Volumetric solar cavity heat absorber with rotary heat absorbing body

A heat absorber and volumetric technology, which is applied in the field of solar heat absorbers and volumetric solar cavity heat absorbers, can solve problems such as uneven distribution of radiant energy, limited number of heat exchange contacts, thermal stress damage of heat absorbers, etc. , to achieve uniform temperature distribution, low cost, and enhanced convective heat transfer intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

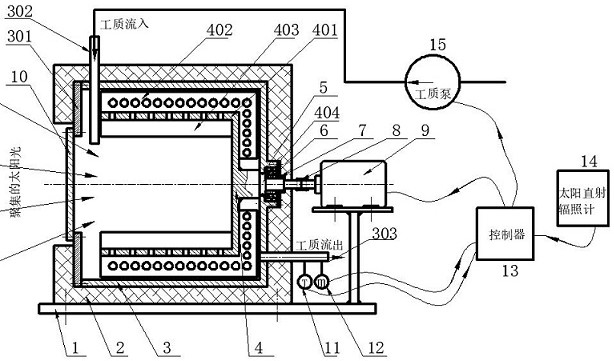

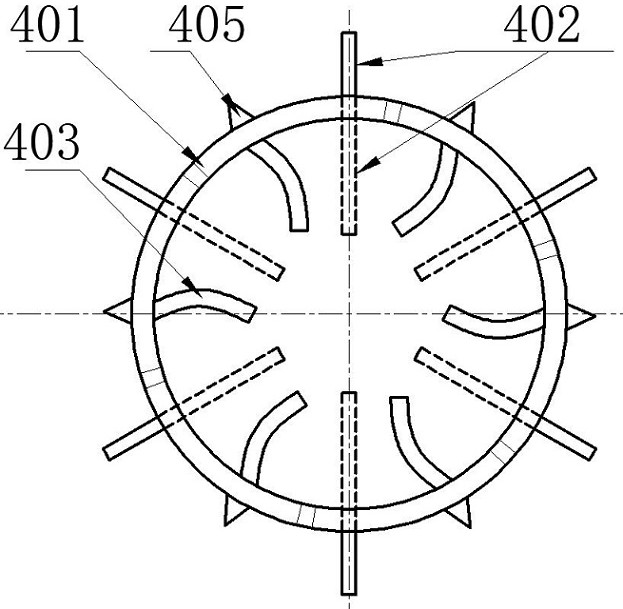

[0018] Such as figure 1 As shown, the present invention includes an outer cylindrical body 3 with an axisymmetric cavity structure and a through hole is opened on its front end plate 301, a heat absorber 4 located in the outer cylindrical body 3 and coaxially arranged with the outer cylindrical body 3, and an installation The opening position of the front end plate 301 is used to seal the glass cover plate 10 of the outer cylinder 3, and the insulation layer 2 wrapped on the outside of the outer cylinder 3 for heat insulation, and the working fluid communicating with the inner cavity of the outer cylinder 3 flows into the Pipe 303 and working fluid outflow pipe 302; the heat absorbing body 4 is composed of a heat absorbing main body 401 with a concave cavity structure with an opening on one side, a plurality of heat absorbing bodies 401 along the outer surface of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com