Patents

Literature

32results about How to "Lower the nucleation barrier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

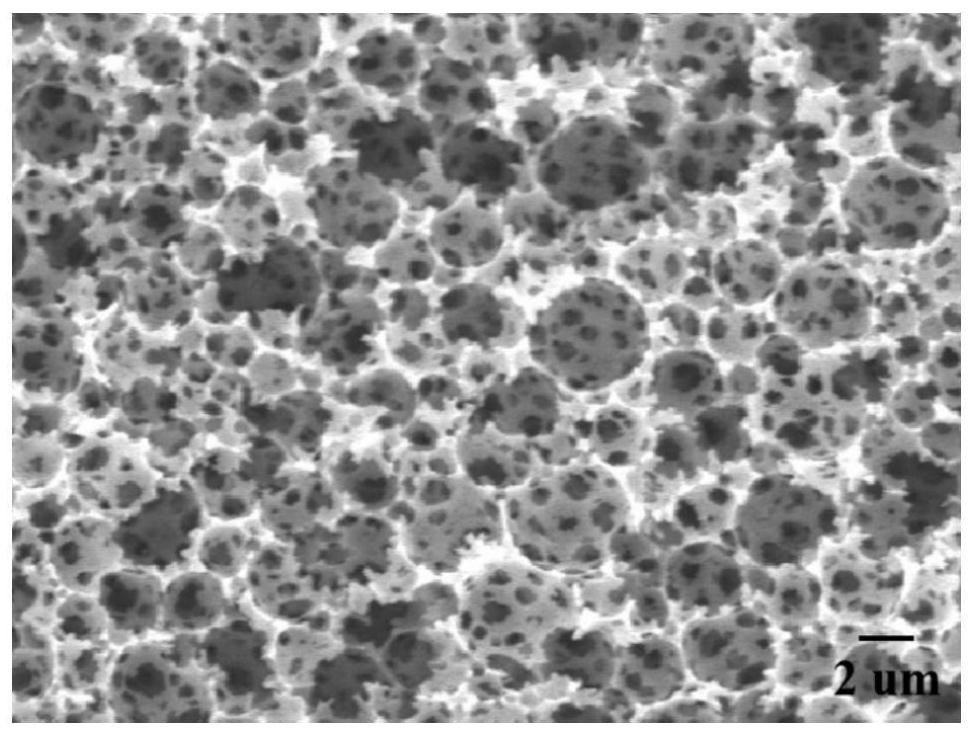

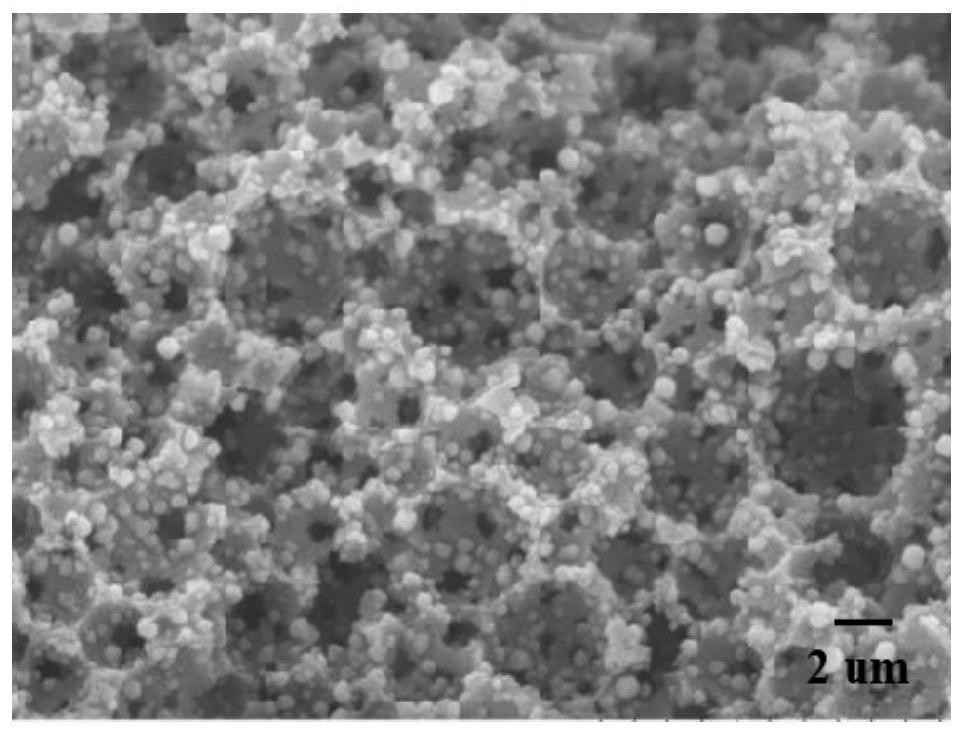

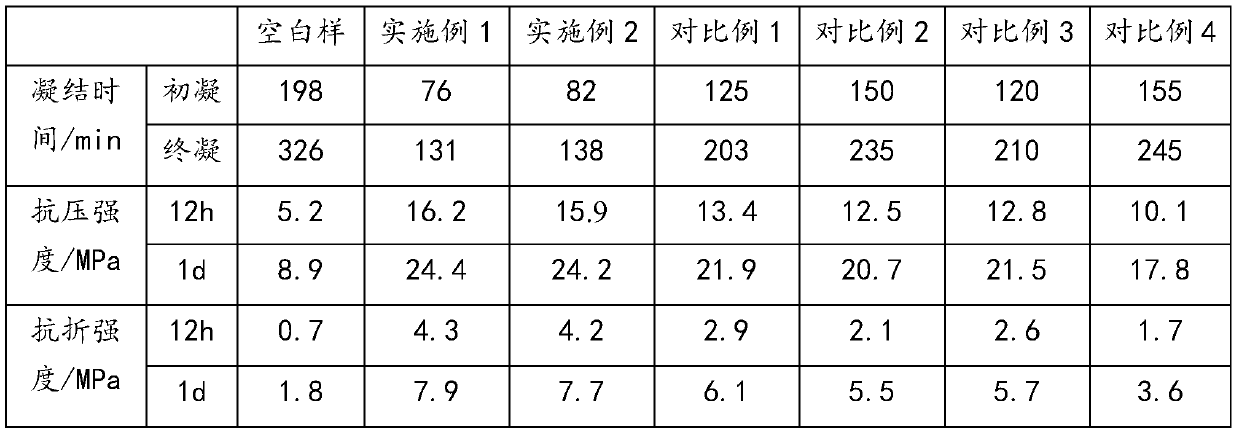

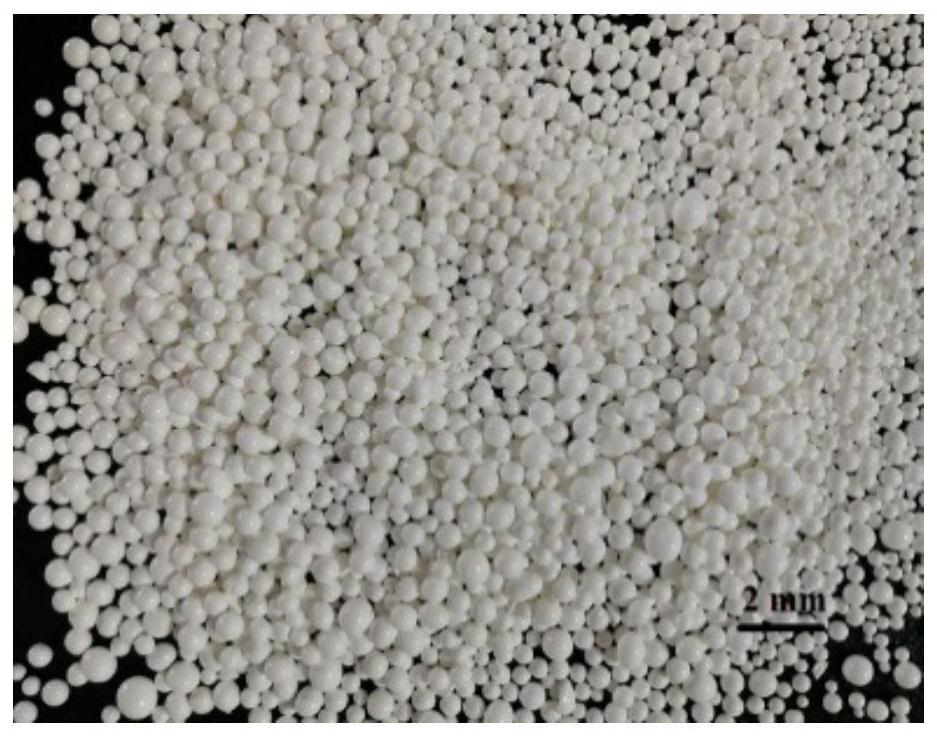

Hydrated calcium silicate early strength agent and preparation method thereof

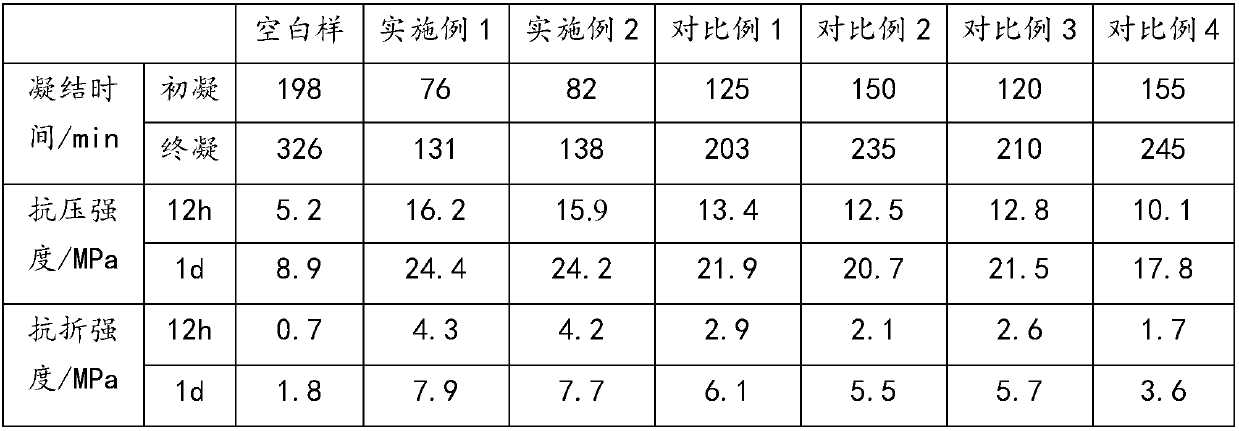

ActiveCN109650398ASmall particle sizeGood dispersionAlkaline-earth metal silicatesCalcium silicatePhenyl Ethers

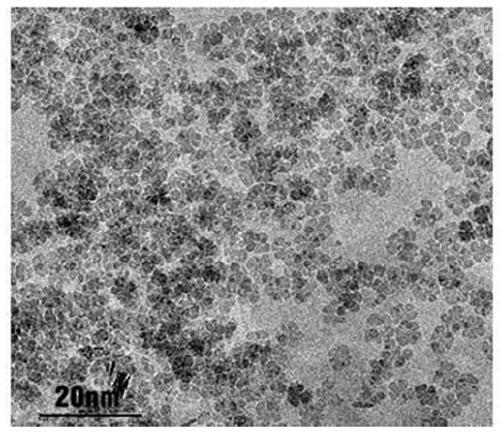

The invention relates to the technical field of building materials, in particular to a hydrated calcium silicate early strength agent and a preparation method thereof. The preparation method of the hydrated calcium silicate early strength agent comprises the following preparation steps of: 1) preparing calcium solution; 2) preparing silicon liquid by taking silicate ester as a silicon source; 3) synthesis of hydrated calcium silicate: placing dispersant solution prepared by compounding polyoxyethylene (5) nonyl phenyl ether and cyclohexane into a shearing and stirring mixing device, keeping stirring at room temperature, adding prepared calcium solution and silicon solution, adjusting the pH value of mixed solution by using alkaline solution, stirring at constant temperature to obtain whitehydrated calcium silicate gel; centrifugally washing obtained white hydrated calcium silicate gel, and drying in a vacuum drying box to obtain the hydrated calcium silicate early strength agent. After the hydrated calcium silicate early strength agent prepared by the preparation method is mixed with cement, the hydration of cement can be promoted, the setting time of cement is obviously shortened, the early strength of cement is improved, and the hydrated calcium silicate early strength agent has important practical application value in the building field.

Owner:KZJ NEW MATERIALS GROUP CO LTD

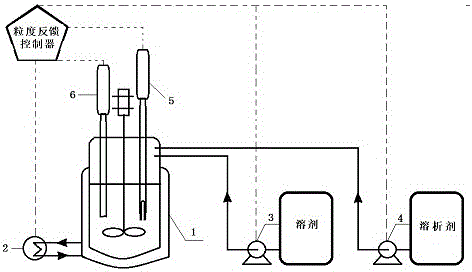

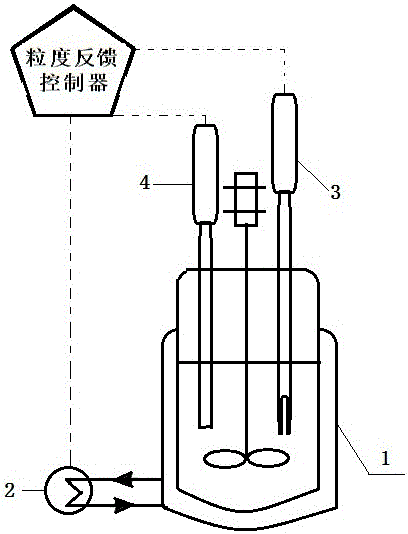

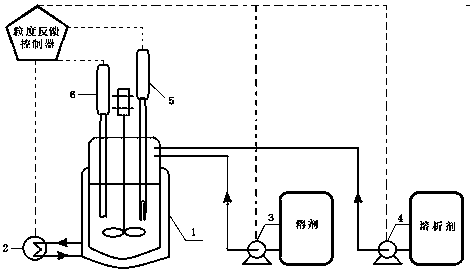

Feedback control method for crystal product granularity in dilution crystallization process

ActiveCN106178583AEliminates manipulations to control crystallizationLower the nucleation barrierSolution crystallizationHeat exchange cooling cystallizationGranularitySolvent

The invention relates to a feedback control method for crystal product granularity in the dilution crystallization process. The method includes the specific steps: estimating the sum of crystal granules according to expected average grain diameter of crystal products, comparing the sum of crystal granules N in crystallization mother liquor measured through an on-line granularity measurement apparatus in real time with the sum of crystal granules Ns specified in production, and synchronously controlling feeding rate of a crystal breaking system, dilution agent and solvent till the crystal products with expected granularity distribution are produced. Compared with the conventional granularity control method in the dilution crystallization process, the method has the advantages that the crystal products with expected granularity distribution can be produced automatically and conveniently as required by only regulating one parameter of the specified sum of crystal granules Ns without re-optimizing new process parameters and the grinding and screening process through plenty of experimental operation, and a granularity controllable regulation function of producing the crystal products with specified granularity distribution as required is realized.

