Micro annular seam liquid film noise reduction device for centrifugal compressor

A centrifugal compressor and micro-ring technology, applied in the field of air-conditioning compressors, can solve the problem of poor noise reduction of fluid dynamic noise, achieve the goal of enhancing condensation heat transfer efficiency, preventing noise transmission, and ensuring good operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

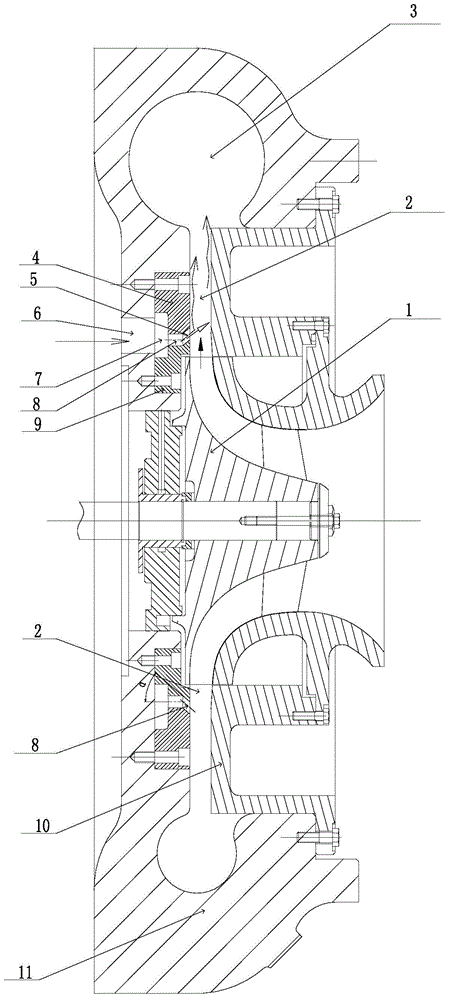

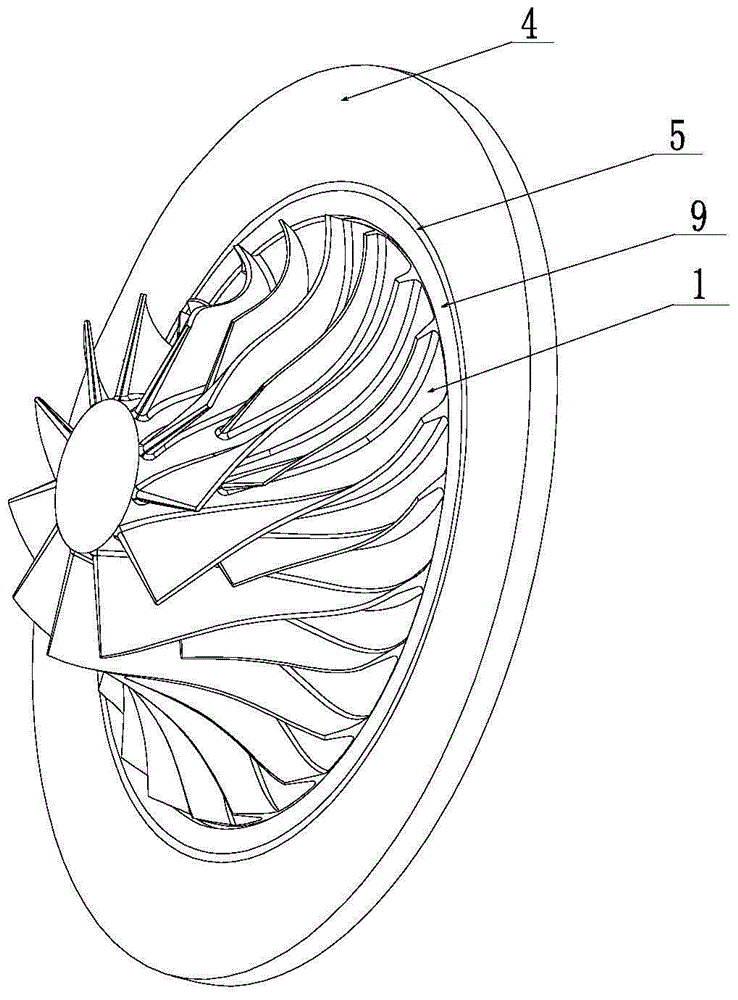

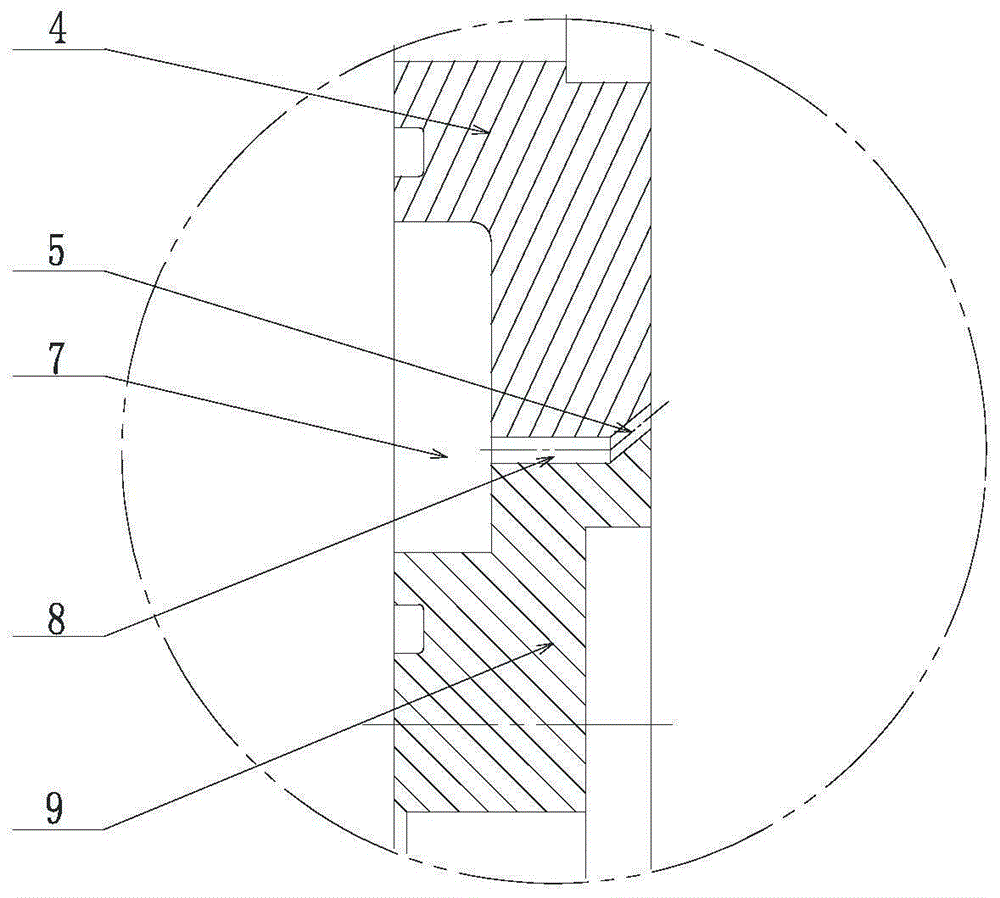

[0028] The centrifugal compressor micro-annular seam liquid film noise reduction device of the present invention comprises an impeller 1, a volute 11, and a diffuser 10, the volute 11 and the diffuser 10 are spaced to form an exhaust flow channel 2, and inside the volute 11 The vortex flow channel 3 is provided, and the vortex flow channel 3 is connected with the exhaust flow channel 2. The outer side of the impeller 1 is provided with a circular liquid storage baffle 4, and the liquid storage baffle 4 is provided with a micro annular seam connecting plate 9 , the space between the liquid storage baffle plate 4 and the micro-annular seam connecting plate 9 forms a micro-annular seam flow channel.

[0029] The micro-annular seam channel includes a liquid storage chamber 7, one side of the liquid storage chamber 7 is connected to the exhaust flow channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com