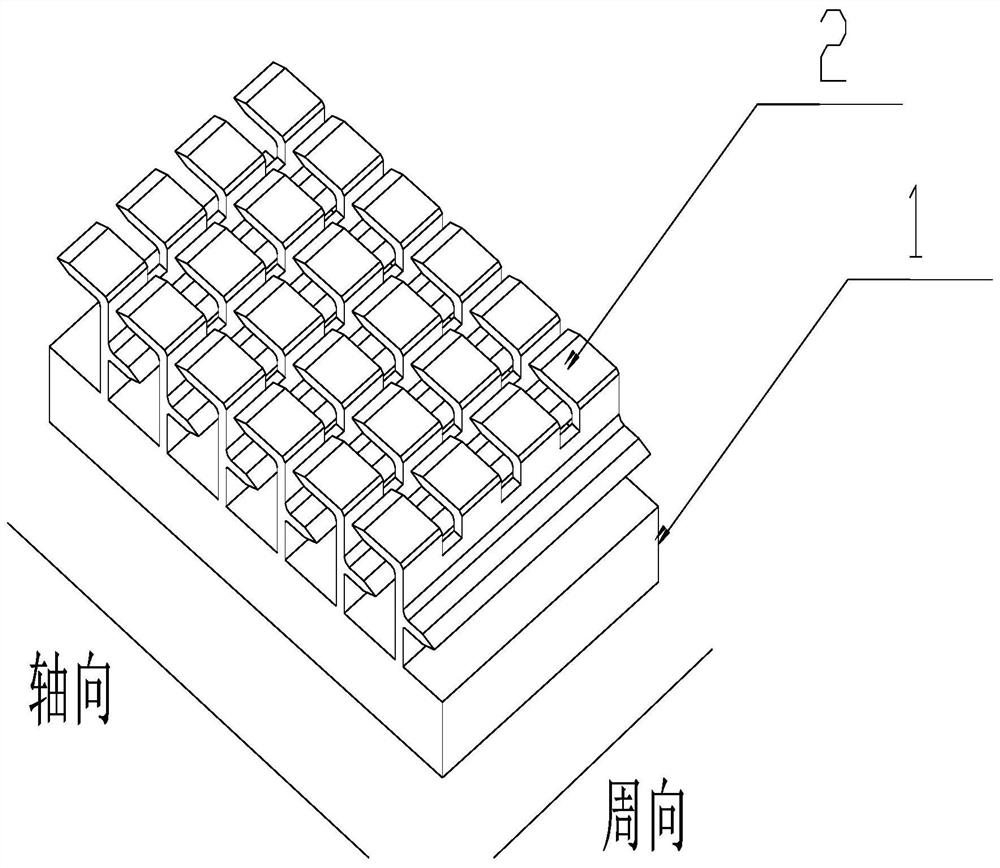

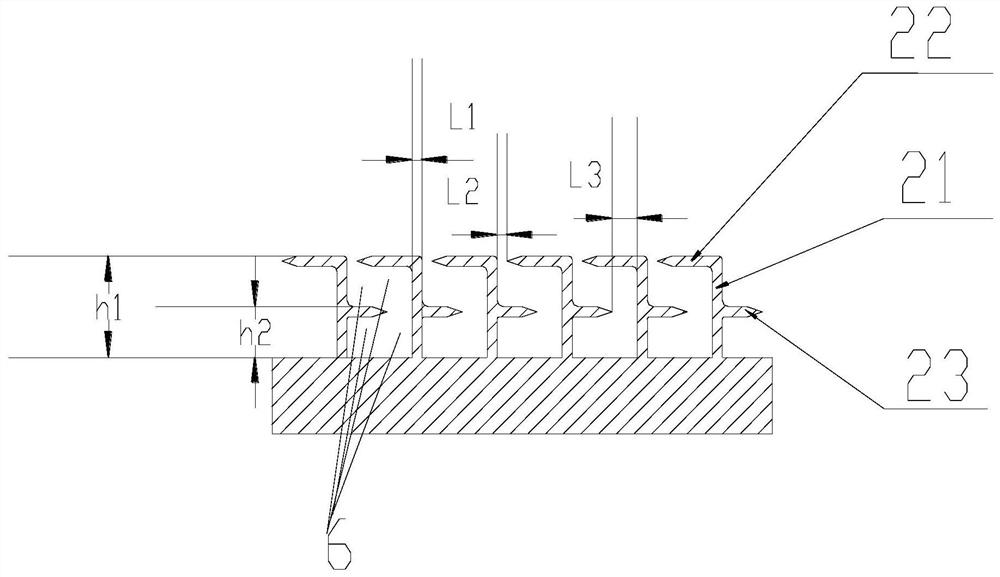

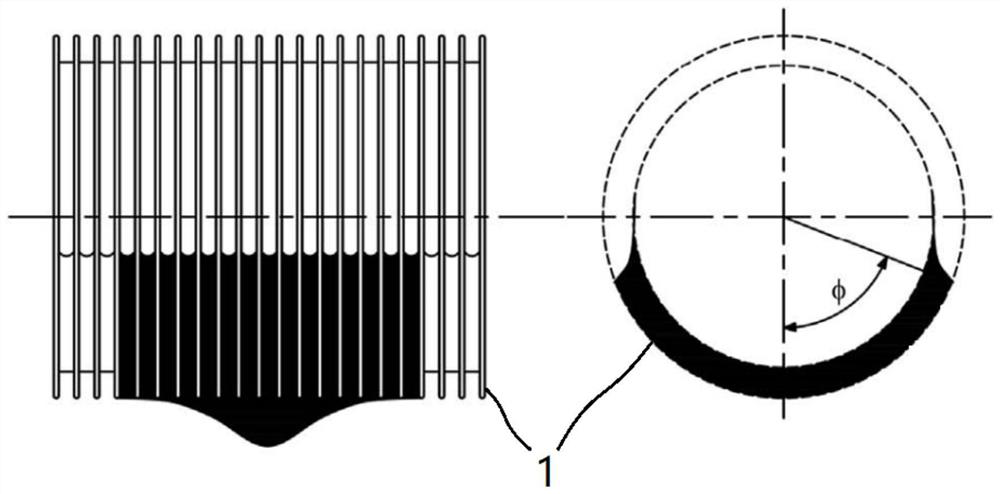

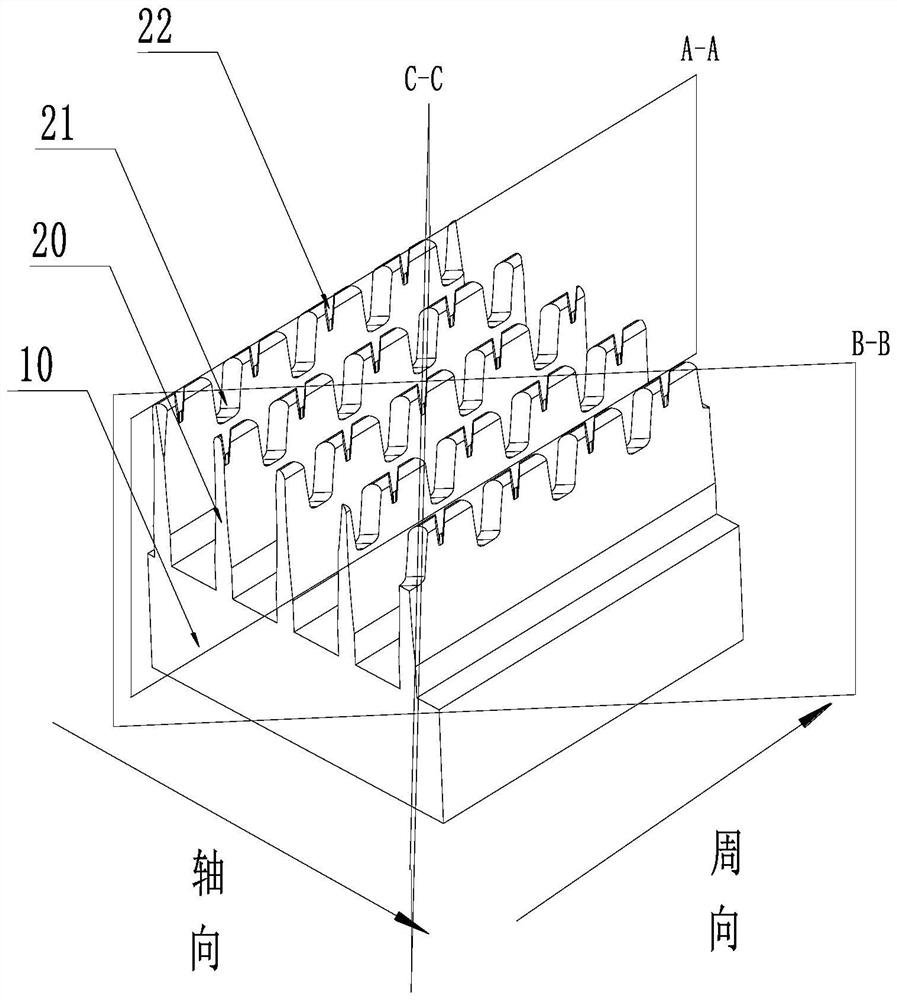

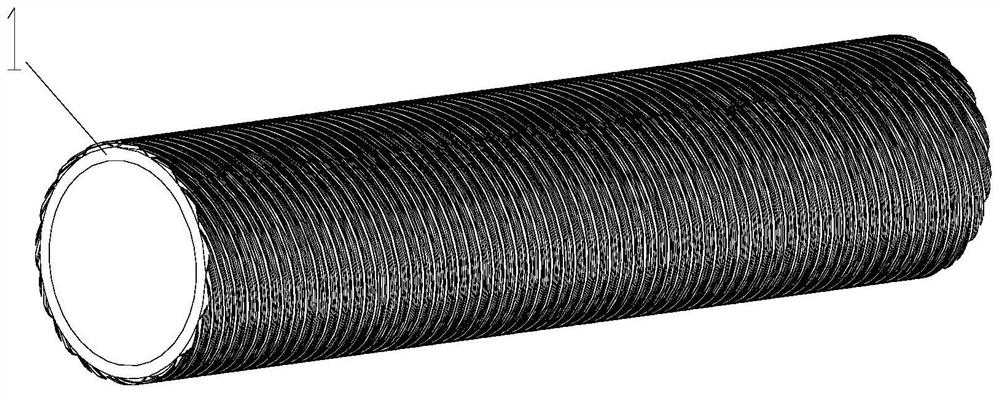

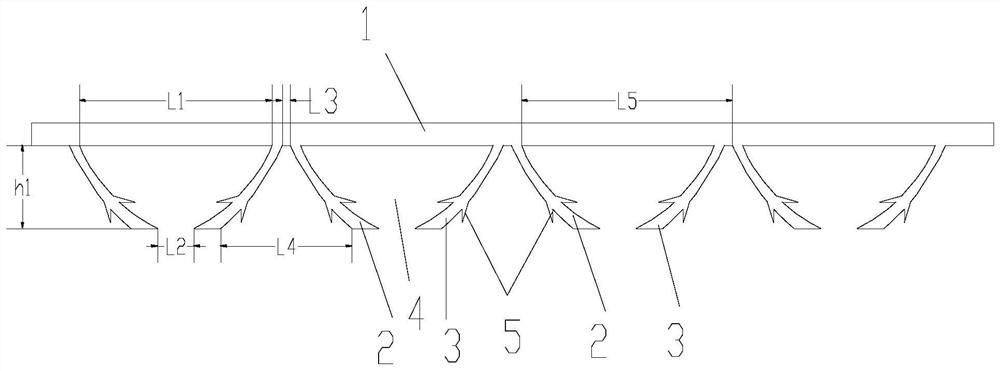

Falling film heat exchange tube, falling film heat exchanger and air conditioner

PendingCN112944976AImprove evaporative heat transfer efficiencyImprove heat transfer efficiency and reduce evaporation heat transfer efficiencyEvaporators/condensersHeat exhanger finsRefrigerationHeat exchanger

The invention provides a falling film heat exchange tube, a falling film heat exchanger and an air conditioner. The falling film heat exchange tube comprises a tube base body (1) and vertical teeth (2) arranged on the outer wall of the tube base body (1), and the vertical teeth (2) extend out from the outer wall of the tube base body (1) in the direction away from the outer wall; and a plurality of vertical teeth (2) are arranged on the tube base body (1), side teeth (5) are further arranged on the side wall between the tops and the bottoms of the vertical teeth (2) in a protruding manner in the horizontal direction, the vertical teeth are arranged in the axial direction and / or the circumferential direction of the tube base body (1), semi-closed evaporation cavities (9) are formed between the adjacent side teeth (5) and the vertical teeth (2), and ribs (6) are further arranged on the upper end faces of the side teeth (5). According to the falling film heat exchange tube, the falling film heat exchanger and the air conditioner, the evaporation heat exchange efficiency of the heat exchange tube and the condensation heat exchange efficiency of the heat exchange tube can be improved under the heating working condition and the refrigeration working condition.

