Gas phase magnesium purification method and device based on pure iron filter material

A filter material and pure iron technology, which is applied in the field of gas phase magnesium purification based on pure iron filter material, can solve the problems that vacuum distillation method cannot meet industrialized large-scale production, low yield of high-purity magnesium, and low efficiency of magnesium purification, etc. The effect of lowering nucleation energy barrier, reducing cost and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

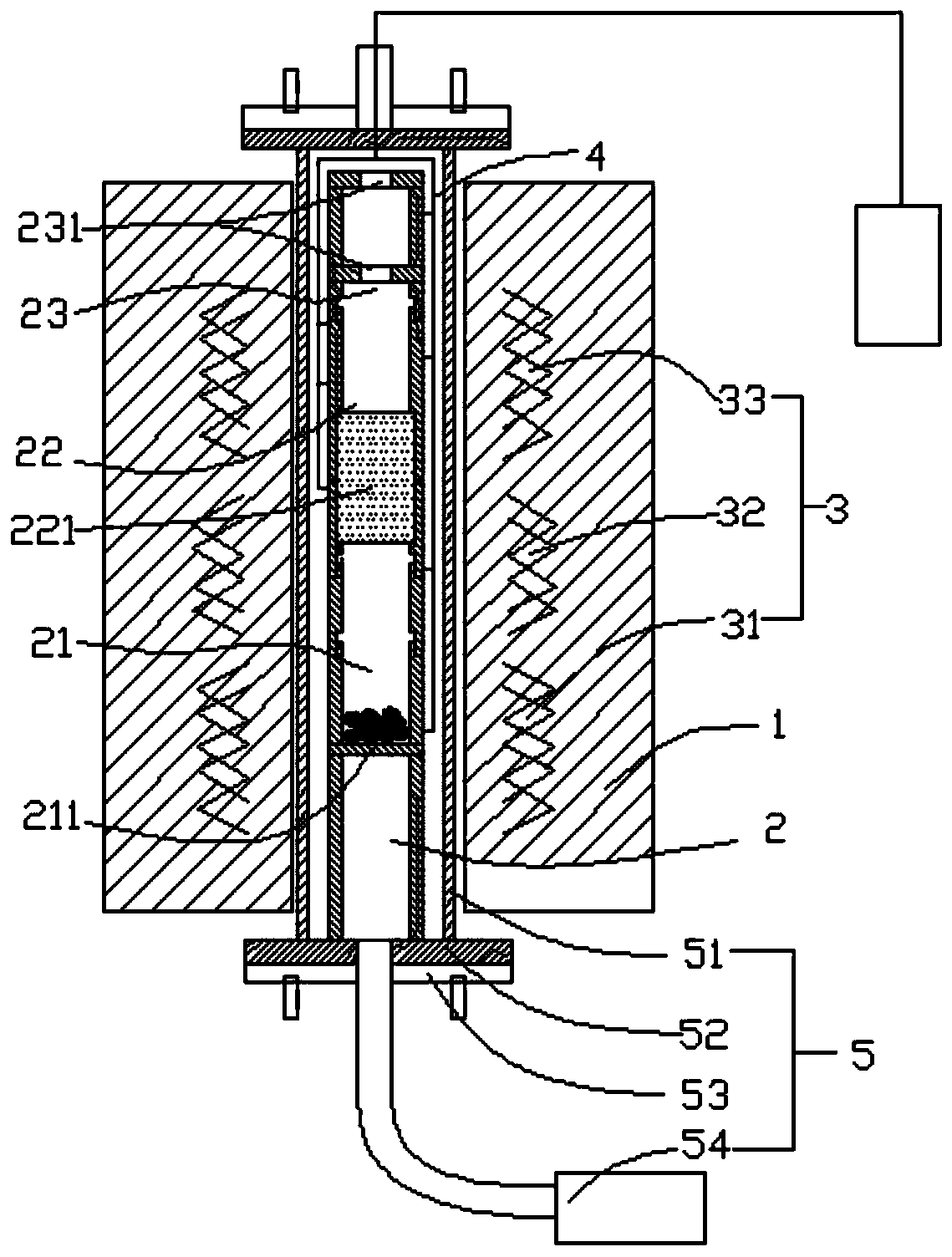

[0068] like figure 2 As shown, a device for purifying gas-phase magnesium containing pure iron filter material includes an electric furnace body 1, a crucible 2, a heating mechanism 3, a thermocouple 4 and a vacuum mechanism 5;

[0069] The crucible 2 includes a reaction zone 21, an impurity condensation zone 22 and a crystallization zone 23 arranged in sequence,

[0070] The reaction zone 21 is provided with a hopper 211,

[0071] The impurity condensation area 22 is provided with a filter assembly 221,

[0072]The filter assembly 221 is provided with a filter material, the filter material is pure iron, the filter material is metal iron foam, the pore diameter of the iron foam is 100ppi, and the purity of the iron is more than 99.2%;

[0073] The crystallization zone 23 is provided with a crystallizer 231;

[0074] The heating mechanism 3 includes a first heating assembly 31, a second heating assembly 32 and a third heating assembly 33; the first heating assembly 31 heats...

Embodiment 2

[0081] A gas-phase magnesium purification device comprising a pure iron filter material is different from Example 1 in that the pore size of the foam metal iron is 30ppi, and the filter assembly 221 is arranged between No. 5 and No. 6 high-purity graphite pipes.

Embodiment 3

[0083] A gas-phase magnesium purification device comprising a pure iron filter material is different from Example 1 in that the filter material is iron fiber, and the iron fiber has a pore size of 100-400 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com