Bionic condensation enhanced heat transfer surface

An enhanced heat transfer, bionic technology, applied in heat transfer modification, steam/steam condenser, heat exchange equipment, etc., can solve the problem of efficient fusion and self-renewal of unfavorable droplets, increased difficulty of droplet nucleation, and update rate Slow and other problems, to achieve the effect of accelerating discharge, increasing nucleation density, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

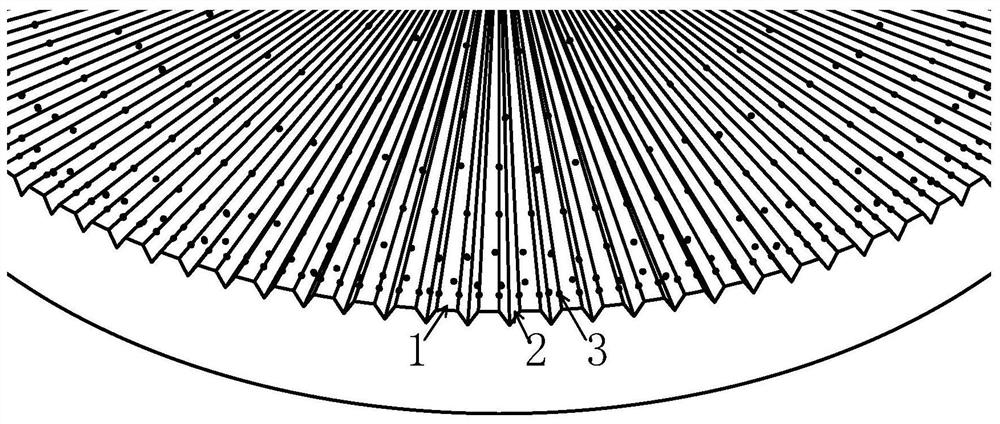

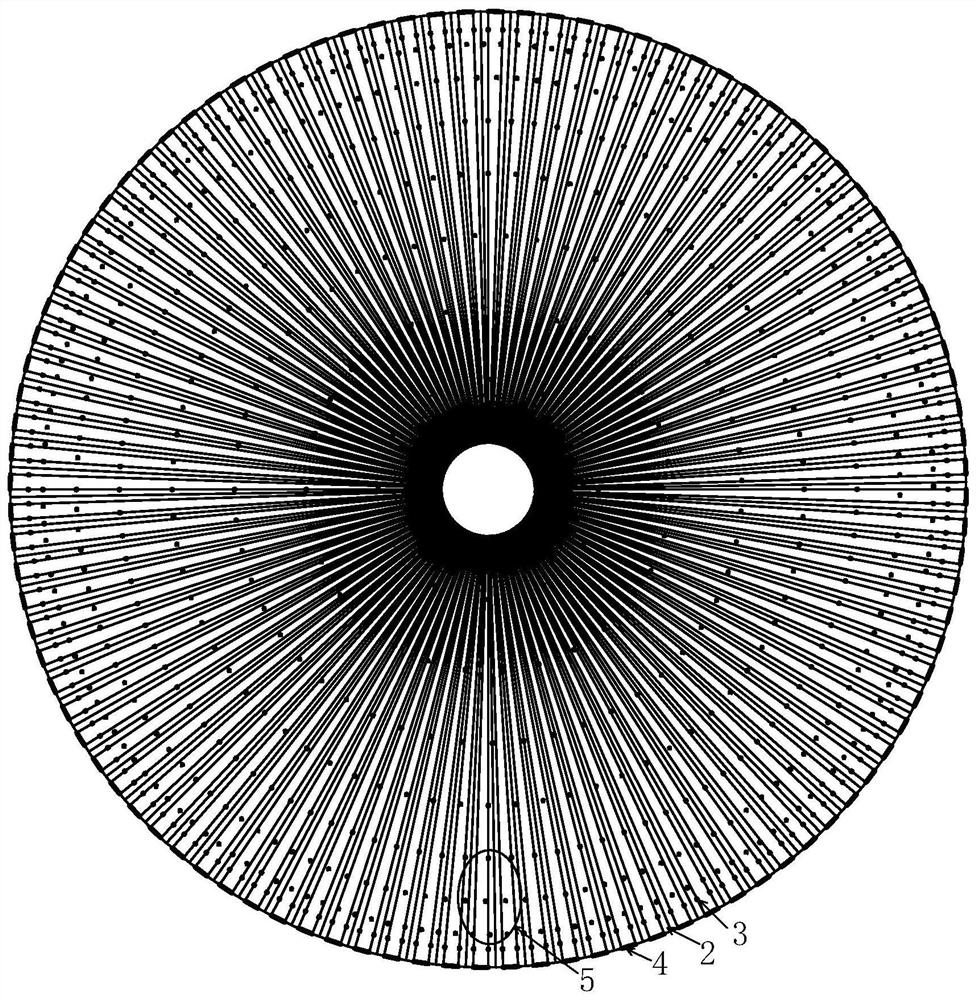

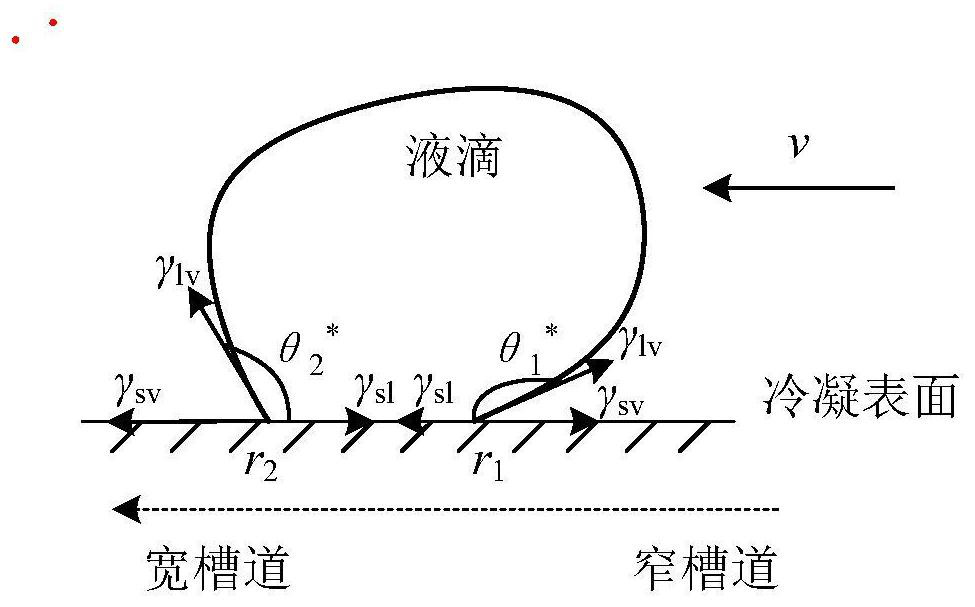

[0027] Such as figure 2 Shown is a plan view of a horizontally placed circular condensation surface 4 and a condensation drop 5 on the circular condensation surface. The cross-sectional area of the hydrophobic micro-grooves distributed on the circular condensation surface 4 increases gradually along the radial direction, and the distribution density of the hydrophilic nucleation points on the circular condensation surface 4 is as follows: figure 2 The direction shown becomes larger along the direction where the width of the hydrophobic microchannel becomes larger. Such as figure 2 As shown, if the area covered by the condensate droplets 5 is divided into two along the vertical direction, the number of hydrophilic nucleation points in the covered area on one side near the center of the circle is smaller than that in the area on the other side. The number of nucleation points. Since the surface free energy of the circular condensing surface 4 becomes larger along the dir...

Embodiment 2

[0054] Such as Figure 4 Shown is a rectangular condensation surface 6 .

[0055] The distribution mode of the hydrophobic microchannel 2 structures distributed on the rectangular condensation surface 6 is as follows Figure 4 As shown, the cross-sectional area gradient changes along the length direction of the hydrophobic microchannel, and the interval between every two adjacent hydrophobic microchannels is consistent with the width of two adjacent hydrophobic microchannels.

[0056] The distribution mode of the structure of the hydrophilic nucleation points 3 distributed on the rectangular condensation surface 6 is as follows Figure 4 As shown, the surface of the hydrophilic nucleation point 3 is a hydrophilic surface with a circular shape. A plurality of hydrophilic nucleation points distributed in the hydrophobic microchannel 2 positions of the same width constitute an artificial hydrophilic nucleation column, and the hydrophilic nucleation points 3 in the same artifici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com