Columnar fin falling film evaporation heat exchange tube

A falling-film evaporation and heat-exchange tube technology is applied in the fields of columnar fin falling-film evaporation heat-exchange tubes, falling-film evaporators, and absorbers, and can solve problems such as jeopardizing the safety of connected equipment, steam carry-off, splashing, etc. To achieve the effect of enhancing the boiling heat transfer efficiency, improving the evaporation heat transfer coefficient, and increasing the flow velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

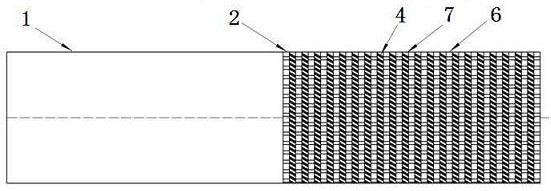

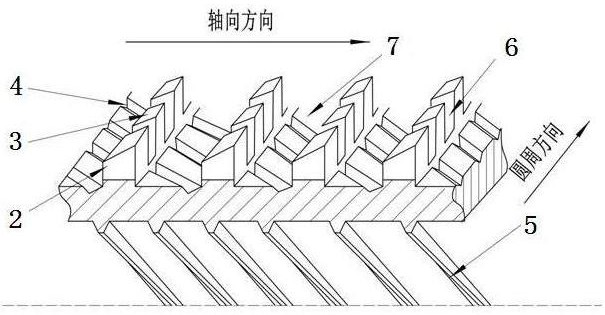

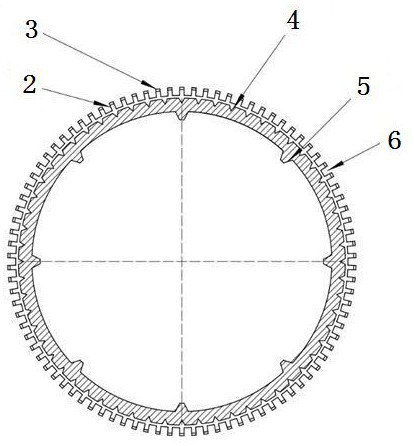

[0030] Such as Figure 1-Figure 6 As shown, a columnar fin falling film evaporation heat exchange tube is The pipe fittings include two parts, the light section 1 and the evaporation surface section. The evaporation surface section is the heat exchange surface. The fins are composed of evenly arranged rectangular columnar fins 2, the rectangular columnar fins 2 are provided with 144 per inch along the axial direction, and the height of the rectangular columnar fins 2 is 0.15-0.5mm (preferably 0.35mm); The aspect ratio of the columnar section is (1.1-4):1, preferably the columnar section of the rectangular columnar fin 2 has a length of 0.57mm and a width of 0.45mm. The top surface 3 of the rectangular columnar fin 2 is an inclined surface, the included angle with the direction of gravity is 30-45 degrees, and the inclined surface faces the axial di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com