Technique for preparing ammonium chloride by employing sodium bicarbonate production wastewater as raw material

A process method, baking soda technology, applied in the direction of ammonium halide, alkali metal chloride, etc., can solve the problems of high production cost, high energy consumption, low thermal efficiency, etc., achieve production cost reduction, increase heat transfer area, evaporation transfer The effect of high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

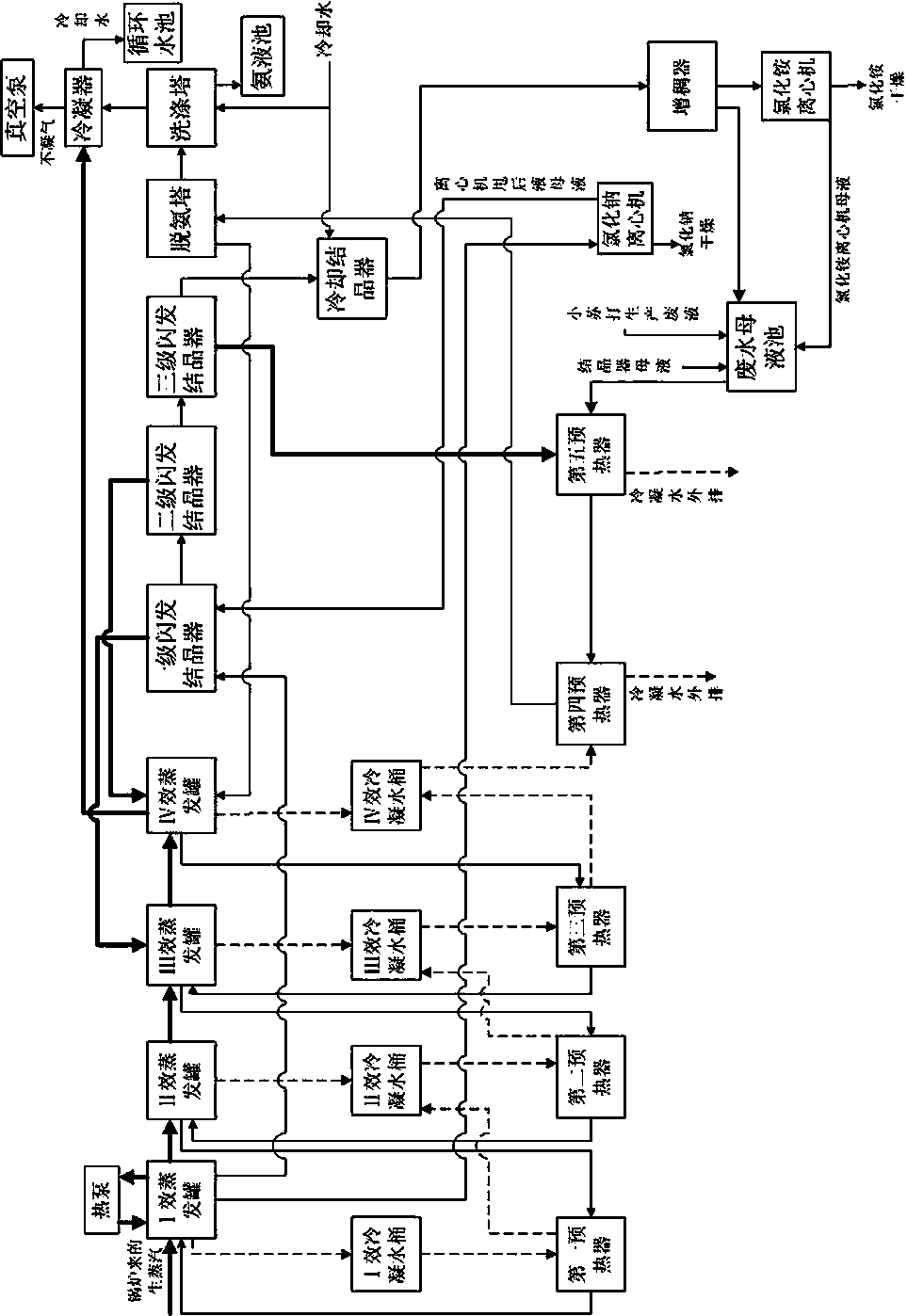

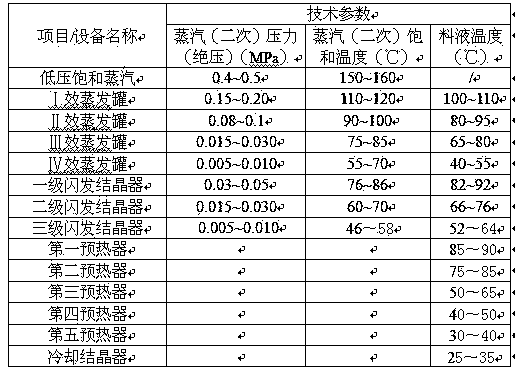

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0026] figure 1 In , the thick solid line represents steam, the thin solid line represents liquid, and the dashed line represents condensed water.

[0027] refer to figure 1 A kind of process of preparing ammonium chloride as a raw material with baking soda production waste liquid of the present embodiment, the steps are as follows:

[0028] 1) Baking soda production waste liquid enters the waste water mother liquor pool, is pumped into the fifth preheater, and then enters the fourth preheater. After heating up to 45°C, it enters the deamination tower for deammonization, and the ammonia gas enters the washing tower. The tail gas enters the condenser, and the ammonia liquid is sent to the ammonia liquid pool;

[0029] 2) The preheated mother liquor is pumped from the deamination tower into the IV effect evaporation tank, evaporated and concentrated (t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com