Bionic surface structure for strengthening evaporation heat exchanging of liquid film

A surface structure, film evaporation technology, applied in heat transfer modification, heat exchange equipment, lighting and heating equipment, etc., can solve problems such as deterioration of heat and mass transfer effects, temporary or permanent rupture of liquid film, and achieve uniform spreading, The effect of reducing the thickness of the liquid film and reducing the heat transfer resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

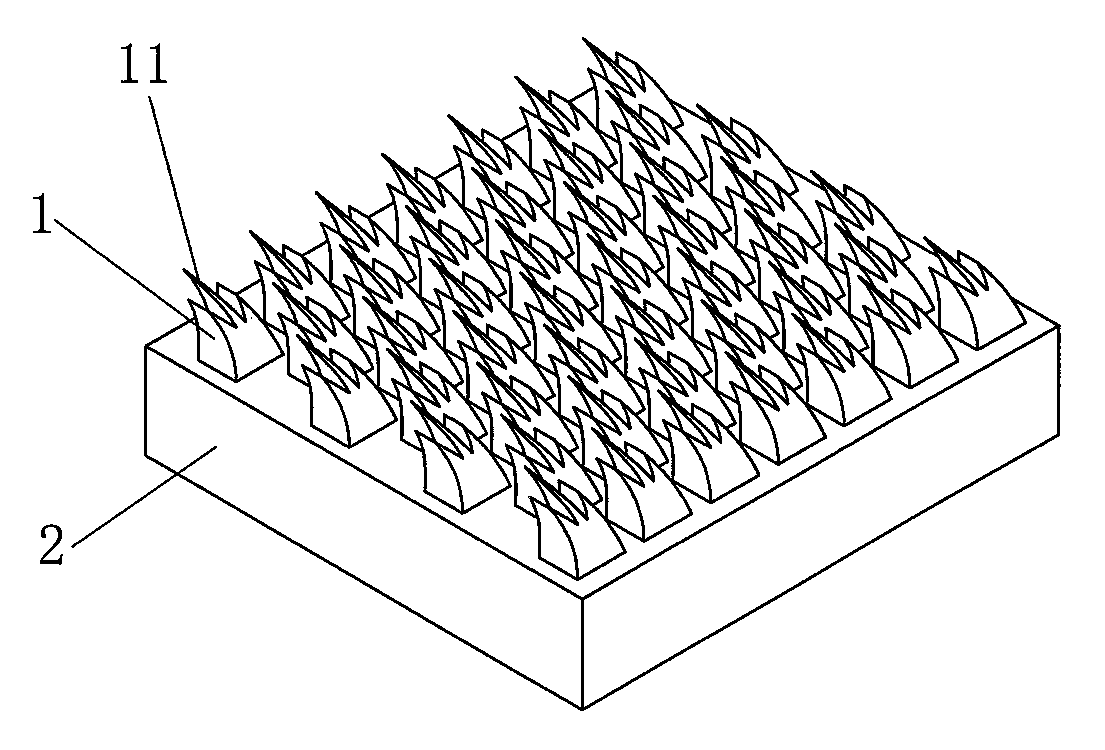

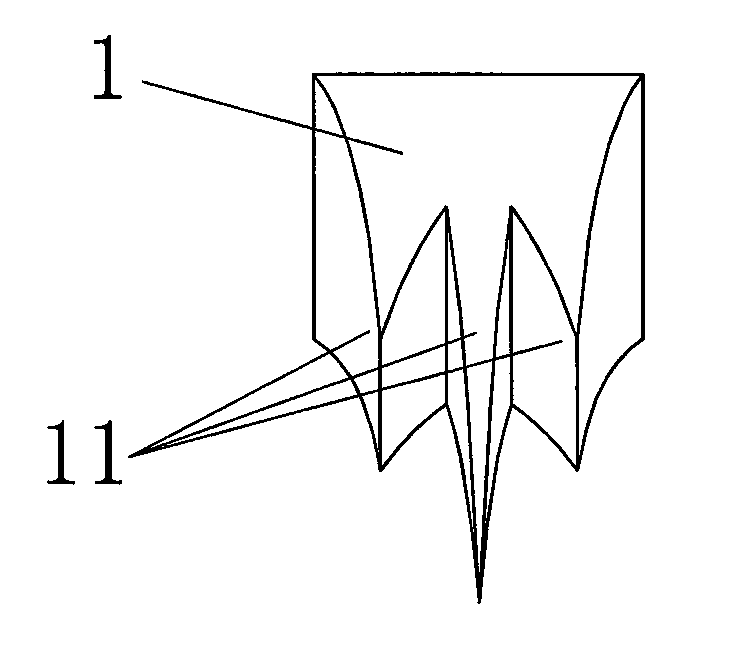

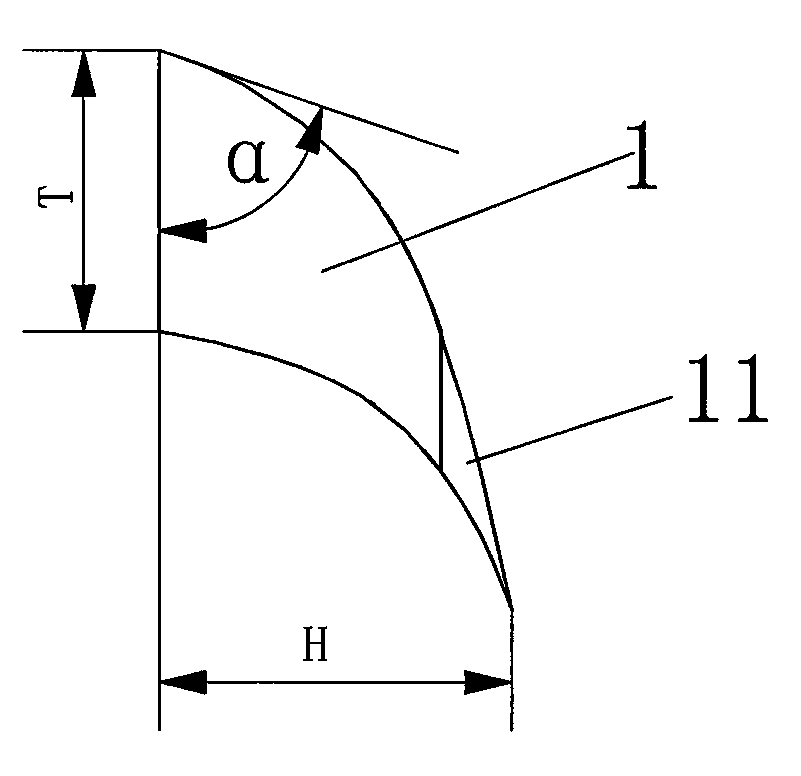

[0023] see figure 1 , figure 2 , image 3 and Figure 4 As shown, in this embodiment, three-dimensional bionic zigzag unit bodies 1 are distributed on the substrate surface 2 of the heat transfer tube or heat transfer plate. overlapping each other and closely arranged, the angle β between the side of the three-dimensional bionic zigzag unit body 1 and the horizontal direction is 70-90°; the width W of the three-dimensional bionic zigzag unit body 1 is 0.2-1mm, and the three-dimensional bionic zigzag unit The thickness T of the zigzag unit body 1 is 0.2-1 mm, and the height H of the three-dimensional bionic zigzag unit body 1 is 0.3-1.2 mm; the three-dimensional bionic zigzag unit body 1 is in an inclined state, and its inclination direction is in line with the flow direction of the liquid film. unanimous.

[0024] The tip of the three-dimensional biomimetic zigzag unit body 1 has three micro-scale micro-zigzag structures 11, and the three micro-scale micro-zigzag structur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com