Multi-shell tube-shell-and-tube -type condenser with heat recoverer

A recoverer and multi-shell side technology, which is applied in the direction of evaporator/condenser, heat exchanger shell, refrigerator, etc., can solve the problem of increasing the overall size of the unit, low fluid velocity on the shell side, and low heat transfer coefficient of the heat exchanger. Advanced problems, to achieve the effect of improving the condensation heat transfer efficiency and reducing the heat transfer temperature difference loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

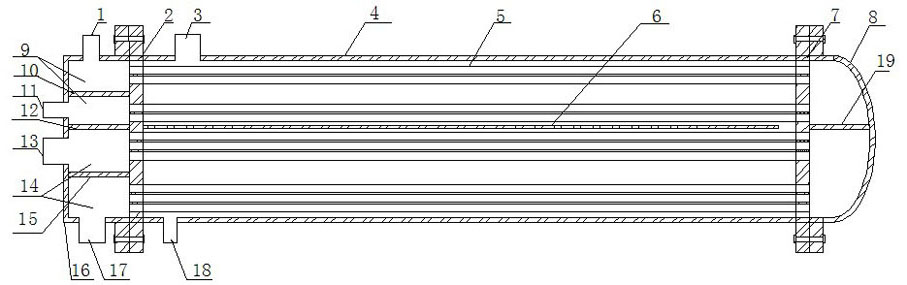

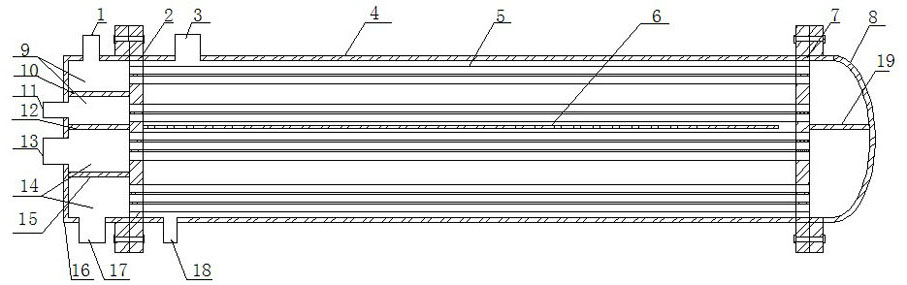

[0019] Such as figure 1 As shown, the multi-shell-side shell-and-tube condenser with heat recovery device of the present invention includes tube box 16, tube plate I2 and plate II7, shell 4, end cover 8 and so on. The tube box 16 is connected to the outside of the tube sheet 2 and a partition I12 is arranged inside to divide the tube box into a heat recovery zone 9 and a condensation zone 14. In the heat recovery zone 9, a partition II10 is provided to separate the heat recovery zone, The tube side above the heat recovery area is provided with a pipe interface I1, the tube side below the heat recovery area is provided with a pipe interface II11, and a partition III15 is provided in the condensation area 14 to divide the condensation area, and the tubes above the condensation area Set the pipe interface III13 on the tube side, and set the tube interface IV17 on the tube side below the condensation area. The end cover 8 is connected to the outside of the tube sheet II7, and a p...

Embodiment 2

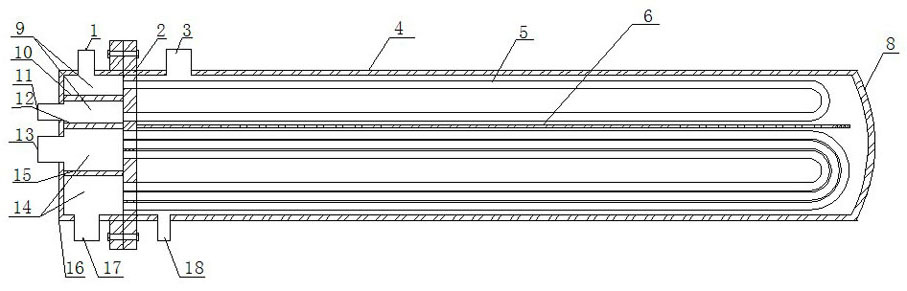

[0022] Such as figure 2 As shown, the heat exchange tube is a U-shaped heat exchange tube, and the rest of the structure is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com