A super-lyophilic-super-slippery patterned surface and its processing method for enhancing droplet condensation heat transfer

A patterned surface, droplet condensation technology, applied in special surfaces, pretreatment surfaces, devices for coating liquids on surfaces, etc. The problem that the condensate cannot be quickly gathered and transported can improve the long-term efficiency of heat transfer, strengthen the heat transfer of dropwise condensation, and improve the efficiency of condensation heat transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

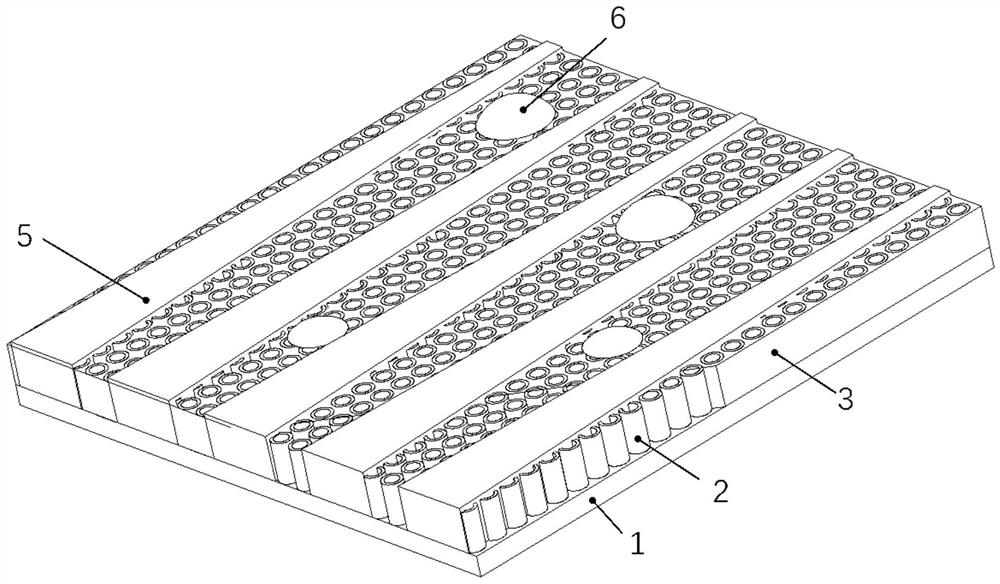

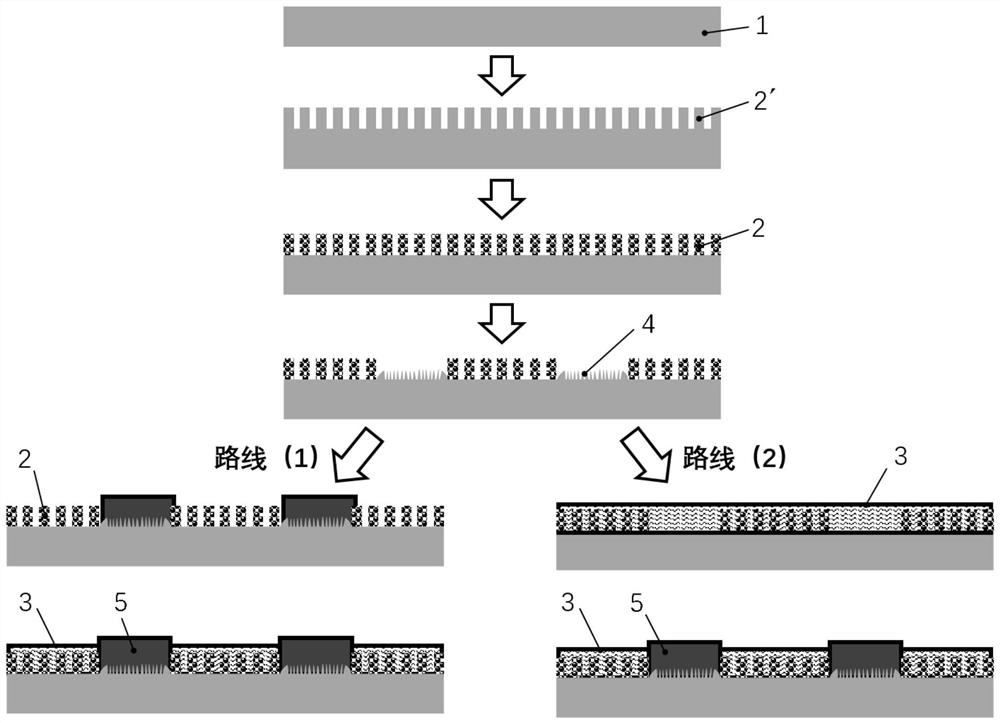

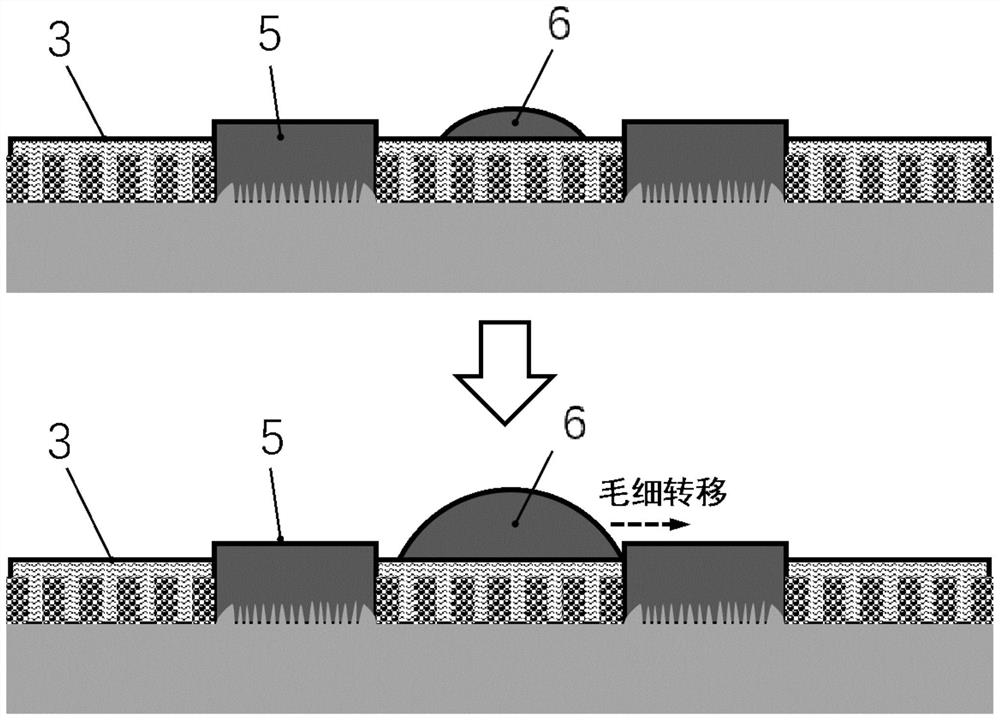

[0033] Such as figure 1 and 2 As shown, the present embodiment provides a super-lyophilic-super-slippery patterned surface that strengthens drop-like condensation heat transfer, including a substrate 1, a super-lyophobic nanostructure 2, a liquid lubricating layer 3, a super-lyophilic pattern 4 and a patterned surface. Water film5.

[0034] The super lyophobic nanostructure 2 is a nanostructure processed on the surface of the substrate and has super lyophobic properties. In this embodiment, the nanostructure is a nanotube structure.

[0035] The liquid lubricating layer 3 is a lubricating liquid layer that is locked by the super lyophobic nanostructure 2 after the lubricating liquid infiltrates the super lyophobic nanostructure 2 .

[0036] The super-lyophilic pattern 4 is a groove-shaped pattern processed in the super-lyophobic nanostructure 2 , that is, the super-lyophilic pattern 4 is depressed in the super-lyophobic nanostructure 2 . In this embodiment, the super-lyoph...

Embodiment 2

[0049] This embodiment provides a super-lyophilic-super-slippery patterned surface that enhances drop-like condensation heat transfer. Its structure is the same as that of Embodiment 1, the only difference is that the nanostructure is a nanowire structure; the super-lyophilic pattern is a square stripe array .

