A passive containment heat export system

A passive containment and heat export technology, applied in the field of nuclear safety control, can solve the problems of weakened condensation heat transfer capacity of water vapor and reduction of condensation heat transfer coefficient, so as to reduce the content of non-condensable gas, improve condensation heat transfer efficiency, Effect of improving heat export efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

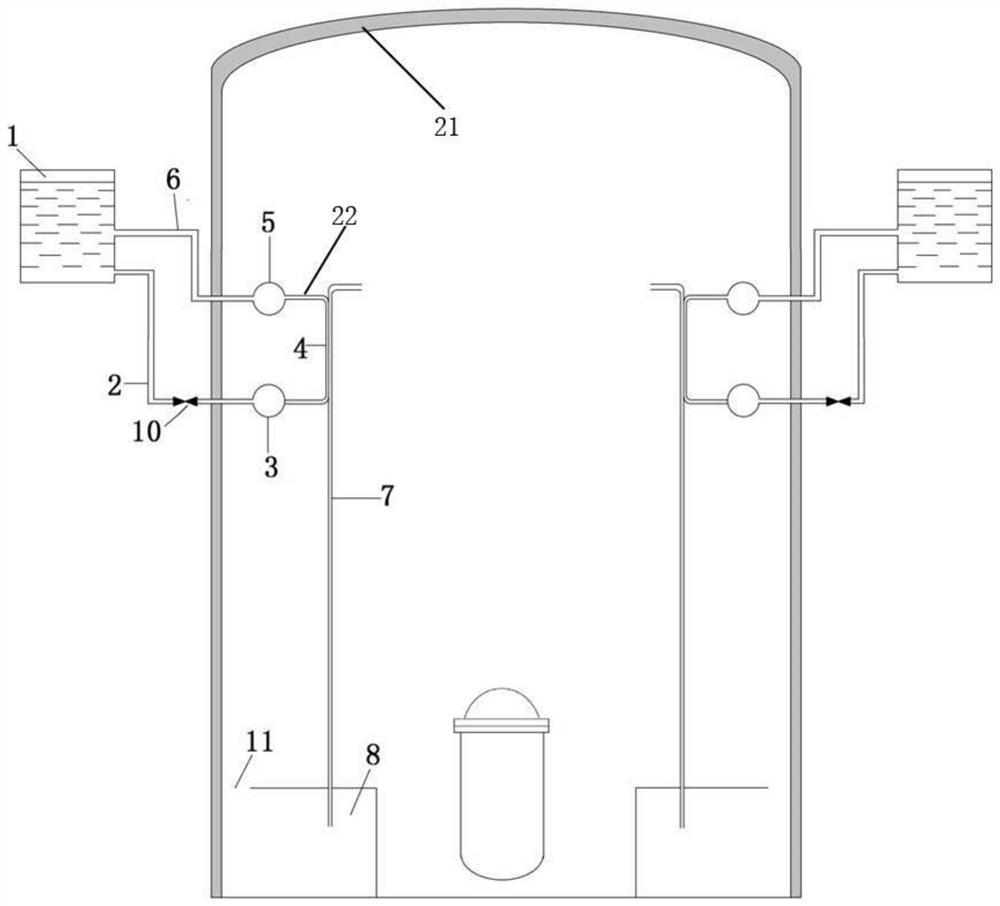

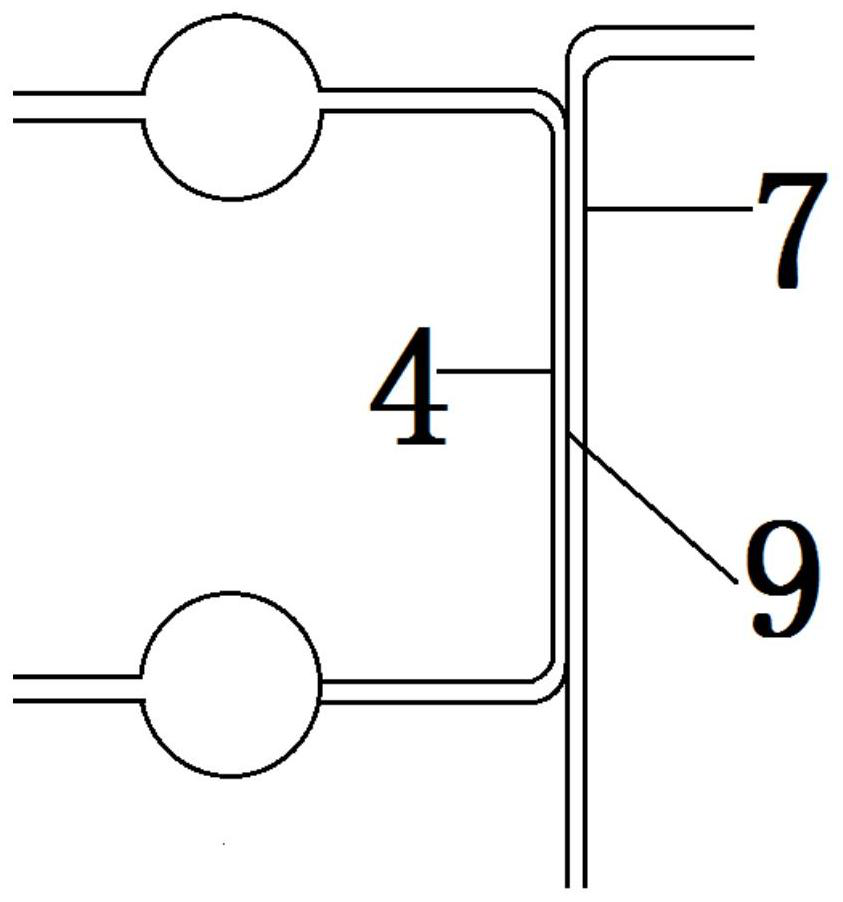

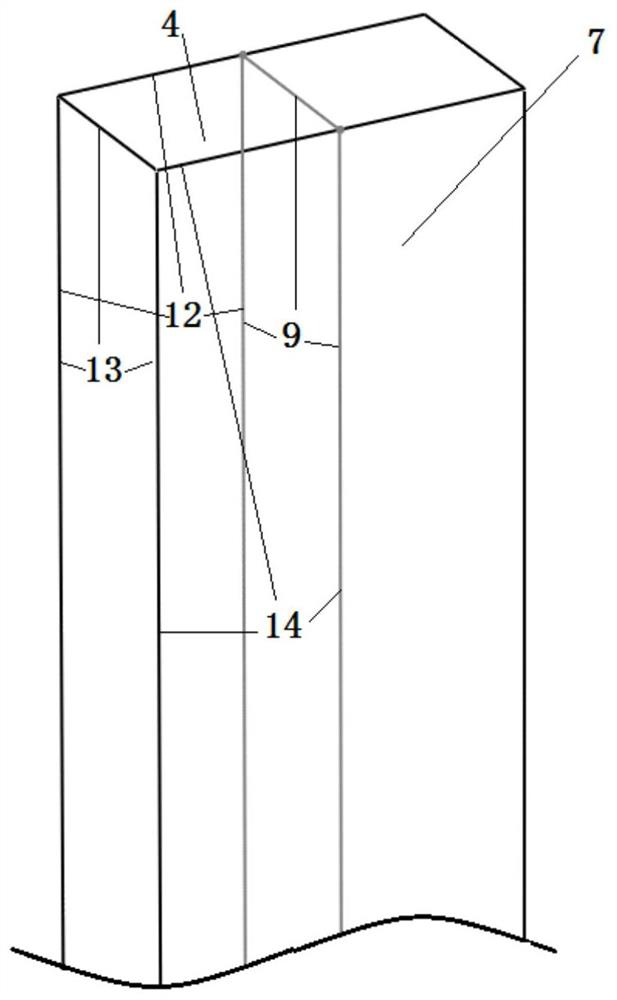

[0028] Exemplary passive containment heat removal system of the present invention such as figure 1 As shown, it includes: a containment vessel 21 and multiple sets of heat export components, wherein each set of heat export components includes a cooling water tank 1 outside the containment vessel, a descending section of the circulation pipeline 2, a heat exchange tube inlet header 3, and a heat exchange tube outlet Header 5, ascending section of circulation pipeline 6, mixed gas guide pipe 7, air retention tank 8, valve 10, heat exchanger group 22.

[0029] The heat exchanger group 22 is arranged in the containment shell 21, including the heat exchange tube 4, the inlet of the cooling water of the heat exchanger group, and the outlet of the cooling water of the heat exchanger group, which are used to divert the cooling water and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com