A Multifunctional Swing Blade Type Multi-pressure Output Rotary Mechanical Mechanism

A rotating machinery and vane-type technology, which is applied in the field of variable-displacement swing-vane hydraulic rotary devices, can solve problems such as unfavorable system safety and stable operation, inability to realize pressure output, transmission noise and wear, and achieve enhanced oil supply continuity , Reduce the effect of reducing flow noise between parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

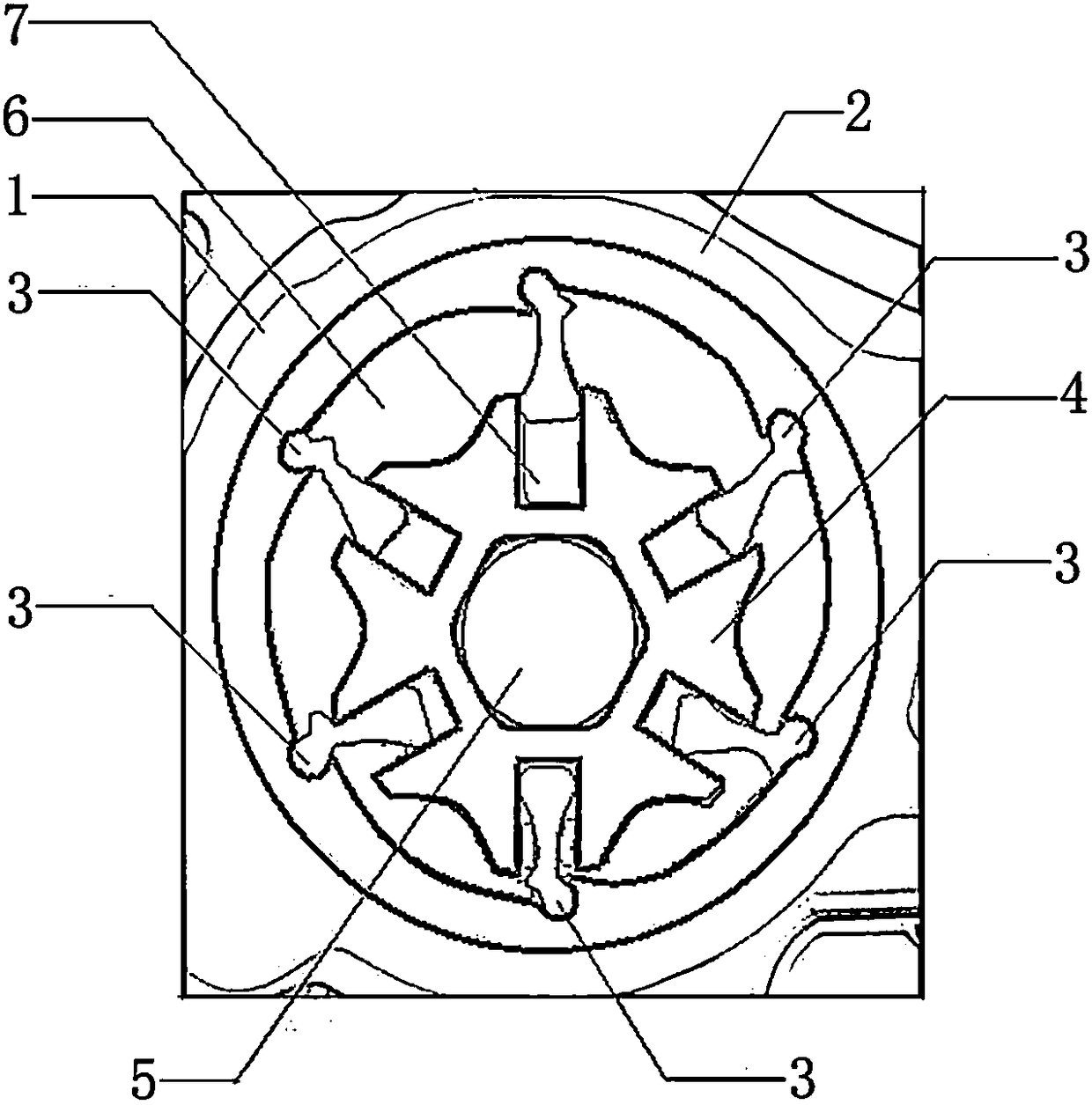

