Piston type pulse detonation engine

A pulse detonation, engine technology, applied in mechanical equipment, intermittent injection devices, etc., to achieve the effect of being conducive to heat dissipation, increasing intake pressure, and enhancing convective heat transfer intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and the specific implementation process.

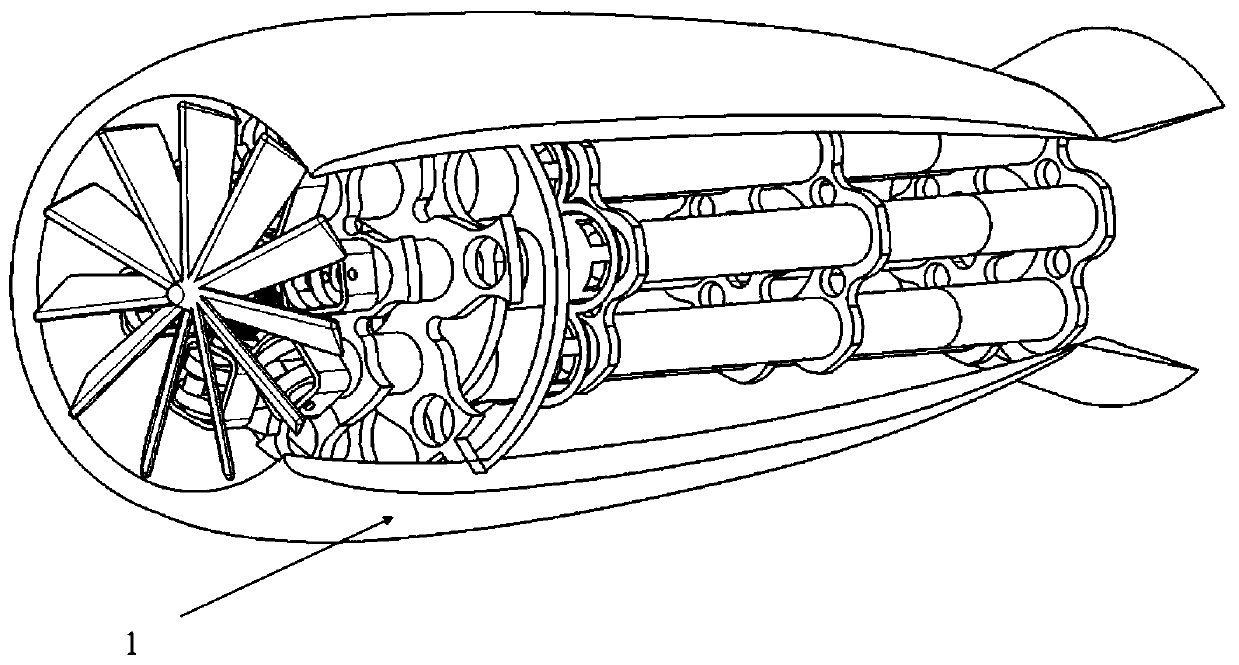

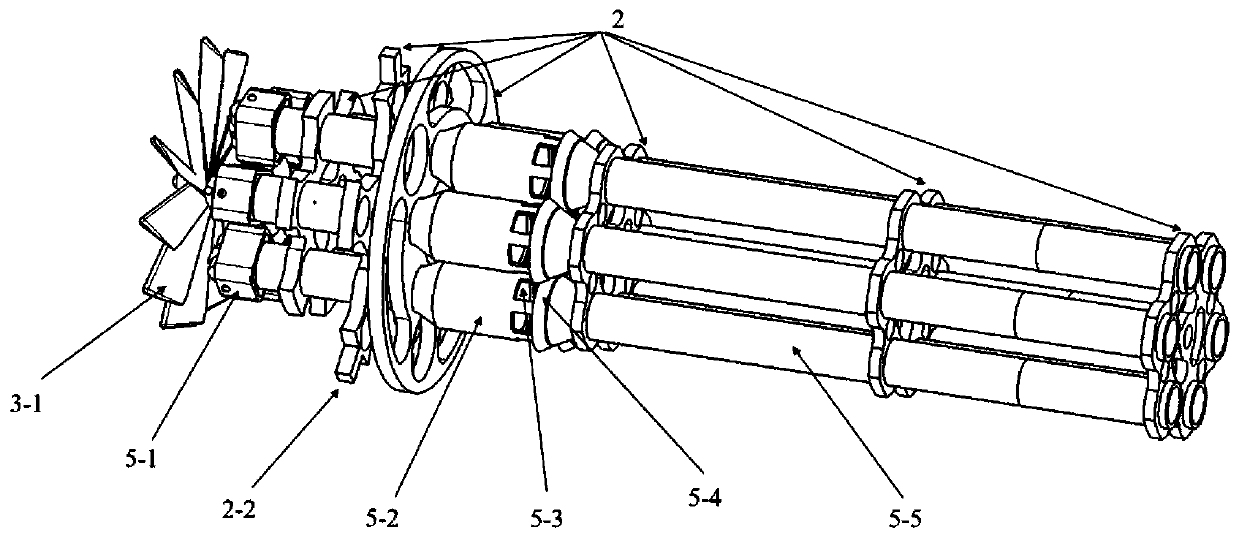

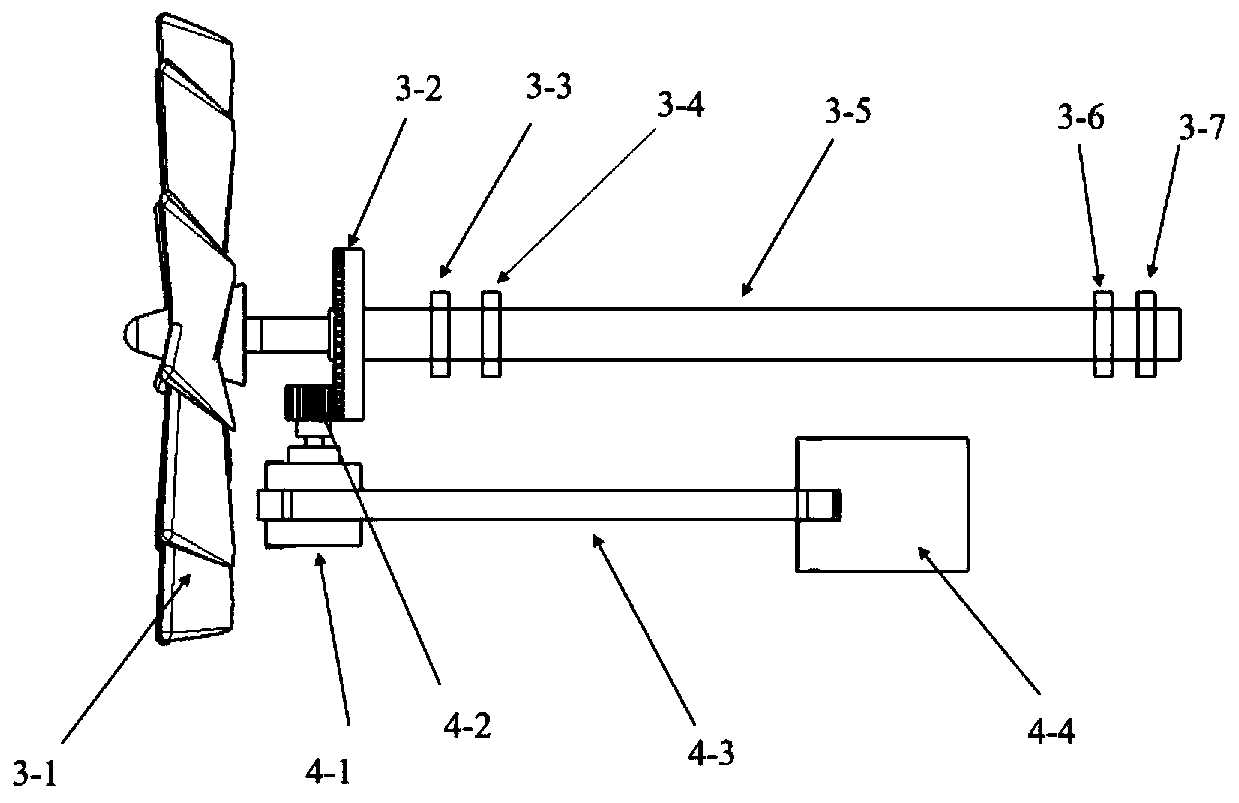

[0023] see figure 1 and figure 2 , The detonation combustion device is evenly distributed at equal angles based on the central axis, the transmission mechanism is installed in the detonation device, and the fan assembly is located at the central axis of the entire system, fixed and restrained by the supporting structure. Part of the energy generated by the detonation combustion device generates thrust by propagating downstream, and the other part propagates upstream and acts on the transmission device. The transmission device drives the fan in the fan assembly to rotate at high speed to generate thrust and improve the heat dissipation capacity of the combustion device. The combustion device, transmission mechanism and fan assembly are fixed and restrained, and the fairing plays the role of rectifying and forming the outer cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com