Owner:JIANGYIN HUACHANG FOOD ADDITIVE CO LTD

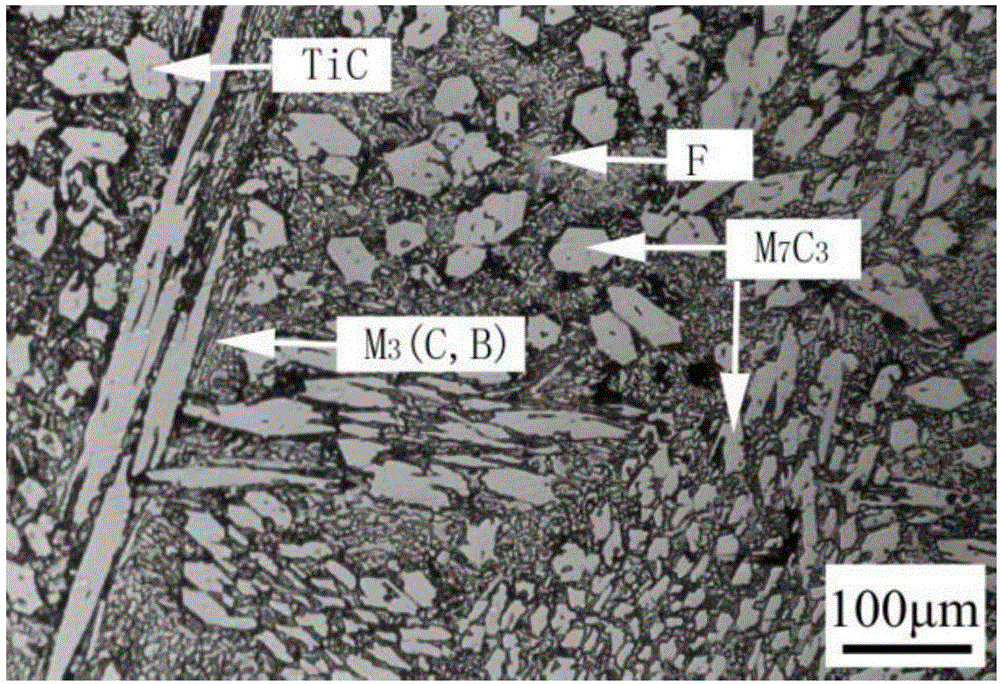

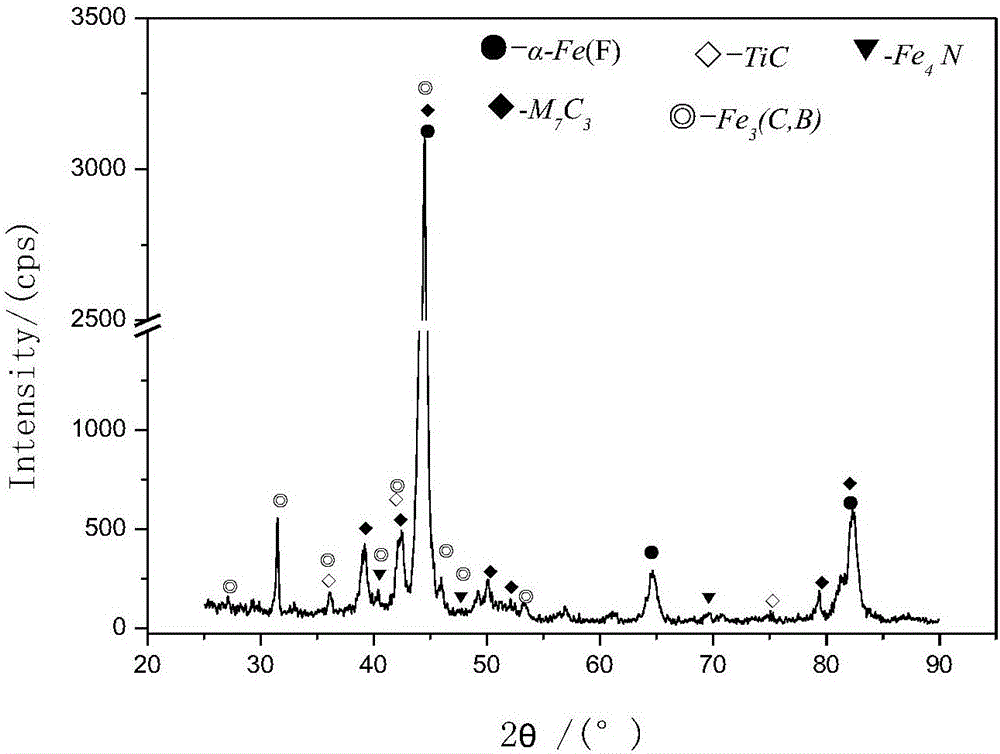

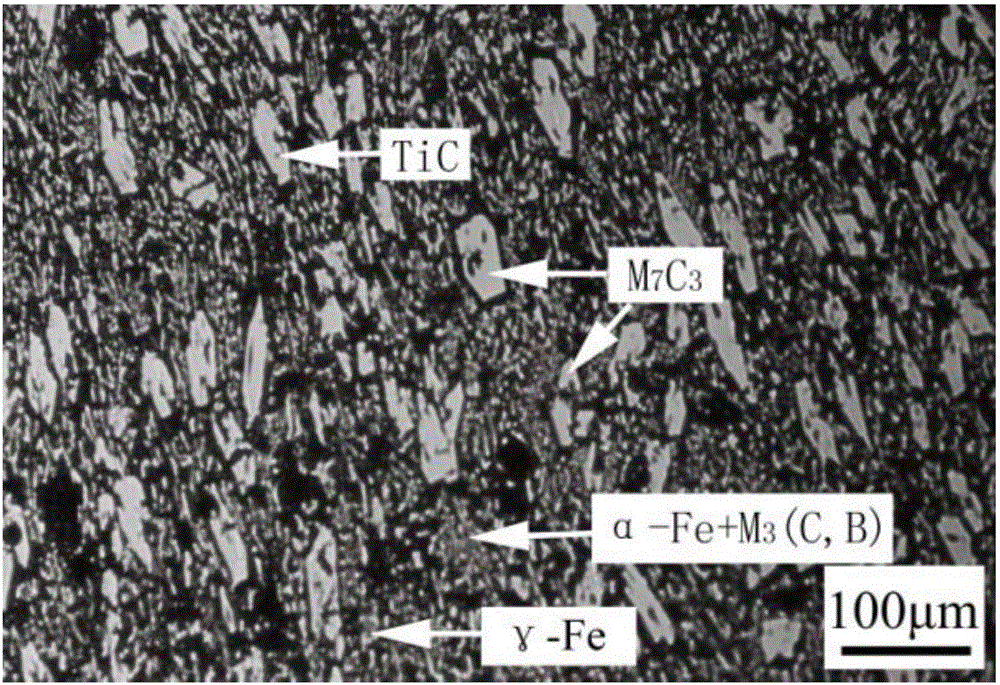

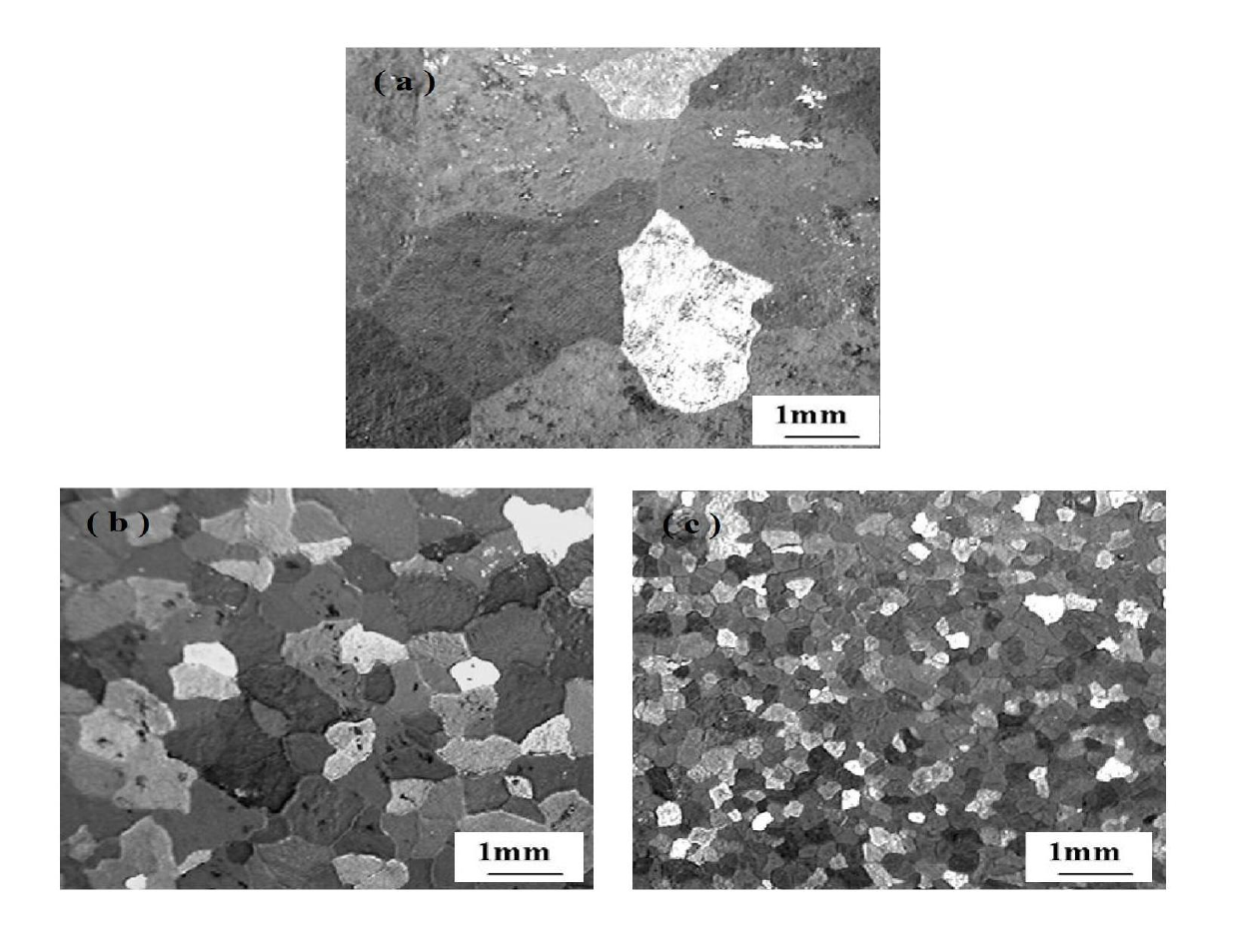

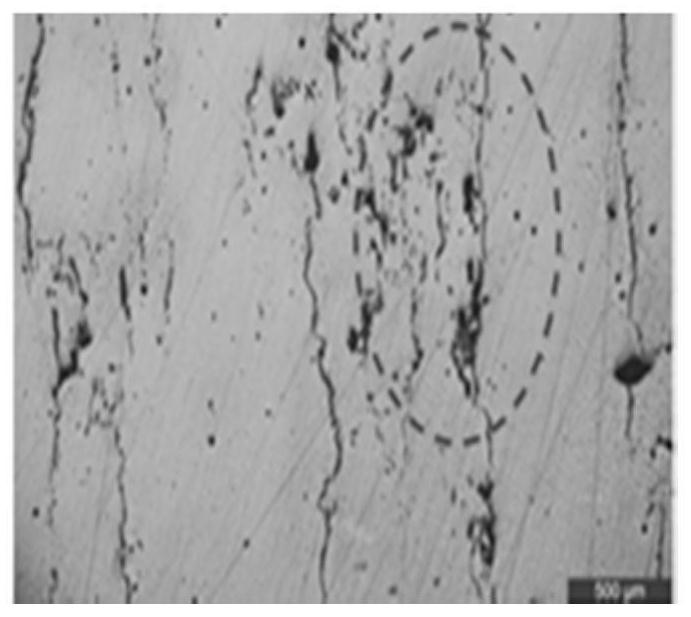

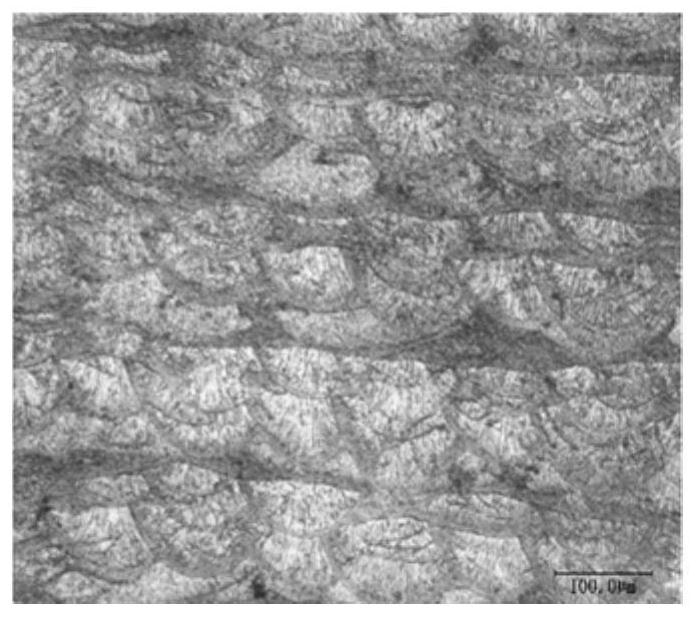

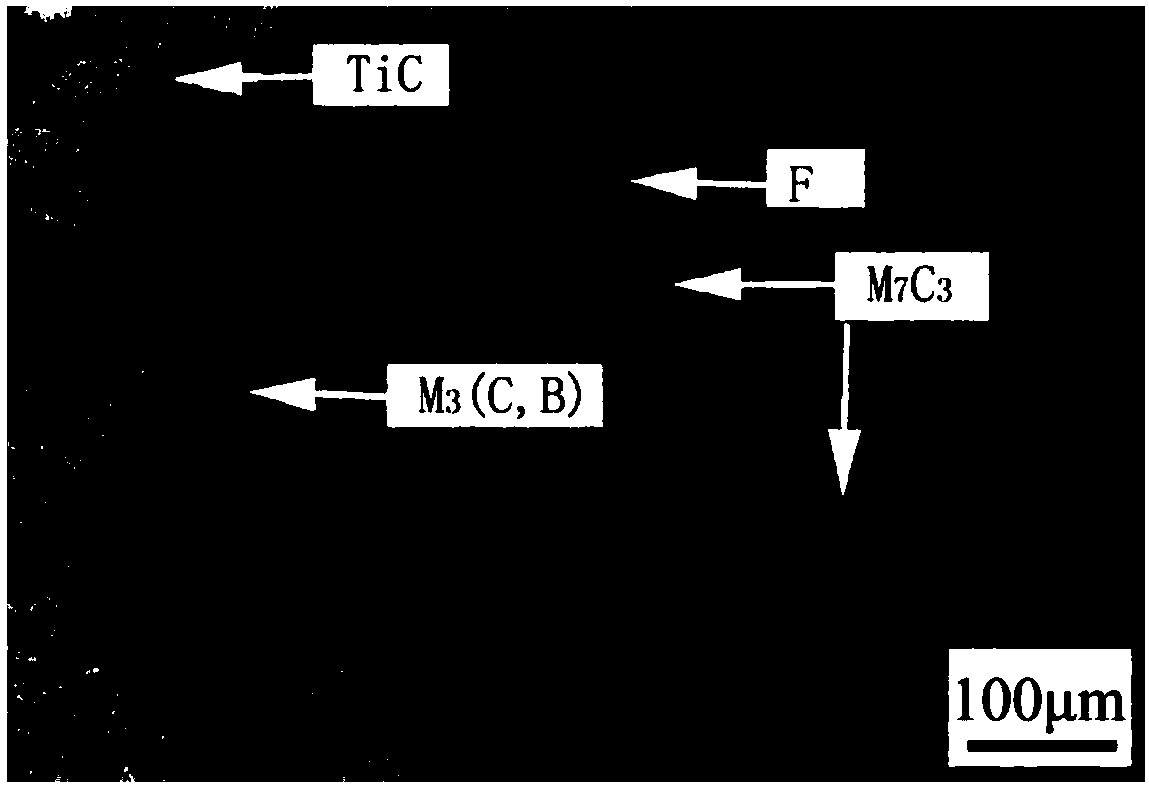

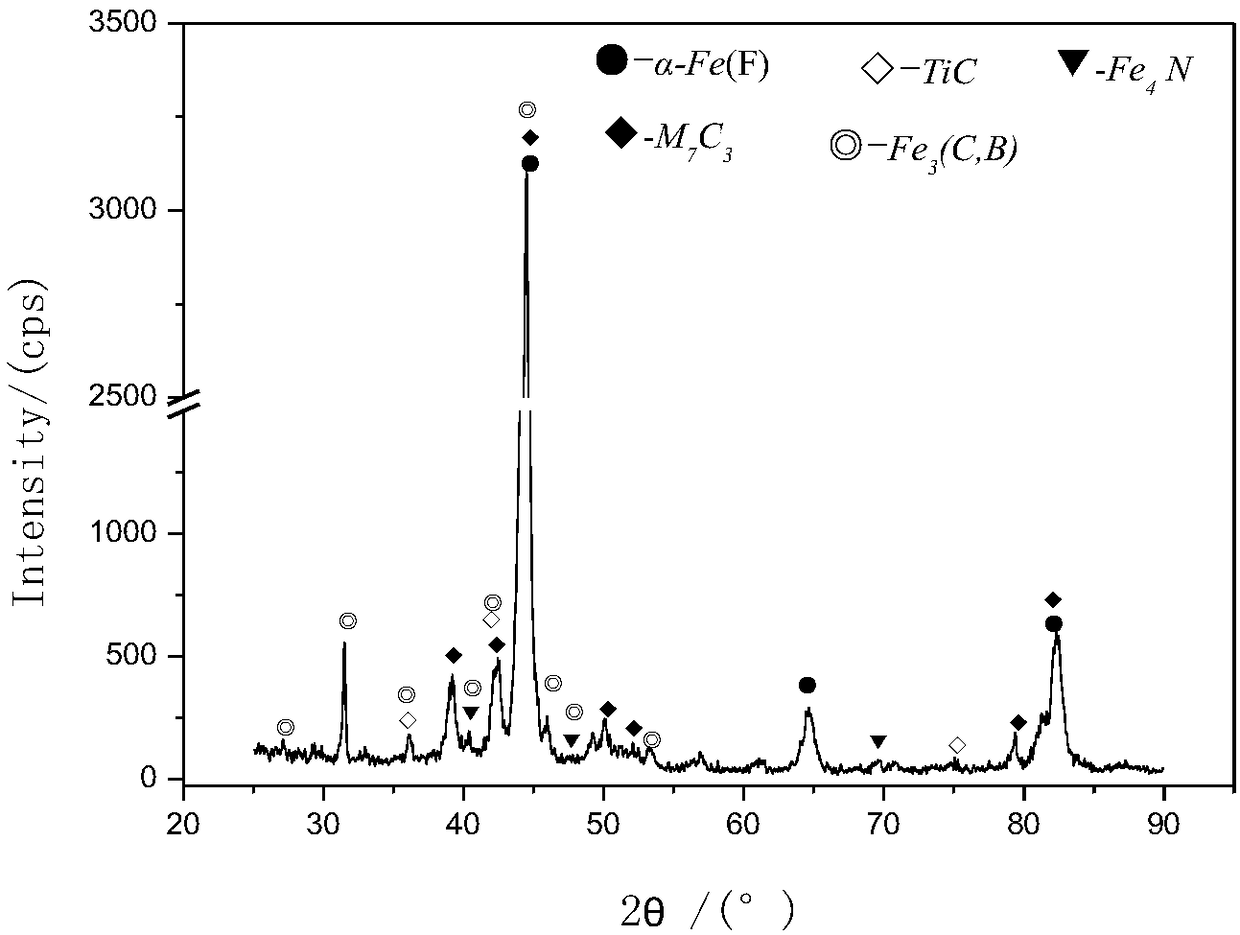

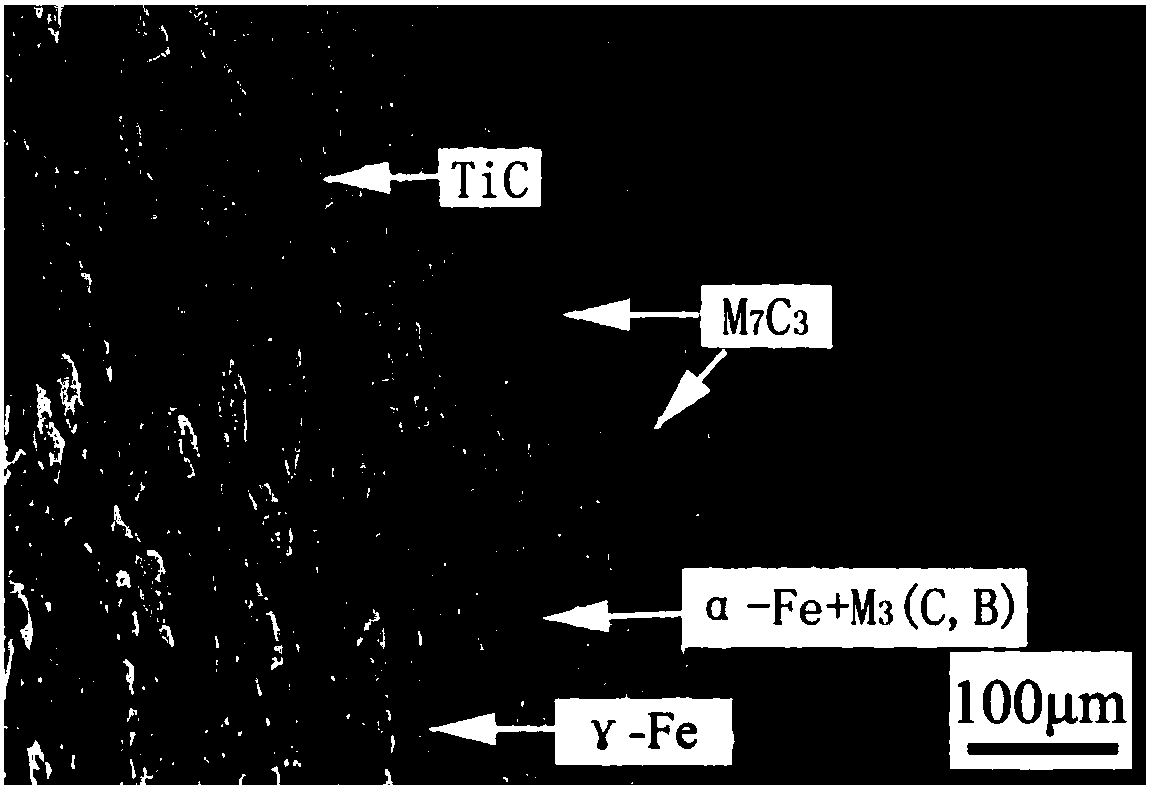

Pre-prepared alloy powder type flux-cored wire and self-protection open arc surfacing welding method of high-chromium alloy

ActiveCN106041361AIncreased welding deposition efficiencyRemarkable effect of energy saving and consumption reductionArc welding apparatusWelding/cutting media/materialsHigh carbonFerrosilicon

The invention discloses a pre-prepared alloy powder type flux-cored wire and a self-protection open arc surfacing welding method of a high-chromium alloy. The adopted technical scheme lies in that a cold rolled thin steel strip manufactured through low-carbon steel H08A as an outer coating, high carbon ferro-chrome, ferrosilicon, graphite and other metal powder are blended inside the coating to form a powder core of the flux-cored wire, and high carbon ferro-chrome, ferroboron, ferrosilicon and reduced iron powder are blended to form pre-prepared alloy powder; and before welding, the alloy powder is placed on a welding bead in advance, the surfacing welding current control value is set, a regulating melt mode combined with the mass of the pre-prepared alloy powder type flux-cored wire is set, a nonhomogeneous melt containing liquid high carbon ferro-chrome atom clusters formed through melting high carbon ferro-chrome particles is formed, and the concretionary high-chromium alloy which adopts the liquid high carbon ferro-chrome atom clusters as component donors, nucleates and grows into primary M7C3 abrasion-resistance phases is formed. According to the method, the problems that the source of components of surfacing welding alloys is single and the chromium content of the surfacing welding alloys is not liable to increase are solved, and the method is widely applied to surfacing welding manufacturing and repairing of parts with the requirement of abrasive wear resistance.

Owner:XIANGTAN UNIV

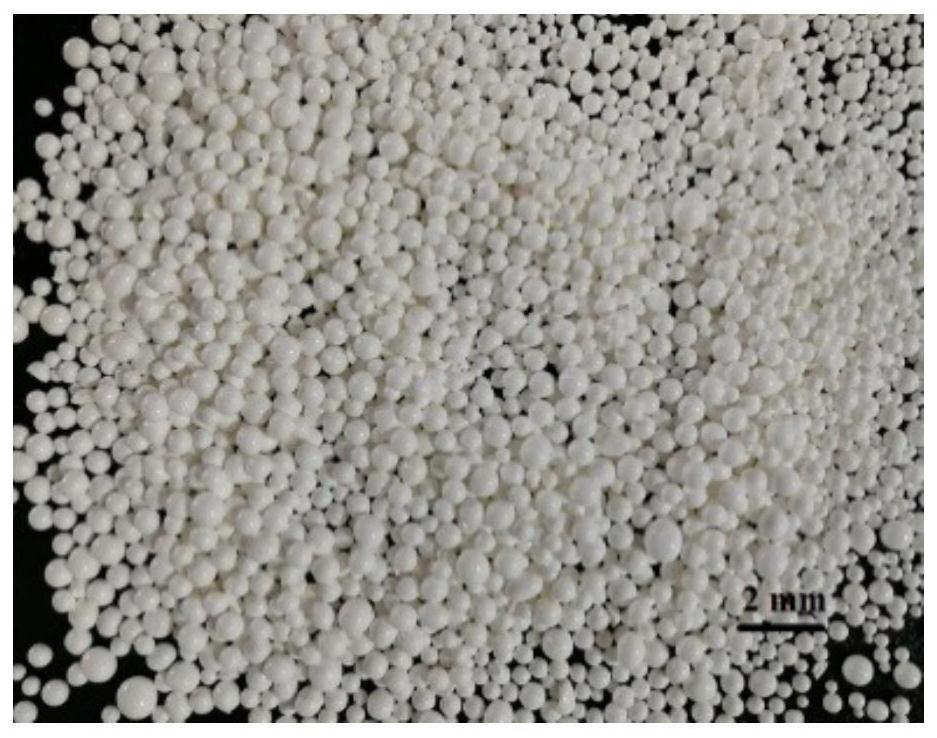

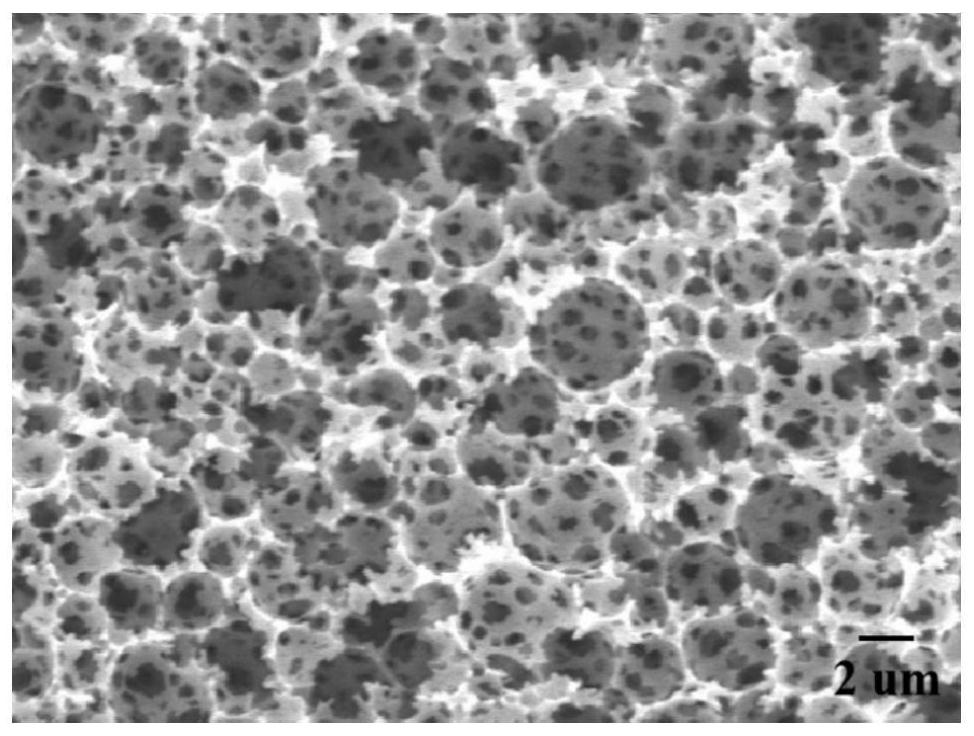

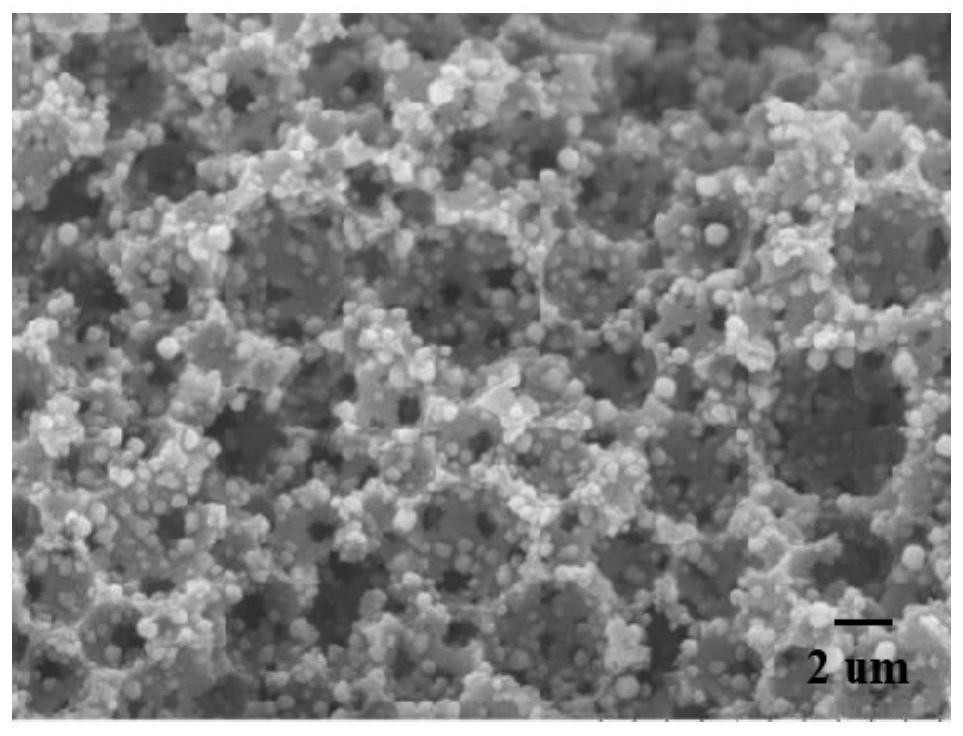

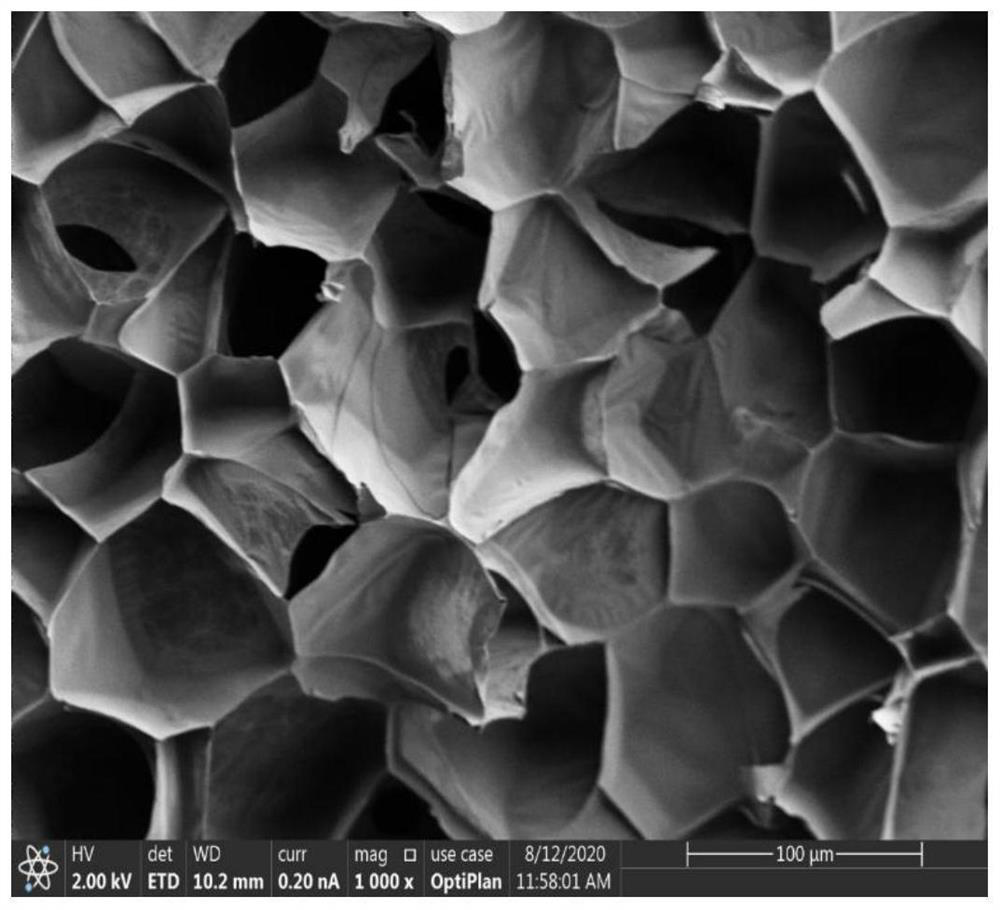

Preparation method of composite material, composite material and application of composite material

