Stop-flow two-dimensional liquid chromatography with a multi-port valve as switching device and its application

A technology of two-dimensional liquid chromatography and switching devices, which is applied in the direction of measuring devices, solid adsorbent liquid separation, instruments, etc. It can solve the problems of large pressure changes at the moment of stop flow, sudden pressure changes, and inability to split flow, etc., to reduce pressure pulses , improve accuracy, reduce the effect of steps and links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

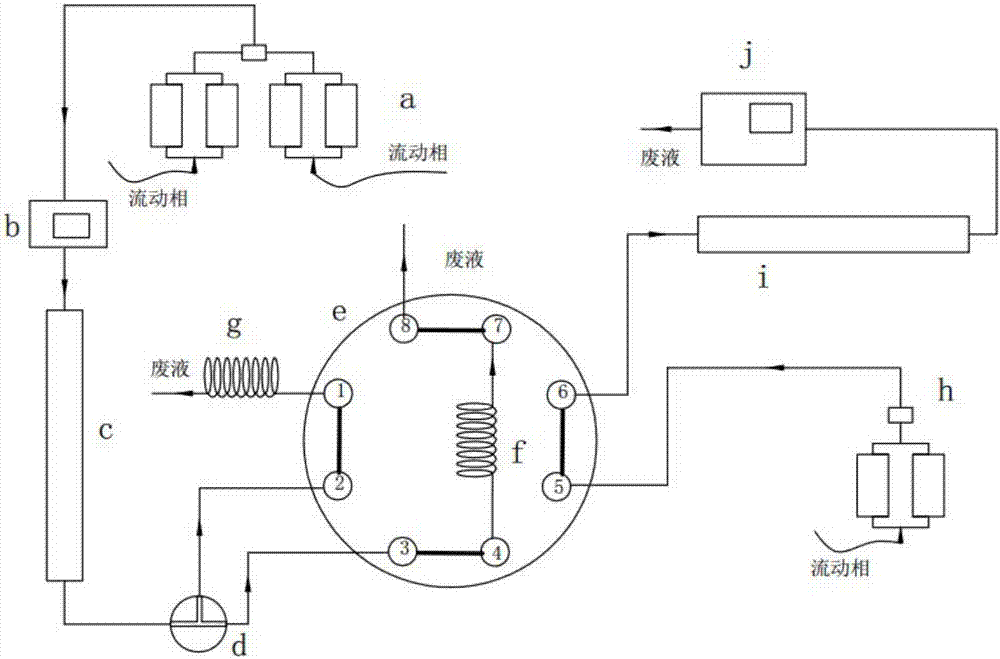

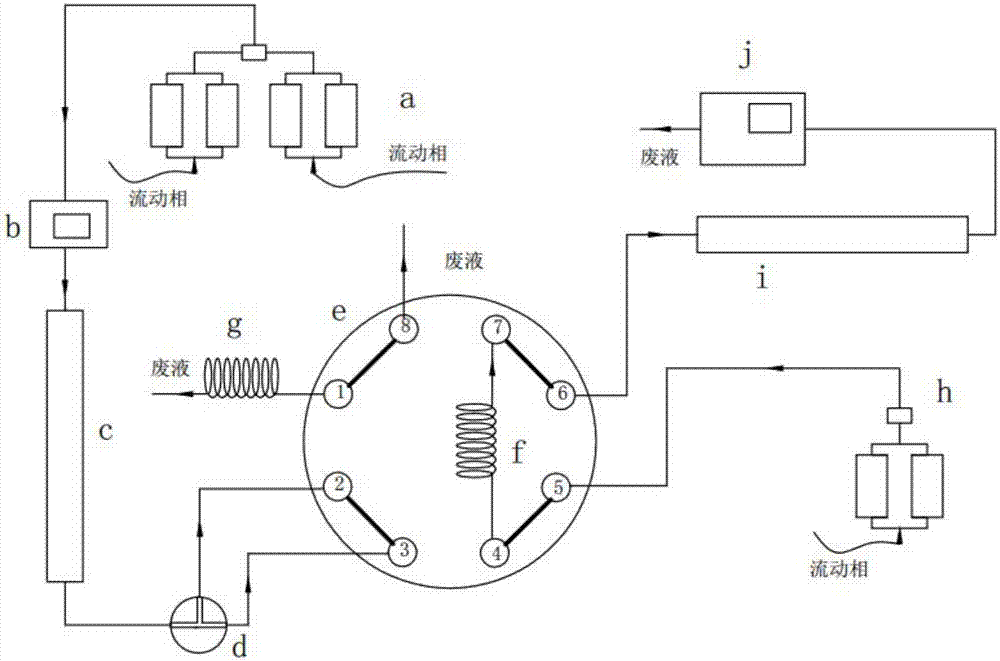

[0043] A stopped-flow two-dimensional liquid chromatography, such as Figure 1-2 As shown, it includes a first-dimensional separation part, a stop-flow switching device, and a second-dimensional separation detection part;

[0044] The stop-flow switching device is a four-slot two-position eight-way valve e;

