Efficient condensation gas water heater for mixed heat exchange and system

A gas-fired water heater and condensate water technology, which is applied to air heaters, fluid heaters, heat exchanger types, etc., can solve the problems of large volume and weight of heat exchangers, high manufacturing costs, etc., and achieve enhanced condensation transmission. The effect of thermal efficiency, reducing the amount of raw materials, and lowering the threshold of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

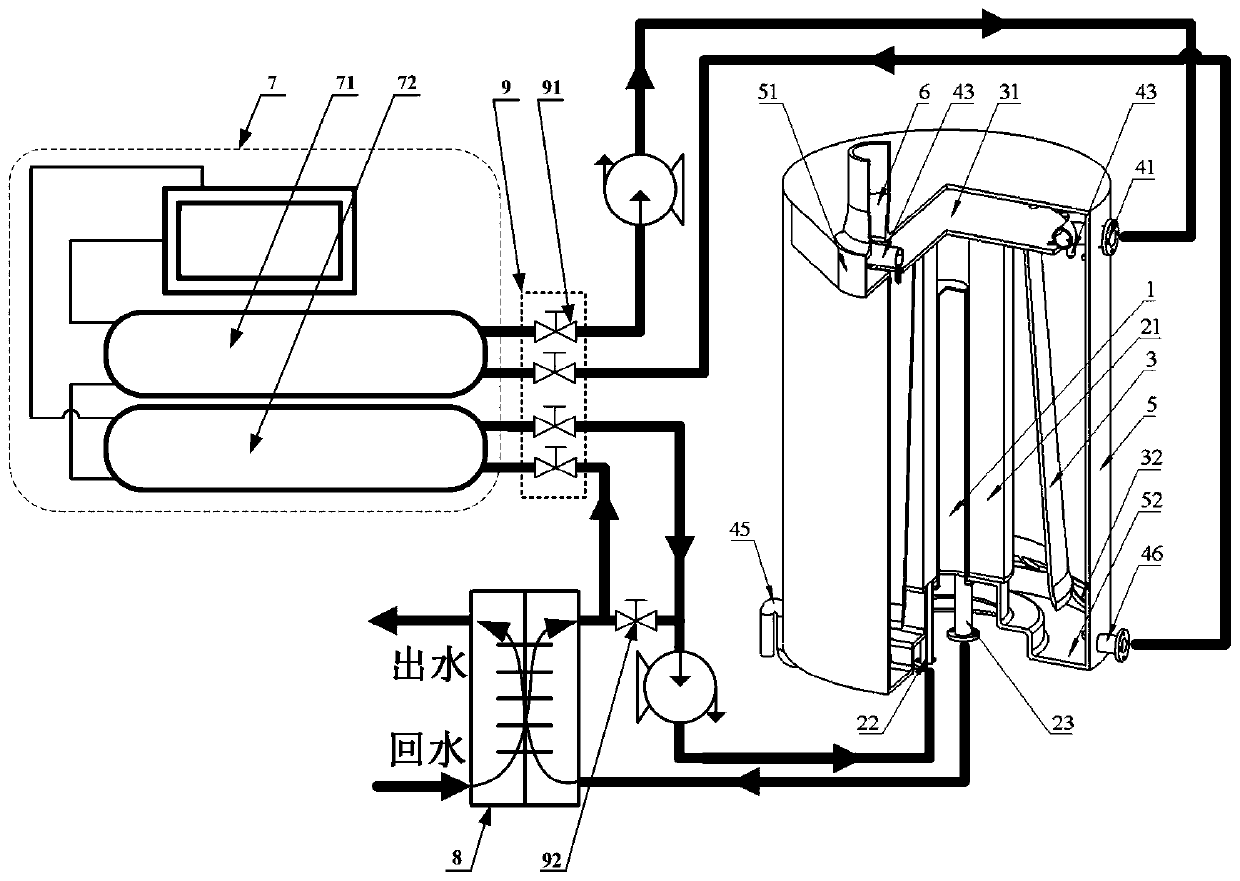

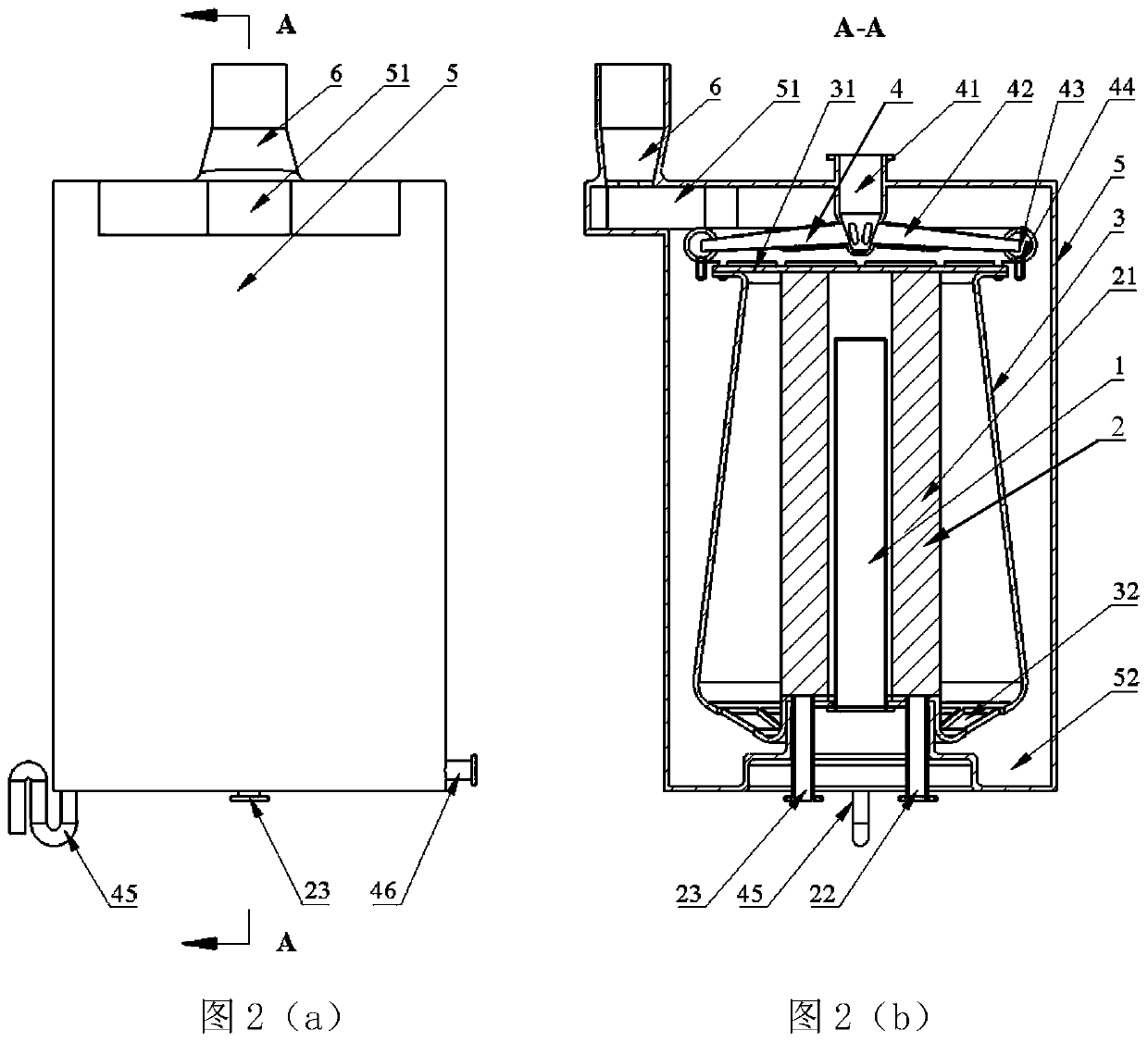

[0040] like figure 2 middle figure 2 (a) and figure 2 As shown in (b), a high-efficiency condensing gas-fired water heater with hybrid heat exchange in the present invention includes a burner 1 that generates high-temperature flue gas by combustion, and a heat exchanger 2 that wraps the burner 1 to absorb the heat of high-temperature flue gas, and is arranged on The spray system (4) on the heat exchanger (2), isolating the spray system (4) from the heat exchanger (2) and forming an equal pressure smoke hood on the outer wall of the heat exchanger (2) to form a flue gas equal pressure channel (3), covering the shell (5) of the burner (1), heat exchanger (2), equal pressure hood (3) and spraying system (4), the chimney (6) arranged on the shell (5) ); the low-temperature flue gas released by the heat exchanger (2) passes through the channel between the shell 5 and the equal pressure fume hood 3, and is further discharged from the chimney 6 after being absorbed by the spray ...

Embodiment example 2

[0055] In this embodiment, the same symbols are assigned to the same structures as those in Embodiment 1, and the same descriptions are omitted.

