A simple method and application of directly growing carbon nanotube arrays on metal

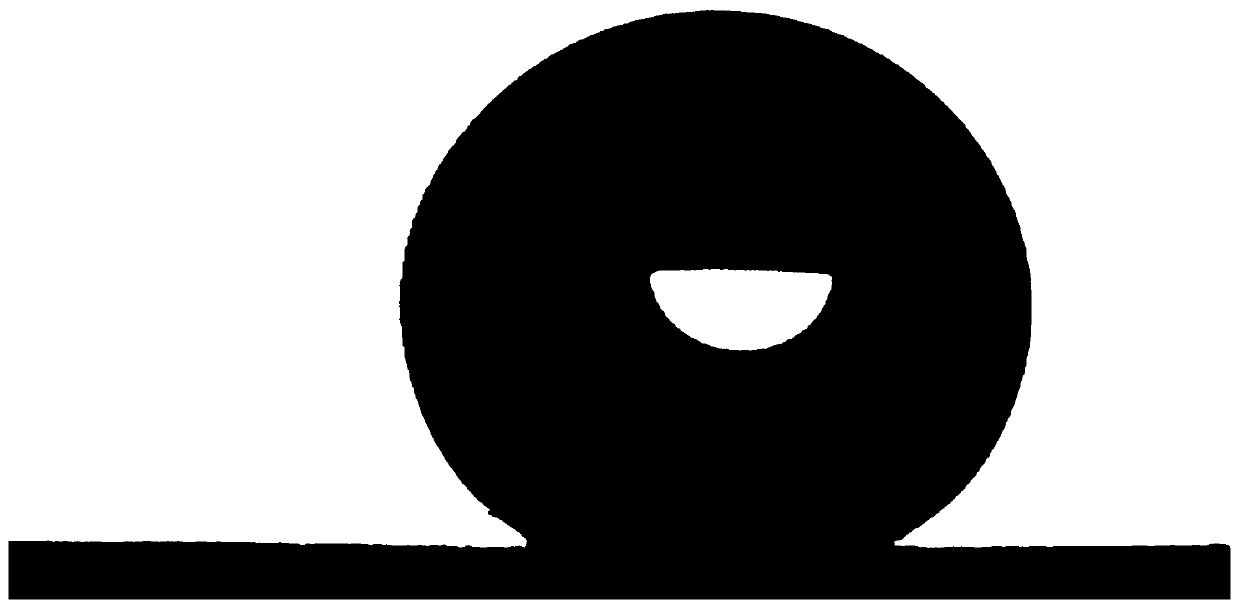

A carbon nanotube array, a direct technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of carbon nanotube carrier gas danger, difficult growth, high solvent toxicity, etc., to improve condensation heat transfer Efficiency, improved safety and reliability, strong binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

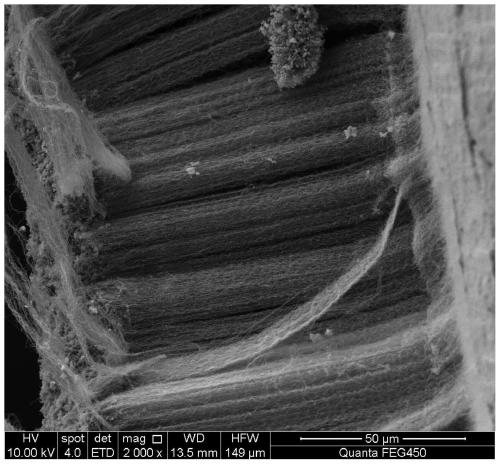

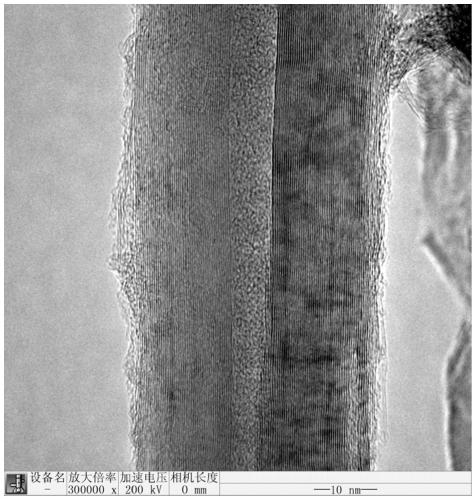

[0030] Specific Embodiment 1: This embodiment is a simple method for directly growing carbon nanotube arrays on metal, which is specifically completed according to the following steps:

[0031] 1. Etching treatment:

[0032] First, immerse the metal substrate in acid and etch for 3min-5min, then take out the metal substrate, use organic solvent as the cleaning agent, and ultrasonically clean it for 5min-10min at an ultrasonic power of 80W-100W, and then use deionized water as the cleaning agent. Ultrasonic cleaning at an ultrasonic power of 80W to 100W for 5min to 10min, and then drying with nitrogen to obtain an etched metal substrate; place the etched metal substrate in a quartz boat, and then put the quartz boat into a tube furnace the reaction zone;

[0033] 2. Add 1000mL min to the tube furnace -1 ~1500mL·min -1 The gas flow rate of the nitrogen gas is passed through for 10min to 20min, and then the flow rate of the nitrogen gas is adjusted to 100mL·min -1 ~500mL·min ...

specific Embodiment approach 2

[0046] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the acid described in the step one is that the mass fraction is 35%~37% hydrochloric acid, the mass fraction is 65%~70% nitric acid and the mass fraction is One of 50% to 60% sulfuric acid or a mixture of several of them. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0047] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the metal substrate described in step 1 is stainless steel. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com