Owner:GREE ELECTRIC APPLIANCES INC

Heat exchange tube, heat exchanger and air conditioner

PendingCN112097562AIncrease the heat transfer area outside the tubeMake full use of the available processing spaceEvaporators/condensersTubular elementsEngineeringRefrigeration

The invention provides a heat exchange tube, a heat exchanger and an air conditioner. The heat exchange tube is characterized in that first fins and second fins are arranged on the outer wall surfaceof a tube base body, each first fin comprises a fin root part perpendicular to the outer wall surface of the tube base body and a fin part parallel to the outer wall surface of the tube base body, each second fin is arranged on the upper part, covered by each fin part, of the tube base body, the tail end of each second fin penetrates out of each fin part, and each fin part is provided with a firstnotch part for the second fin to penetrate through. According to the heat exchange tube, the heat exchange area outside the heat exchange tube is remarkably increased, due to the design that the first notch parts extend upwards from the tube base body and penetrate through the first fins, the machinable space of the surface of the heat exchange tube is fully utilized, under the refrigeration working condition, a semi-closed structure formed by the first fins is beneficial to evaporation of a liquid refrigerant, the second fins increase the uneven degree of the surface to strengthen heat exchange, and under the heating working condition, the second fins can rapidly puncture a condensate film, and condensate can be rapidly discharged to the outer wall face of the tube base body.

