Passive steel containment heat export system

A technology of steel containment and heat extraction, applied in the field of nuclear power plant reactor safety systems, can solve the problems of limited contact area of heat exchanger 3, weakening the ability of steam condensation and heat transfer, reducing heat exchange and cooling efficiency, etc. Effective cooling time, high natural circulation ability, the effect of reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

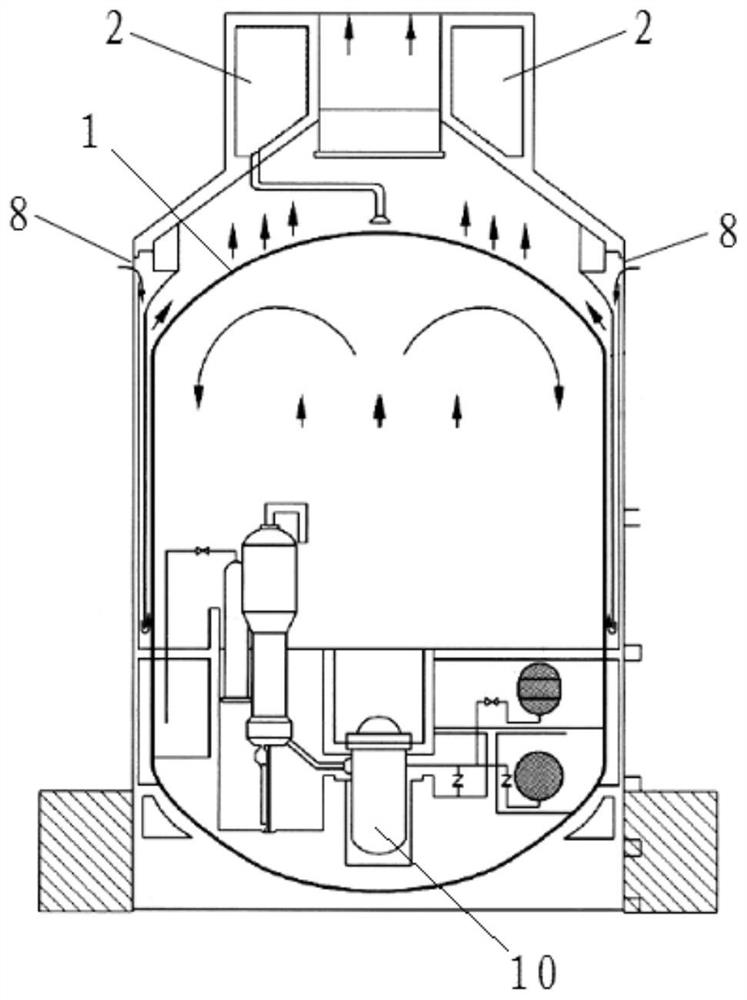

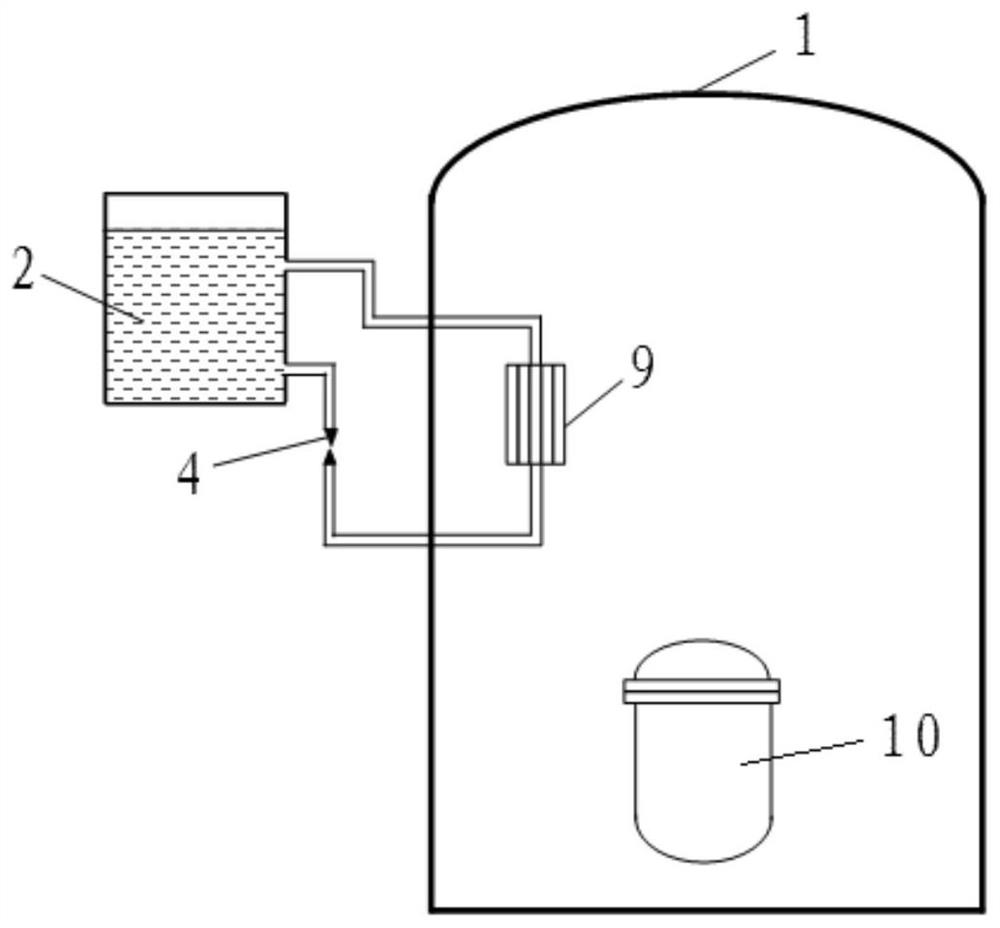

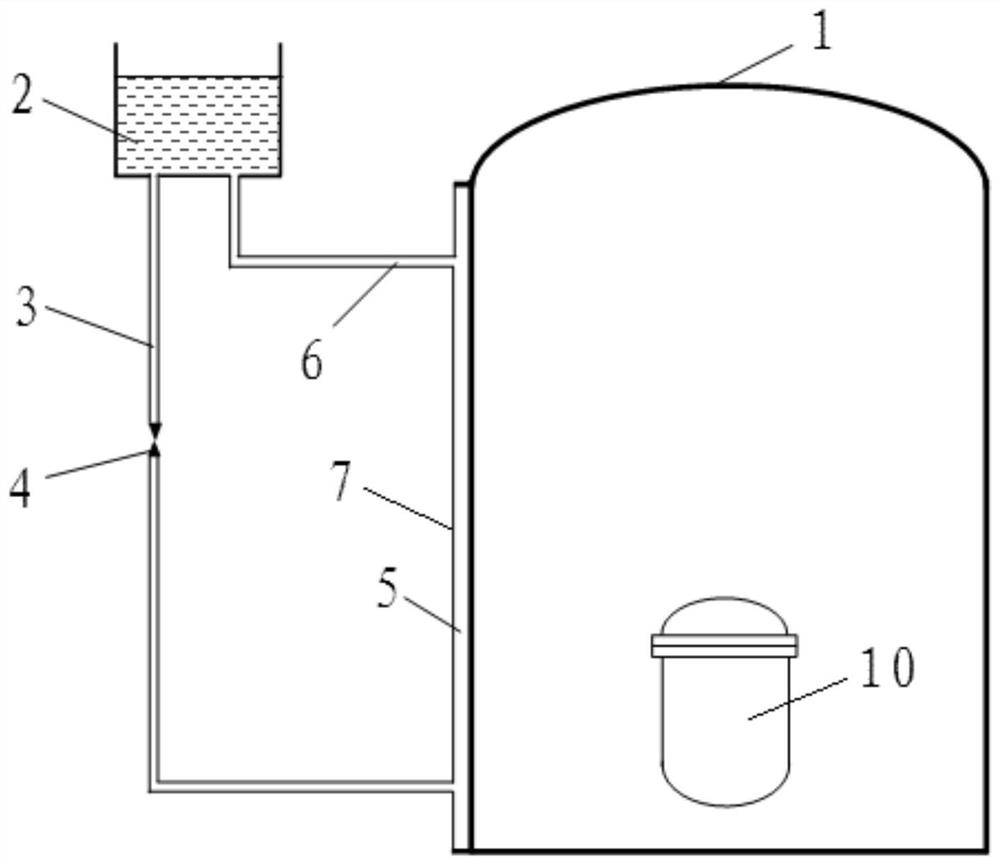

[0030] Such as image 3 , Figure 4 As shown, a passive steel containment heat extraction system provided by the present invention includes a cooling cover 7 arranged on the side wall of the containment vessel 1 of the reactor and the containment vessel 1 to form a closed annular cavity 5 together. The cooling cover 7 There is a cooling water circuit on the top, when the containment vessel 1 needs to cool down, the cooling water circuit can inject cooling water into the annular cavity 5 from the bottom of the cooling cover 7 in a passive way (depending on gravity), and the annular cavity 5 sucks The heated cooling water can flow back into the cooling water circuit from the top of the cooling cover 7 in a passive way (depending on the gravity pressure head formed by the fluid density difference); the material of the containment vessel 1 is stainless ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com