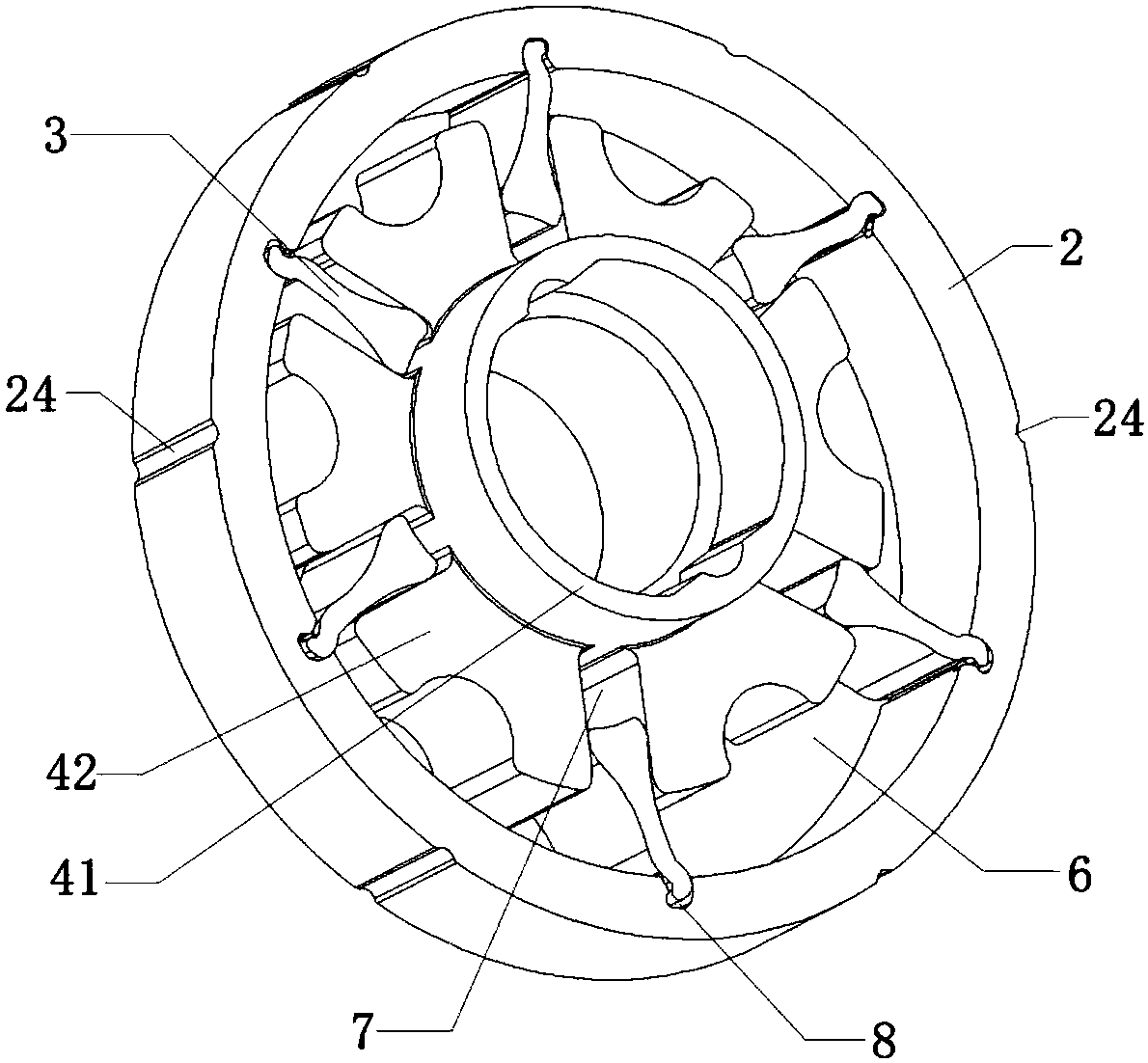

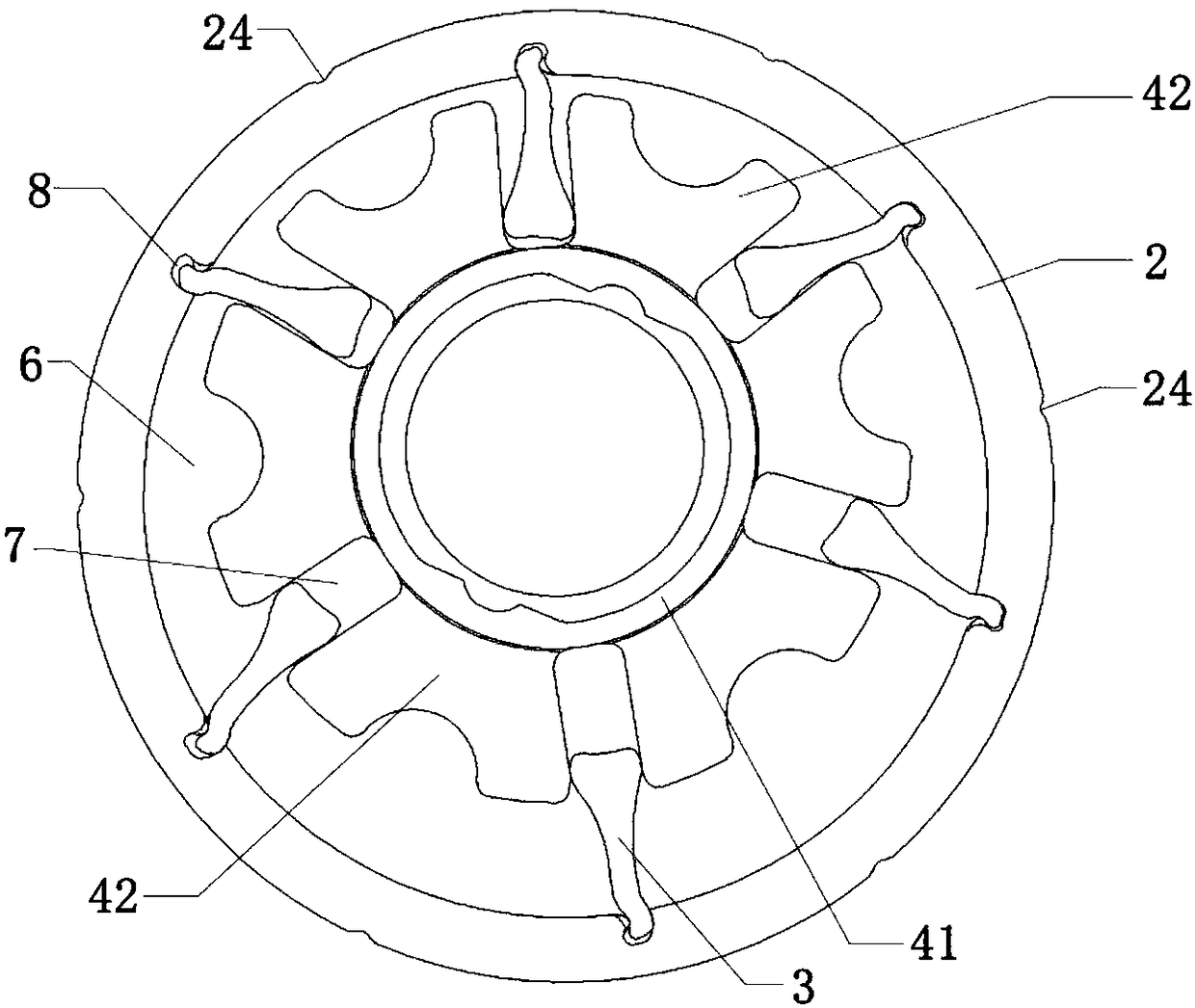

[0044] A multi-functional swing blade type multi-pressure output rotary mechanical mechanism, which is fixed on the bracket 1 through the eccentric shaft 5, such as Figure 2-3 As shown, the multi-function swing vane type multi-pressure output rotary mechanical mechanism includes a swing plate slotted ring 2 , a set of swing plates 3 and a serrated grooved plate 4 .

[0045] Among them, such as Figure 4-5 As shown, the swing piece 3 includes a swing piece head 31 and a swing piece foot 32 , the swing piece head 31 has a swing piece head concave portion 311 , and the swing piece foot 32 has a swing piece foot concave portion 321 . In addition, the head 31 of the pendulum piece 31 passes through the front neck 33 of the pendulum piece 3 sunken toward the middle of the pendulum piece 3 and the chest 34 of the pendulum piece protruding toward the middle of the pendulum piece 3 on the front side of the pendulum piece 3, and further extends to the foot 32 of the pendulum piece. An...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com