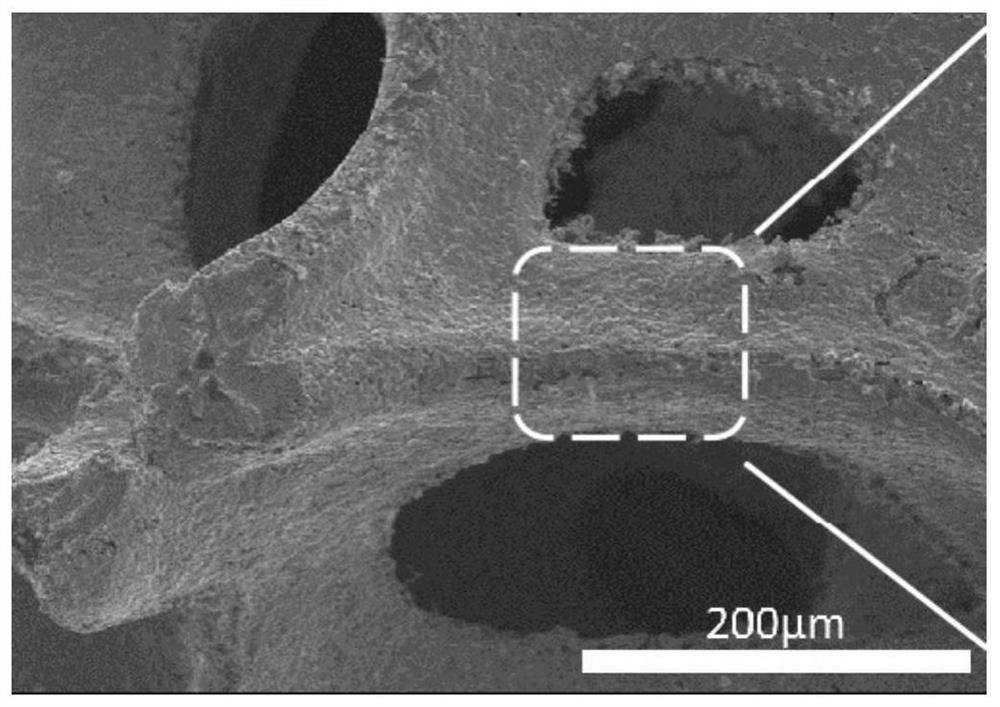

ActiveCN111892791AIncrease mass transfer rateImprove adsorption efficiencyGas treatmentOther chemical processesWater vaporPolyacrylamide

The invention discloses a preparation method of a composite material, a product and application of the composite material. According to the method, a precursor solution is impregnated into polymer particles, in-situ loading of MOFs one-time forming is achieved, structural design is conducted on the porous composite material by adjusting the concentration of metal salt and organic ligands and adding an adjusting agent, and regulation and control over the size of MOFs crystals are achieved. According to the composite material prepared by the method, the space structure advantages of polyacrylamide materials which are communicated with one another and have hierarchical pore structures can be utilized; by combining with active amino on the pore wall, uniform spreading of a nano MOFs layer is realized, the mass transfer rate and the adsorption efficiency of the material in water vapor trapping are greatly improved, and the material can be suitable for water vapor trapping in different humidity environments. The method is simple in preparation mode, easy to form, high in mechanical strength and suitable for industrial production.

Owner:BEIJING UNIV OF CHEM TECH

Feedback control method of granularity for crystal product in intermittent cooling and crystallization process

ActiveCN106267880AReduce stepsLower the nucleation barrierSolution crystallizationHeat exchange cooling cystallizationSynchronous controlGranularity

The invention relates to a feedback control method of the granularity for a crystal product in an intermittent cooling and crystallization process. According to the technical scheme, the feedback control method comprises the following specific realization steps: estimating the total quantity Ns of crystal particles according to an expected needed crystal product average grain diameter; comparing the total quantity N of crystal particles in crystallization mother liquid, which is determined through an online granularity detector in real time, with the total quantity Ns of the crystal particles specified by production; synchronously controlling heating and cooling speeds in a crystal crushing system II and a crystallizer until crystal products with expected granularity distribution are produced. Compared with a traditional granularity control method of the intermittent cooling and crystallization process, only one specified parameter, namely the total quantity Ns of the crystal particles, needs to be adjusted, a novel process parameter and a grinding and sieving process do not need to be optimized through a lot of experiment operation, and the crystal products with the expected specified granularity distribution can be automatically and conveniently produced according to requirements; a granularity controllable adjustment function of the crystal products produced according to the requirements and having the specified granularity distribution is realized.

Owner:JIANGYIN HUACHANG FOOD ADDITIVE CO LTD

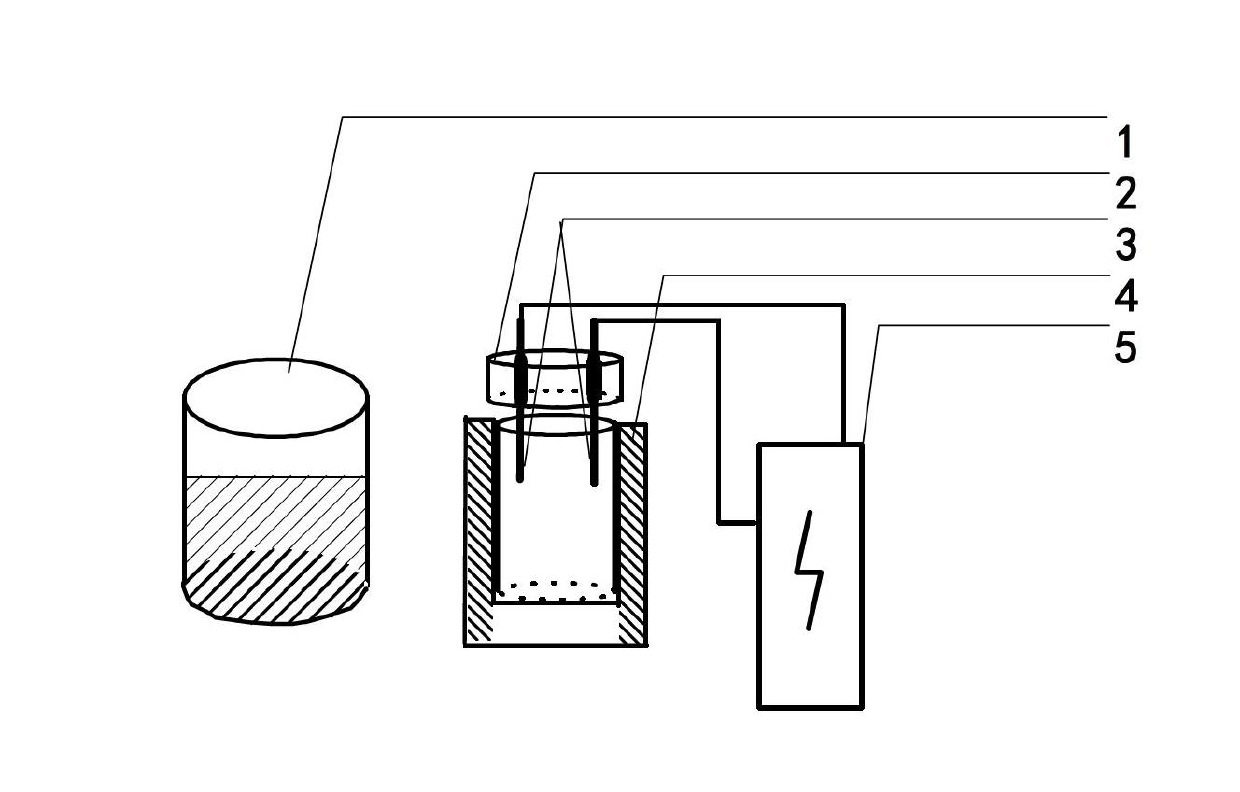

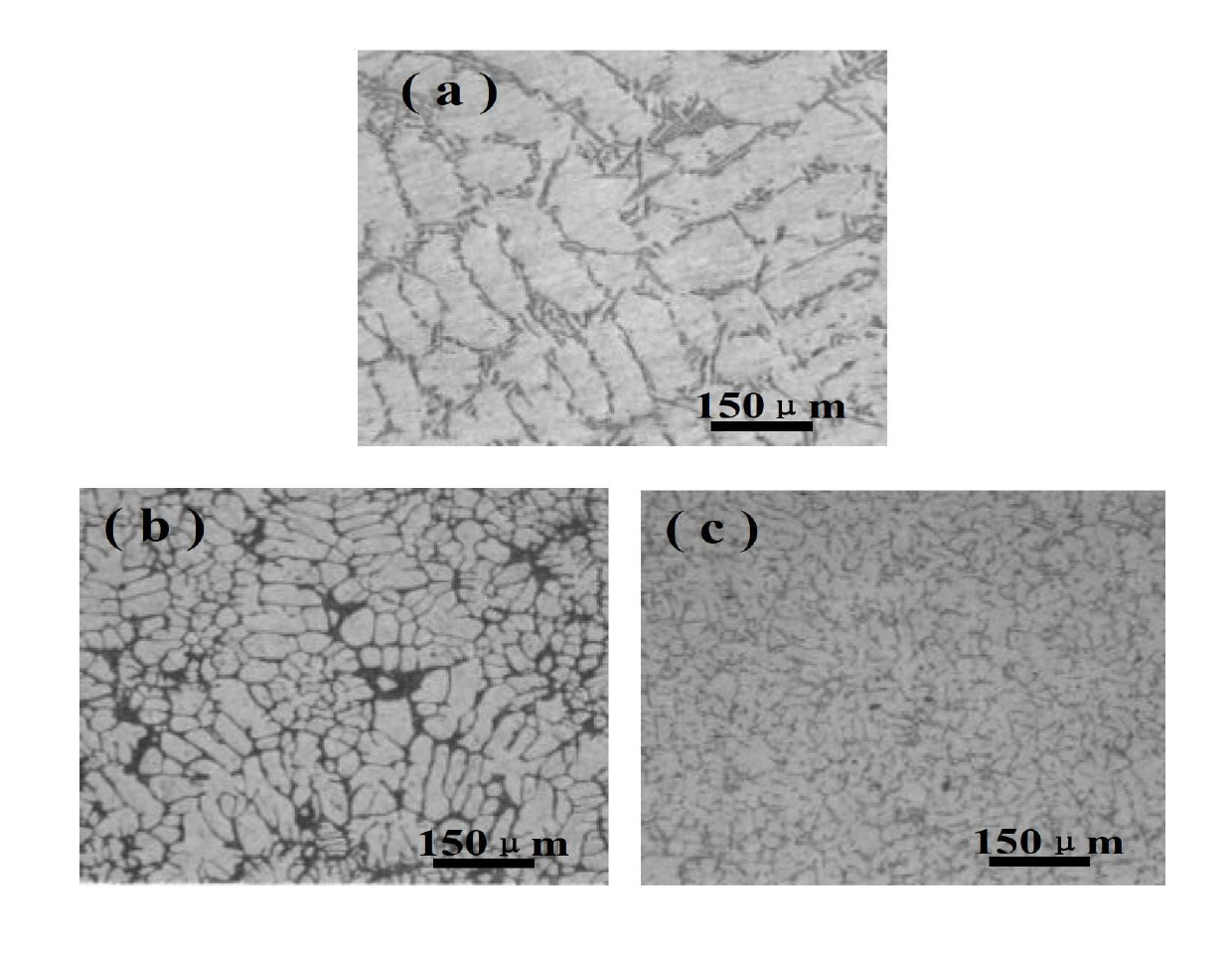

Method for complexly refining aluminum alloy solidified structure by using current and crystal grain refining agent

The invention provides a method for complexly refining aluminum alloy solidified structure by using a current and a crystal grain refining agent. The crystal grain refining agent is added in a process of smelting an aluminum alloy and a direct current is introduced in an aluminum alloy solidifying process until an aluminum alloy is completely solidified. The method comprises the following steps of: (1) placing an electrode in a casting mould, connecting the electrode with a power supply, and adjusting current parameters; (2) smelting the aluminum alloy through conventional smelting, refining, degassing and de-slagging procedures; (3) after the temperature of an aluminum alloy mother solution is stabilized to a pre-set temperature, adding the crystal grain refining agent and agitating; and (4) pouring the aluminum alloy mother solution, simultaneously switching on the power supply, and continuously introducing the current until a casting piece is completely solidified. According to the invention, a complex method of combining physical refining and chemical is adopted, so that an aluminum alloy structure with finer crystal grains, more uniform structure and obviously-reduced defects can be obtained and he mechanical property of the aluminum alloy can be improved; and meanwhile, the situation that the industry depends on the imported crystal grain refining agent for a long period is broken through, and the method is suitable for solidifying and refining pure aluminum or the aluminum alloy.

Owner:SHANGHAI JIAO TONG UNIV

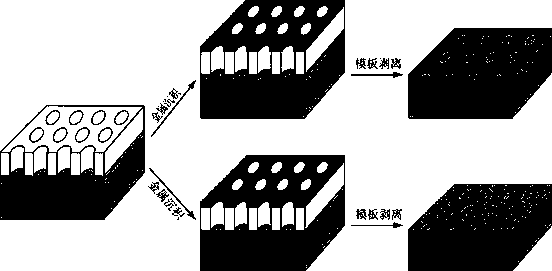

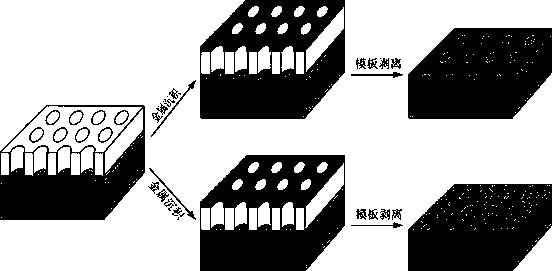

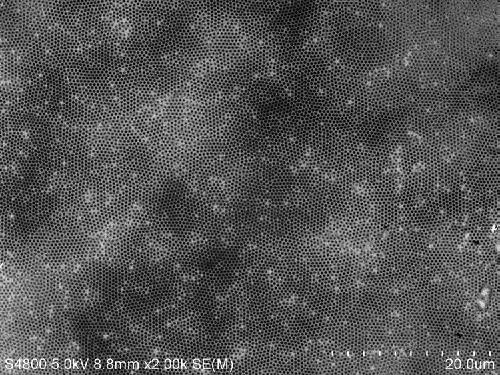

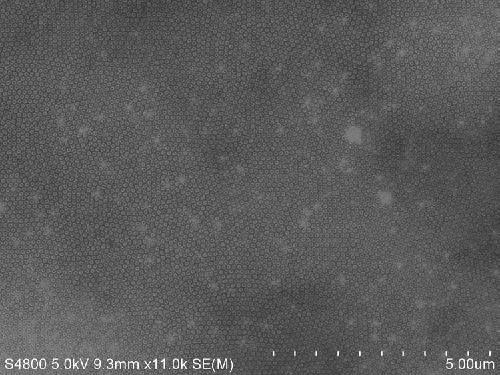

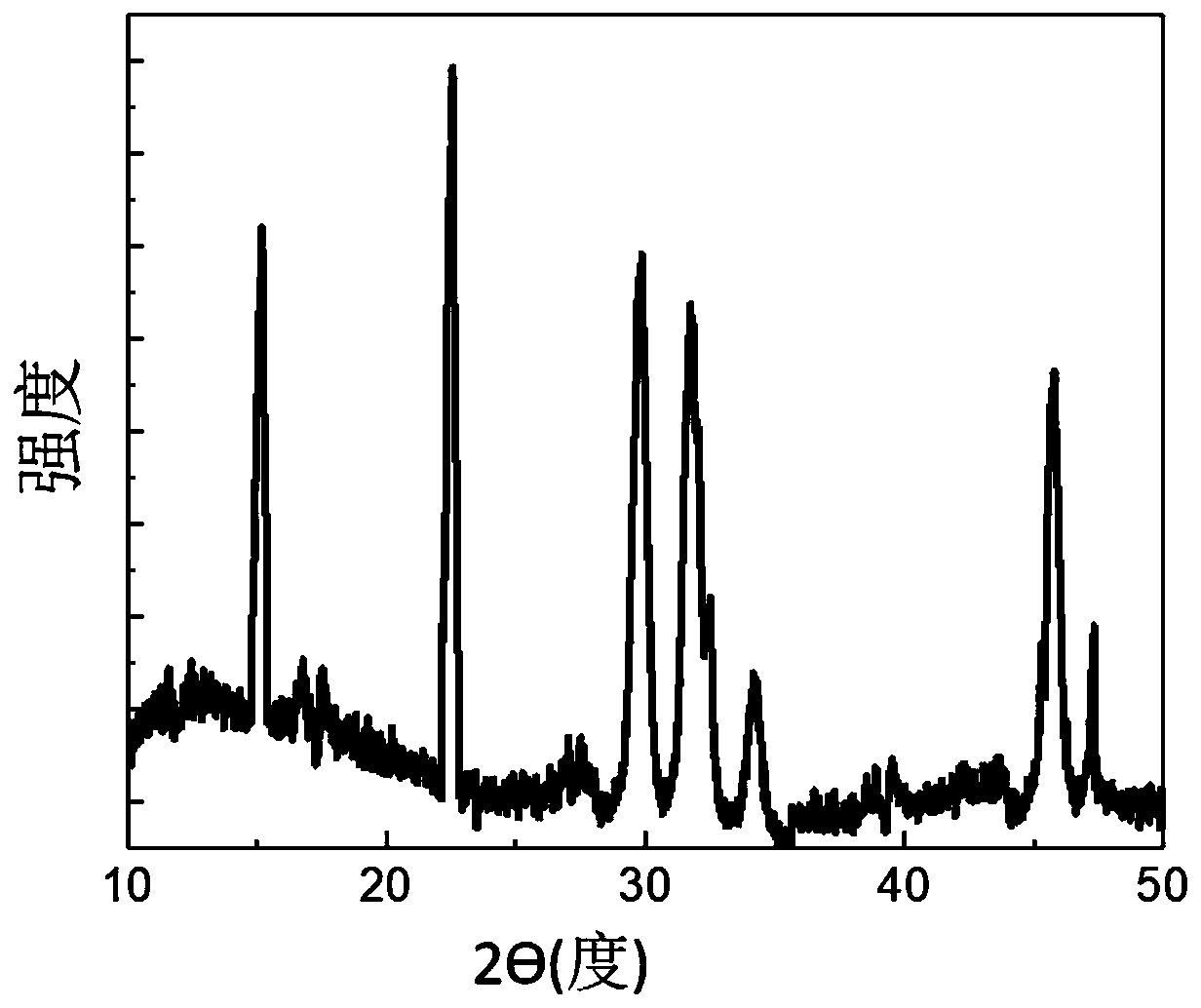

Manufacturing method of metal nanostructure array based on interface induction growth

ActiveCN108417475AImprove controllabilitySimple processMaterial nanotechnologySemiconductor/solid-state device manufacturingGas phaseNanostructure

The invention relates to the manufacturing method of a metal nanostructure array based on interface induction growth. The method comprises the following steps of 1, cleaning a substrate; 2, transferring a template, and transferring an ultrathin porous alumina template to the cleaned substrate; adjusting an adhesive force, standing a sample acquired from the step2 for several hours so that an adhesive force portion between the template and the substrate is relaxed, or through low temperature annealing, strengthening the adhesive force between the template and the substrate; 4, depositing metal,and depositing the metal on the surface of the sample obtained from the step3 by using a physical vapor deposition method; and 5, peeling the template, after the deposition is completed, using an adhesive tape to peel the template so that an ordered metal nanostructure array is left on the surface of the substrate, wherein under an adhesive force relaxation condition, an ordered nano-pore array is acquired, and under an adhesive force strengthening condition, an ordered nano-ring array is acquired. The technology of the method is simple, cost is low, and the method can be expanded to a waferscale.

