A sheet metal heating system for hot stamping experiments

A heating system and hot stamping technology, applied in the field of hot stamping sheet heating, can solve the problems of uncontrollable heating speed, uneven heating, and easy oxidation of the sheet, so as to improve the uniformity of temperature distribution, prevent oxidation, and reduce temperature difference greater effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific structure of the present invention and its implementation will be further described below through examples and with reference to the accompanying drawings.

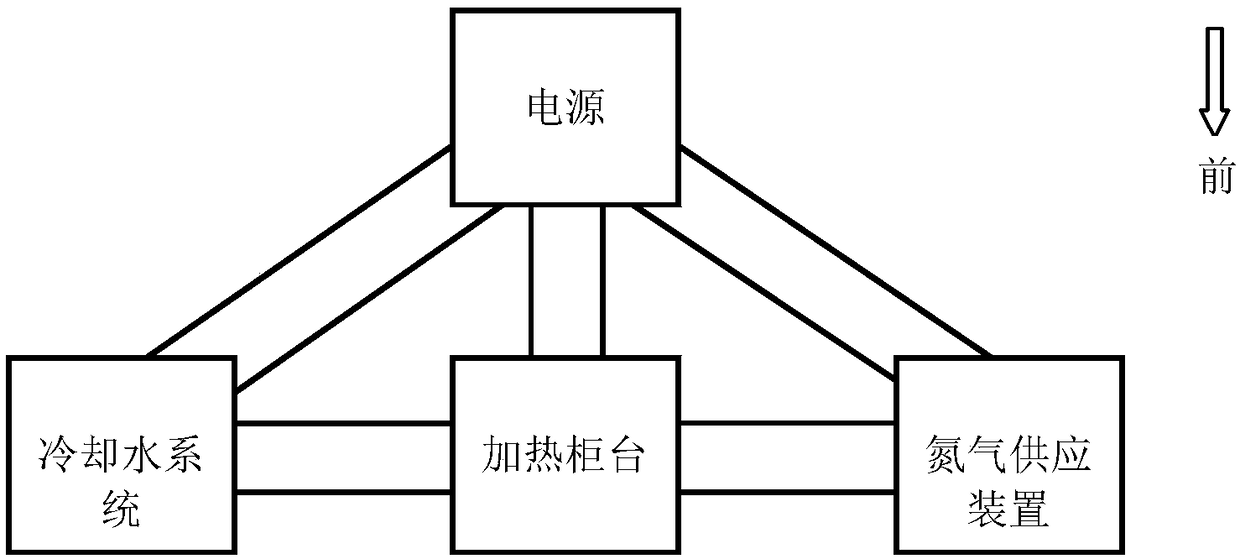

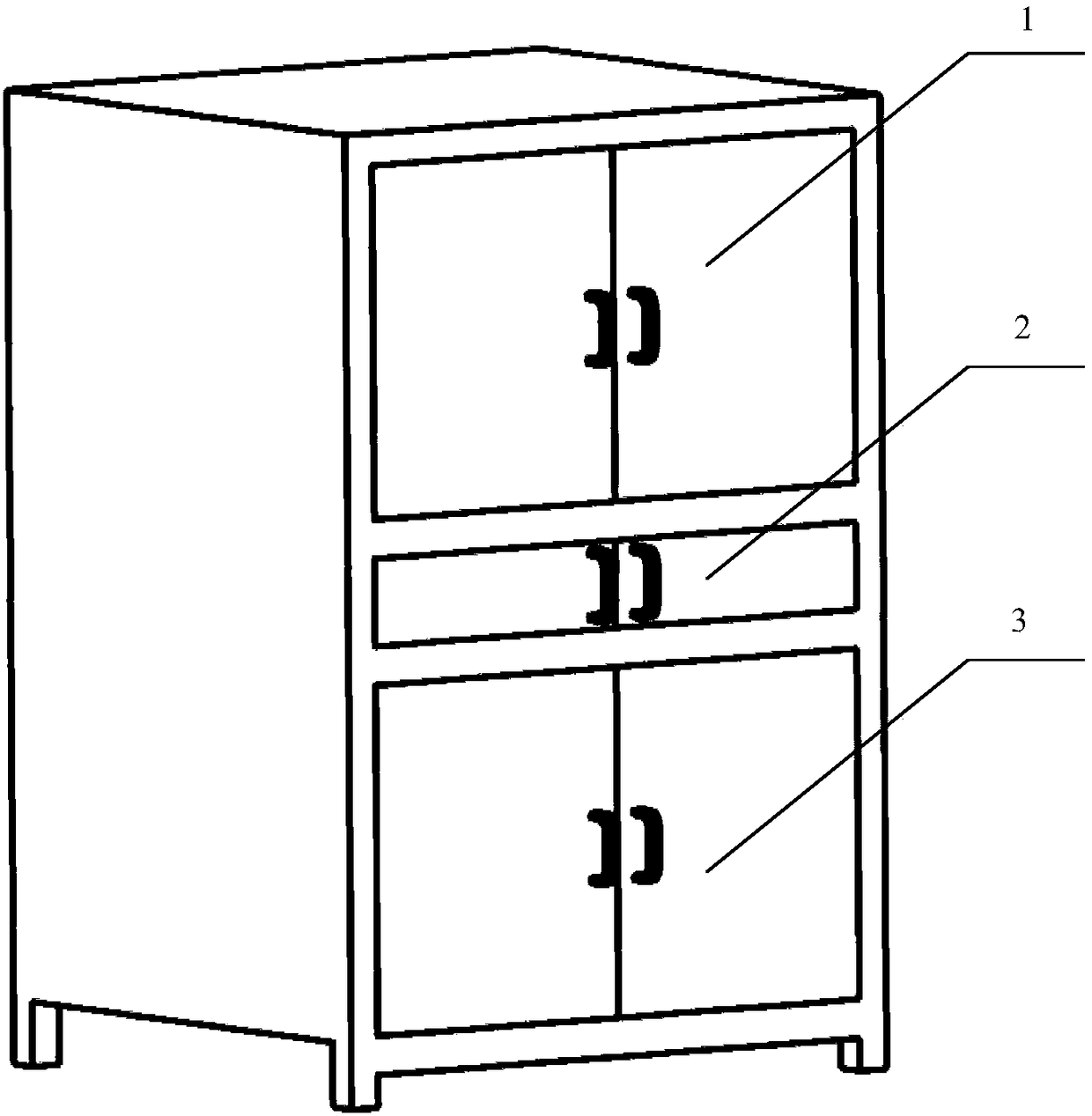

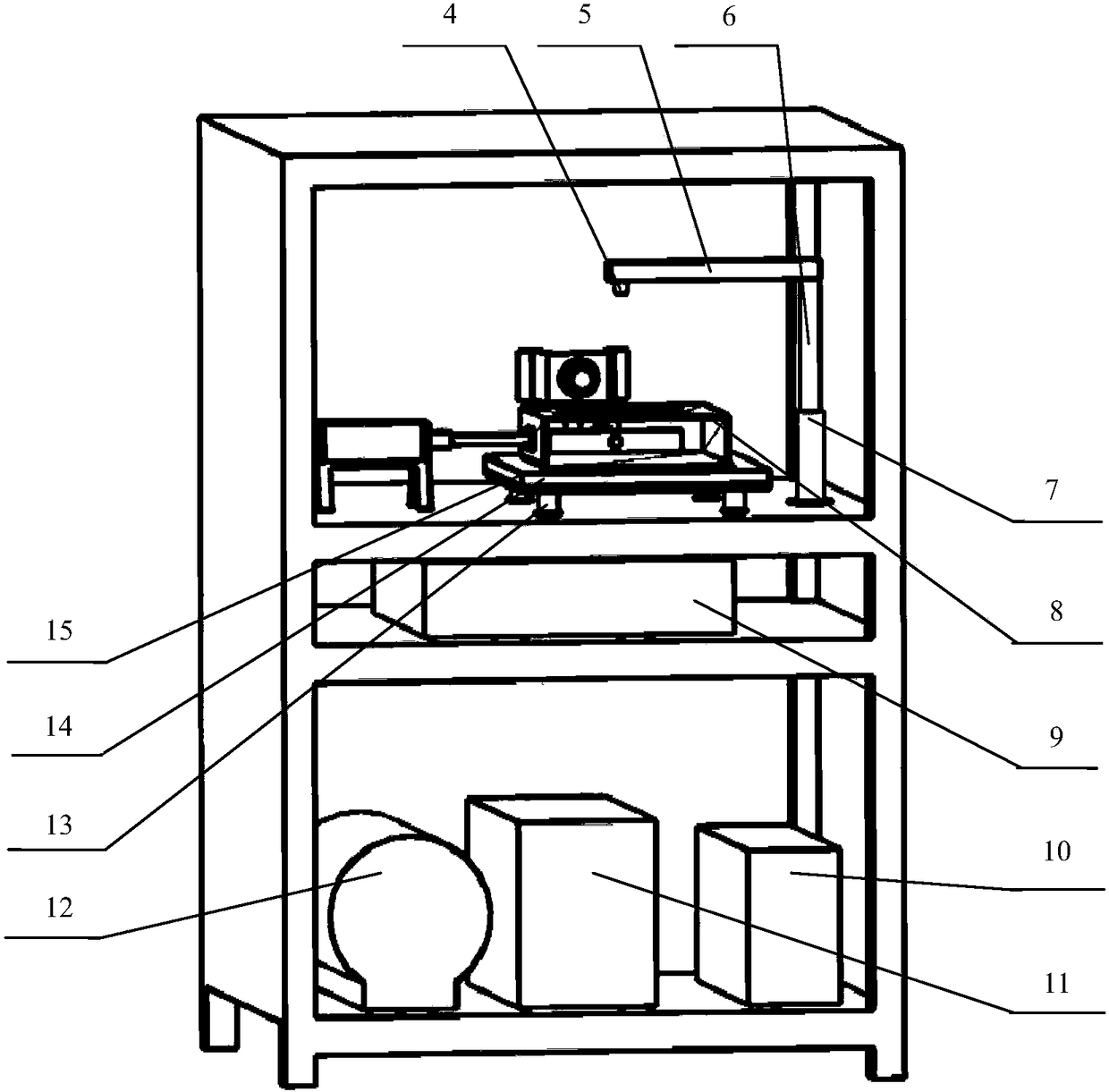

[0020] Such as figure 1 , figure 2 and image 3 As shown, a sheet metal heating system for hot stamping experiments is composed of four parts: power supply, cooling water system, nitrogen supply device and heating counter; the heating counter is composed of upper, middle and lower parts, and the upper part is Heating area 1, the middle part is the control box placement area 2, and the lower part is the storage area 3; the components of the heating counter include: infrared probe 4, bracket cross bar 5, bracket connecting rod 6, temperature measuring bracket base 7, heating Tray 8, control box 9, transformer 10, electric control box 11, air pump 12, sensor fixing frame 13, flat sensor 14, mica plate 15, nozzle fixing frame 16, nitrogen conduit 17, nitrogen nozzle 18, second cylinder 19. The second c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com