Owner:GREE ELECTRIC APPLIANCES INC

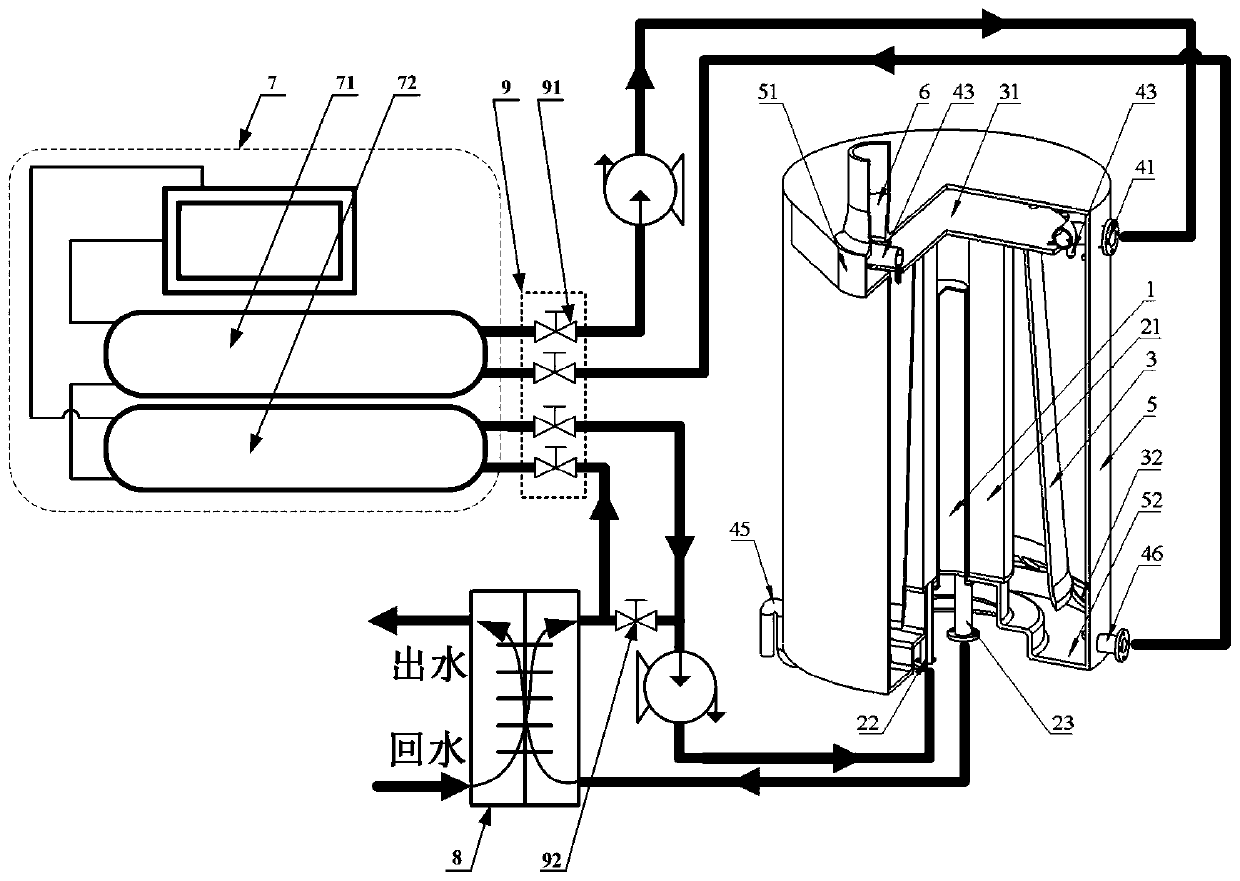

Efficient condensation gas water heater for mixed heat exchange and system

PendingCN110645709AReduce the temperatureImprove condensation heat transfer efficiencyAir heatersStationary conduit assembliesSmoke hoodHeat pump

The invention discloses an efficient condensation gas water heater for mixed heat exchange and a system. The water heater comprises a combustor, a heat exchanger, an equal-pressure smoke cover for separating a spraying system for direct contact heat exchange from the heat exchanger, and a chimney; through reasonable thermal performance design, high-temperature smoke is cooled after heat exchange by the heat exchanger, and no condensed water is generated; due to no need to consider the condensed water corrosion of the heat exchanger, the material grade and the process cost of a dividing wall heat exchange device can be reduced; the spraying system for direct contact heat exchange atomizes and sprays out cyclic spraying liquid to fully absorb latent heat of low-temperature smoke; the cyclicspraying liquid can adopt organic working mediums or water working mediums with safety, no poison, low viscosity and dewatering property; the efficient condensation gas water heater is connected witha heat pump to form an efficiency improvement and energy conservation system, so that the temperature of the cyclic spraying liquid is lowered, the condensation heat transfer efficiency of the low-temperature smoke is further improved, and the overall operation efficiency of the water heater and the system is improved; and the efficient condensation gas water heater effectively improves the overall system operation efficiency, and further reduces the smoke carbon emission through a spraying system.