Owner:ANHUI NORMAL UNIV

Quantum dot fluorescent probe for pH detection as well as preparation method and application of quantum dot fluorescent probe

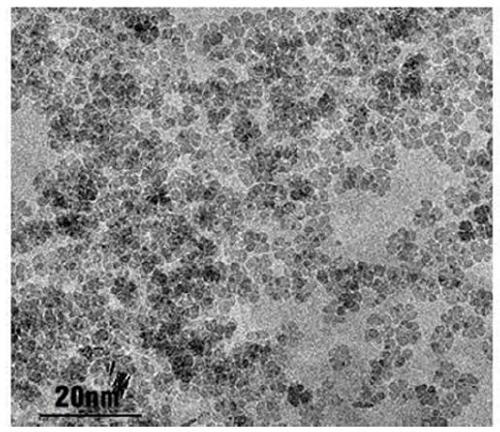

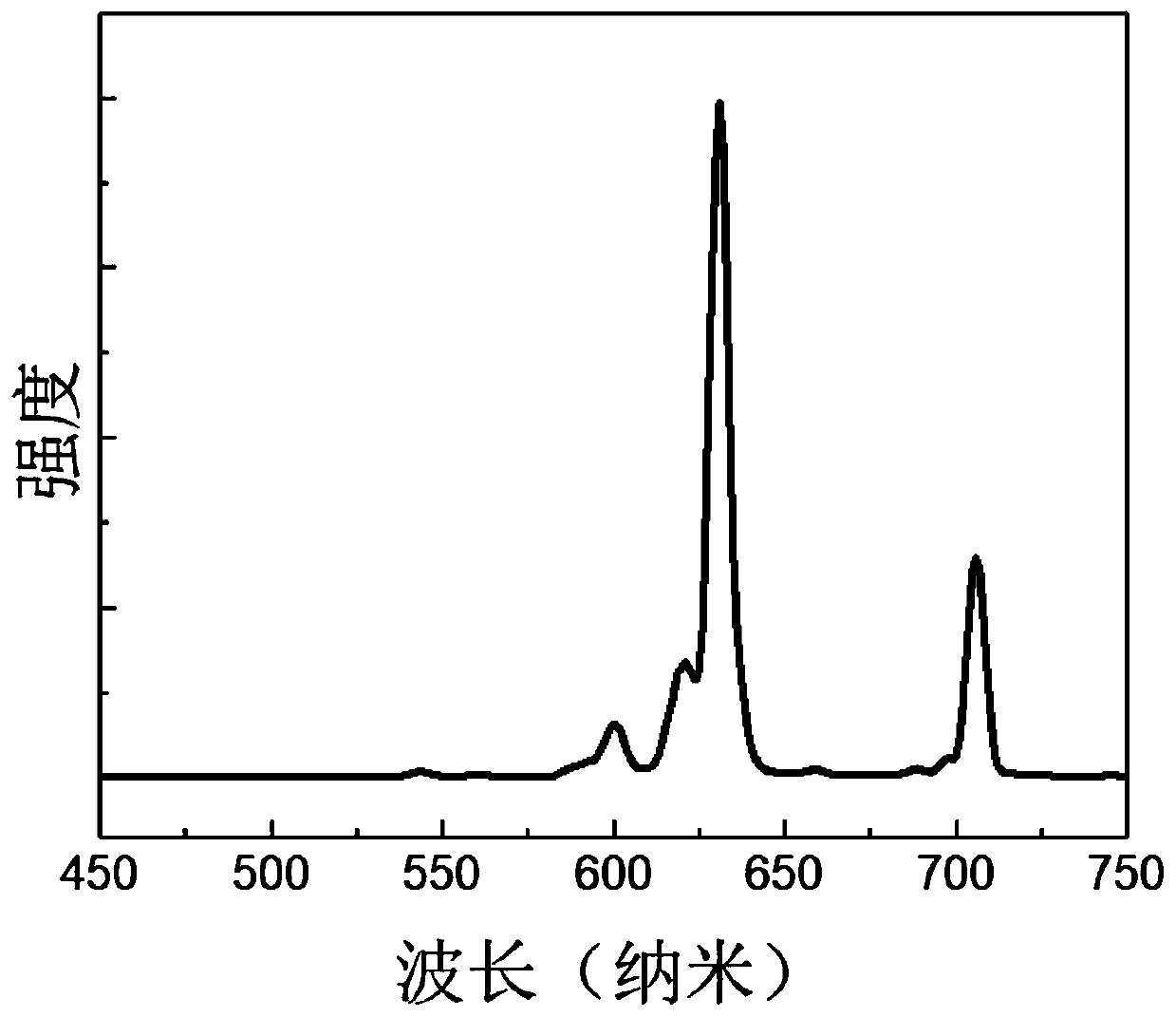

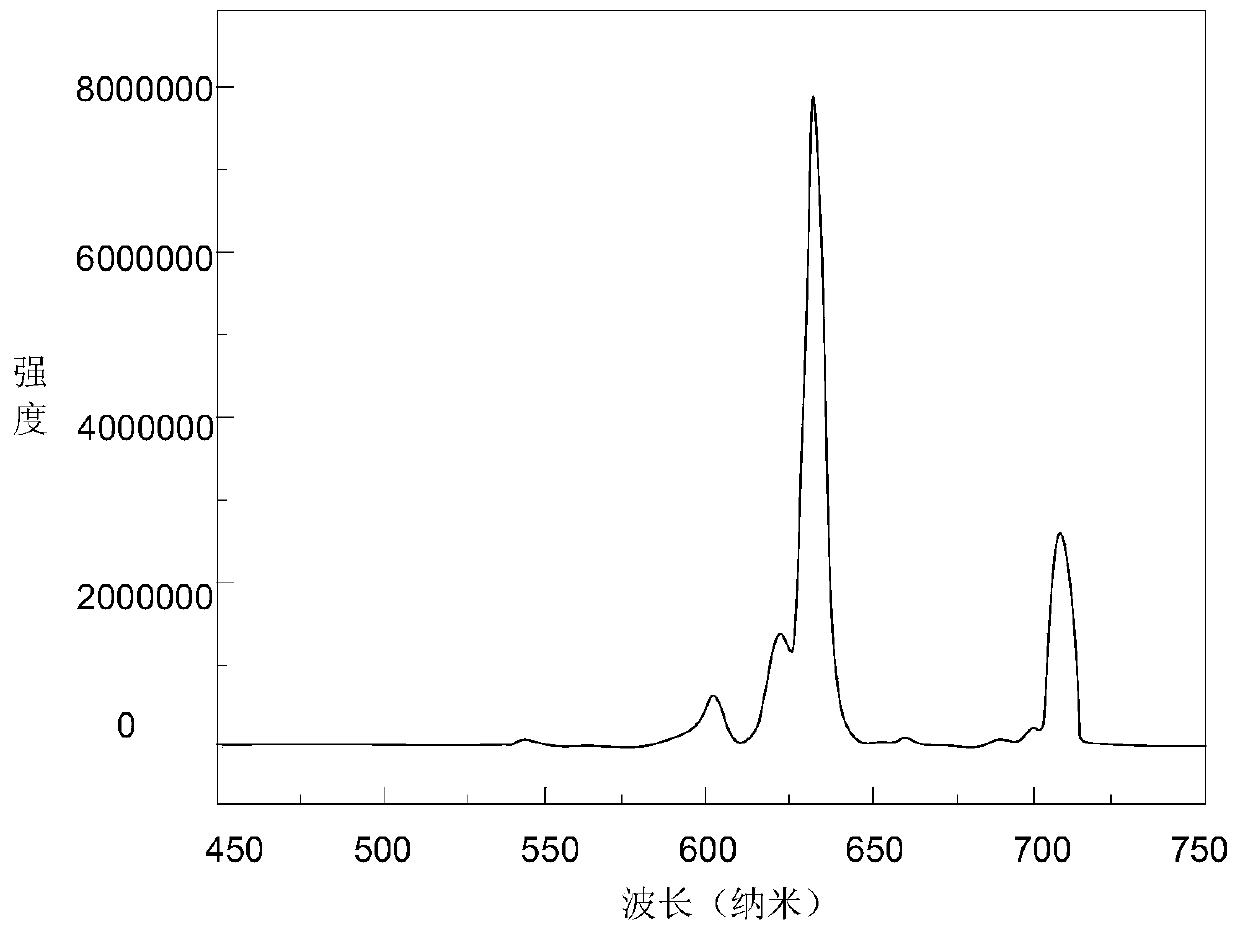

InactiveCN111286327ALower the nucleation barrierDecreased fluorescence intensityMaterial nanotechnologyNanoopticsCarboxylic groupQuantum dot

The invention belongs to the field of inorganic luminescent materials. The invention relates to preparation of a calcium ion and europium ion co-doped bismuth oxysulfide nanocrystal and an applicationof the nanocrystal in pH detection. A quantum dot fluorescent probe for pH detection is formed by modifying the surface of a citric acid ligand with 10Ca / 6Eu: Bi2O2S nanocrystals, and the molar ratioof the citric acid ligand to the 10Ca / 6Eu: Bi2O2S nanocrystals is (2-10): 1. In the process of preparing the nanocrystal, alkaline earth calcium ions are added, so that the nucleation energy barrierof the bismuth oxysulfide nanocrystal is reduced, and the growth of the bismuth oxysulfide nanocrystal is further promoted. On the basis, through surface ligand exchange, the surface of the nanocrystalline is provided with the citric acid ligand. Along with the increase of the pH value, carboxyl in citric acid is gradually ionized, and the electronegativity of the surface of the nanocrystal is gradually reduced, so that the electronic layout on a charge migration band is inhibited, and the fluorescence intensity of Eu<3+> ions is further reduced. The simple fluorescence pH detection method provides a new idea for exploring a novel pH probe.

Owner:杭州众道光电科技有限公司

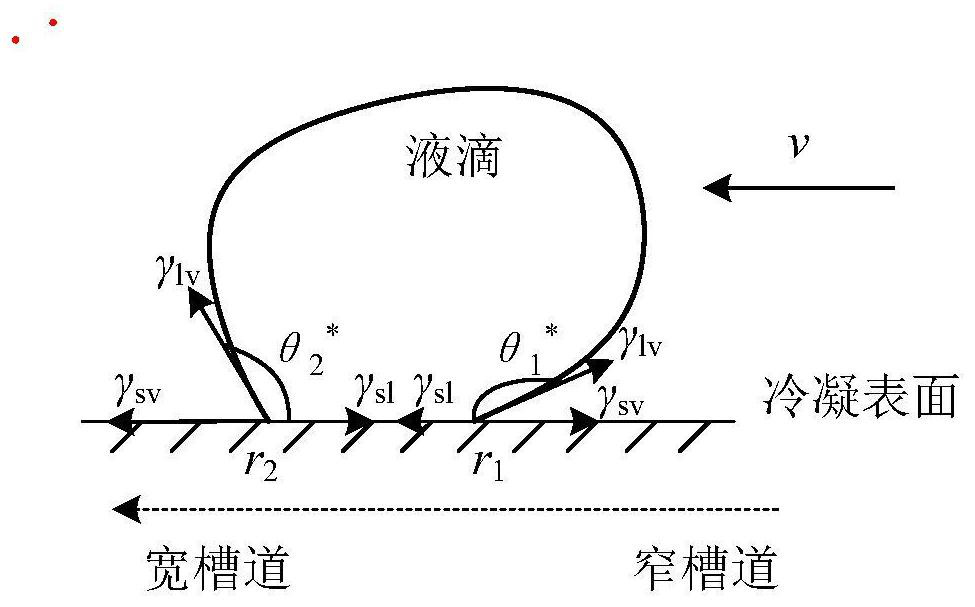

Bionic condensation enhanced heat transfer surface

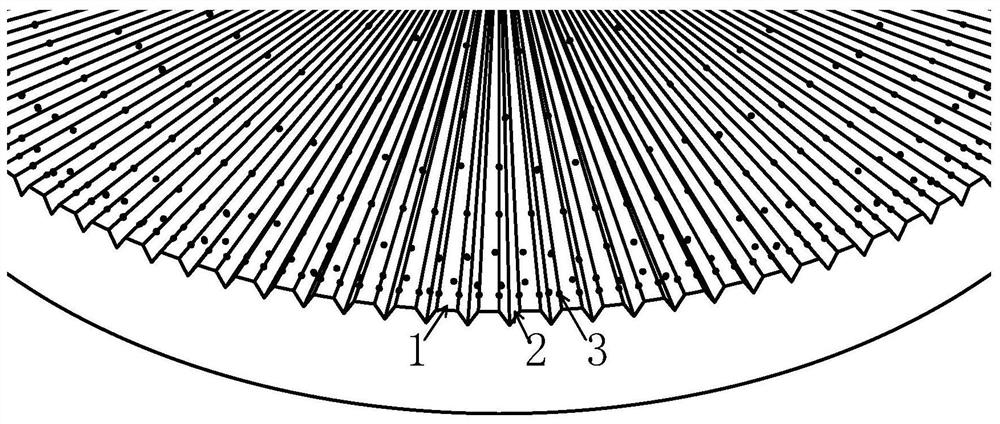

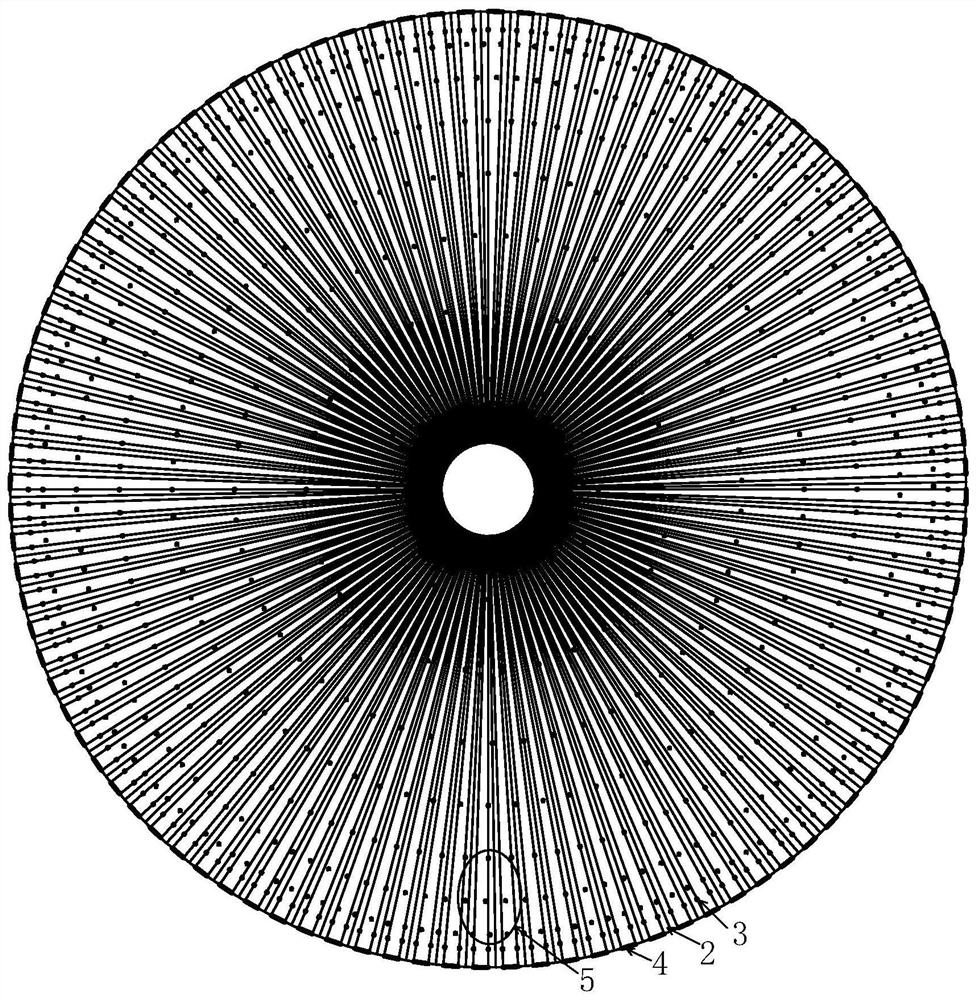

InactiveCN112229234AEasy dischargeAccelerates the draining processSteam/vapor condensersHeat transfer modificationCondensation processFree energies

The invention discloses a bionic condensation enhanced heat transfer surface. The bionic condensation enhanced heat transfer surface comprises a substrate, micro-channels and hydrophilic nucleation points, wherein the substrate has hydrophobicity; the micro-channels are dispersed on the substrate at the same central angle in the radial direction of a circle center, and the circle center is locatedon the substrate or not located on the substrate; the hydrophilic nucleation points are distributed on the substrate; and the width between the adjacent micro-channels is increased in a gradient manner in the length direction. According to the condensation heat transfer surface, the surface free energy gradient is used for generating driving force on condensed liquid drops, liquid discharging ofa condensation surface is accelerated, nucleation of the condensed liquid drops on the condensation surface is accelerated through the hydrophilic nucleation points distributed on the surface of a hydrophobic substrate, a more stable bead-shaped condensation process is formed on the condensation surface, and smooth conduction of condensation circulation is guaranteed. The bionic condensation enhanced heat transfer surface can effectively improve the nucleation and updating rate of the condensed liquid drops, ensure continuous and stable bead-shaped condensation behaviors and enhance the condensation phase change heat transfer performance.