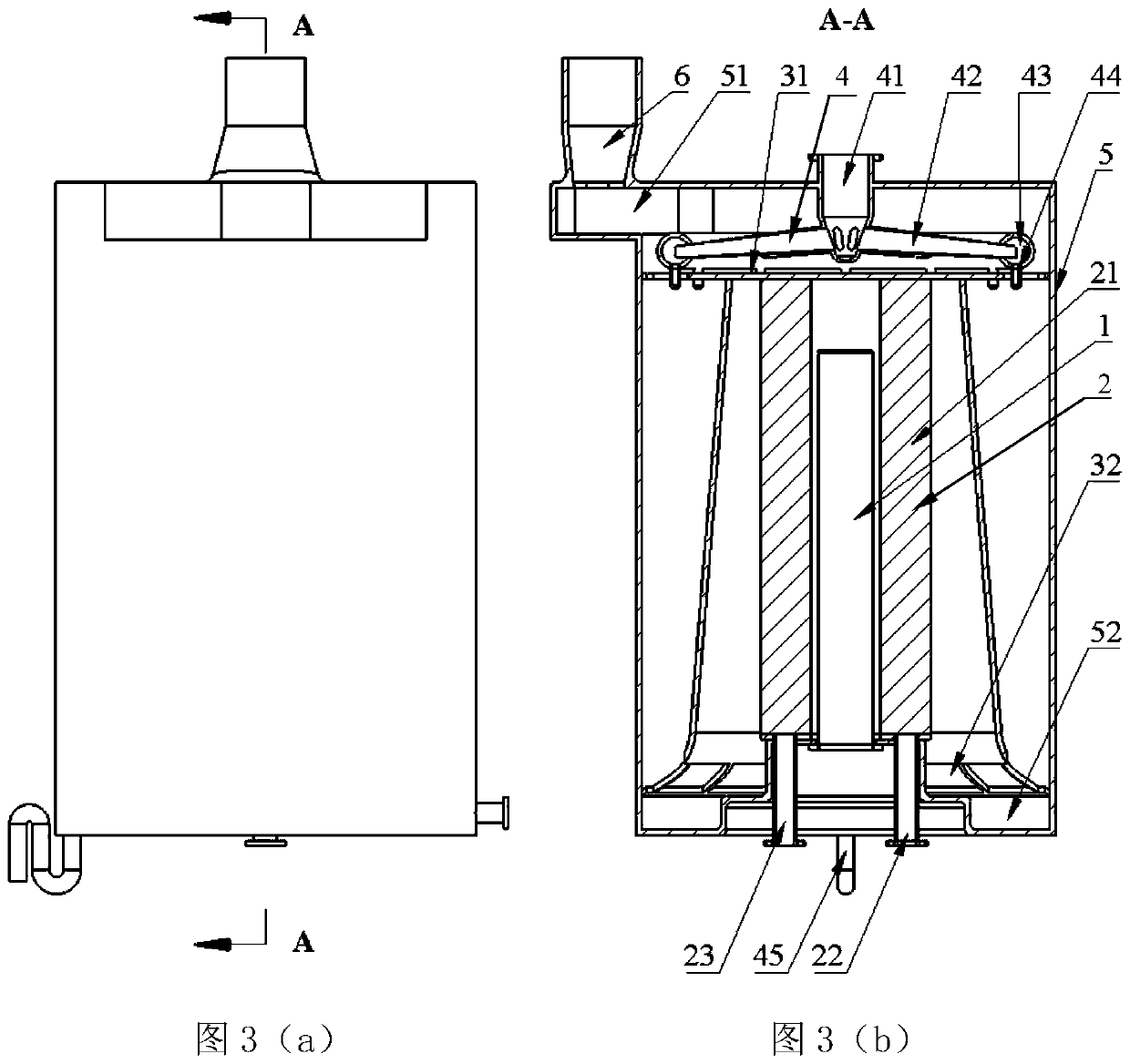

[0056] like image 3 middle image 3 (a) and image 3 As shown in (b), the equal pressure fume hood 3 is connected to the shell 5, and the equal pressure fume hood 3 and the shell 5 can be integrally formed by injection molding process or cast iron or aluminum alloy, so as to facilitate the installation and heat exchange of the heat exchanger 2 The arrangement of the water inlet 22 of the heat exchanger and the water outlet 23 of the heat exchanger.

Embodiment example 3

[0058] In this embodiment, the same symbols are assigned to the same structures as those in Embodiment 1, and the same descriptions are omitted.

[0059] like Figure 4 middle Figure 4 (a), Figure 4 (b) and Figure 4 As shown in (c), the spray liquid inlet 41 is arranged on the side of the housing 5, adopting a single-side or double-side liquid inlet method, and adopting a high-pressure flow-equalizing spraying method to cancel the structure of the flow-equalizing pipe 42 and simplify the manufacturing process And ensure the structural strength.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com