High energy efficiency dry shell and tube condensing heat exchanger with tube for subcooling

A condensing heat exchanger, high energy-efficiency technology, applied in subcoolers, evaporators/condensers, refrigerators, etc., can solve problems such as difficulty in meeting production requirements, increase in internal condensing temperature, and increase in external load, and achieve overall The effect of reducing the adverse factors of circulation, improving the efficiency of condensation heat exchange, and reducing the load of the refrigerant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

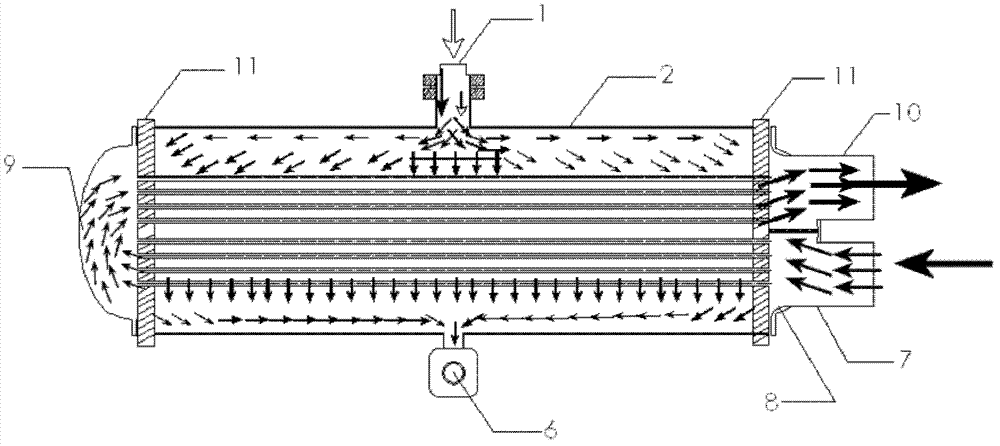

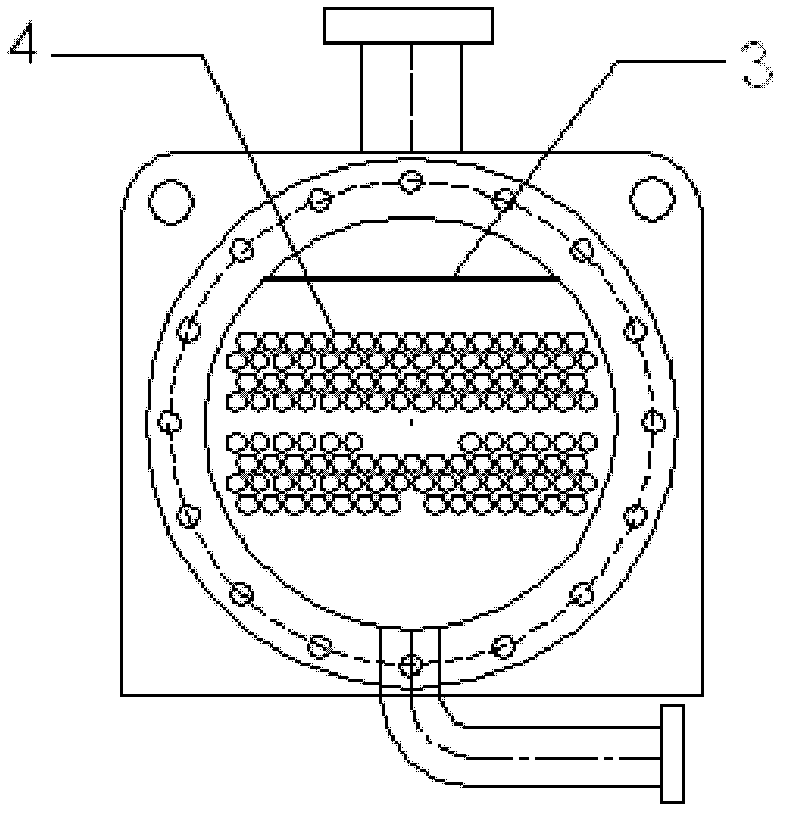

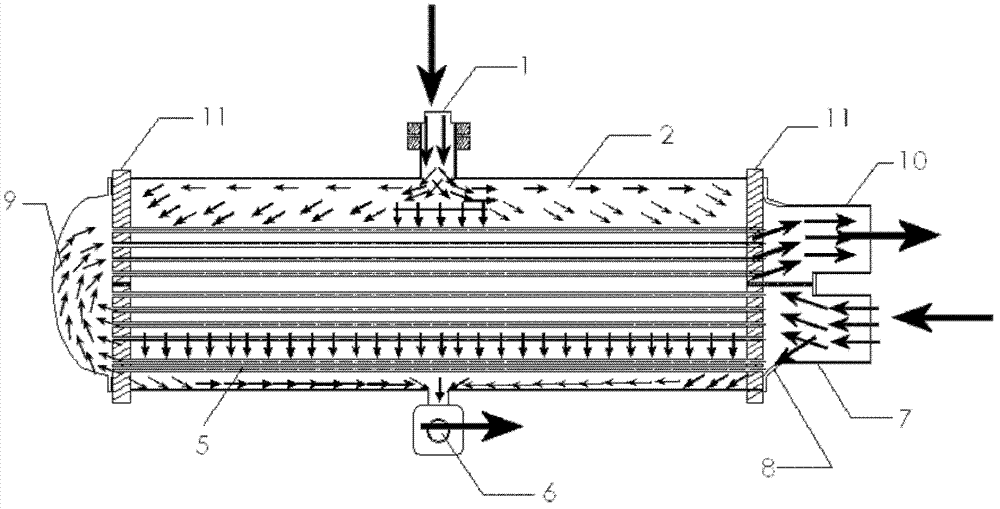

[0014] Depend on Figure 2A , Figure 2B It can be seen that the present invention includes: a casing group 2; a heat exchange tube core group 4 is fixedly placed in the casing group 2; the two ends of the heat exchange tube core group 4 are fixed on the end plate 11 by expansion joint; Above the heat exchange tube core group 4 is a dispersing plate 3; the top of the shell group 2 is provided with a refrigerant inlet 1, and the bottom end is provided with a refrigerant liquid outlet 6; one side of the shell group 2 An end cover 8 is arranged, a brine inlet 7 is arranged on its lower part, and a brine outlet 10 is arranged on its upper part; an end cover 9 without a partition plate is arranged on the other side of the shell group 2; Cooling tube core group 5 ; the supercooled tube core group is fixedly placed in the shell group 2 and at the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com