Owner:SOUTHEAST UNIV

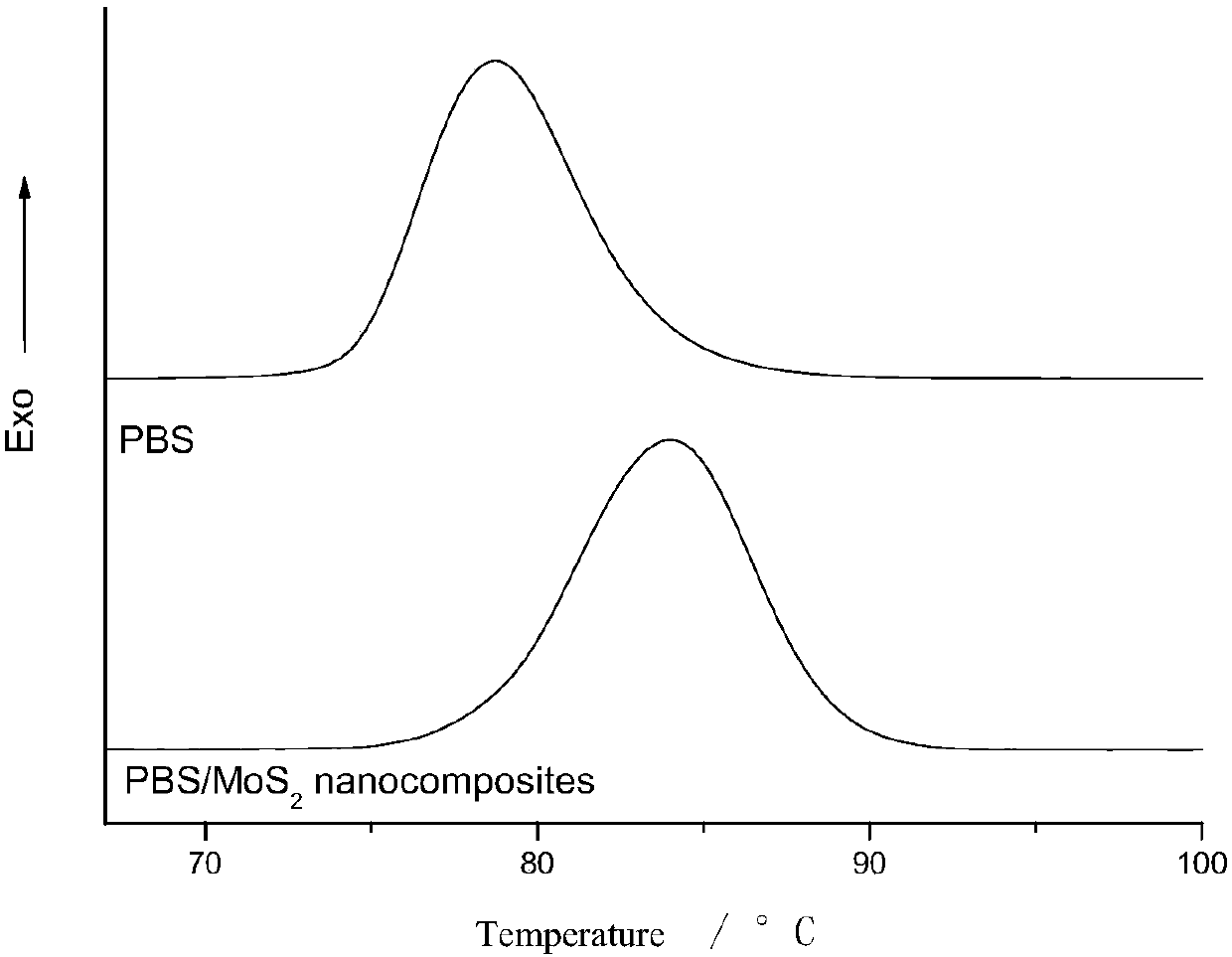

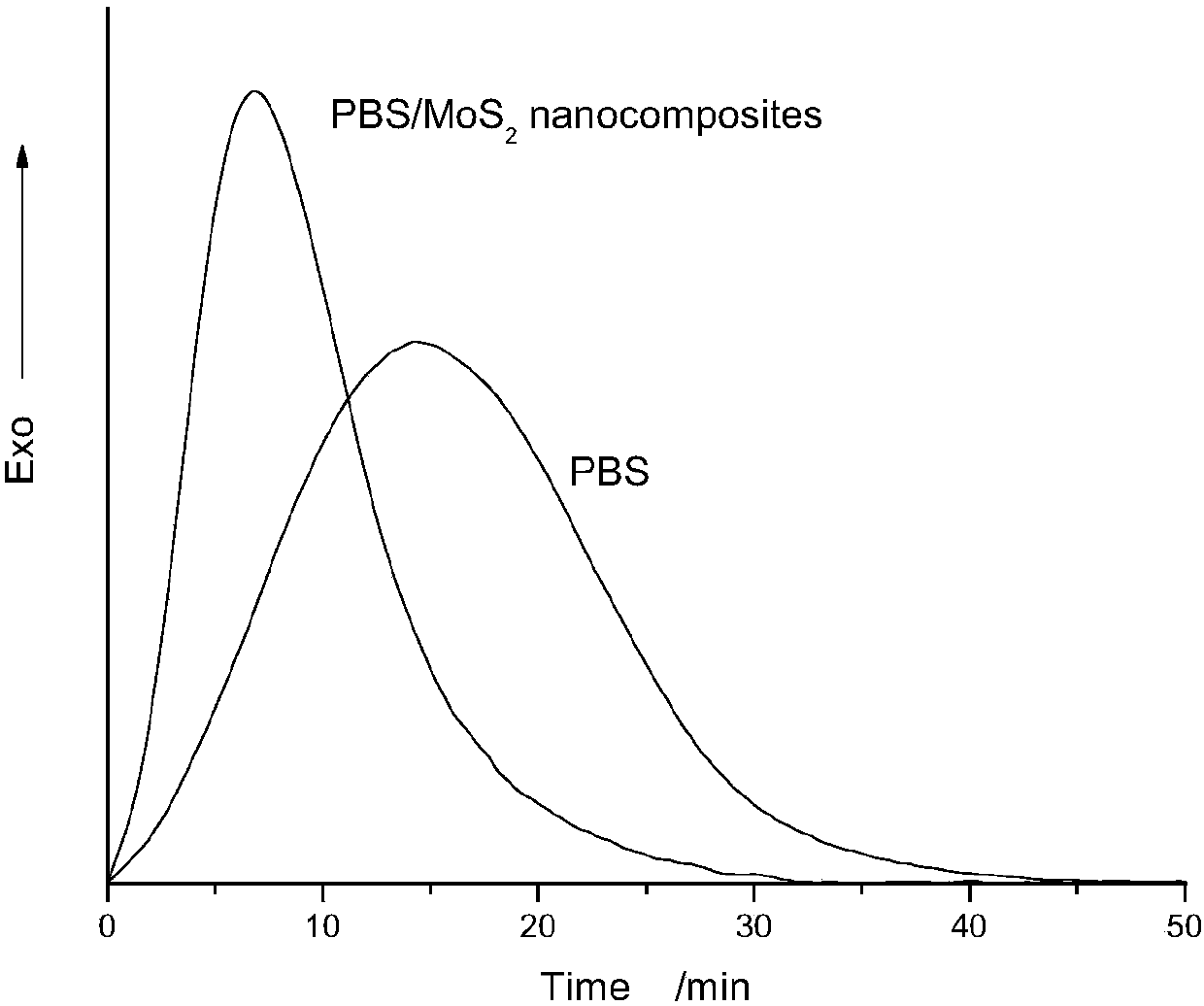

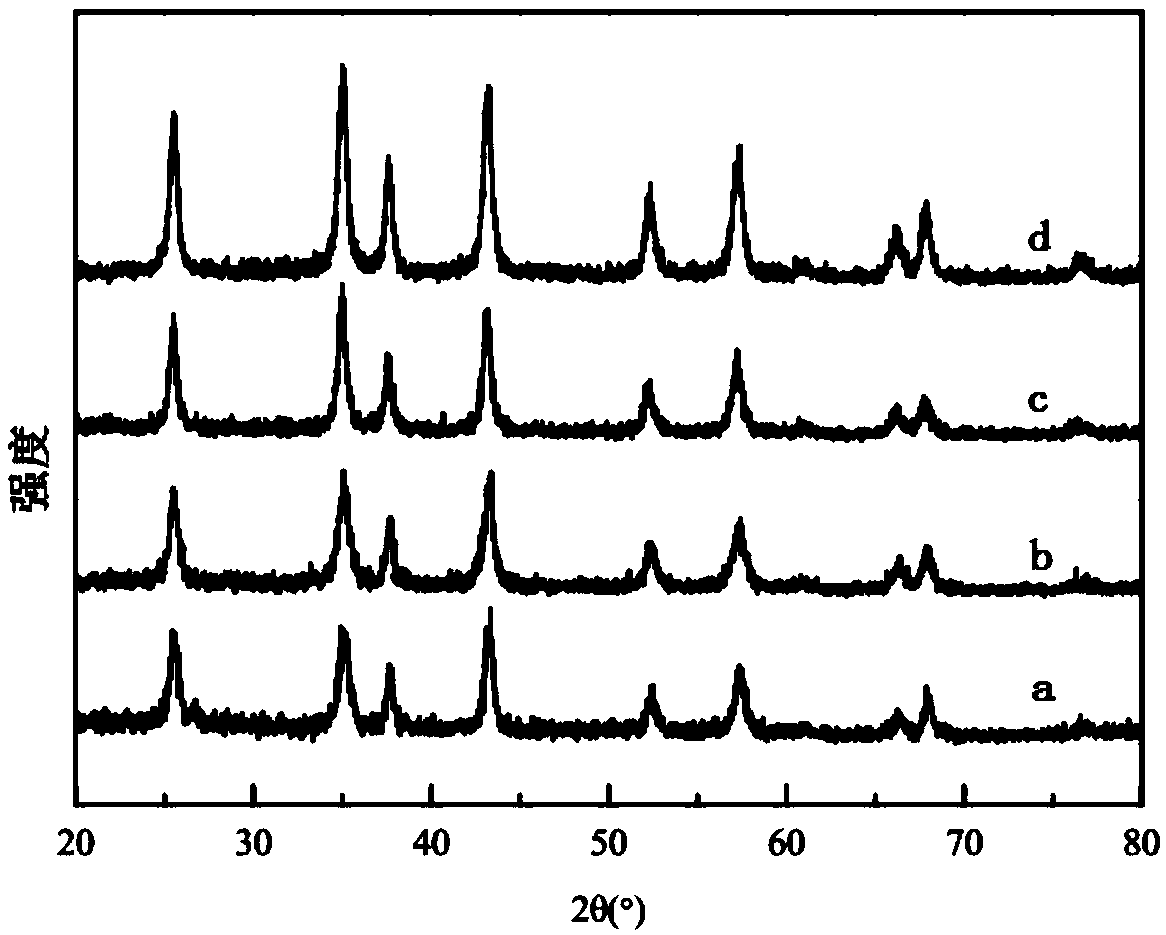

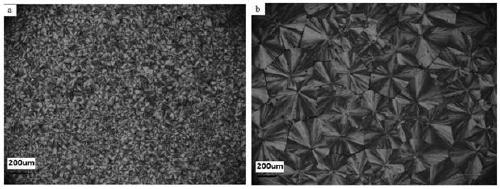

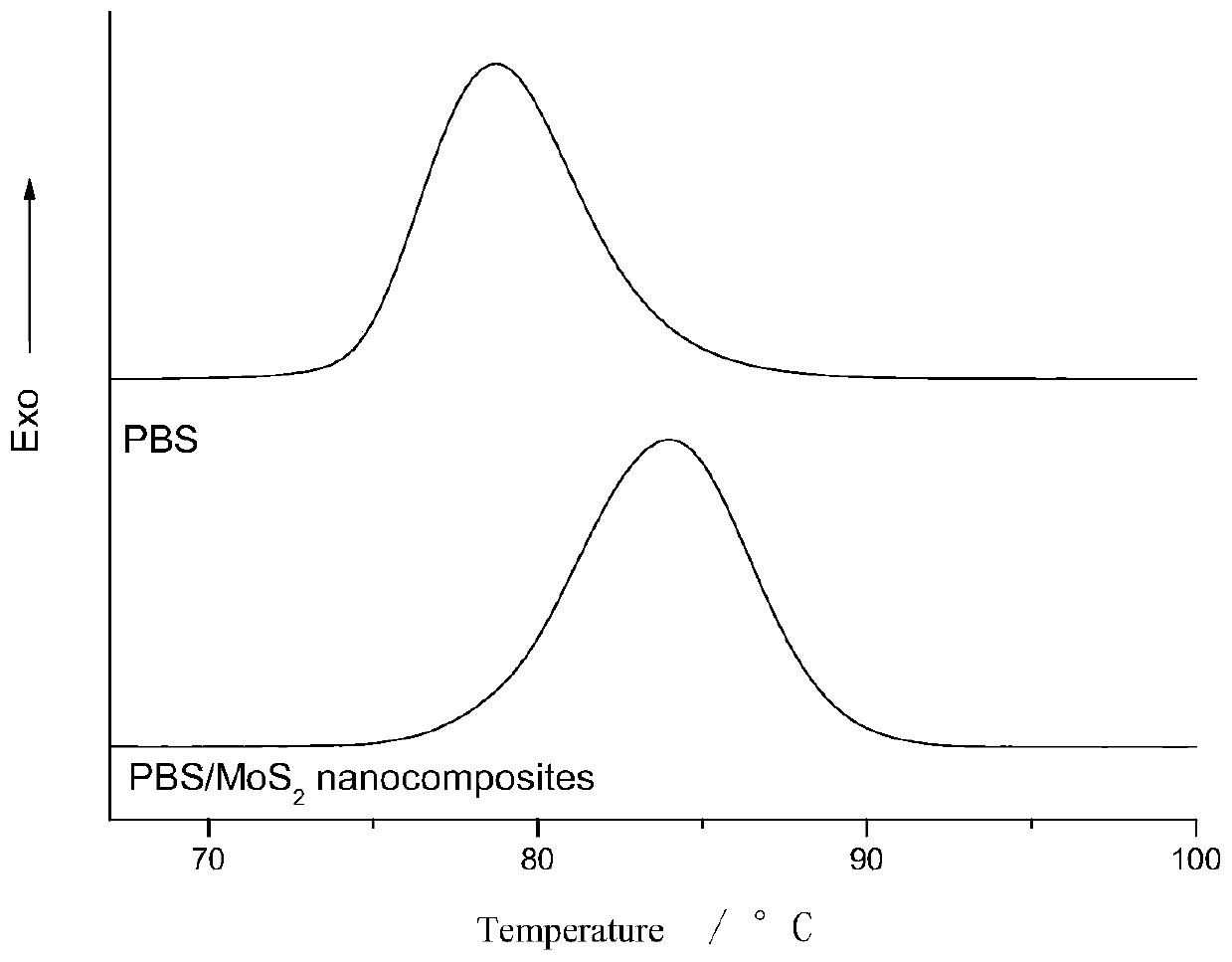

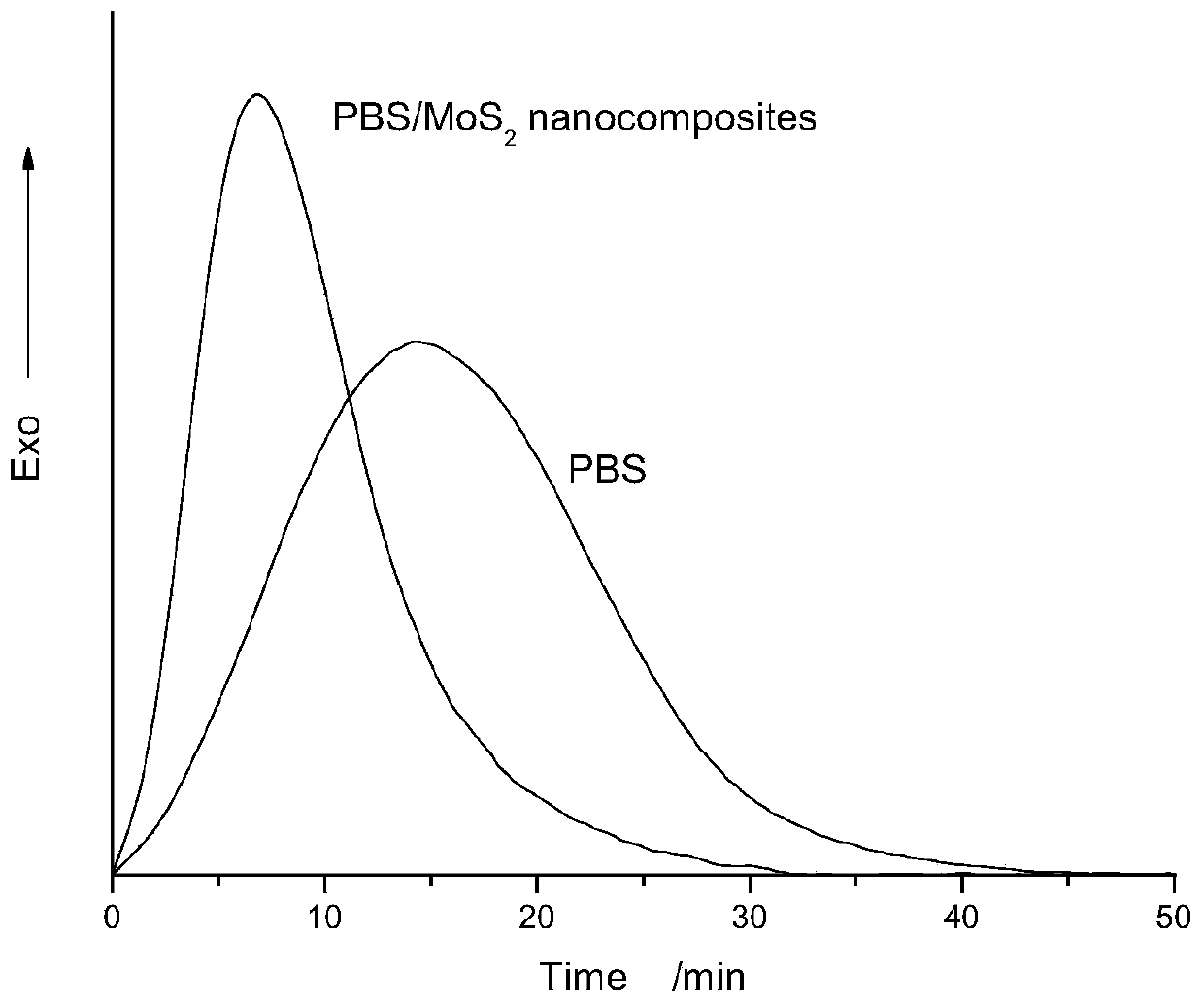

Preparation method for polybutylene succinate/graphene-molybdenum-disulfide-like nanocomposite material

InactiveCN107722246ASolve the problem of easy agglomeration and difficulty in uniform dispersionLow priceSuccinic acidButanediol

The invention discloses a preparation method for a polybutylene succinate / graphene-molybdenum-disulfide-like nanocomposite material. The preparation method comprises the following steps: adding molybdenum disulfide powder to mixed liquid of butanediol and water, and centrifugally separating after the room temperature liquid phase ultrasonic treatment; adding a succinic acid to upper deep green liquid obtained by the centrifugal separation, strongly and mechanically stirring until no water is generated in 150-225 DEG C of the temperature under the nitrogen protection, to obtain a terminal hydroxyl prepolymer containing the graphene-molybdenum-disulfide-like; rapidly adding a catalyst to the terminal hydroxyl prepolymer under the stirring condition, and warming to 210-250 DEG C, and vacuumizing to 50-250 Pa, continuously stirring until the obvious pole-climbing occurs, and ending the reaction, to obtain the polybutylene succinate / graphene-molybdenum-disulfide-like nanocomposite material.The composite material is capable of improving the crystallization temperature of the polybutylene succinate, shortening the crystallization time, and refining the crystal grains of the polybutylenesuccinate.

Owner:LANZHOU CITY UNIV

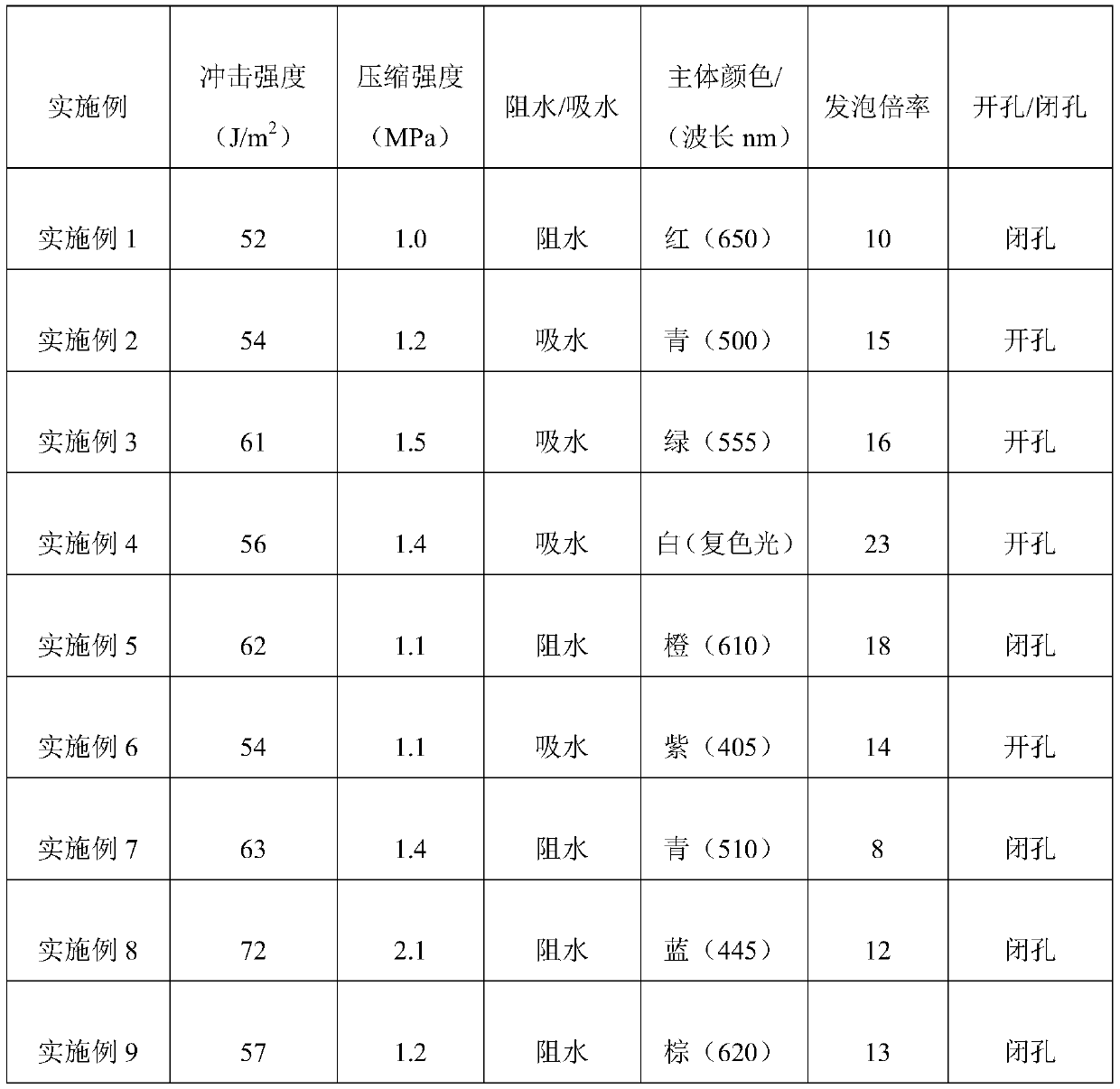

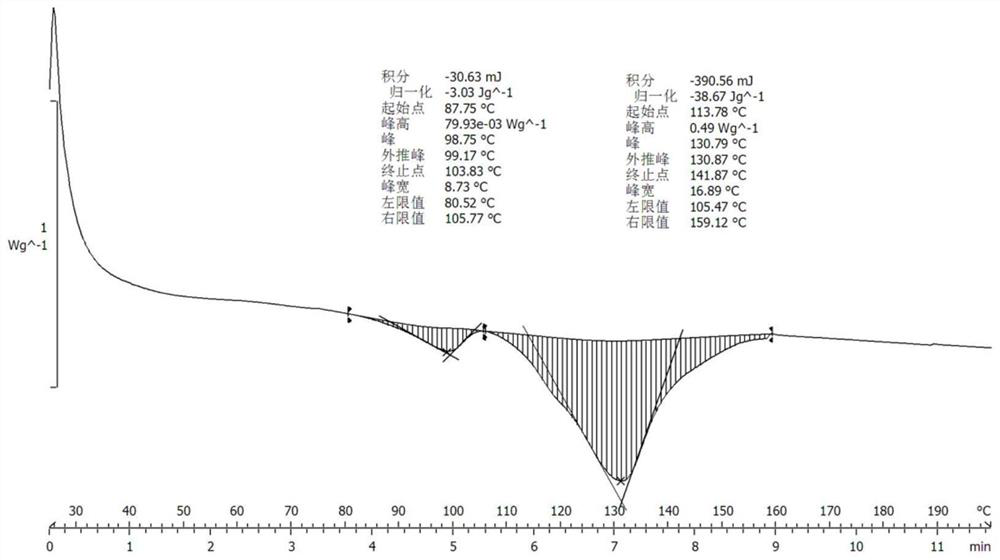

Foaming material, preparation method thereof and foaming product

The invention relates to a luminescent material, a preparation method thereof and a foaming product, the foaming material is mainly prepared from poly-4-methyl-1-pentene and a reinforcing agent through a supercritical foaming process, and the particle size of the reinforcing agent is 40-100 nm. The foaming material has excellent impact strength and compression strength.

