A falling film air cooler and wastewater treatment process based on evaporative air cooling technology

An evaporative air-cooling, falling film technology, applied in evaporator/condenser, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of tube wall stuttering, low permeability, and large loss of heat transfer temperature difference and other problems, to achieve the effect of good heat transfer and mass transfer synchronization, high heat transfer coefficient, and small heat transfer temperature difference loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below with reference to the accompanying drawings.

[0029] Wherein the same parts are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to directions in the drawings, and the words "bottom" and "top" "Face", "inner" and "outer" refer to directions toward or away from the geometric center of a particular part, respectively.

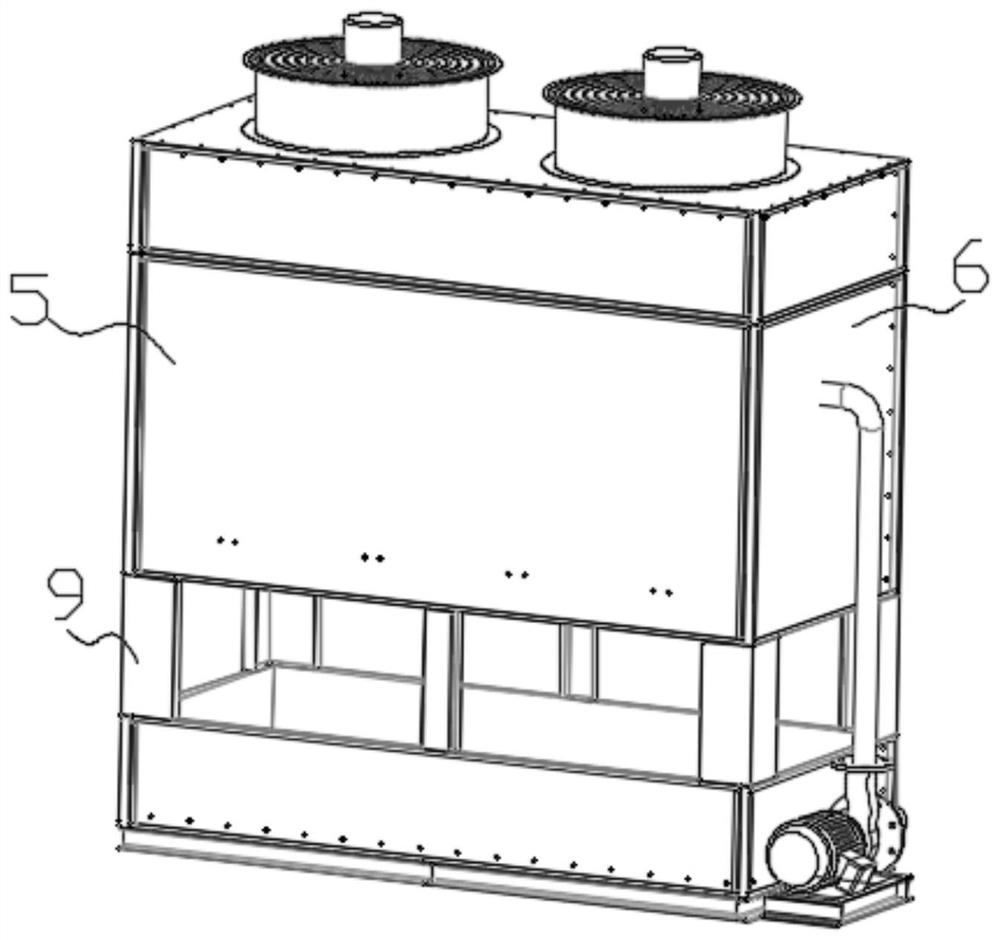

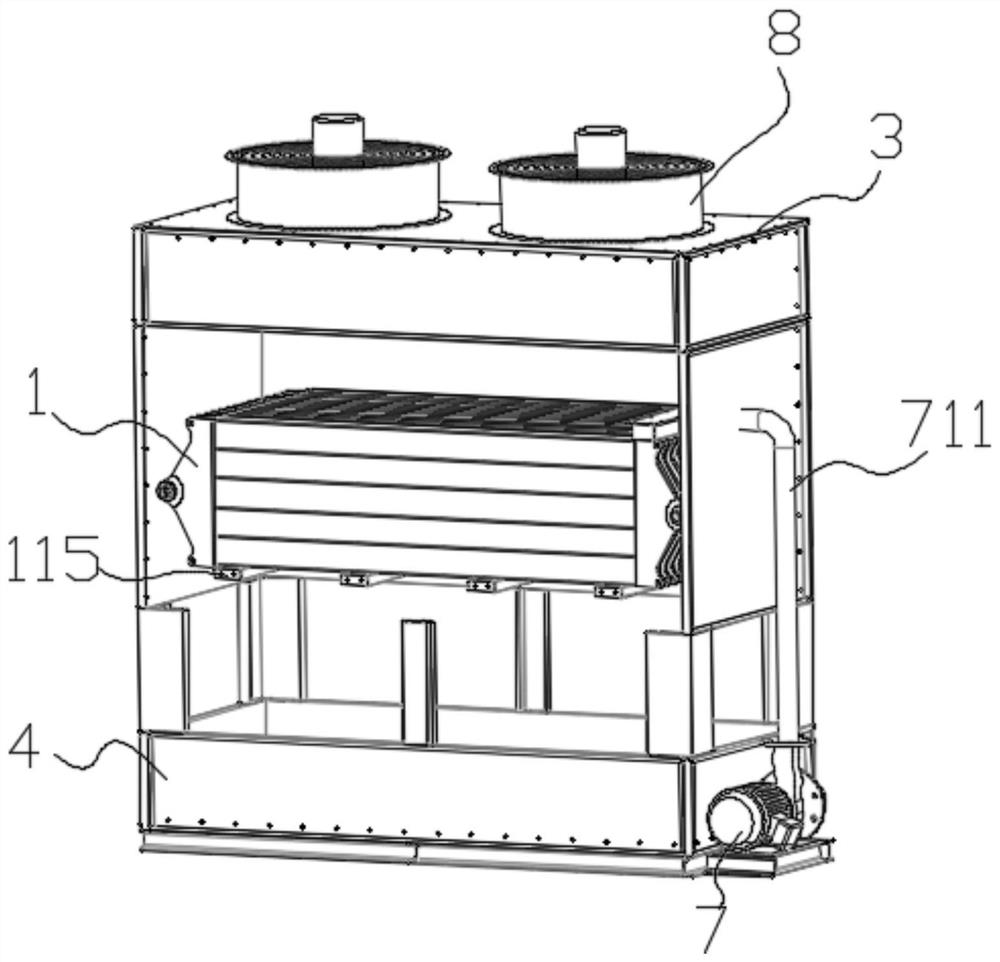

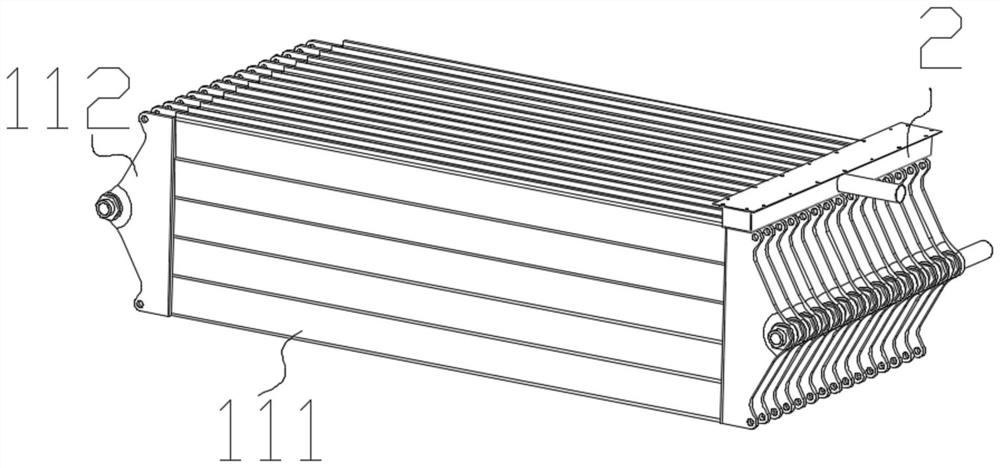

[0030] like Figure 1-5 As shown, a falling film air cooler based on evaporative air cooling technology includes a fan 8 frame 3, a water tank 4, front and rear side panels 5, left and right side panels 6, a pump 7, a fan 8, a number of falling film panels 1 and a water collection tank 2. Several falling film panels 1 are arranged vertically and longitudinally. The water collecting tank 2 is located on the top right side of several falling film panels 1 and communicates wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com