Phase change cooling system

A cooling system and phase change cooling technology, applied in the field of electronics, can solve the problems of pressure and temperature fluctuation, difficulty in heat dissipation and temperature control, and difficulty in accurate control of system temperature, so as to alleviate pressure rise and fluctuation and improve condensation heat transfer. Efficiency and the effect of ensuring stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

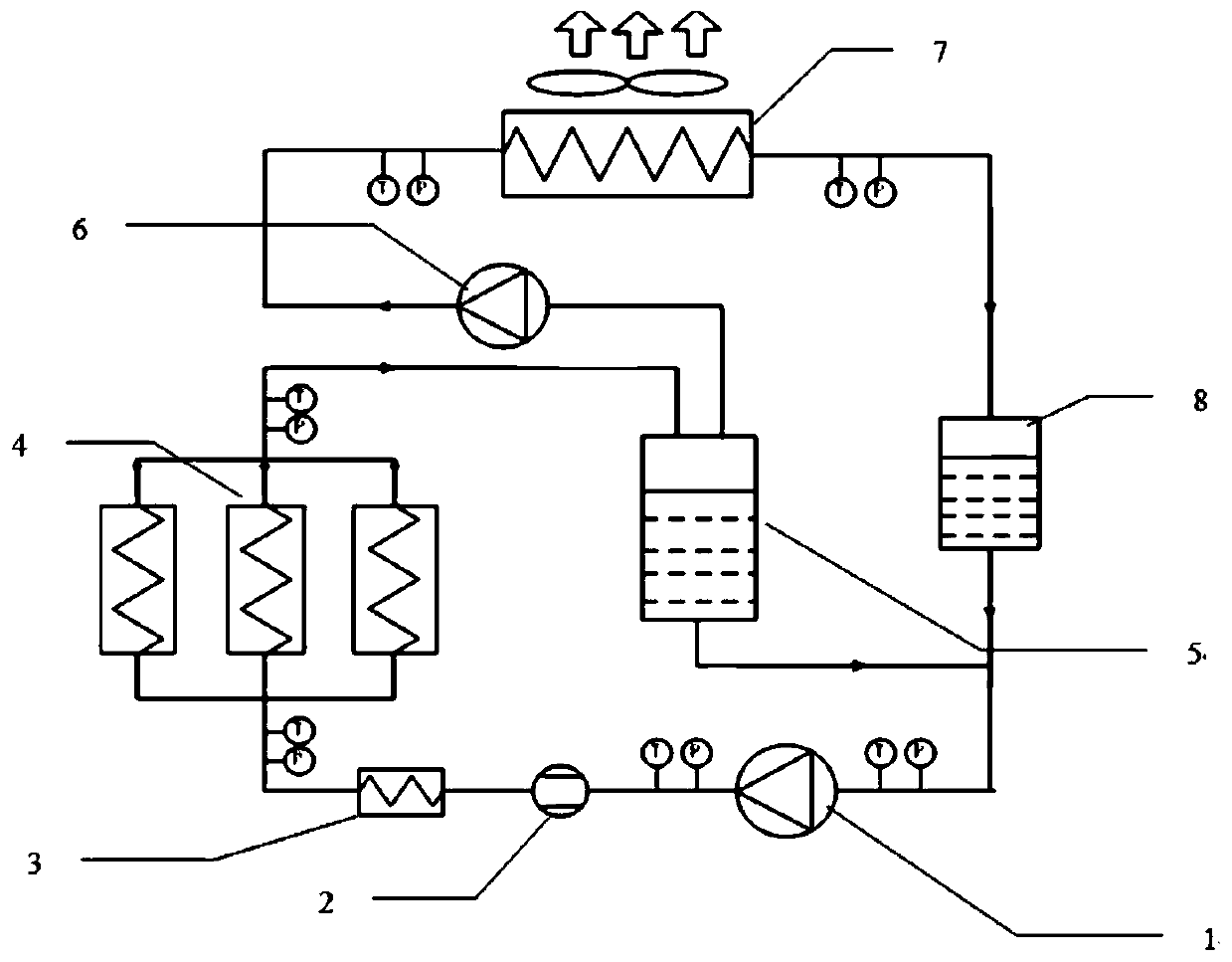

[0016] The pump-driven two-phase cooling system is mainly composed of a liquid pump 1, an evaporator 4, a condenser 7, a preheater 3, a vapor-liquid separator 5, a liquid storage tank 8, a gas pump 6, and connecting pipelines. To achieve liquid phase conversion heat, accurate temperature control, and safe and stable operation, temperature and pressure sensors are installed at the inlet and outlet of evaporator 4, condenser 7, and liquid pump 1 to monitor the operating pressure and temperature of the system. The schematic diagram of the principle is as follows figure 1 shown.

[0017] Driven by the pump, the liquid working medium enters the preheater 3 to be preheated to a nearly saturated state, and then enters the flow channel of the evaporator 4 to be h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com