Owner:NINGBO CHANGYANG TECH

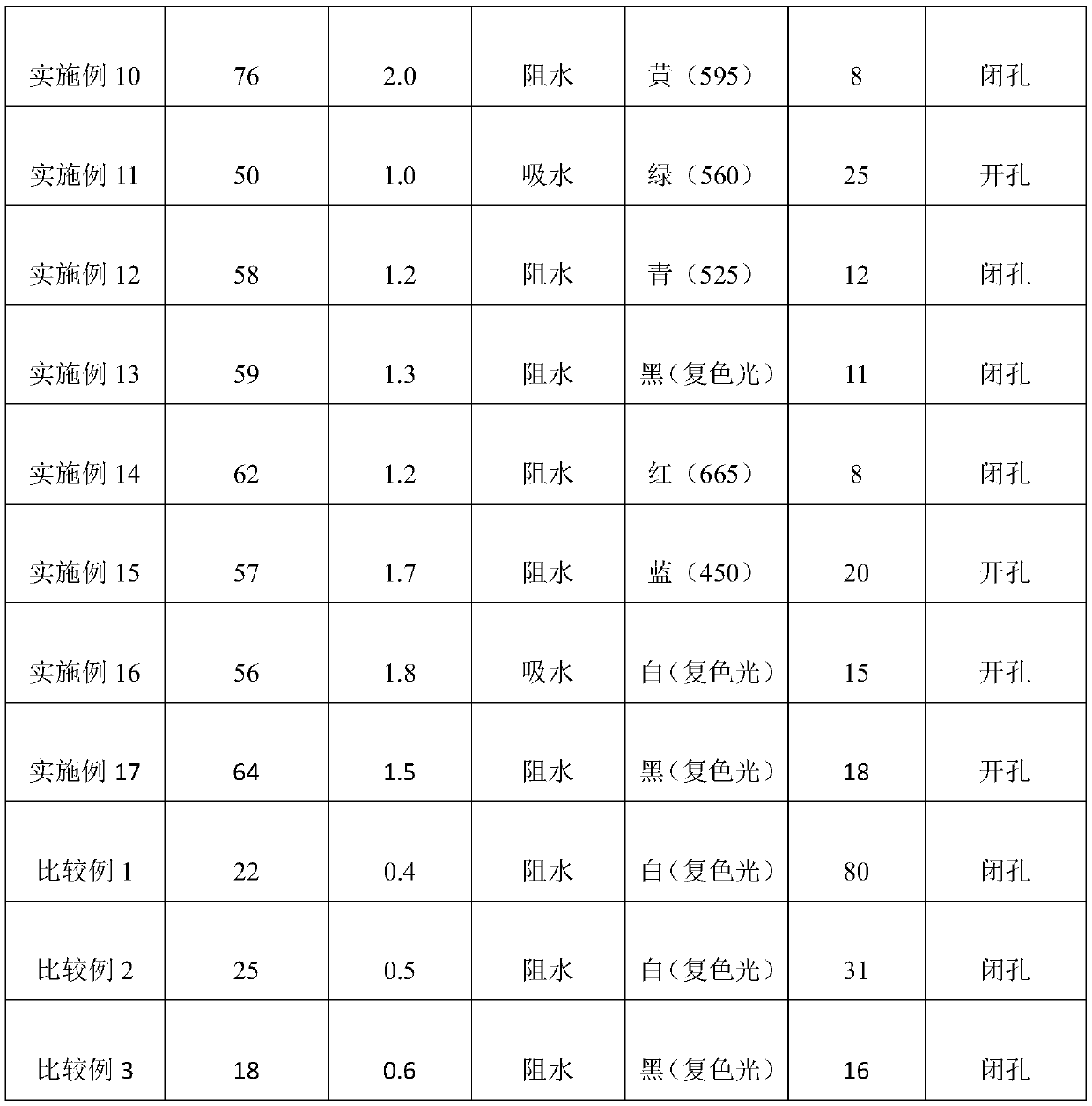

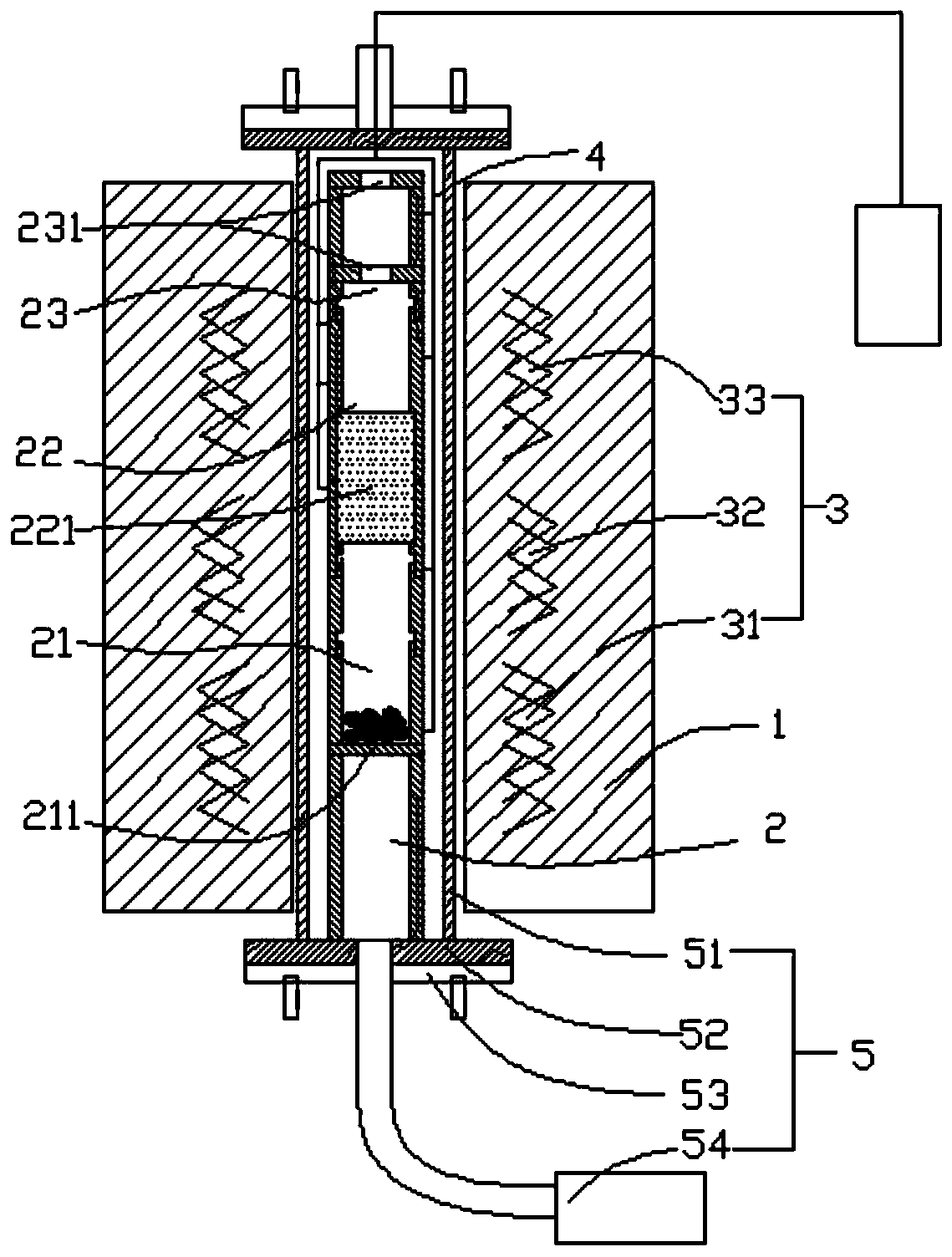

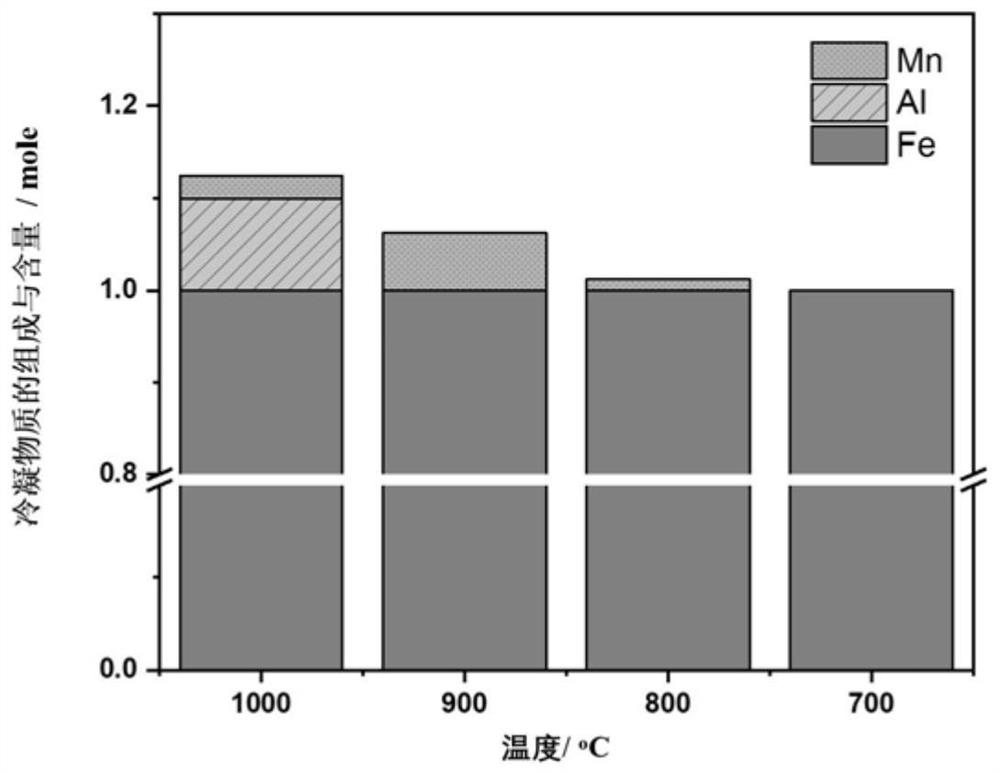

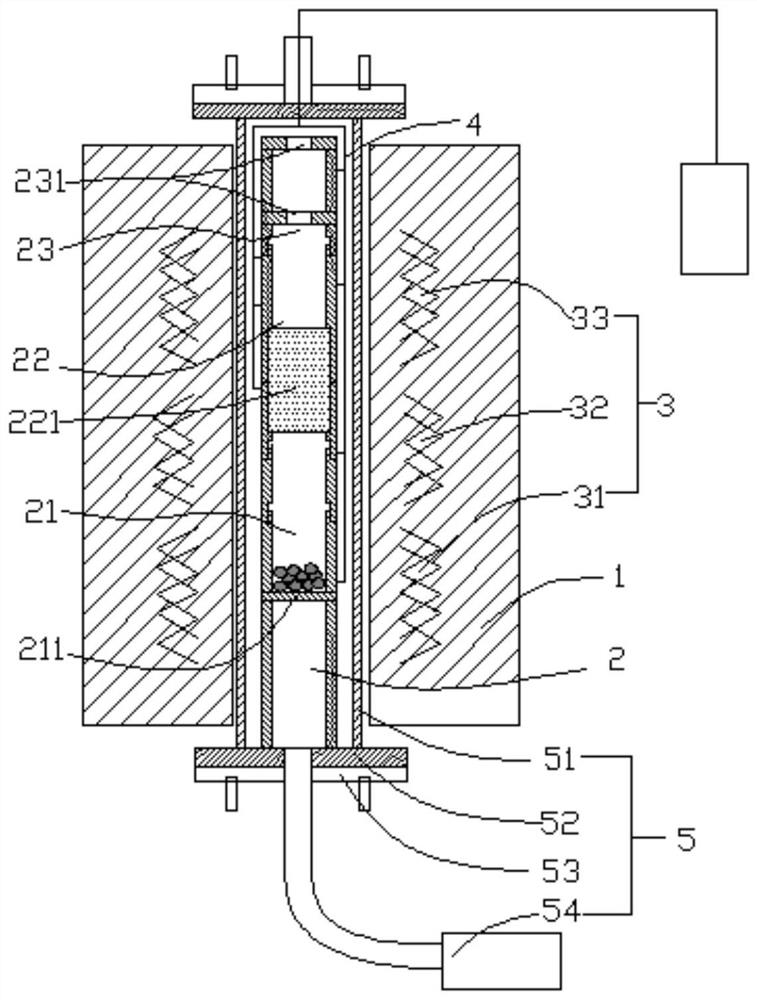

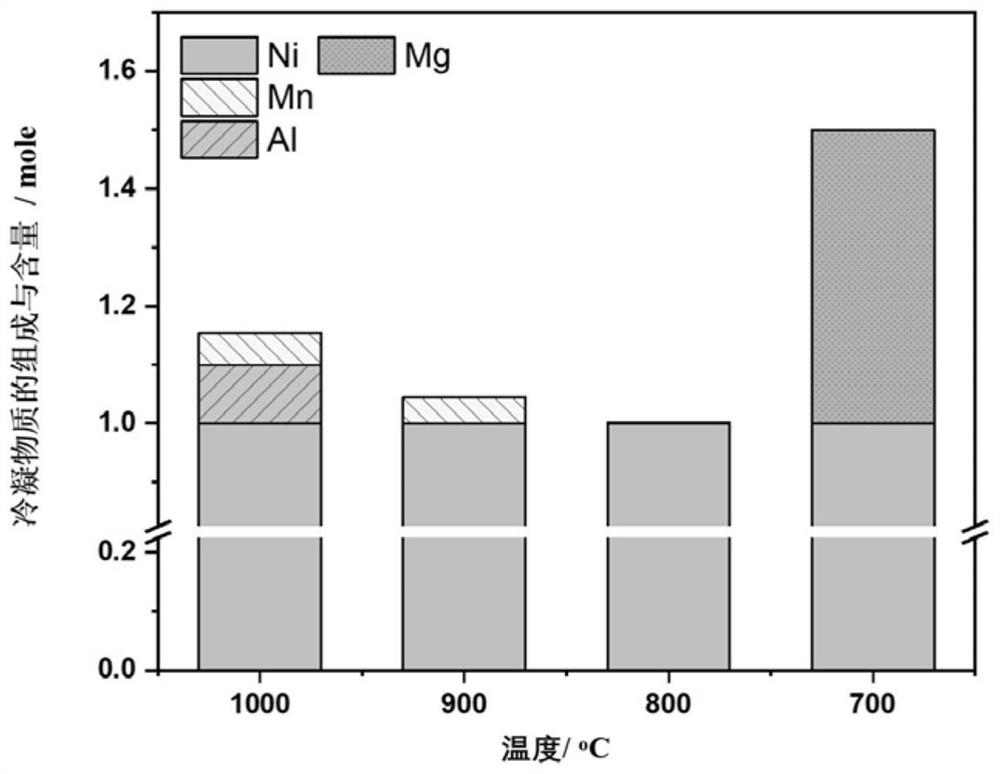

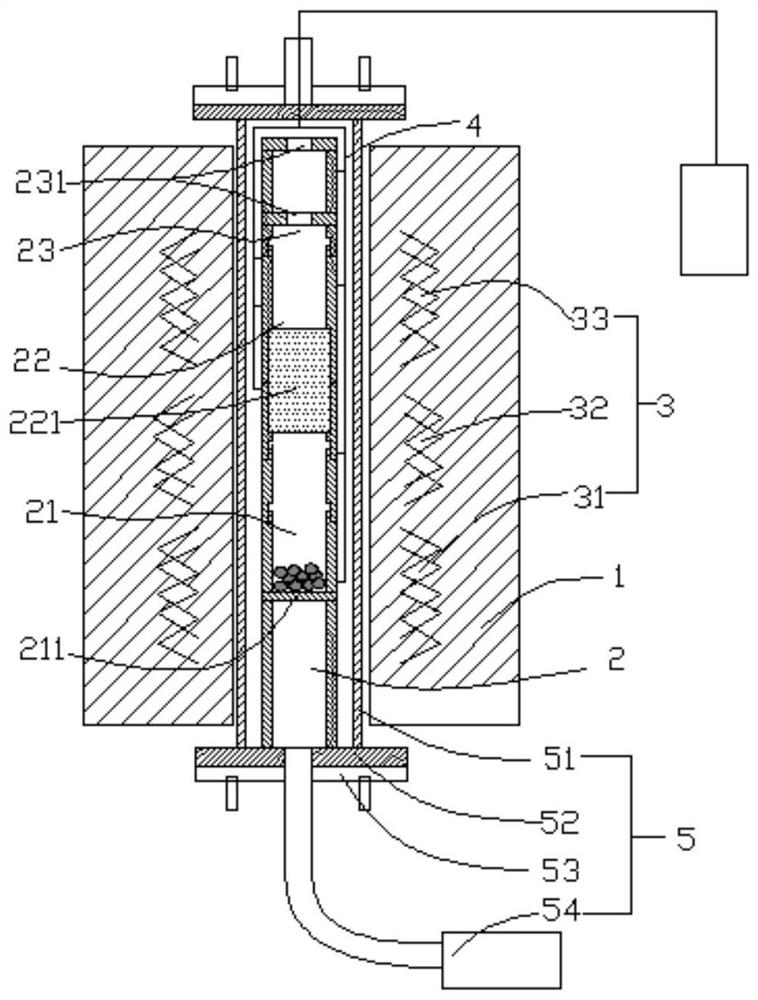

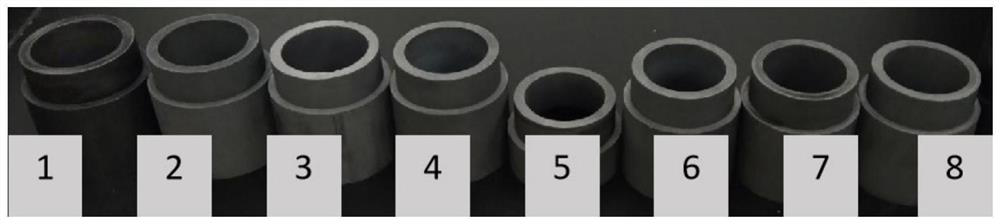

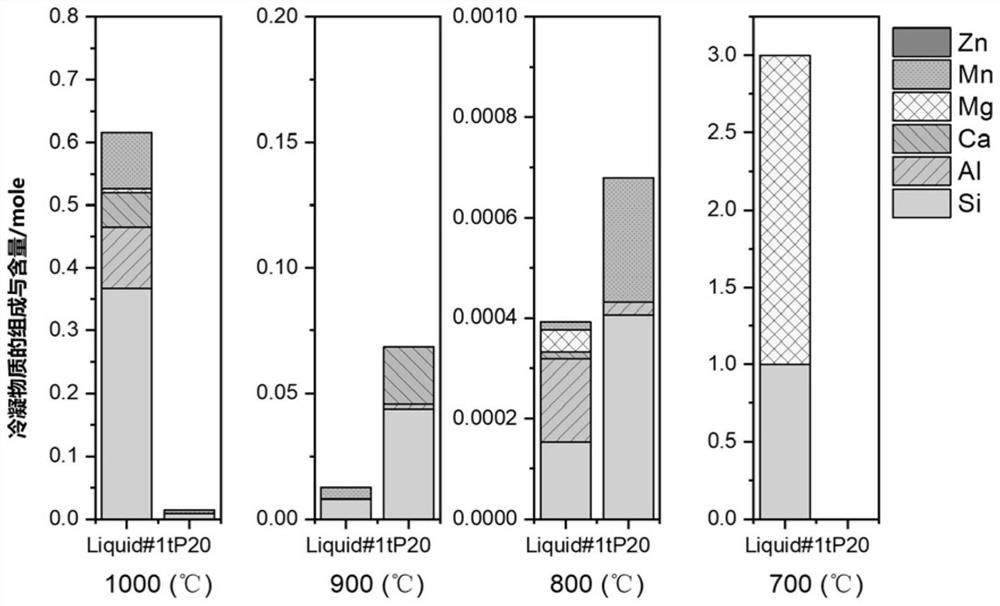

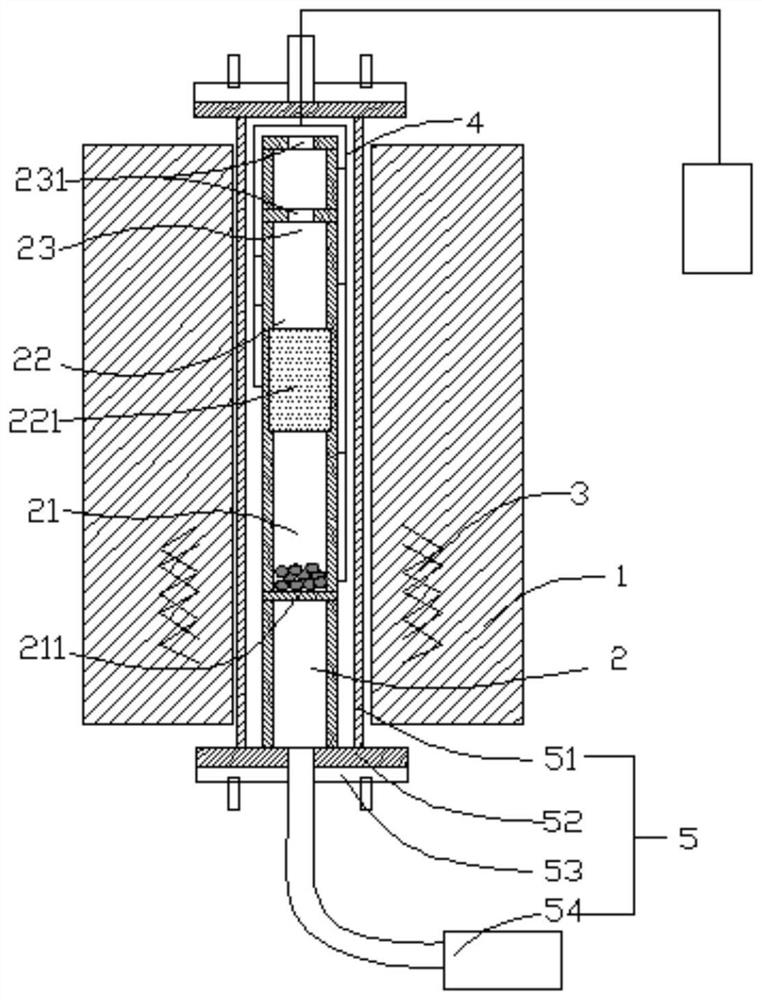

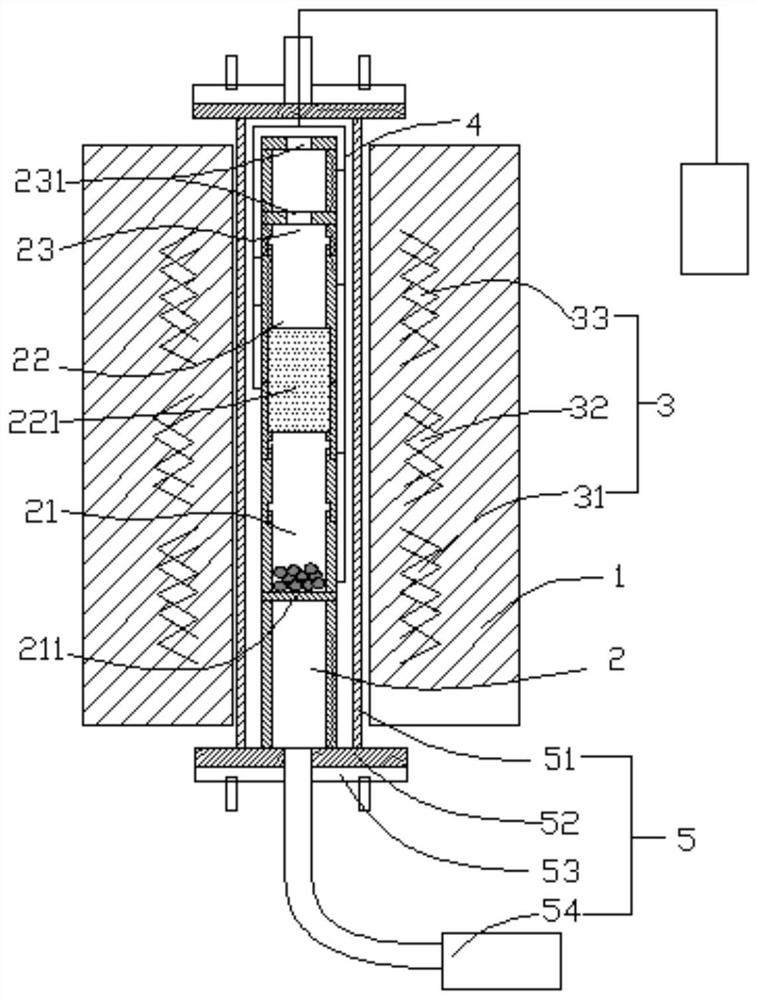

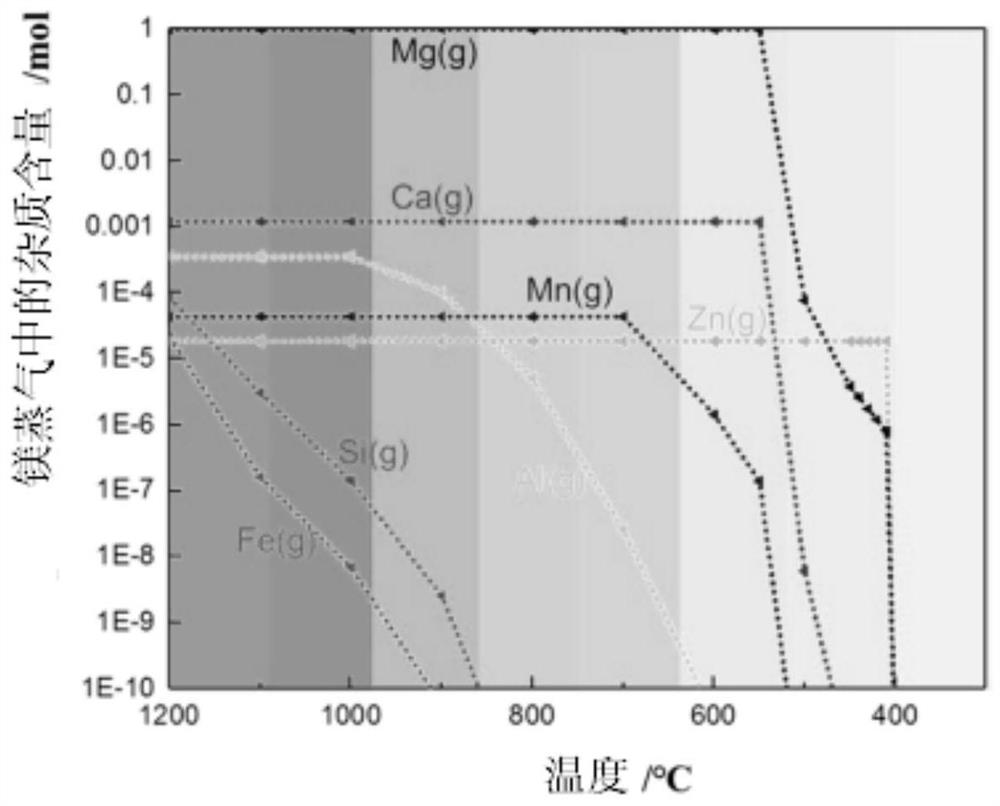

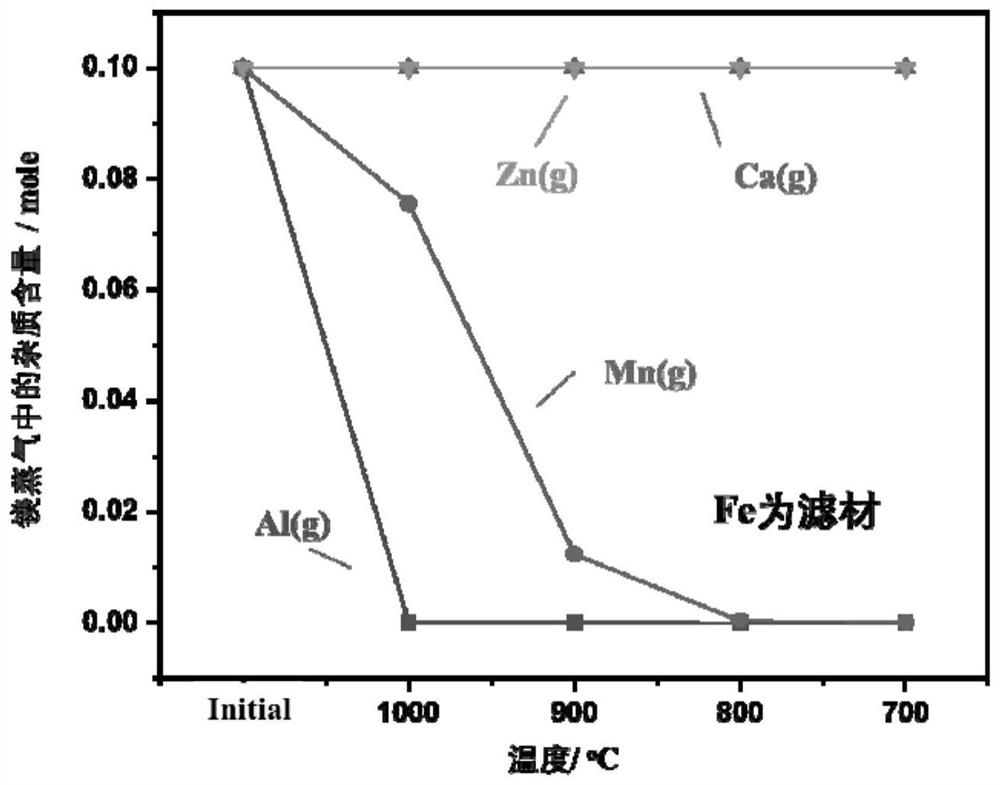

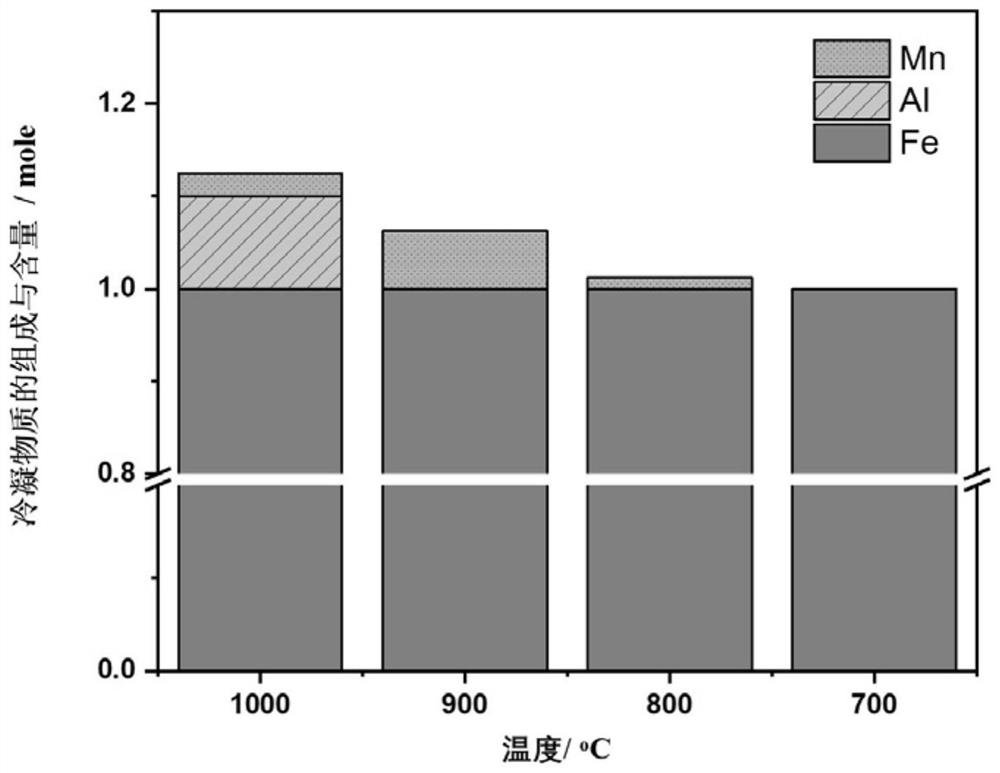

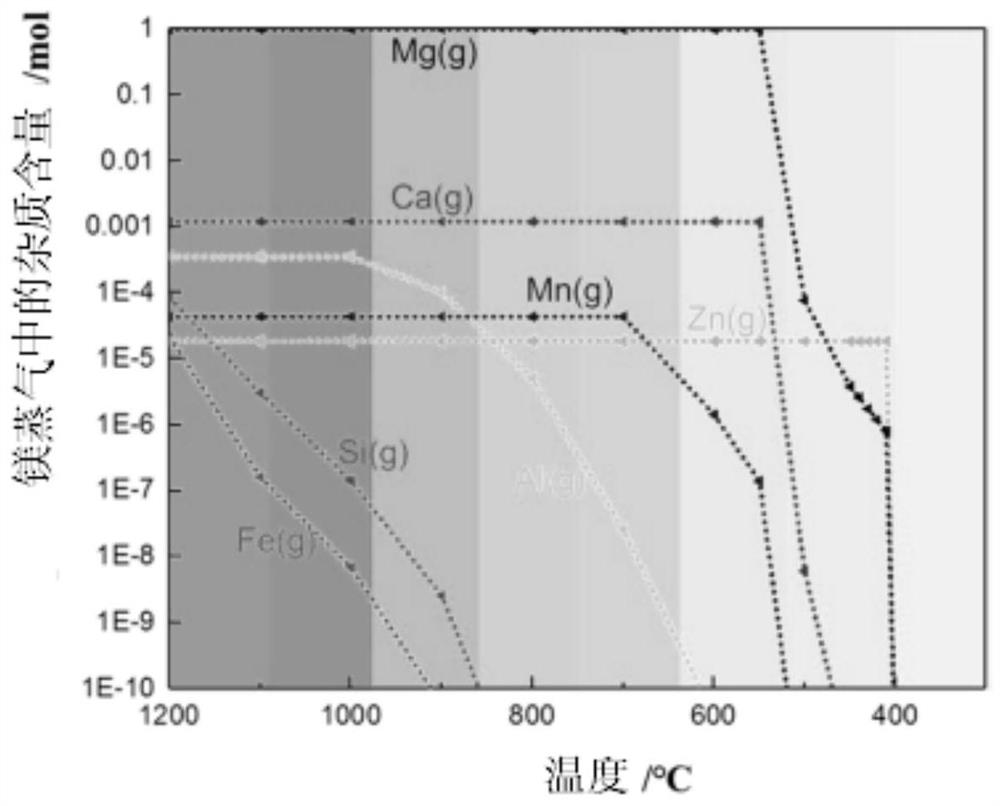

Gas phase magnesium purification method and device based on pure iron filter material

