Sc/Zr modified high-modulus and high-strength aluminum-lithium alloy and laser forming method thereof

An aluminum-lithium alloy, laser forming technology, applied in the direction of process efficiency improvement, energy efficiency improvement, additive manufacturing, etc., can solve problems such as poor adaptability of laser forming process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

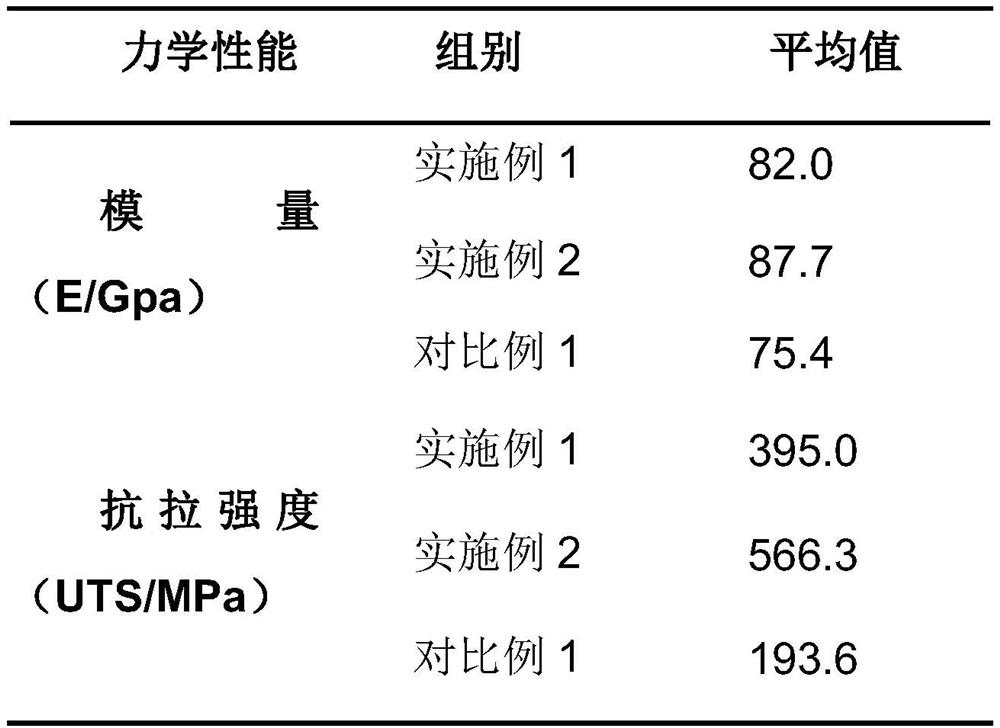

Embodiment 1

[0031] A laser forming method of a Sc / Zr modified high-modulus high-strength aluminum-lithium alloy, comprising the following steps:

[0032] S1: Preparation of raw material powder

[0033] Add ingot Sc and ingot Zr to 1460 aluminum-lithium alloy, the mass ratio of ingot Sc to ingot Zr is 4:1, and the above-mentioned Sc / Zr modified high-modulus high-strength aluminum-lithium alloy powder is adopted by gas atomization process The preparation of the body obtained a Sc / Zr modified high modulus high strength aluminum-lithium alloy powder; in terms of mass percentage, its composition was 1.83wt% Li; 3.02wt% Cu; 0.002wt% Mg; 0.020wt% %Ti; 0.06wt% Fe; 0.014wt% Si; 0.72wt% Sc; 0.19wt% Zr; the balance is Al;

[0034] The powder particle size of Sc / Zr modified high-modulus high-strength aluminum-lithium alloy powder is 15um~53um;

[0035] Drying the Sc / Zr-modified high-modulus high-strength aluminum-lithium alloy powder at 120° C. for 6 hours to obtain the dried Sc / Zr-modi...

Embodiment 2

[0039] A laser forming method of a Sc / Zr modified high-modulus high-strength aluminum-lithium alloy, comprising the following steps:

[0040] S1: Preparation of raw material powder

[0041] Add ingot Sc and ingot Zr to 1460 aluminum-lithium alloy, the mass ratio of ingot Sc to ingot Zr is 2:1, and the above-mentioned Sc / Zr modified high-modulus high-strength aluminum-lithium alloy powder is adopted by gas atomization process A Sc / Zr modified high-modulus high-strength aluminum-lithium alloy powder was obtained; in terms of mass percentage, its composition was: 2.4wt% Li; 2.95wt% Cu; 0.002wt% Mg; 0.036 wt% of Ti; 0.072wt% of Fe; 0.0170wt% of Si; 1.23wt% of Sc; 0.60wt% of Zr; the balance is Al;

[0042] The powder particle size of Sc / Zr modified high-modulus high-strength aluminum-lithium alloy powder is 15um~53um;

[0043] Drying the Sc / Zr-modified high-modulus high-strength aluminum-lithium alloy powder at 150°C for 3 hours to obtain the dried Sc / Zr-modified high...

Embodiment 3

[0047] The difference from Example 1 is that in S1, the mass ratio of the ingot Sc to the ingot Zr is 2:1, and a Sc / Zr modified high-modulus high-strength aluminum-lithium alloy powder is obtained; in terms of mass percentage, its The composition is 2.04wt% Li; 2.69wt% Cu; 0.05wt% Mg; 0.05% Ti; 0.012wt% Fe; 0.1wt% Si; 1.4wt% Sc; 0.5wt% Zr; The balance is Al; drying is at 120°C for 4.5 hours for powder drying;

[0048] In S2, the laser power of laser forming is 360W, the laser scanning rate is 800mm / s, other steps and parameters are the same as in Example 1, and a Sc / Zr modified high-modulus high-strength aluminum-lithium alloy is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Powder particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com