Owner:XI AN JIAOTONG UNIV

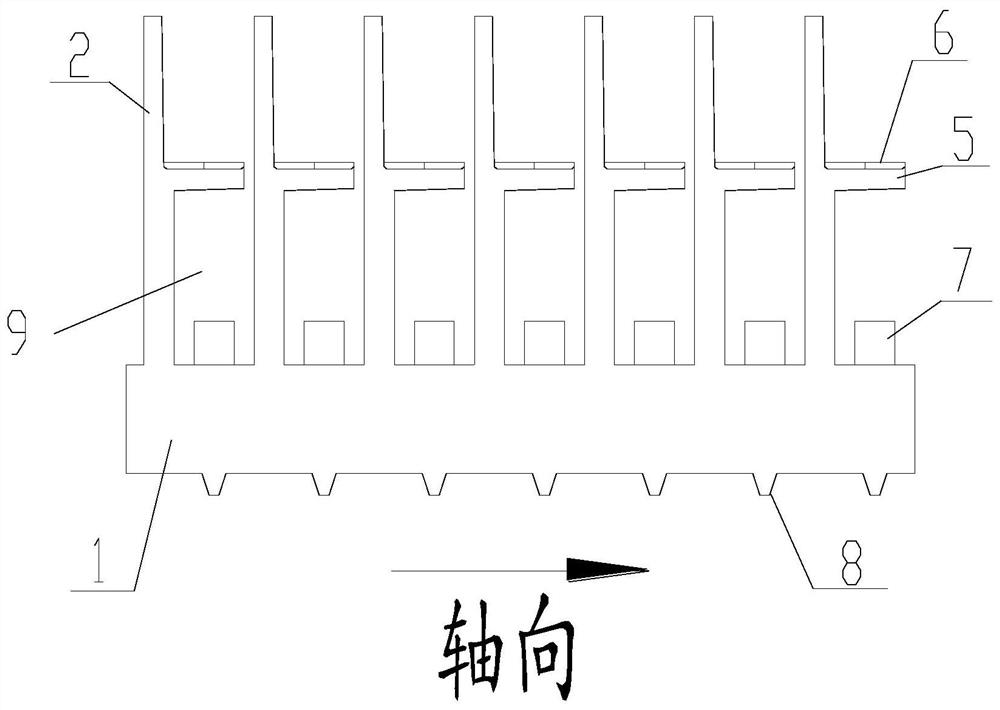

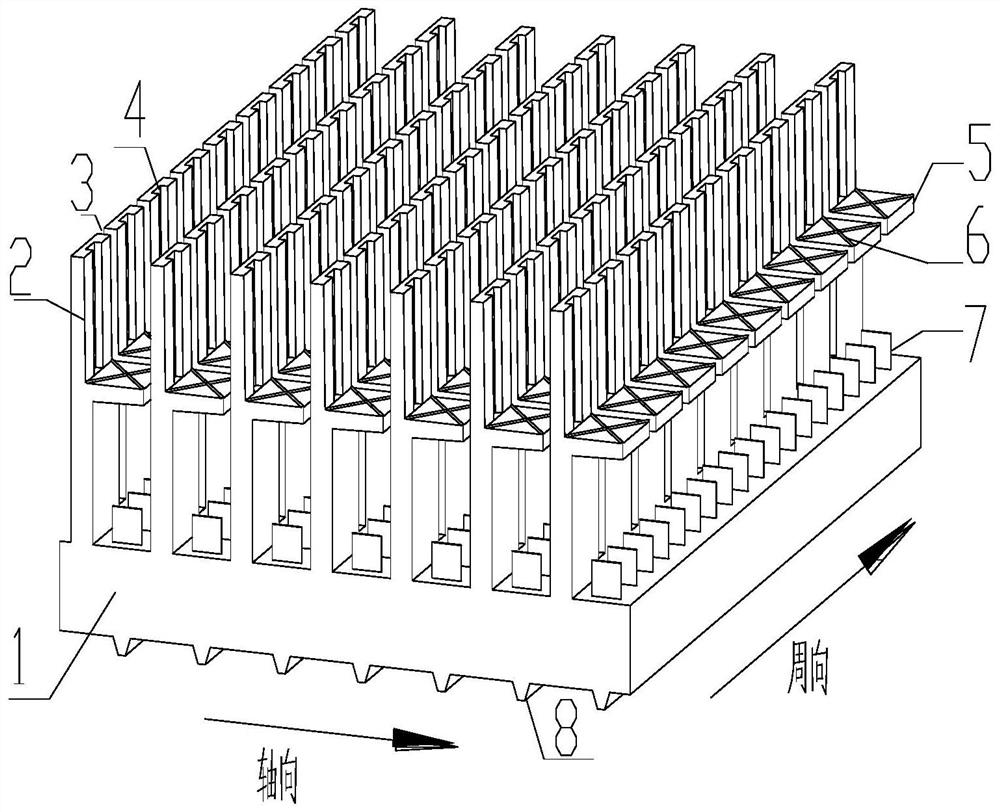

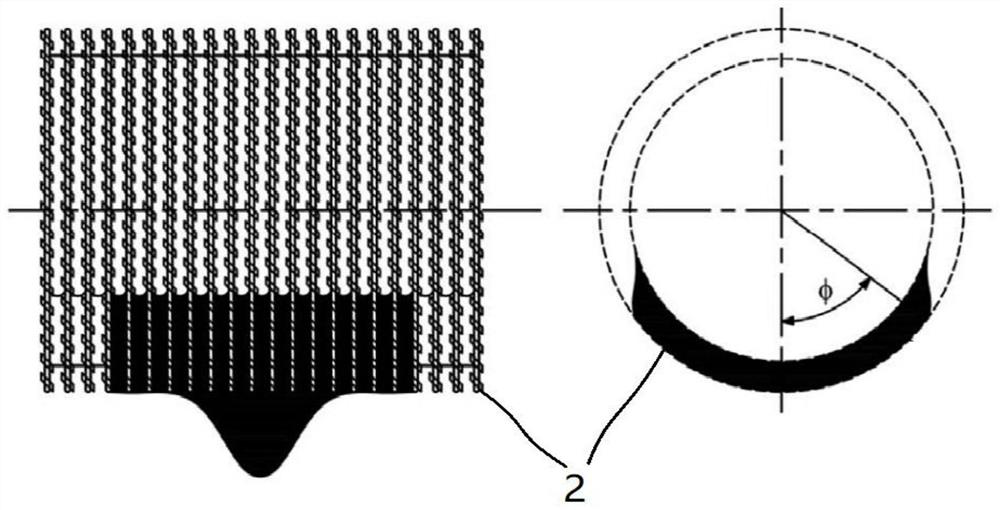

Falling film heat exchange tube, falling film heat exchanger and air conditioner

PendingCN112944974AExpand volume spaceImprove evaporative heat transfer effectEvaporators/condensersHeat exhanger finsEngineeringHeat exchanger

The invention provides a falling film heat exchange tube, a falling film heat exchanger and an air conditioner. The falling film heat exchange tube comprises a tube base body and vertical teeth arranged on the outer wall of the tube base body, the vertical teeth extend out of the outer wall of the tube base body in the direction away from the outer wall, and first side teeth horizontally protruding in the first direction are arranged at the tops of the vertical teeth; second side teeth are further arranged on the side walls between the tops and the bottoms of the vertical teeth in a protruding manner in the second direction, and the first direction is opposite to the second direction; the multiple vertical teeth are arranged in the axial direction and / or the circumferential direction of the tube base body; and semi-closed evaporation cavities can be formed between the first side teeth and the vertical teeth which are adjacent, between the first side teeth and the second side teeth which are adjacent, between the second side teeth and the vertical teeth which are adjacent, between the first side teeth and the vertical teeth which are connected with each other, and between the second side teeth and the vertical teeth which are connected with each other. According to the falling film heat exchange tube, the evaporation heat exchange efficiency of the heat exchange tube and the condensation heat exchange efficiency of the heat exchange tube can be improved under the heating working condition and the refrigeration working condition.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

Heat exchange tube and air conditioner

PendingCN111678374ASpeed up the flowReduced stagnation zoneEvaporators/condensersHeat exhanger finsCondensation heat transferEngineering

The invention provides a heat exchange tube and an air conditioner. The heat exchange tube comprises a tube body and fins arranged on the tube body. A first notch and a second notch are formed in thetop of each fin. The depth of each first notch is larger than that of the corresponding second notch. The extending direction of each first notch is arranged at a positive angle relative to the circumferential direction of the corresponding fin. The extending direction of each second notch is arranged at a negative angle relative to the circumferential direction of the corresponding fin. By the adoption of the technical scheme, the bridging phenomenon of liquid between the fins can be weakened, more liquid can flow along with dripping condensate between the adjacent fins, and therefore the condensate retention area is further reduced, the retention angle is further reduced, the heat transfer area of steam and the tube body is increased, and the condensation heat transfer efficiency is improved.