The invention provides a gas phase magnesium purification method based on a pure iron filter material. The method uses the pure iron filter material to filter magnesium vapor, on one hand, the pure iron does not react with the magnesium vapor, and no new impurities are brought to the system; on the other hand, impurities Al, Mn and iron in the magnesium vapor have special affinity, and stable solid solution can be formed with iron; meanwhile, pure iron can be used as a site for nucleation of certain impurities in the magnesium vapor, so that the nucleation energy barrier can be reduced, the certain impurities can be deposited in advance, and impurities can be removed. The method can be applied to industrial large-scale gas phase magnesium purification, the production efficiency of magnesium purification is improved on the order of magnitude through increasing the temperature, the content of impurities Mn in the magnesium raw material is reduced to 10 ppm or below, the content of Al isreduced to 10 ppm or below, the content of Ca is reduced to 20 ppm or below, and meanwhile, non-metal impurity elements such as F, Cl and S can be removed to obtain the magnesium with the purity of 99.99% or above.

Owner:国科镁业科技(河南)有限公司

A method and device for gas-phase magnesium purification based on pure iron filter material

The invention provides a gas-phase magnesium purification method based on a pure iron filter material. The method uses a pure iron filter material to filter magnesium vapor. On the one hand, pure iron will not react with magnesium vapor and will not bring new impurities to the system; on the other hand, the impurities Al and Mn in magnesium vapor have special affinity with iron and can form a stable solid solution with iron ; At the same time, pure iron can be used as the nucleation site of some impurities in the magnesium vapor, lowering the nucleation energy barrier, allowing some impurities to deposit in advance, and removing impurities. The method provided by the invention can be applied to industrial large-scale gas-phase magnesium purification, and the production efficiency of magnesium purification can be increased by an order of magnitude by increasing the temperature, so that the content of impurity Mn in the magnesium raw material is reduced to below 10 ppm, and the content of Al is reduced to below 10 ppm. The Ca content is reduced to below 20ppm, and at the same time, non-metallic impurity elements such as F, Cl, and S can be removed to obtain magnesium with a purity of more than 99.99%.

Owner:国科镁业科技(河南)有限公司

A method and device for gas-phase magnesium purification based on nickel-based filter material

The invention provides a method for purifying magnesium in the vapor phase based on a nickel-based filter material. The method uses a nickel-based filter material to filter magnesium vapor. Under a certain temperature and vacuum degree, the nickel material does not react with the magnesium vapor on the one hand. It will not bring new impurities to the system; on the other hand, the nickel material has a special affinity with the impurities Al and Mn in the magnesium vapor, and can form a stable solid solution; at the same time, the nickel material can also be used as some impurities in the magnesium vapor The nucleation site lowers the nucleation energy barrier and enables some impurities to be deposited in advance to achieve removal. The method provided by the invention can be applied to industrialized large-scale gas-phase magnesium purification, while improving the production efficiency by an order of magnitude, the Mn content in magnesium is reduced to below 10ppm, the Al content is reduced to below 10ppm, and the Si content is below 20ppm. Non-metallic impurity elements such as F, Cl, S, etc. improve product purity, and the purity of the obtained magnesium is above 99.99%.

Owner:国科镁业科技(河南)有限公司

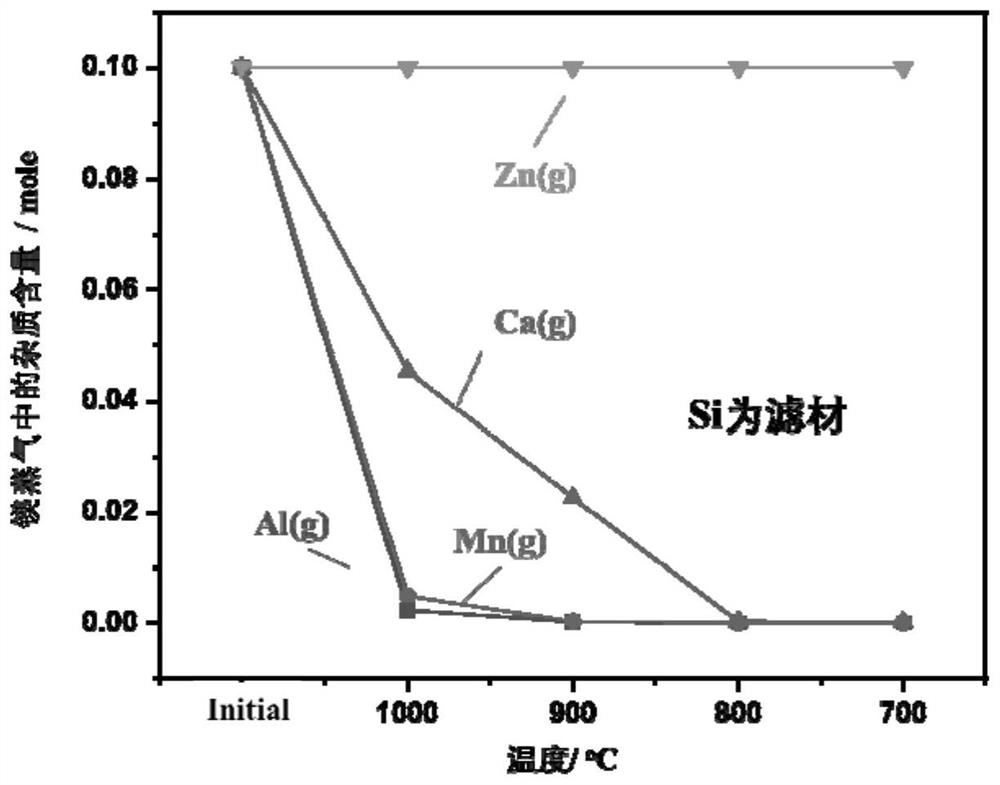

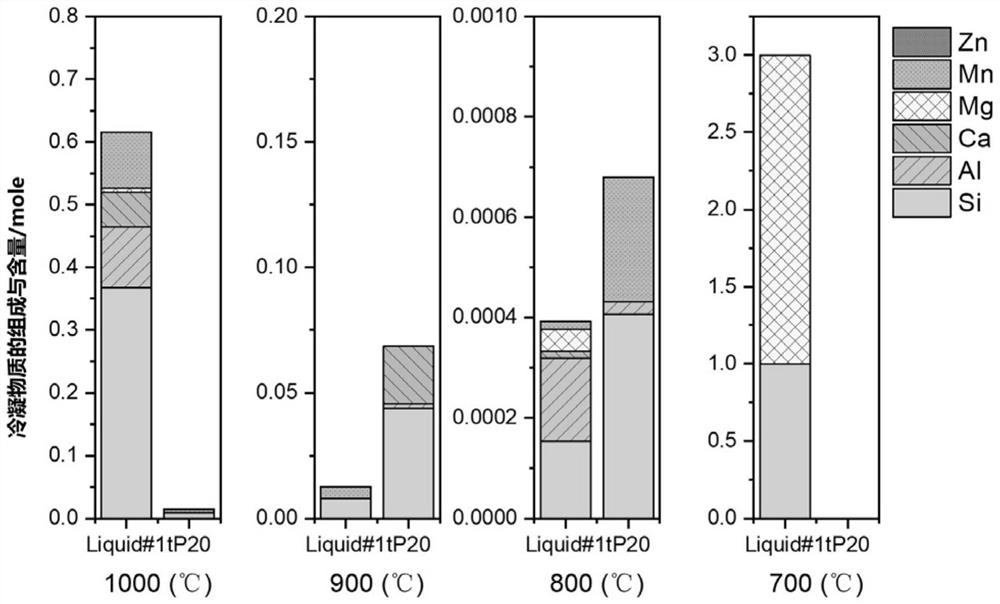

A method and device for gas-phase magnesium purification based on elemental silicon filter material

ActiveCN110835694BAchieve removalWon't bringProcess efficiency improvementPhysical chemistryImpurity

Owner:国科镁业科技(河南)有限公司

A Feedback Control Method of Crystal Product Particle Size in the Process of Dissolution and Crystallization

ActiveCN106178583BEliminates manipulations to control crystallizationLower the nucleation barrierSolution crystallizationHeat exchange cooling cystallizationGranularityDissolution

Owner:JIANGYIN HUACHANG FOOD ADDITIVE CO LTD

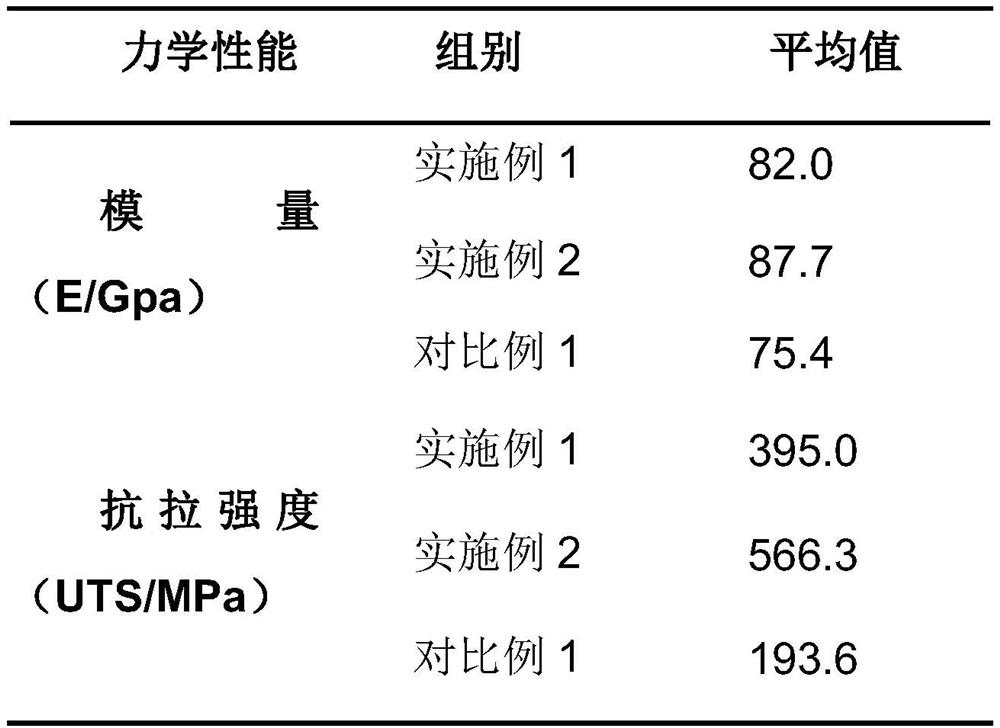

Sc/Zr modified high-modulus and high-strength aluminum-lithium alloy and laser forming method thereof

ActiveCN114082985AHigh strengthShort Freeze Feeding ChannelAdditive manufacturing apparatusIncreasing energy efficiencyUltimate tensile strengthAluminium-lithium alloy

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Pre-alloy powder type flux-cored welding wire and method for self-shielded open arc surfacing welding of high chromium alloys

ActiveCN106041361BIncreased welding deposition efficiencyRemarkable effect of energy saving and consumption reductionArc welding apparatusWelding/cutting media/materialsIron powderFerrosilicon

The invention discloses a pre-prepared alloy powder type flux-cored wire and a self-protection open arc surfacing welding method of a high-chromium alloy. The adopted technical scheme lies in that a cold rolled thin steel strip manufactured through low-carbon steel H08A as an outer coating, high carbon ferro-chrome, ferrosilicon, graphite and other metal powder are blended inside the coating to form a powder core of the flux-cored wire, and high carbon ferro-chrome, ferroboron, ferrosilicon and reduced iron powder are blended to form pre-prepared alloy powder; and before welding, the alloy powder is placed on a welding bead in advance, the surfacing welding current control value is set, a regulating melt mode combined with the mass of the pre-prepared alloy powder type flux-cored wire is set, a nonhomogeneous melt containing liquid high carbon ferro-chrome atom clusters formed through melting high carbon ferro-chrome particles is formed, and the concretionary high-chromium alloy which adopts the liquid high carbon ferro-chrome atom clusters as component donors, nucleates and grows into primary M7C3 abrasion-resistance phases is formed. According to the method, the problems that the source of components of surfacing welding alloys is single and the chromium content of the surfacing welding alloys is not liable to increase are solved, and the method is widely applied to surfacing welding manufacturing and repairing of parts with the requirement of abrasive wear resistance.

Owner:XIANGTAN UNIV

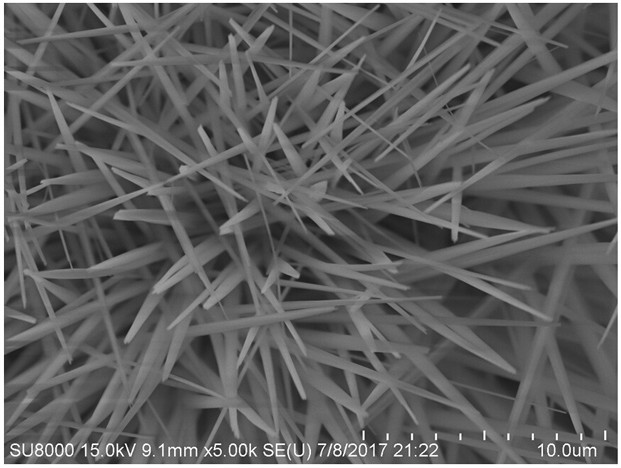

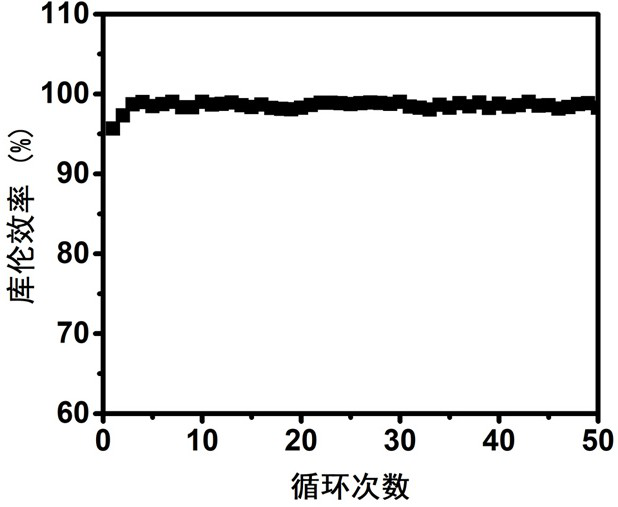

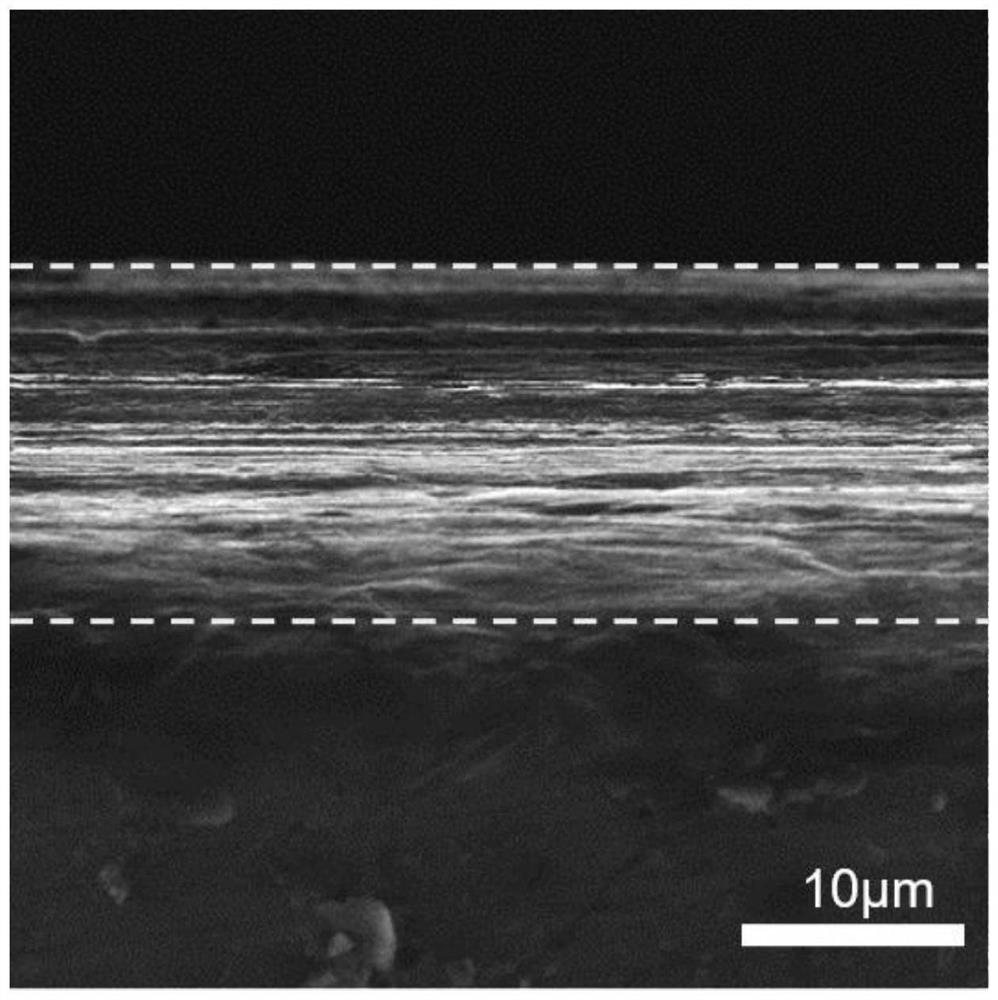

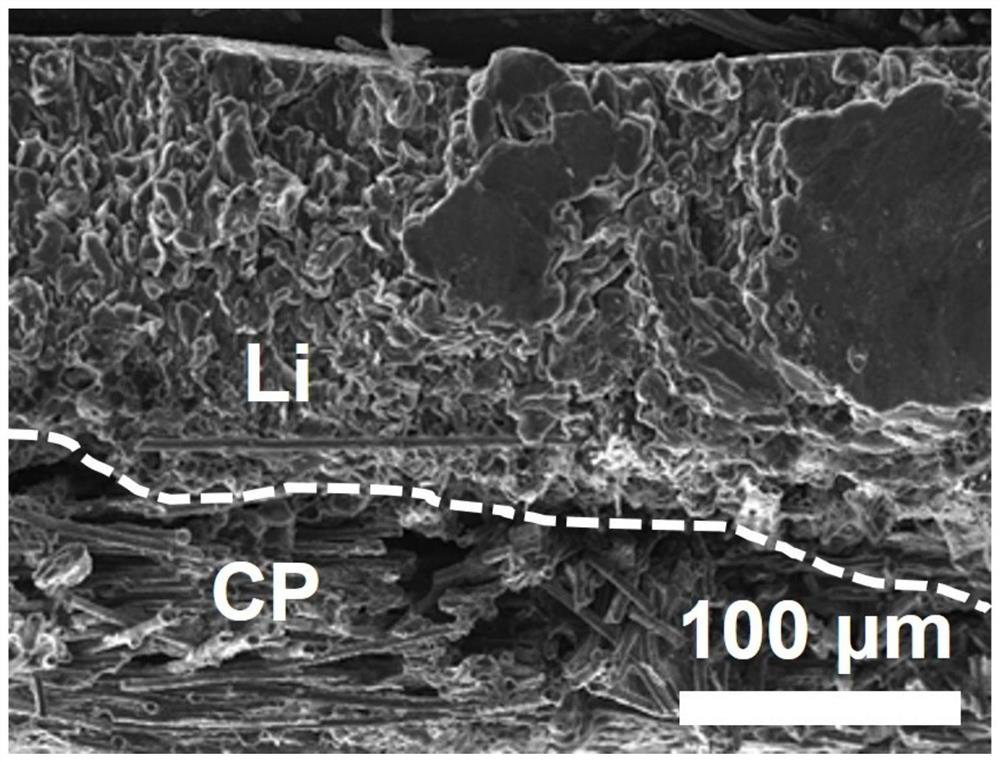

A preparation method and application of a modified metal lithium negative electrode current collector

ActiveCN110085871BDeposition stabilityImprove securityElectrochemical processing of electrodesElectrode carriers/collectorsMetallic lithiumElectrical battery

The invention discloses a preparation method and application of a modified metal lithium negative electrode current collector. The method comprises the following steps: step 1, adding a halogen salt into a solvent, stirring and mixing evenly to obtain a halogen salt solution; step 2, The current collector to be modified is placed in the brine salt solution prepared in step 1 for soaking modification treatment. The present invention improves the lithium affinity of the surface of the metal lithium negative electrode current collector through a simple current collector surface modification treatment method, avoids dendrite growth, and thereby realizes the practical application of the lithium metal battery. The preparation method is simple to operate, low in energy consumption, and can be operated on a large scale, and can modify the current collector with the array / coating layer grown on the surface. The lithium metal battery with good cycle stability and safety performance can be prepared by using the modified metal lithium negative electrode collector of the present invention, and the practical process of high specific energy lithium metal battery is promoted.

