A kind of calcium silicate hydrate accelerator and preparation method thereof

A technology of calcium silicate hydrate and early-strength agent, applied in the direction of silicate, alkaline earth metal silicate, etc., can solve the problem of reducing the performance effect of calcium silicate hydrate, large particle size of calcium silicate hydrate and precipitation. The problem of long time required for the method to achieve the effect of shortening the coagulation time, high dispersion, and reducing the nucleation energy barrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

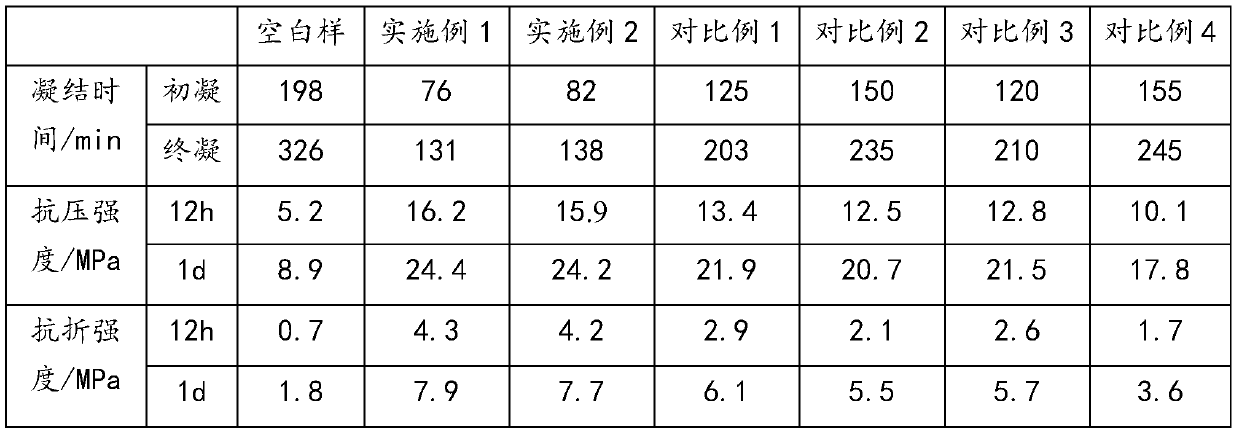

Examples

Embodiment 1

[0033] (1) Calcium liquid preparation: select papermaking waste lime mud as the calcium source, after further crushing, first raise the temperature to 150°C at a rate of 5°C / min, and keep the temperature constant for 30 minutes; then, heat up at 10°C / min The heating rate was raised to 600°C, and the temperature was kept constant for 1 hour; finally, the temperature was raised to 800°C at a heating rate of 5°C / min, and the temperature was kept constant for 2 hours; after natural cooling, the obtained product was sieved and washed 4 times with distilled water repeatedly. Soak in 0.5 mol / L nitric acid solution for 12 hours, filter out impurities; add distilled water to the filtrate to adjust the solubility of calcium ions to 3 mol / L, age for 10 hours, and use it as a calcium solution for later use.

[0034] (2) Preparation of silicon liquid: select tetraethylorthosilicate as the silicon source, add distilled water, adjust the solubility of silicon ions to 1 mol / L, and use it as th...

Embodiment 2

[0038] This example is basically the same as the preparation method of a calcium silicate hydrate accelerator described in Example 1, except that the reaction temperature in step (4) is increased from 25°C to 50°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com