[0045] When in the sampling state ( figure 1 ), the first-dimensional liquid chromatography pump a pumps the mobile phase to the autosampler b, and pumps the sample into the chromatographic column c. The effluent components are then split through the three-way pipe d, and one of the flow paths passes through the multi-way valve Positions 2 and 1 of e flow to the waste tank through the pressure balance loop g, and the other flow path passes through positions 3 and 4 of the multi-way valve e in turn, and then enters the sampling loop f for filling, and then passes Positions 7 and 8 flow to the waste liquid bucket, and the effluent of the second-dimensional liquid chromatography ...

Embodiment 2

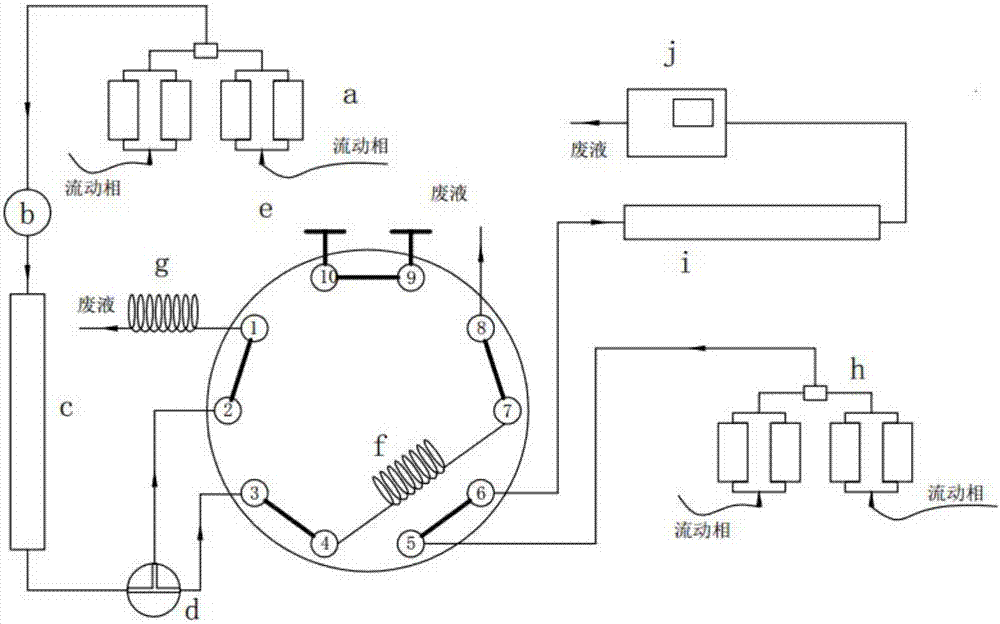

[0053] A stopped-flow two-dimensional liquid chromatography, such as Figure 3-4 As shown, the difference from Embodiment 1 is that the multi-way valve e for stopping flow is a five-slot, two-position, ten-way valve, and positions 9 and 10 are closed with plugs. In addition, the sampling device b adopts a manual injector, and the second-dimensional liquid chromatography pump h adopts a double pump. Otherwise, its structure and working principle are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com