Owner:GREE ELECTRIC APPLIANCES INC

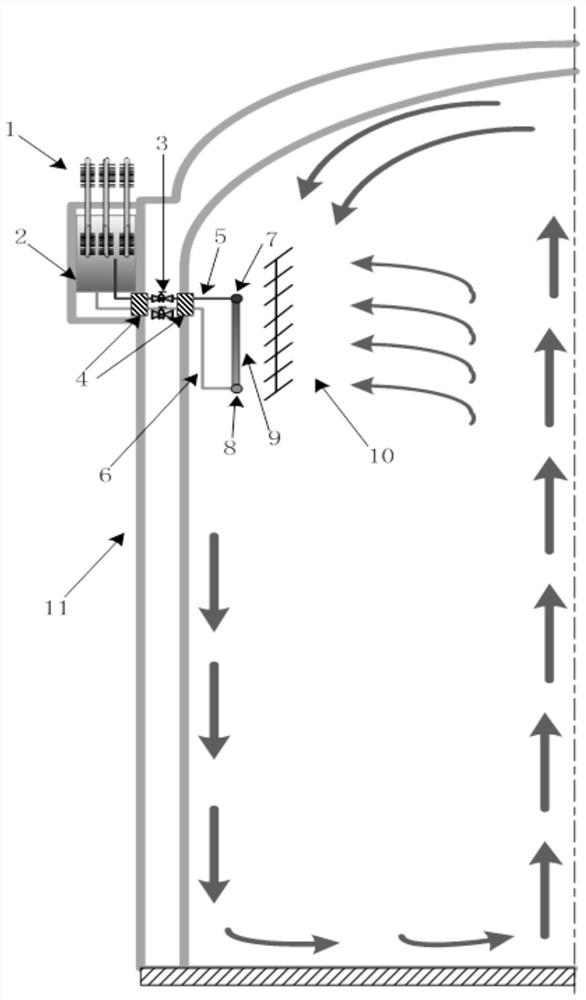

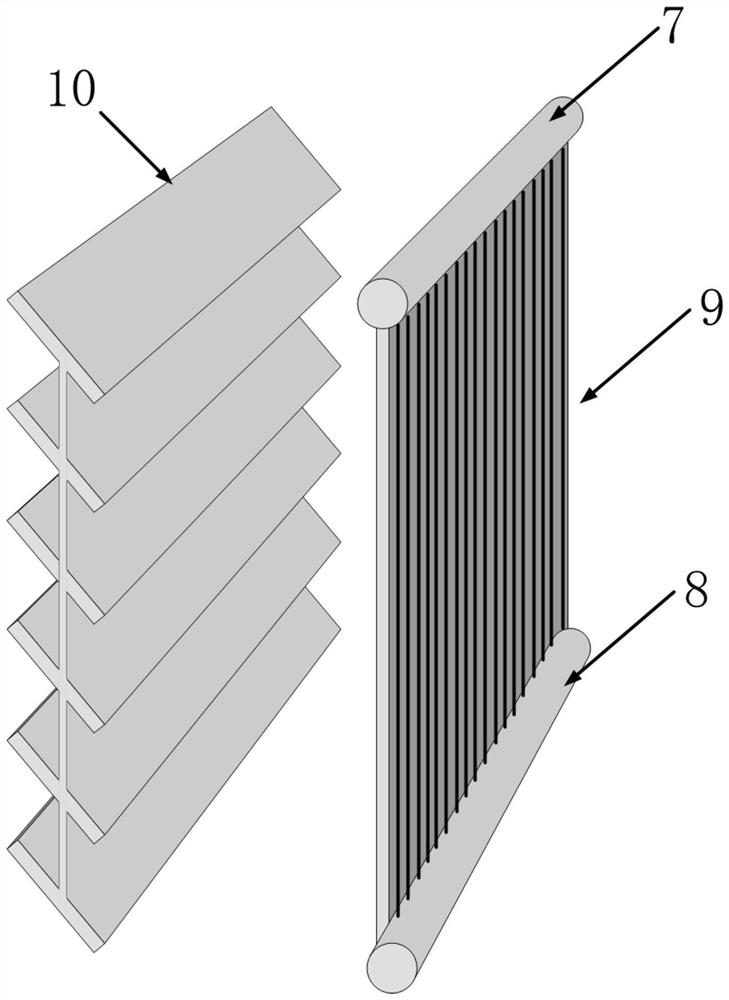

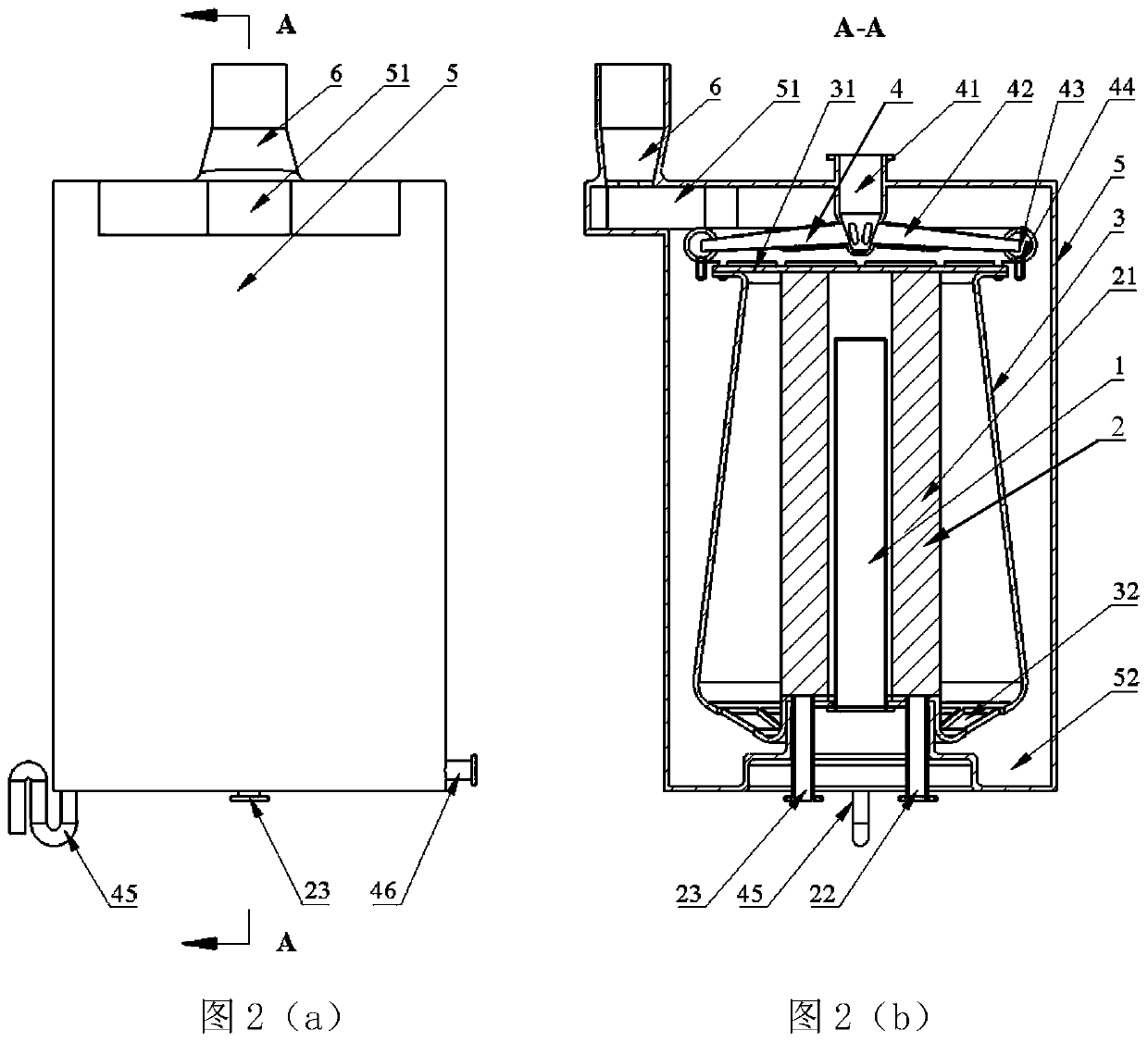

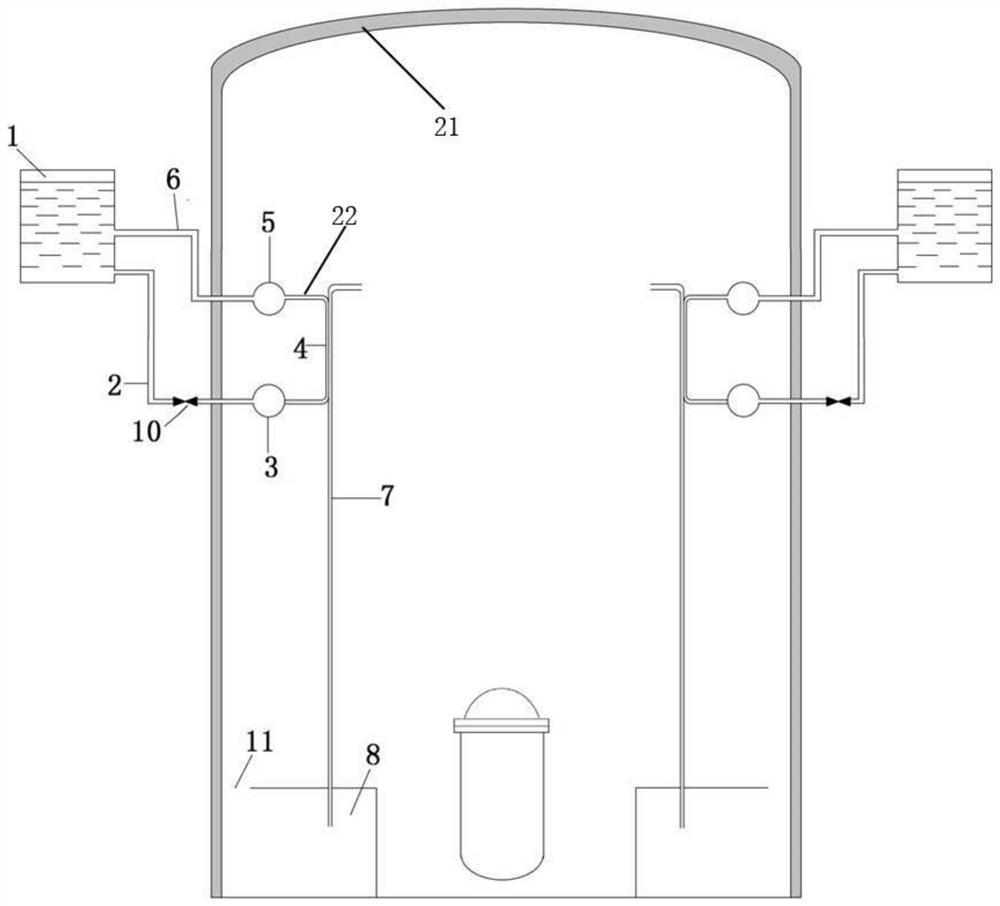

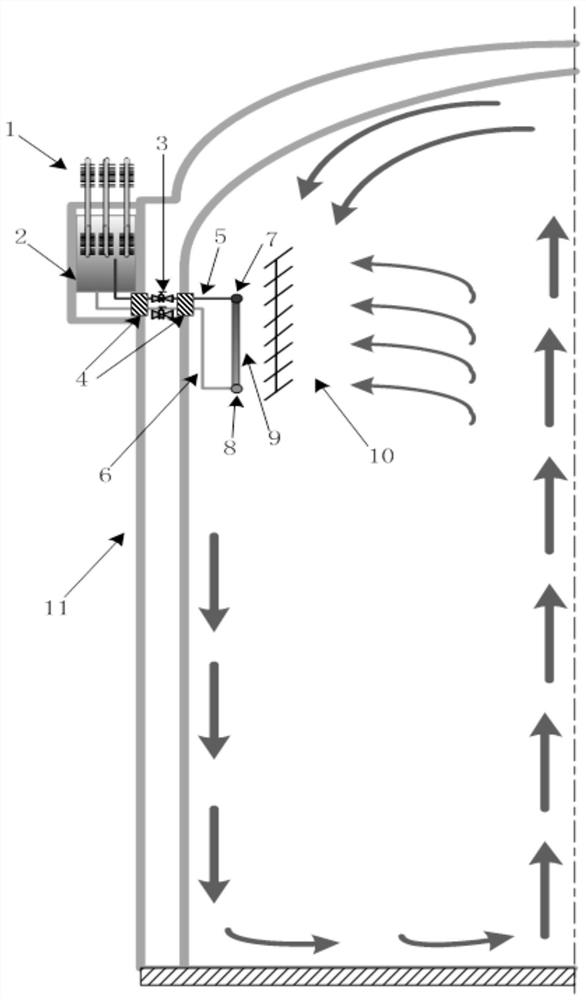

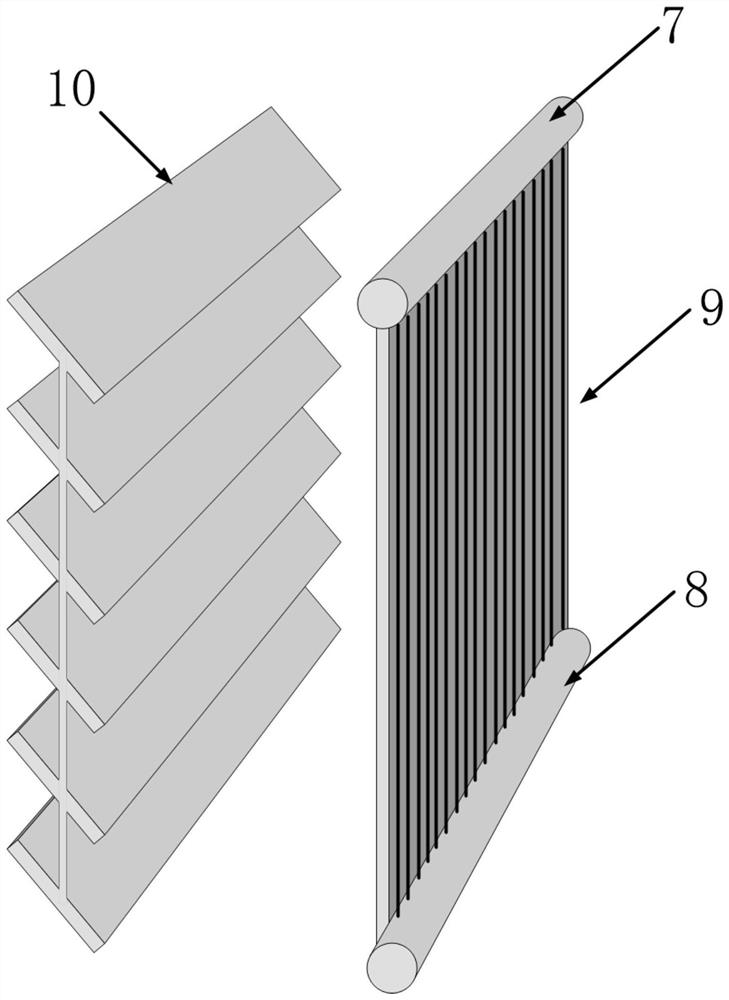

A passive containment heat export system

ActiveCN107170493BImprove condensation heat transfer efficiencyReduced non-condensable gas contentNuclear energy generationCooling arrangementHoneycombProcess engineering

The invention belongs to the technical field of nuclear safety control, and relates to a heat removing system for a passive containment system. The heat removing system comprises a containment and a heat removing component, wherein the heat removing component comprises an external coolant liquid tank for the containment, a circulating pipeline, a heat exchanger unit, a mixed gas honeycomb duct and an air retention box; the heat-exchanger unit is arranged in the containment and comprises a heat exchanger tube, a coolant liquid inlet for the heat-exchanger unit and a coolant liquid outlet for the heat exchanger unit; the circulating pipeline is divided into two sections; the external coolant tank for the containment is arranged outside the containment, and the arranging position of the coolant liquid tank is higher than that of the heat exchanger unit; the mixed gas honeycomb duct is arranged in the containment; two ends of the mixed gas honeycomb duct are opened, and at least one section of the mixed gas honeycomb duct makes contact with at least one section of the heat exchange tube through a contact face; the air retention box is arranged in a lower space of the containment and is provided with an opening hole. By using the heat removing system disclosed by the invention, the heat removing efficiency of the passive containment system can be improved by improving the condensation and heat transfer efficiency.

Owner:CHINA NUCLEAR POWER ENG CO LTD

A passive containment heat export system with diversion structure

ActiveCN113140336BImprove mobilityImprove heat transfer efficiencyNuclear energy generationCooling arrangementNuclear reactorEngineering

The invention relates to the field of passive safety systems for nuclear reactors, in particular to a passive containment heat export system with a flow guiding structure. The system is arranged on the inner and outer sides of the containment, including the inner part of the containment and the outer part of the containment; the inner part of the containment is located on the upper part of the inner side wall of the containment, and the main body includes an internal heat exchanger and a flow guiding structure; the said The outer part of the containment is located above the outer sidewall of the containment, and the main structure includes an external cooling water tank and a steam-water separator; the inner part of the containment and the outer part of the containment are connected by pipelines and valves. According to the characteristics of gas flow distribution in the containment under accident conditions, the invention effectively improves the gas flow near the internal heat exchanger of the PCS by arranging a diversion structure near the heat exchanger, and reduces the accumulation of non-condensable gas near the internal heat exchanger. The deteriorating effect of condensation heat exchange, and the heat exchange efficiency of PCS is improved.

