Preparation method of alpha-Al2O3 nanoparticles

A nanoparticle, -fe2o3 technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of toxicity of organic solvents, long process flow, reduction of hard agglomeration, etc., and achieve easy industrialization Simple production and pickling process, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The concrete steps of embodiment one are as follows:

[0036] 1. Fe(NO 3 ) 3 9H 2 O and Al(NO 3 ) 3 9H 2 O dissolved in deionized water, so that the final obtained Fe 2 o 3 The mass of Fe 2 o 3 and Al 2 o 3 30% of the total mass;

[0037] 2. In a water bath at 70°C, use a peristaltic pump to drop (NH 4 ) 2 ·CO 3 Solution, stop dripping immediately after the sol is produced, and the pH value is about 5.5 at this time;

[0038] 3. Aging the sol gel in step 2 at room temperature for 24 hours to obtain a gel;

[0039] 4. Then dry the gel in an oven at 100°C for 24 hours to obtain the precursor;

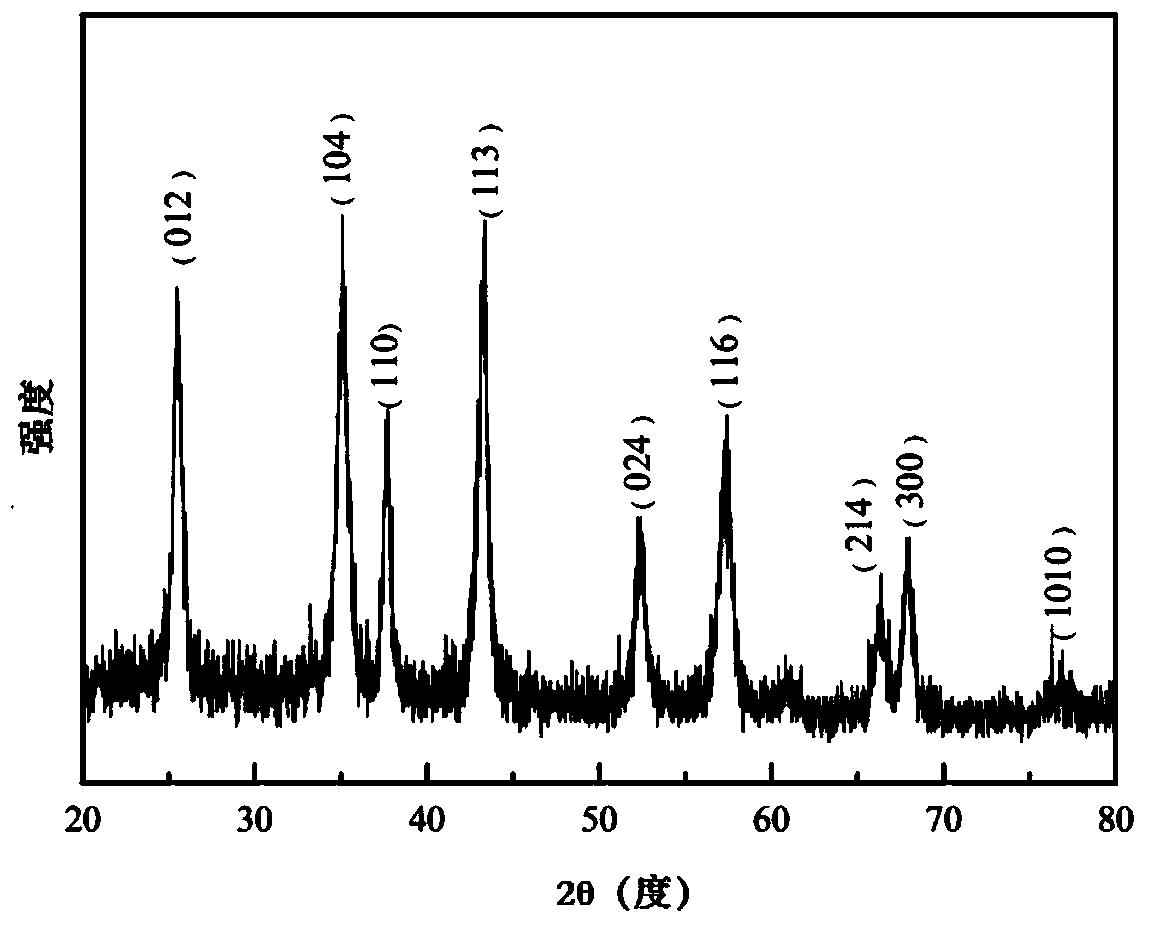

[0040] 5. Then the precursor was calcined at 650°C for 5 hours at a heating rate of 2°C / min to obtain α-Fe 2 o 3 / α-Al 2 o 3 Complex;

[0041] 6. Add α-Fe 2 o 3 / α-Al 2 o 3 The complex was incubated with 5mol / L hydrochloric acid in a reaction vessel at 100°C for a certain period of time until the α-Fe was washed away. 2 o 3 particles and other impurities,...

Embodiment 2

[0043] The concrete steps of embodiment two are as follows:

[0044] Preparation of α-Al 2 o 3 The method and embodiment one are basically the same, the difference is that the calcination time in step 5 is 20h.

