Split type multi-stage heat pipe system

A split type, heat pipe technology, applied in the field of heat exchange, can solve the problems of large heat exchange temperature difference loss and low total heat exchange efficiency, and achieve the effects of reducing heat exchange temperature difference loss, great flexibility, and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

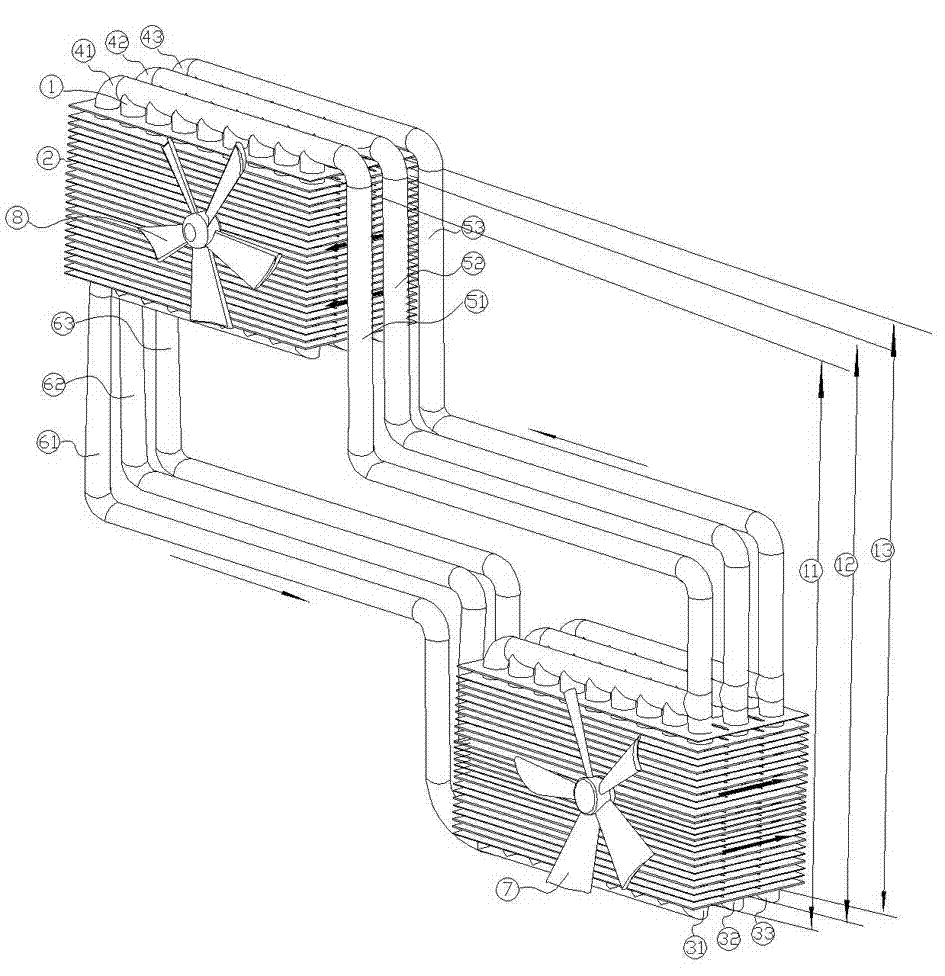

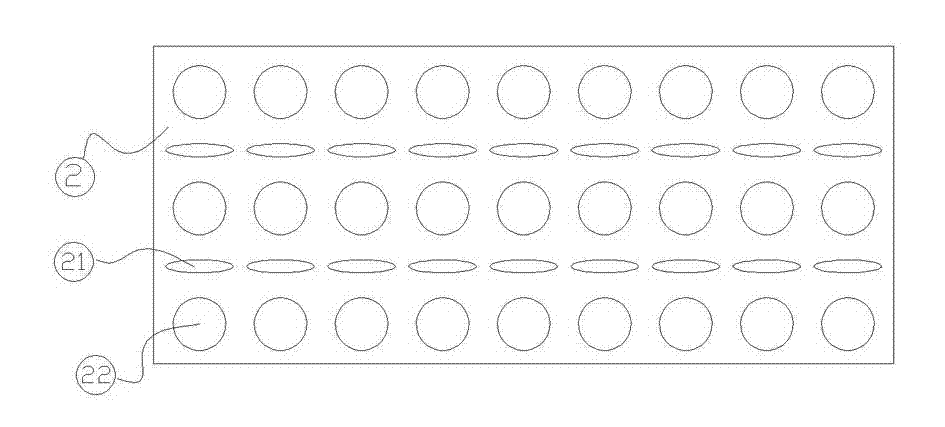

[0024] The simple structural diagram of this embodiment is as follows: figure 1 As shown; the main structure of the system device involved in the implementation of this embodiment includes a heat pipe unit (1), a primary heat pipe group (11), a secondary heat pipe group (12), a tertiary heat pipe group (13), and cooling fins (2 ), thermal insulation seam (21), perforation (22), evaporator of the primary heat pipe group (31), evaporator of the secondary heat pipe group (32), evaporator of the third heat pipe group (33), primary heat pipe The condenser (41) of the second heat pipe group, the condenser (42) of the second heat pipe group, the condenser (43) of the third heat pipe group, the steam channel (51) of the first heat pipe group, the steam channel (52) of the second heat pipe group ), the steam channel (53) of the third-stage heat pipe group, the liquid channel (61) of the first-stage heat pipe group, the liquid channel (62) of the second-stage heat pipe group, the liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com