Owner:CHINA NUCLEAR POWER ENG CO LTD

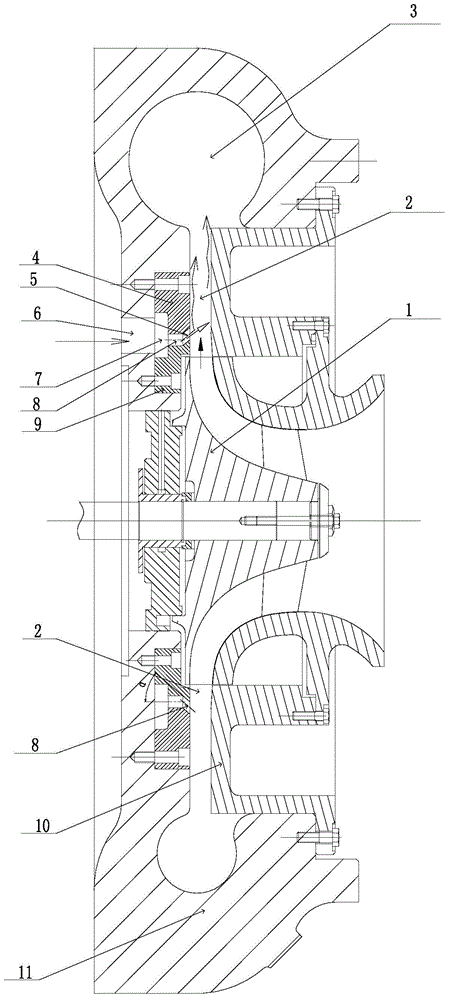

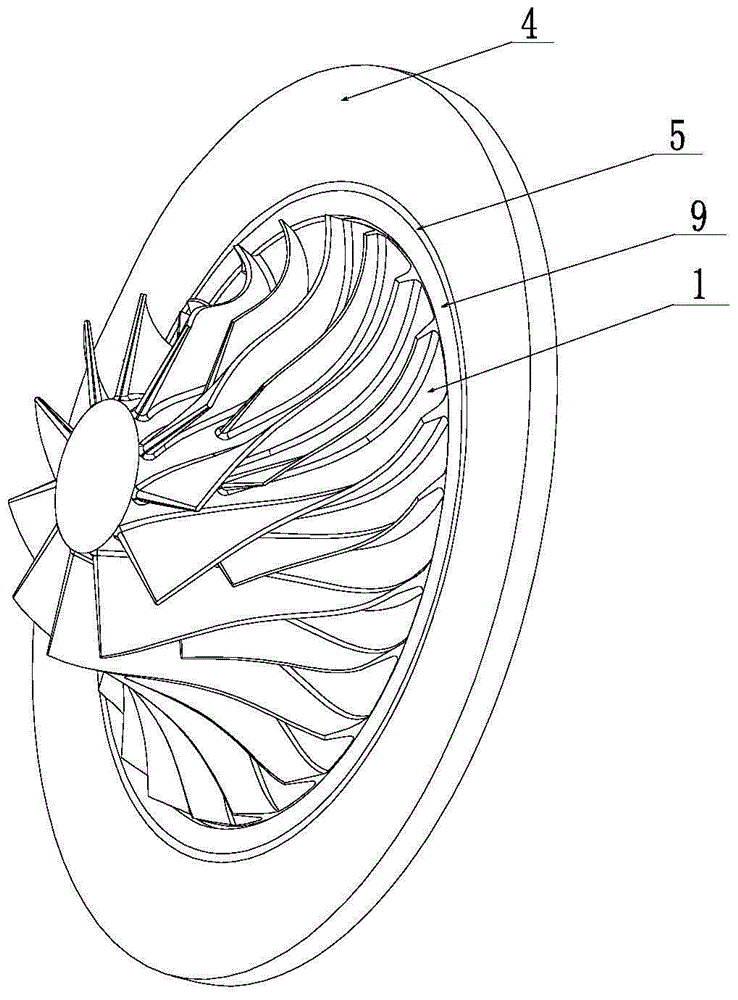

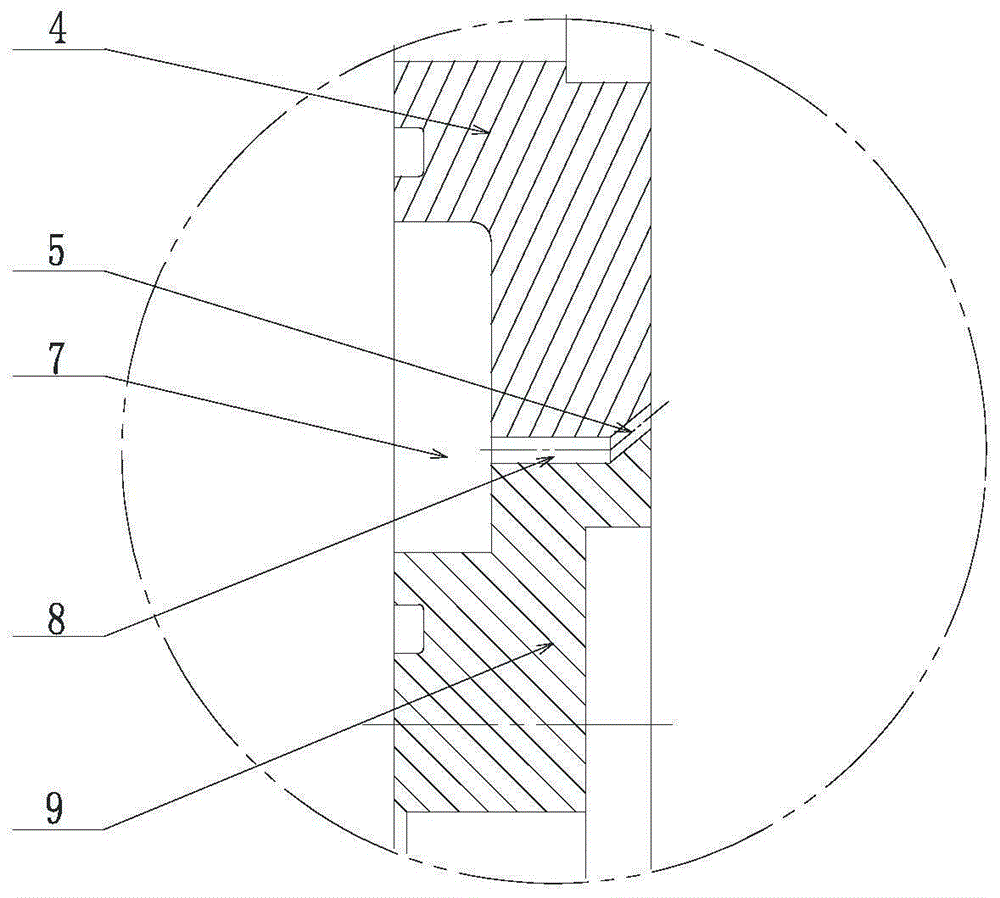

Micro annular seam liquid film noise reduction device for centrifugal compressor

ActiveCN103498817BEffective isolationEffective absorptionPump componentsPumpsEngineeringNoise reduction