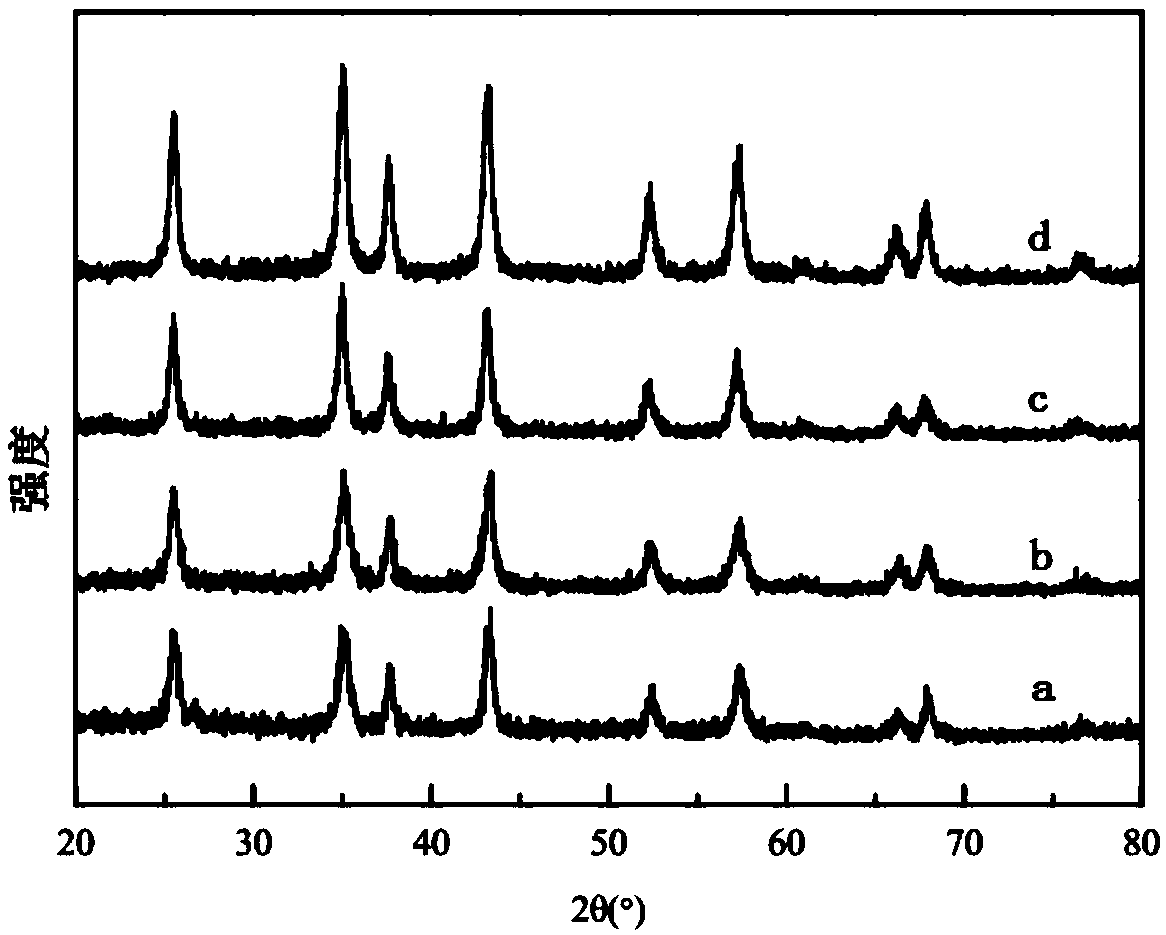

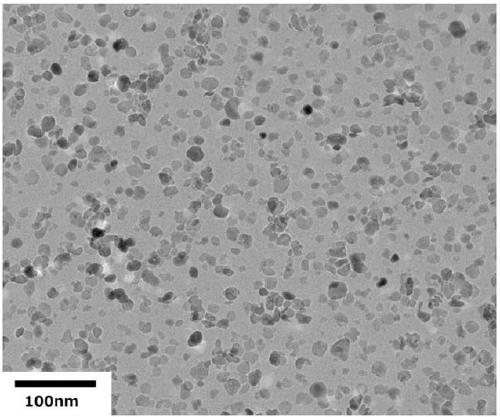

[0045] X-ray diffraction spectrum confirms that the final product is α-Al 2 o 3 (Exactly consistent with 10-0173JCPDS card), no other miscellaneous peaks, such as figure 2 (a). Final product α-Al 2 o 3 The nanoparticles are small in size, uniform in distribution, good in dispersion and high in purity.

Embodiment 3

[0046] The concrete steps of embodiment three are as follows:

[0047] Preparation of α-Al 2 o 3 The method is basically the same as in Example 1, except that the temperature of the water bath heating in the water bath is 80°C, and the calcination temperature in step 5 is 750°C.

[0048] X-ray diffraction spectrum confirms that the final product is α-Al 2 o 3 (Compatible with 10-0173JCPDS card exactly). No other miscellaneous peaks, such as figure 2 (b). Final product α-Al 2 o 3 The nanoparticles are small in size, uniform in distribution, good in dispersion and high in purity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size distribution | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com