Solution-spraying heat pump unit

A heat pump unit and solution pump technology, applied in heating and cooling combinations, refrigerators, household heating and other directions, can solve the problems of circulating water freezing, unable to achieve heating, increase initial investment in equipment, etc., and reduce metal materials. , Avoid defrosting problems and reduce the effect of initial investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

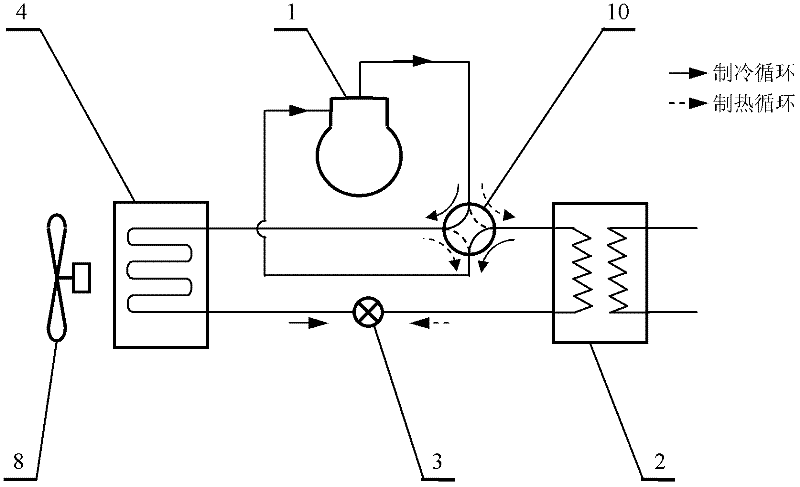

[0034] Figure 4 It is the structural principle diagram of the first embodiment of the solution spray type heat pump unit provided by the present invention. This embodiment uses the recooling and heat of the high-pressure liquid refrigerant as the regeneration heat source of the solution, and it includes a compressor 1 and an indoor heat exchanger 2 , an outdoor throttling device 3, an outdoor heat exchanger 4, a solution collection tray 5 located at the lower part of the outdoor heat exchanger, a first solution pump 6a, a heat exchanger shower 7, a fan 8 and a heat exchanger housing 9; The lower part of the heat exchanger shell 9 is provided with an air inlet, and the outdoor air flows out of the heat exchanger shell 9 through the outdoor heat exchanger 4 under the action of the fan 8; the solution spray type heat pump unit also includes a four-way valve 10 and a solution- Refrigerant heat exchanger 11; the solution-refrigerant heat exchanger 11 is arranged outside the heat e...

Embodiment 2

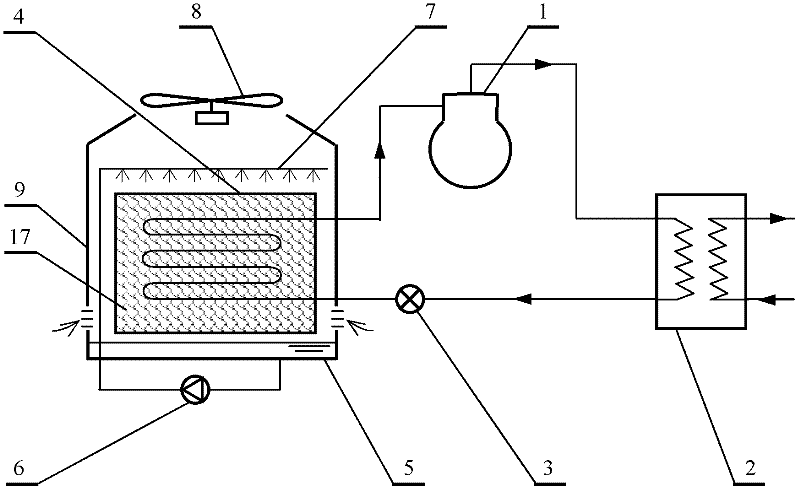

[0038] Figure 5 It is the structural principle diagram of the second embodiment of the solution spray heat pump unit provided by the present invention. In this embodiment, the recooling and heating of the high-pressure liquid refrigerant is used as the regeneration heat source of the solution. Compared with the first embodiment, the difference is that: Compressor 1, four-way valve 10, indoor heat exchanger 2, solution-refrigerant heat exchanger 11, outdoor throttling device 3, outdoor heat exchanger 4 and four-way valve 10 constitute the vapor compression heat pump circulation loop, A connecting pipe is added between the outlet of the refrigerant side of the indoor heat exchanger 2 and the inlet of the outdoor throttling device 3, and a first valve 12 is arranged on the connecting pipe; A second valve 13 is set on the road; a solution regenerator 16 is set above the outdoor heat exchanger 4 inside the heat exchanger housing 9, and a porous filler 17 is set in the solution reg...

Embodiment 3

[0043] Figure 6 It is the structural principle diagram of the third embodiment of the solution spray heat pump unit provided by the present invention. This embodiment uses the recooling and heat of the high-pressure liquid refrigerant as the regeneration heat source of the solution, and it includes a compressor 1 and an indoor heat exchanger 2 , an outdoor throttling device 3, an outdoor heat exchanger 4, a solution collection tray 5 located at the lower part of the outdoor heat exchanger, a first solution pump 6a, a heat exchanger shower 7, a fan 8 and a heat exchanger housing 9; The lower part of the heat exchanger shell 9 is provided with an air inlet, and the outdoor air flows out of the heat exchanger shell 9 through the outdoor heat exchanger 4 under the action of the fan 8. The solution spray type heat pump unit also includes a four-way valve 10 and a solution- Refrigerant heat exchanger 11, the solution-refrigerant heat exchanger 11 is placed in the solution collectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com