Falling film heat exchange tube, falling film heat exchanger and air conditioner

A technology of heat exchange tubes and heat exchangers, which is applied in the direction of evaporators/condensers, heat sinks, tubular elements, etc., can solve the problems of low heat exchange efficiency of falling film heat exchange tubes, so as to prevent the efficiency of evaporators from decreasing and improve Heat exchange efficiency, effect of ensuring directivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

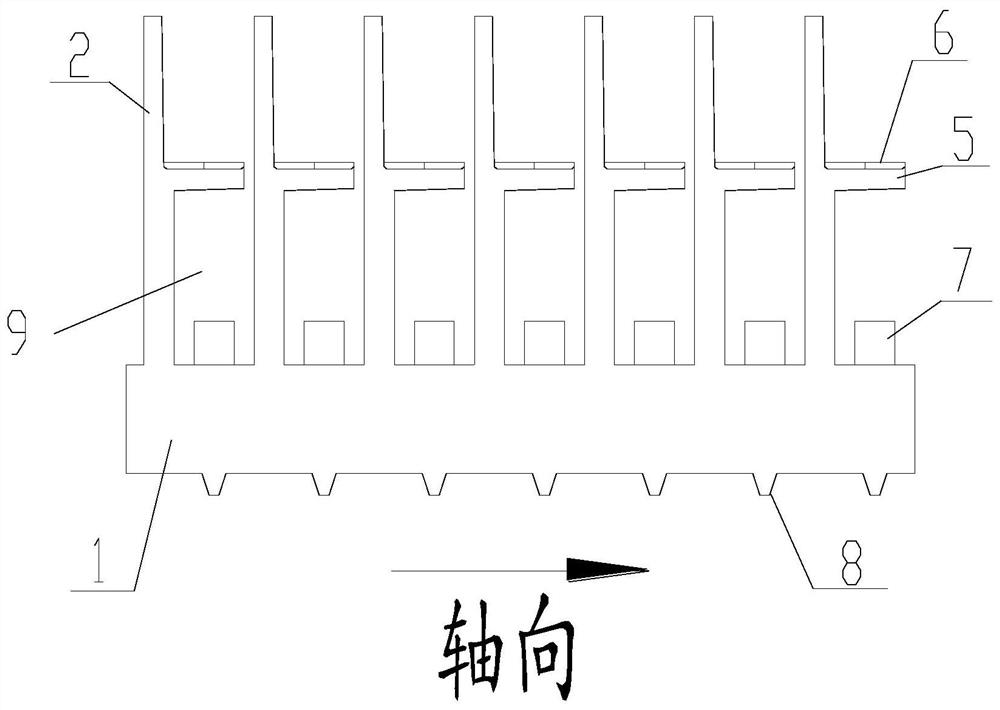

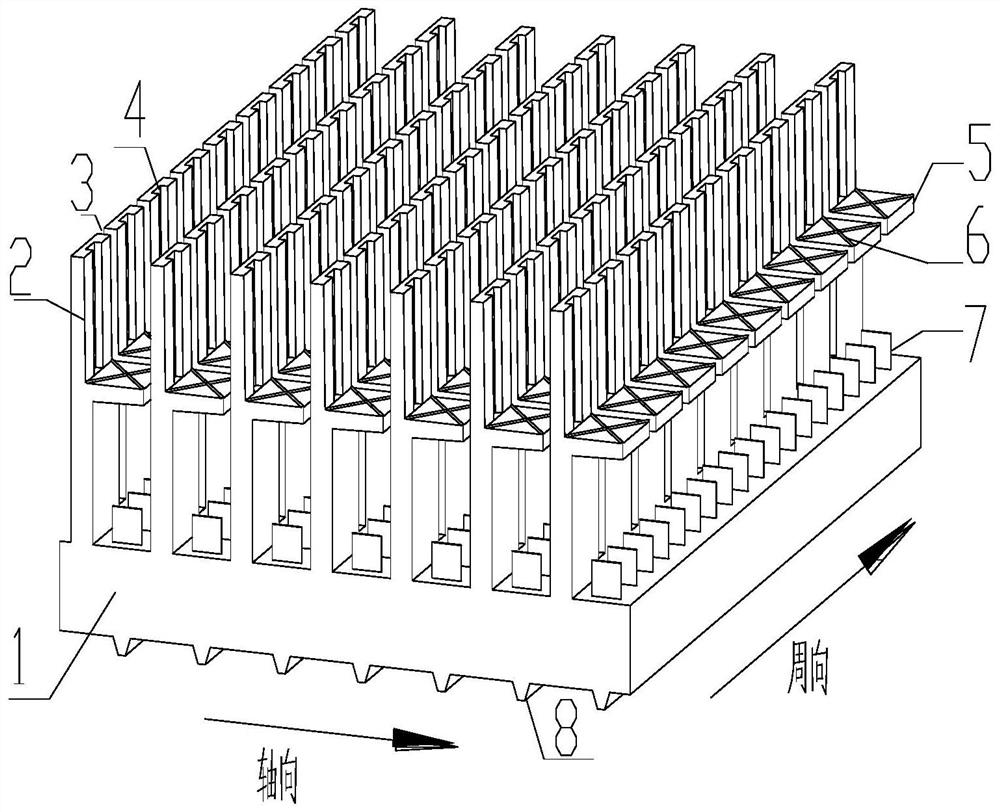

[0040] Such as Figure 1-2 Shown, the present invention provides a kind of falling film heat exchange tube, it comprises:

[0041]The tube base 1 and the vertical teeth 2 arranged on the outer wall of the tube base 1, the vertical teeth 2 protrude from the outer wall of the tube base 1 in a direction away from the outer wall, at the top of the vertical teeth 2 and On the side wall between the bottoms and protruding in the horizontal direction, side teeth 5 are provided. There are multiple vertical teeth arranged along the axial and / or circumferential direction of the tube base 1. A semi-closed evaporation chamber 9 is formed between the side teeth 5 and the vertical teeth 2, and ribs 6 are also arranged on the upper end surface of the side teeth 5.

[0042] In the present invention, through the vertical teeth arranged on the outer wall of the tube base and the side teeth extending laterally on the side walls of the vertical teeth, a semi-closed evaporation chamber can be form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com