Owner:乐金空调(山东)有限公司

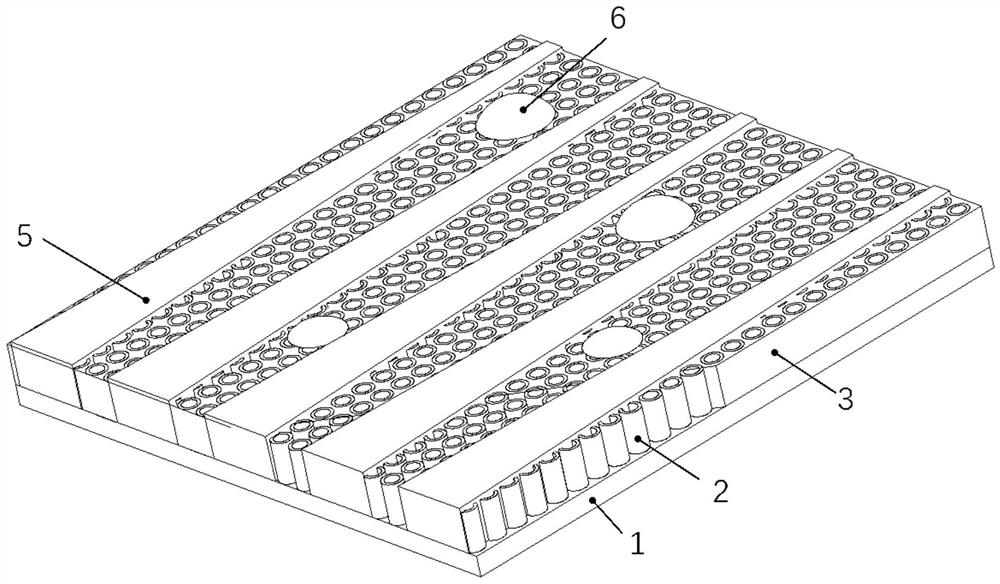

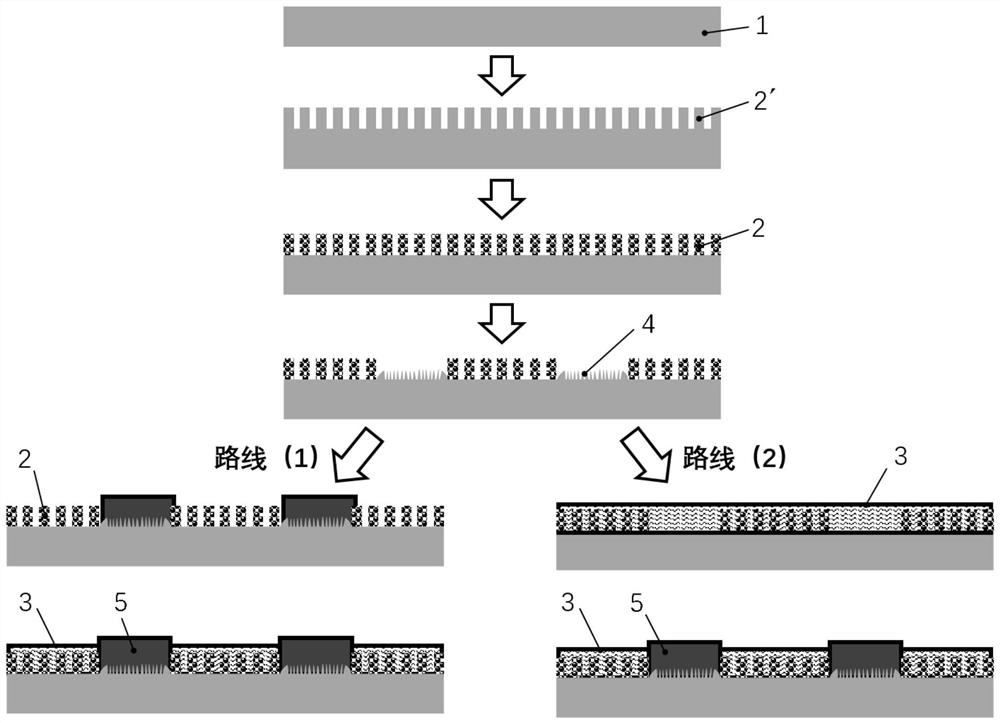

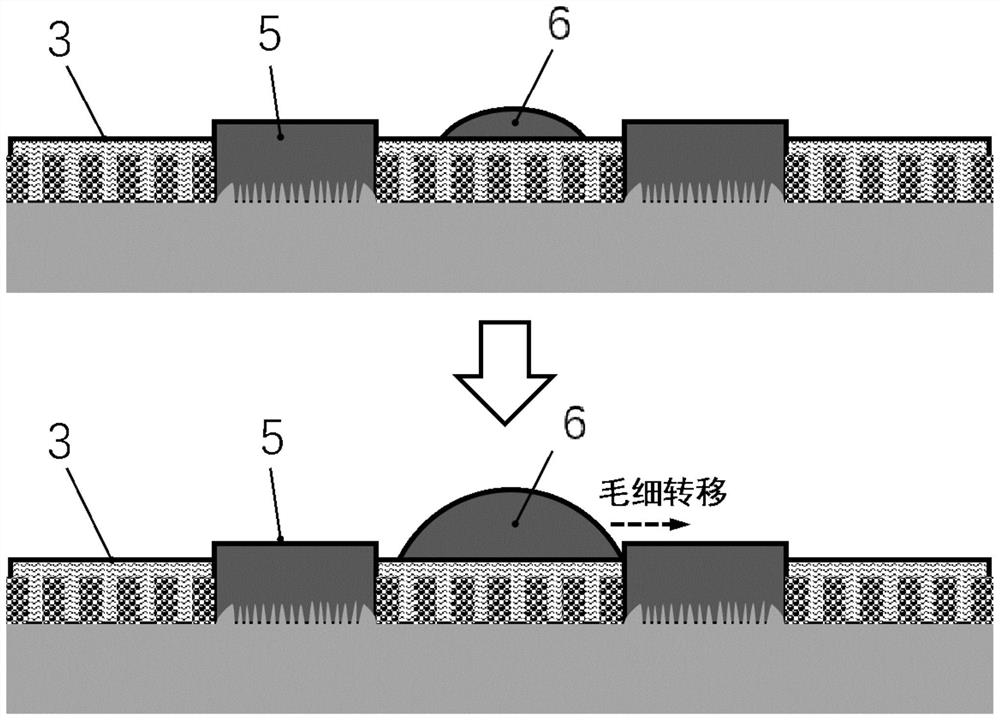

A super-lyophilic-super-slippery patterned surface and its processing method for enhancing droplet condensation heat transfer

ActiveCN113102200BIntegrated capillary capacityIntegrated Steady-State Droplet Condensation FeatureAnodisationPretreated surfacesLiquid layerNano structuring

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

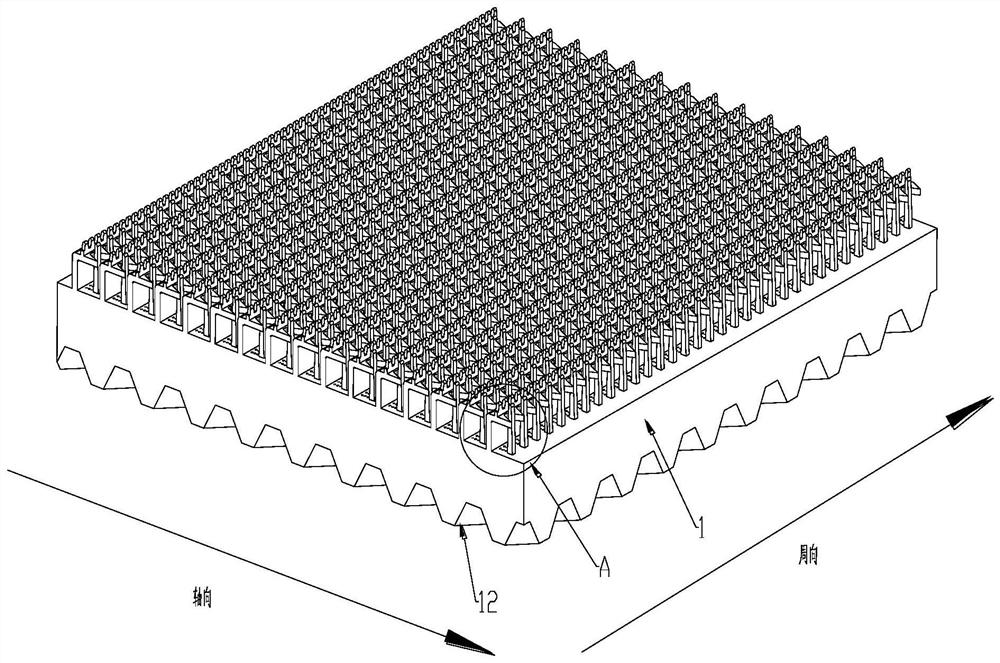

Flooded heat exchange tube, flooded heat exchanger and air conditioner

PendingCN112944982AImprove evaporative heat transfer efficiencyImprove condensation heat transfer efficiencyEvaporators/condensersHeat exhanger finsEngineeringThermal efficiency

The invention provides a flooded heat exchange tube, a flooded heat exchanger and an air conditioner. The flooded heat exchange tube comprises a tube base body (1), first teeth (2) and second teeth (3), wherein the first teeth (2) and the second teeth (3) are arranged on the outer wall of the tube base body (1); the first teeth (2) extend out from the outer wall of the tube base body (1) in the direction away from the outer wall and facing the second teeth (3); the second teeth (3) extend out from the outer wall of the tube base body (1) in the direction away from the outer wall and facing the first teeth (2); a semi-closed evaporation cavity (4) is formed between the first teeth (2) and the second teeth (3); and the first teeth (2) and / or the second teeth (3) are further provided with fin tips (5) protruding outwards. By means of the flooded heat exchange tube, the flooded heat exchanger and the air conditioner, the evaporation heat exchange efficiency and the condensation heat exchange efficiency of the heat exchange tube can be improved under the heating work condition and the refrigeration work condition, and the machining difficulty of the heat exchange tube is effectively lowered.

Owner:GREE ELECTRIC APPLIANCES INC

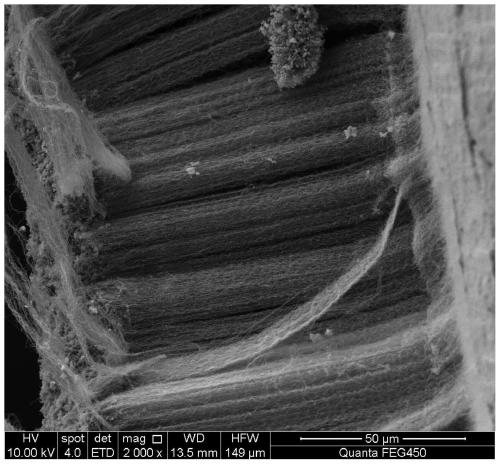

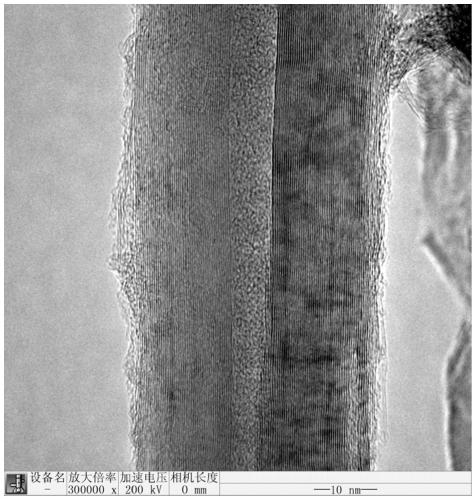

A simple method and application of directly growing carbon nanotube arrays on metal

ActiveCN107400928BSimple reaction conditionsImprove bindingPolycrystalline material growthFrom chemically reactive gasesTube furnaceCarbon nanotube

A simple method and application for directly growing carbon nanotube arrays on metals, which relates to a method and application for modifying metal surfaces. The purpose of the present invention is to solve the low structural strength of existing carbon nanotubes and silicon substrates, it is difficult to grow carbon nanotubes on metal substrates and the risk of carrier gas used to grow carbon nanotubes on the alloy surface, the solvent is highly toxic, and is not suitable for industrialization problem of promotion. Method: 1. Etching treatment; 2. Introduce nitrogen gas and start the tube furnace; 3. Inject the mixture of ferrocene and cyclohexane and react for 30min to 120min; 4. Close the tube furnace and let it naturally Cool to room temperature to obtain a metal substrate with carbon nanotube arrays grown on the surface. The shear bonding strength of the carbon nanotube array prepared by the invention and the metal base reaches 0.95 MPa. The invention can obtain a simple method for directly growing the carbon nanotube array on the metal.

Owner:NORTHEAST GASOLINEEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com