[0050] The processing method of the super-lyophilic-super-slippery patterned surface of the enhanced droplet condensation heat transfer comprises the following steps:

[0051] Step 1, using alkaline oxidation to process super-lyophilic nanostructures on the copper substrate. Among them, the solution is 2.5mol L -1 Potassium hydroxide and 0.065mol L -1 Potassium persulfate mixed aqueous solution, the temperature of the aqueous solution is 70°C, and the oxidation time is 40min.

[0052] Step 2. The super-lyophilic nanostructure obtained in step 1 is soaked in 1 wt% fluorosilane ethanol solution for 90 minutes to obtain a super-lyophobic nanostructure.

[0053] Step 3...

Embodiment 3

[0058] This embodiment provides a super-lyophilic-super-slip patterned surface that enhances drop-like condensation heat transfer. Its structure is the same as that of Embodiment 1, the only difference is that the nanostructure is a nano-fluff structure; the super-lyophilic pattern is a wedge-shaped stripe array .

[0059] The processing method of the super-lyophilic-super-slippery patterned surface of the enhanced droplet condensation heat transfer comprises the following steps:

[0060] Step 1, using nanosecond ultraviolet laser ablation to process super-lyophilic nanostructures on stainless steel / copper substrates. Among them, the laser power is 3W, the laser frequency is 100kHz, the line-fill scanning spacing is 5μm, and the line scanning speed is 500mm / s.

[0061] Step 2. The super-lyophilic nanostructure obtained in step 1 was soaked in 1 wt% fluorosilane ethanol solution for 120 minutes to obtain a super-lyophobic nanostructure.

[0062] Step 3, using nanosecond laser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com