Owner:HARBIN INST OF TECH

Preparation method and application of zinc sheet with surface coating

PendingCN114597329ASimple preparation conditionsLow costElectrode thermal treatmentSecondary cellsElectrical batteryZinc ion

The invention relates to a preparation method and application of a zinc sheet with a surface coating, and the preparation method comprises the following steps: 1) slowly adding laponite powder into a solvent under a stirring condition, and continuously stirring to obtain a uniform dispersion liquid; 2) uniformly coating the surface of a zinc sheet with the dispersion liquid prepared in the step 1) according to a preset thickness; and (3) rapidly transferring the zinc sheet treated in the step (2) to a vacuum drying condition, heating to 60 DEG C, preserving heat, taking out and cooling to obtain the zinc sheet with a surface coating. The preparation conditions are simple, the uniform surface coating for protecting the negative electrode of the zinc ion battery can be obtained only through the steps of mixing, stirring, smearing, drying and the like, harsh reaction conditions are not needed, the cost is low, and the efficiency is high; moreover, the adopted laponite is rich in reserves and low in price, toxic and harmful solvents are not needed in the preparation process, the preparation method is environmentally friendly, and the obtained surface coating is uniform, stable in electrochemical property and good in cycling stability.

Owner:XI AN JIAOTONG UNIV

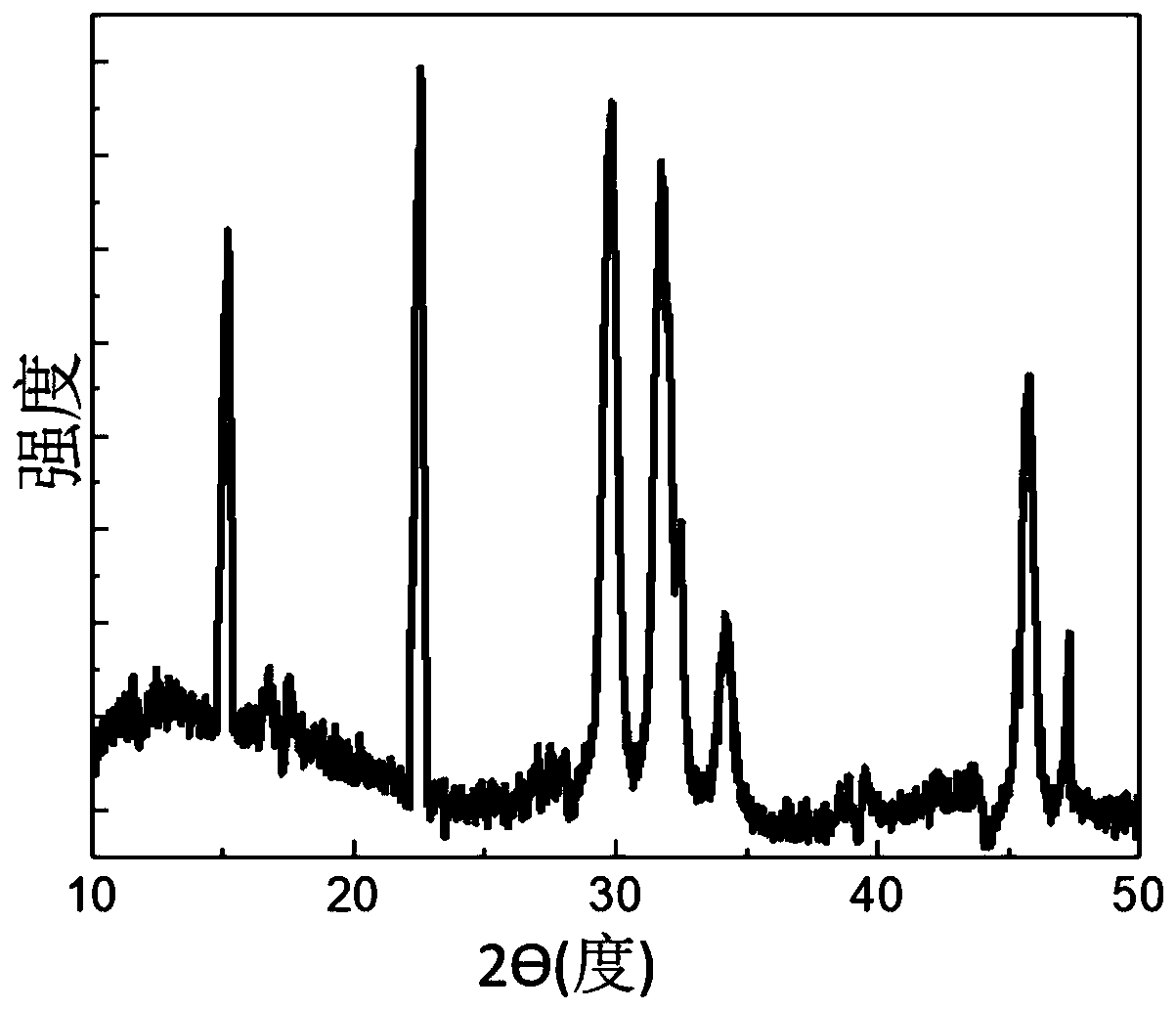

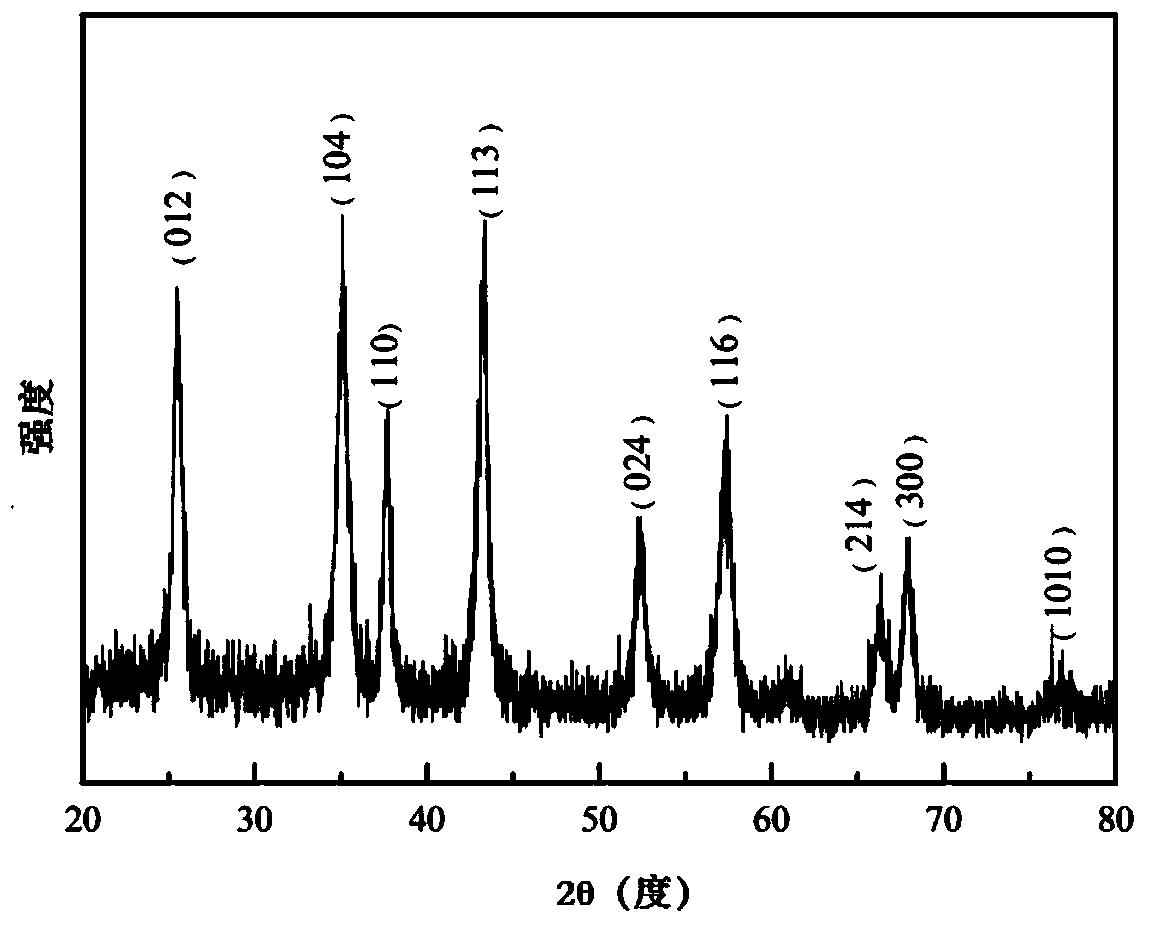

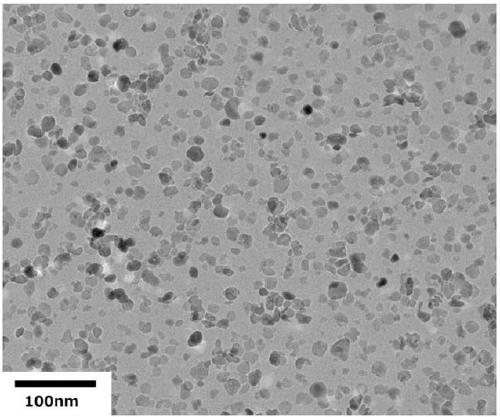

Preparation method of alpha-Al2O3 nanoparticles

InactiveCN109516483ALow costReduce pollutionMaterial nanotechnologyAluminium oxides/hydroxidesNanoparticleAcid washing

The invention discloses a method for preparing alpha-Al2O3 nanoparticles. The method comprises the following steps that 1, water-soluble ferric salt and water-soluble aluminium salt are dissolved in deionized water according to a molar ratio of ferric ions to aluminium ions of 0-1; 2, a (NH4)2.CO3 solution with the concentration of 1-4 mol / L is added into a mixture in the step (1) dropwise, and after sol is generated, dropping adding is stopped immediately; 3, the sol is aged at a room temperature to prepare gel; 4, the gel is placed in an oven for drying to prepare a precursor; 5, the precursor is calcined with a heating rate of 1-3 DEG C / min at 600-850 DEG C to obtain an alpha-Fe2O3 / alpha-Al2O3 nanometer compound; 6, acid washing is conducted on the alpha-Fe2O3 / alpha-Al2O3 nanometer compound material to remove alpha-Fe2O3 particles to obtain the alpha-Al2O3 nanoparticles. According to the method for preparing the alpha-Al2O3 nanoparticles, the calcination temperature is reduced, energy consumption is reduced, and the operation steps are simple.

Owner:SHANGHAI UNIV

A kind of calcium silicate hydrate accelerator and preparation method thereof

ActiveCN109650398BSmall particle sizeGood dispersionAlkaline-earth metal silicatesCalcium silicatePhenyl Ethers

The invention relates to the technical field of building materials, in particular to a calcium silicate hydrate early strength agent and a preparation method thereof. The preparation method of calcium silicate hydrate early strength agent comprises the following preparation steps: 1) preparation of calcium liquid; 2) preparation of silicon liquid with silicate as silicon source; 3) synthesis of calcium silicate hydrate: polyoxo The dispersant solution compounded with ethylene (5) nonylphenyl ether and cyclohexane was placed in a shear stirring mixing device, kept stirring at room temperature, and added the prepared calcium liquid and silicon liquid, and then used alkaline The solution adjusts the pH value of the mixed solution, maintains constant temperature and stirs, and obtains white calcium silicate hydrate gel; washes the obtained white calcium silicate hydrate gel by centrifugation, and then dries in a vacuum drying oven to obtain hydrated silicic acid Calcium early strength agent. After the calcium silicate hydrate accelerator prepared by the above preparation method is mixed into cement, it can promote the hydration of cement, significantly shorten the setting time of cement, and improve its early strength at the same time, which has important practical application value in the field of construction.

Owner:KZJ NEW MATERIALS GROUP CO LTD

A kind of preparation method of polybutylene succinate/graphene-like molybdenum disulfide nanocomposite material

The invention discloses a preparation method for a polybutylene succinate / graphene-molybdenum-disulfide-like nanocomposite material. The preparation method comprises the following steps: adding molybdenum disulfide powder to mixed liquid of butanediol and water, and centrifugally separating after the room temperature liquid phase ultrasonic treatment; adding a succinic acid to upper deep green liquid obtained by the centrifugal separation, strongly and mechanically stirring until no water is generated in 150-225 DEG C of the temperature under the nitrogen protection, to obtain a terminal hydroxyl prepolymer containing the graphene-molybdenum-disulfide-like; rapidly adding a catalyst to the terminal hydroxyl prepolymer under the stirring condition, and warming to 210-250 DEG C, and vacuumizing to 50-250 Pa, continuously stirring until the obvious pole-climbing occurs, and ending the reaction, to obtain the polybutylene succinate / graphene-molybdenum-disulfide-like nanocomposite material.The composite material is capable of improving the crystallization temperature of the polybutylene succinate, shortening the crystallization time, and refining the crystal grains of the polybutylenesuccinate.

Owner:LANZHOU CITY UNIV

Preparation method of composite material, composite material and application thereof

ActiveCN111892791BIncrease mass transfer rateImprove adsorption efficiencyGas treatmentOther chemical processesWater vaporPolyacrylamide

Owner:BEIJING UNIV OF CHEM TECH

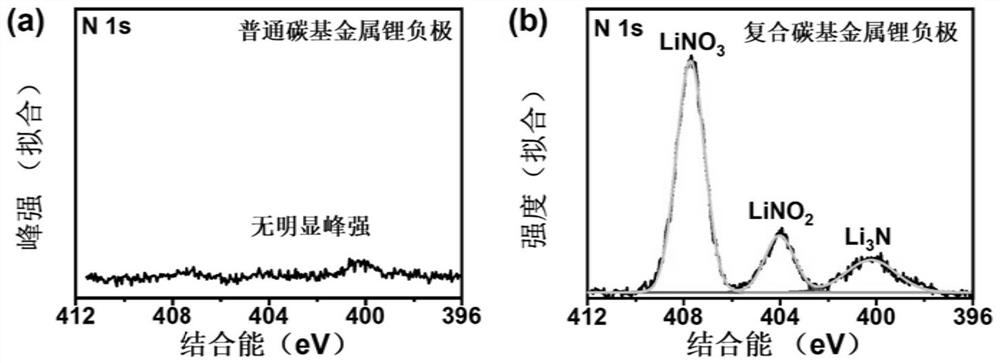

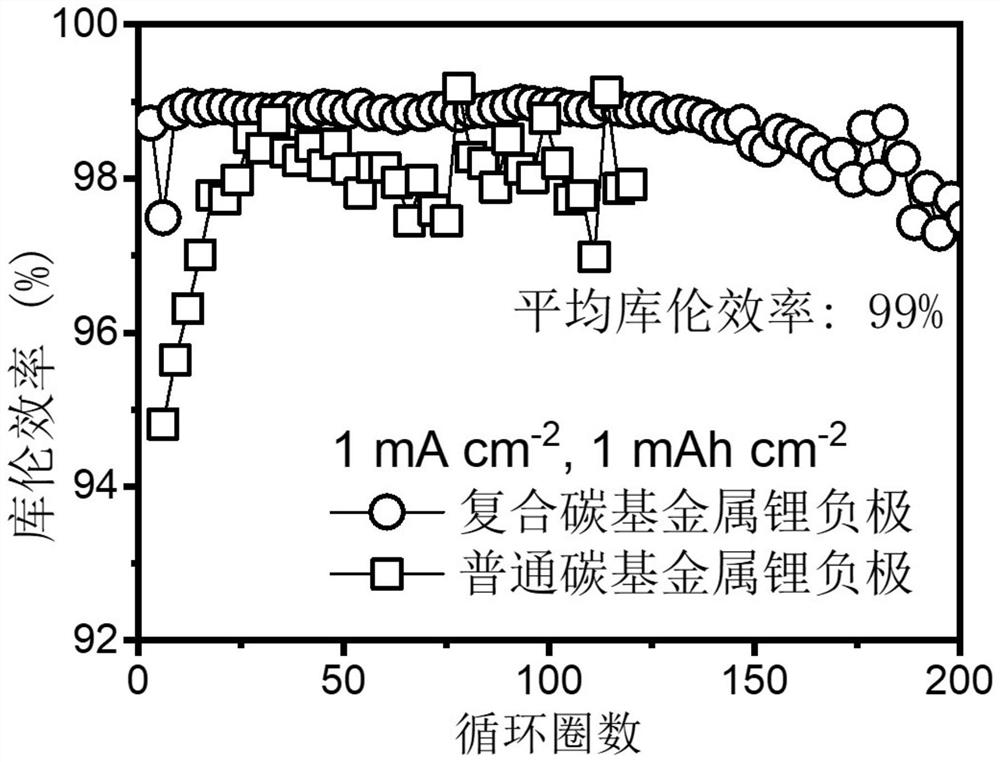

A composite metal lithium negative electrode and its preparation method and application

ActiveCN113629236BLower the nucleation barrierAvoid irreversible decayElectrode carriers/collectorsSecondary cellsMetallic lithiumCurrent collector

The invention belongs to the technical field of lithium batteries, and specifically discloses a composite metal lithium negative electrode and a preparation method and application thereof. The negative electrode comprises a three-dimensional carbon-based current collector with a porous structure, and a metal attached to the surface of the three-dimensional carbon-based current collector and in the internal pores. Lithium, and a protective film covering metal lithium; the protective film includes a lithiophilic metal and a lithium salt, and the lithiophilic metal is a metal that can be reduced and replaced by lithium metal; the composite metal lithium negative electrode is in the first charge and discharge process with the electrolysis The liquid reacts to form a stable solid electrolyte phase interface, and the solid electrolyte phase interface will not decompose during subsequent charge and discharge processes. The three-dimensional carbon-based current collector, lithiophilic metal and lithium salt in the composite metal lithium negative electrode of the invention play the roles of relieving the volume strain of the negative electrode, inducing uniform deposition of lithium and forming a stable SEI film on the surface of the negative electrode, and the preparation method is simple, practical and cost-effective. Low, it is used in metal lithium secondary batteries, which can greatly improve the cycle life of the battery and improve the battery performance.

Owner:HUAZHONG UNIV OF SCI & TECH

Application of pure iron filter material in gas phase magnesium purification and its production system

The invention provides an application of a pure iron filter material in gas-phase magnesium purification. In the process of gas-phase magnesium purification, magnesium vapor passes through the pure iron filter material, and impurities Al and Mn in the magnesium vapor form stable ions with iron in advance before the magnesium condenses. solid solution, so as to remove the magnesium vapor; in addition, the pure iron filter material can be used as the nucleation site of some impurities, reduce the nucleation energy barrier of some impurities, thereby providing attachment sites for these impurities, so that the impurities are condensed and enriched in advance , out of the magnesium vapor system; and the pure iron filter material can also remove part of the impurities through physical adsorption; the pure iron filter material of the present invention can effectively remove the impurities in the magnesium vapor through various effects, greatly improving the magnesium content. Purity, the purity of the obtained magnesium is above 99.99%. The gas-phase magnesium purification production system comprising pure iron filter material provided by the present invention has a simple structure, is convenient to set up, is suitable for large-scale industrial production, can effectively improve the efficiency of magnesium purification, and reduce the cost of magnesium purification.

Owner:国科镁业科技(河南)有限公司

Application of Elemental Silicon Filter Material in Gas Phase Magnesium Purification and Production System Containing It

ActiveCN110724833BAchieve removalSpecial affinityProcess efficiency improvementPhysical chemistryMaterials science

The invention provides the application of elemental silicon filter material in gas-phase magnesium purification. In the gas-phase magnesium purification process, magnesium vapor passes through the elemental silicon filter material. In a certain range of temperature and vacuum degree, elemental silicon will not interact with magnesium vapor on the one hand. The reaction will not form a more stable substance with magnesium in thermodynamics, and will not bring new impurities to the system; on the other hand, the impurities Mn, Al, and Ca in silicon and magnesium vapor have special affinity and can form more Stable solid solution, so as to achieve removal; at the same time, elemental silicon can be used as the nucleation site of certain impurities in magnesium vapor, lowering the nucleation energy barrier, allowing certain impurities to deposit in advance, thereby achieving removal. The invention can effectively remove impurities in the magnesium vapor through the function of the elemental silicon filter material, greatly improve the purity of the magnesium, and the purity of the obtained magnesium is above 99.99%. The production system provided by the invention is suitable for large-scale industrial production, can effectively improve the efficiency of magnesium purification, and reduce the cost of magnesium purification.

Owner:国科镁业科技(河南)有限公司

A Fabrication Method of Metal Nanostructure Arrays Based on Interface Induced Growth

ActiveCN108417475BLower the nucleation barrierEasy to spreadMaterial nanotechnologySemiconductor/solid-state device manufacturingAdhesion forceAdhesive belt

Owner:ANHUI NORMAL UNIV

Co-doped red-light fluorescent light-emitting nanocrystalline material as well as preparation method and application thereof

InactiveCN111073647AReduce luminous intensityLower the nucleation barrierFluorescence/phosphorescenceLuminescent compositionsLuminous intensityFluorescent light

The invention discloses a co-doped red-light fluorescent light-emitting nanocrystalline material as well as a preparation method and application thereof. According to the nanocrystalline material, under the excitation condition of 254 nm, the luminous intensity of Eu<3+> ions is continuously weakened along with the increase of the concentration of Pb<2+> ions; under the excitation condition of 311nm, the luminous intensity of the Eu<3+> ions is not changed along with the increase of the concentration of the Pb<2+> ions; the ratio of the luminous intensity of the Eu<3+> ions to the concentration of the Pb<2+> ions can be applied to ratio type Pb<2+> ion detection; the ratio type fluorescence detection method is not interfered by external factors and has good accuracy. Under the excitationcondition of 254nm, the luminous intensity of the Eu<3+> ions is continuously weakened along with the increase of the concentration of the Pb<2+> ions, the luminous intensity of the Eu<3+> ions is notchanged along with the increase of the concentration of the Pb<2+> ions under the excitation condition of 311 nm, and the ratio of the luminous intensity of the Eu<3+> ions to the Pb<2+> ion concentration can be applied to ratio-type Pb<2+> ion detection.

Owner:杭州众道光电科技有限公司

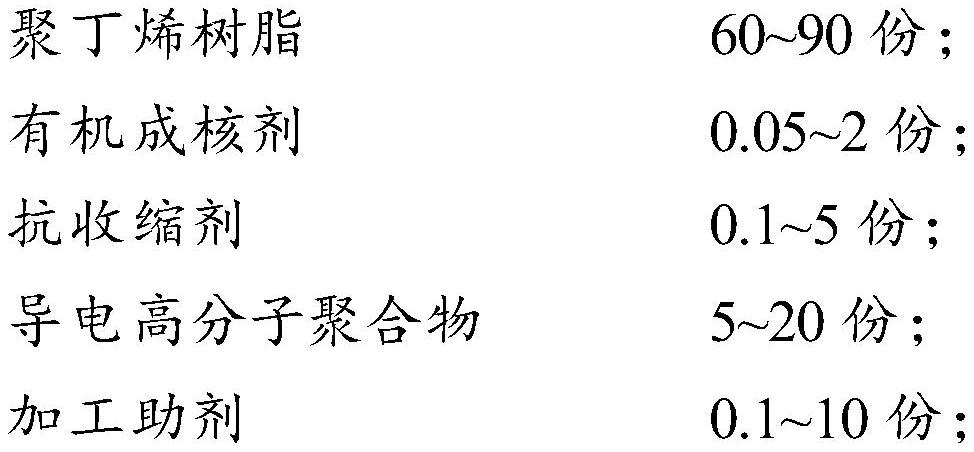

Conductive polybutylene foaming material and preparation method thereof

ActiveCN114685842ALow shrinkageSmall cell sizeBulk chemical productionPolymer scienceInjection molding machine

The invention provides a conductive polybutylene foaming material and a preparation method thereof. The preparation method provided by the invention comprises the following steps: uniformly mixing the polybutylene resin, the organic nucleating agent, the anti-shrinking agent, the conductive high-molecular polymer and the auxiliary agent, extruding and granulating by an extruder, then molding into a plate by an injection molding machine, and foaming the injection-molded plate by using supercritical fluid in mold pressing foaming equipment, thereby obtaining the high-temperature-resistant and high-pressure-resistant composite material. The obtained foaming material is low in shrinkage rate, small in foam hole size and good in impact property, has electrical conductivity and is a functional polymer foaming material with excellent comprehensive performance.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com